Shining 3D AccuFab-L4D User manual

User Manual

V3.3.20

AccuFab-L4D

Foreword

General

The user manual (hereinafter referred to as "the manual") introduces the functions,

installation, operation and maintenance of the AccuFab-L4D printer (hereinafter

referred to as "the printer").

AccuWare is the data preparation software for AccuFab printers.

Fab Cure is the curing unit for AccuFab printers

FabWare is the operating software for AccuFab printers.

Please use original consumables and spare parts. Any change to the printer

without the manufacturer's permission will result in printer failure and will

invalidate warranty.

General

Foreword

Safety Instructions

Additional information

Improper actions or conditions that may damage the product or result in personal

injuries, and consequently void your warranty or service contract or lose the data.

Revision History

1V3.3.20

No. Version Revision Content Release Date

December, 2021

Update network connection features.

Update FabWare snapshots and features.

FCC Regulations

Please note that changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

RF exposure statement

This equipment complies with radio frequency exposure limits set forth by the FCC for an uncontrolled environment.

This equipment should be installed and operated with a minimum distance of 20 cm between the device and the user or bystanders.

This device must not be co-located or operating in conjunction with any other antenna or transmitter.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Foreword

The user manual (hereinafter referred to as "the manual") introduces the functions,

installation, operation and maintenance of the AccuFab-L4D printer (hereinafter

referred to as "the printer").

RF exposure statement

The Manual is related to your safety, lawful rights and responsibilities. Please read it

carefully before installing and using the product.

About the User Manual

Shining 3D Tech Co., Ltd. (hereinafter referred to as "the Company") owns complete

intellectual property rights of the Manual. No part of the Manual may be reproduced,

transmitted, distributed, adapted, compiled or translated in any form or by any

means without the prior written consent of the Company.

This equipment complies with radio frequency exposure limits set forth by the FCC for

an uncontrolled environment.

This device must not be co-located or operating in conjunction with any other antenna

or transmitter.

This equipment should be installed and operated with a minimum distance of 20 cm

between the device and the user or bystanders.

The Manual is a guidance for installing, operating, and maintaining the product,

including the device, software, or other products provided by the Company, to which

the Manual is applicable. The Manual does not serve as the quality guaranty for the

product. Every effort has been made in the preparation of the Manual to ensure

accuracy of the contents. The company reserves the right to interpret and modify

possible errors and omissions therein. Contents of the Manual are subject to changes

without notice.

Images and diagrams in the Manual are presented to provide convenience to readers.

If any of them is inconsistent with the actual product, the actual product shall prevail.

Please read the Manual carefully before using related products. Trained professionals

or technicians are recommended to operate related products. The Company shall

not be held responsible for any damages and/or losses caused by negligence,

environmental factors, improper maintenance, improper use, and/or any other

non-quality problems.

Disputes arising from the Manual and/or related products thereof shall be governed

by the laws of the People’s Republic of China.

If you have any ambiguity or suggestion about the contents of the Manual, please

contact us by the contact information provided in the Manuals.

Import printer profile

Operation- Open File

Operation- Layout

Operation- Support

Operation- Slice

Operation- Send print job

Update software and

material profile

Function

Remote Assistance

Accuracy Calibration

Workflow

(Optional) Clean Resin Tank

Resin tank setting

Choose printing file

Local Printing

Flash Drive Printing

Printing Status

Remove Model

Post Processing

1.1

1

1.2

1.3

1.4

1.5

2

2.1

2.2

2.3

3.1

3.1.1

3

3.1.2

3.1.3

3.2

4

4.1

4.2

4.3

5

5.1

5.2

5.2.1

5.2.2

5.3

5.3.1

5.3.2

5.4

5.4.1

5.4.2

Clean Model

Cleaning

Clean Build Platform

Model Post Cure

Remove Support

CONTENT

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.4.8

5.4.9

5.4.10

5.4.11

5.4.12

Print

6

6.1

6.3

6.2

6.4

6.4.1

6.4.2

6.5

7.1

Material Contact

Safety

Ultraviolet Light

Ethanol

Sharp Tools

Electromagnetic Interference

Operation Environment

Site Requirements

PC Recommended Configuration

for AccuWare

Material Storage

AccuFab L4D

Overview

Product Overview

Technical Parameters

Accessories

Fab Cure

Printer Setup

Unpacking

Install the Printer

Add Material

Fabware

Software operation

Connecting to Network

LAN Network

Wireless network

Fabware Update

Online Update

Offline update

Accuware

Installation

Import printer profile

7

7.2.1

7.2

7.2.2

7.3

7.4

1

2

3

4

CONTENT

1

1 Safety

1

1.1 Material Contact

1

1.2 Ultraviolet Light

1

1.3 Ethanol

1

1.4 Sharp Tools

1

1.5 Electromagnetic Interference

2

2 Operation Environment

22.1 Site Requirements

2

2.2 Material Storage

3

3 Product Overview

3

3.1 AccuFab L4D

3.2 Accessories 4

54 Printer Setup

5

4.1 Unpacking

6

4.2 Install the Printer

7

4.3 Add Material

5 8

FabWare

5.1 Connecting to Network 9

5.1.1 LAN Network 9

5.1.2 Wireless Network 9

5.2 FabWare Update 10

5.2.1 Online Update 10

5.2.2 Offline Update 10

7.1 17

Remove Model

7.2 18

Cleaning

7.2.2 18

Clean Build Platform

7.2.1 18

Clean Model

7.3 19

Model Post Cure

7.4 19

Remove Support

7 Post Processing 17

6.1 11

Workflow

6.5 14

Choose Printing File

6.2 11

Resin Tank setting

6.4 13

Clean Resin Tank(Optional)

6.5.1 14

Local Printing

6.6 16

Printing Status

6.5.2 15

Flash Drive Printing

6 11

Print

6.3 Platform level (Optional) 12

Safety

1

1.1 Material Contact

The printing material of AccuFab printer is photo-polymerized resin material independently

developed by SHINING 3D. The resin is stable, safe, and no substances harmful to the

human body found in the test, but direct contact with skin may cause adverse irritating

reactions. Operators should follow the Material Safety Data Sheet (MSDS) instructions.

And operators should wear nitrile disposable gloves when in contact with material.

Eye contact: Flash the eye with water for at least 15mins.And seek medical attention.

Ingestion: Induce vomiting and seek medical attention.

Skin contact: Take off contaminated clothing and wash the skin area thoroughly with

soap and water.

Do not touch the liquid material by hand. Please refer to the latest Material Safety

Data Sheet (MSDS) or call local authorities for the material handling hazard

and treatment.

Note:

Warning:No smoking, eating, or drinking in the workplace. Keep the material properly

and keep away from the children.

1.2 Ultraviolet Light

During the printer and Fab-cure operation, Ultraviolet light with a wavelength of 405 nm

will be emitted, which is may bring damage to your eyes. Please avoid direct contact.

A safety interlock is enabled to avoid printing when the cover is open.

Ethanol is a flammable and explosive chemical. Please store in a cool and ventilated

environment and keep the bottle cap of the container closed. Keep away from children.

Ethanol is recommended to clean printed part (Alcohol concentration of 75% or above)

1.3 Ethanol

Wear disposable gloves when clean part surface with ethanol. Avoid direct contact.

1.4 Sharp Tools

AccuFab 3D printer equipped with a set of accessories including sharp tools such as

flat-headed tweezers, cleaning shovels, and utility knives. Personal safety protection is

required when using these tools.

1.5 Electromagnetic Interference

Electromagnetic, produced by AccuFab printer and Fab Cure during operation, has passed

CE/FCC standard test and is complied with Class A digital device limits, which will not

cause harm to the human body.

1

Operation Environment

2

2.1 Site Requirements

Ignoring the requirement of the environment may lead to print failure or part

accuracy issue

Note:

Temperature

Maximum Output Power

Power Supply 100-240V/360W

20°C-35°C

Humidity 30%-70%

Environment Dust free, Ultraviolet light avoided, Ventilated

Frequency Range 2400–2483.5MHz

18dBm

AccuFab 3D Printer

Power Supply

Fab Cure Post-Curing Unit

Temperature

Humidity

Environment

100-240V

20°C-30°C

40%-60%

Dust free, Ventilated

2

2.2 Material Storage

Temperature

Storage Conditions

10°C-30°C

In a cool and ventilated room and avoid

direct sunlight.

Resin Materials

The bottle shall be kept closed at all times to avoid contact with

fire sources.

Note:

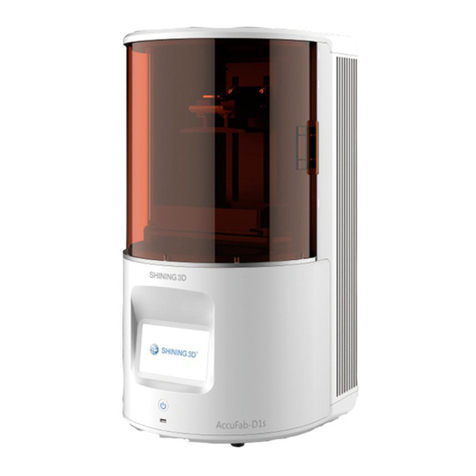

3.1 AccuFab L4D

Network port

B-type USB port

Power port

Power button

Chamber door

Build platform bracket

Resin tank

Touch screen

Build platform

Product Overview

4

3

Network port

B-type USB port

Power port

Power button

3

Chamber door

Build platform bracket

Resin tank

Touch screen

Build platform

3.2 Accessories

Product Overview

3

Power Cable

USB flash drive

Harness

network cable (2m) USB cable

Scraper Brush

Angular Knife Putty knife

Cloth*2 PET Card*20

Disposable Gloves*10

Cleaning box(accessories)

Resin tank

Quality Certification

Bolt*2

Wrench

4

Detailed information please refer to Quick Start Guide

Note:

Wrench

Resin tank

cleaner

Cloth PET Card Bolt

Putty knife

Disposable Gloves Scraper Angular Knife Brush

USB cable

Cleaning box USB flash drive Network cable

Power Cable Quick Start Guide

Quality Certification

Spare Resin tank

4.1

4

Precaution: Do not plug in the printer before the unpacking process is

complete. Or the initialization action may cause stuck of the filling

materials inside printer

1

23

4

1

1

2

2

1

3

4

3

4

Take out the printer from the package.

23

Remove the package and place the printer

on the table. Remove the fixing foam .

1Take out accessory box from fixing foam .

2 1

Remove the package and place the

printer on the table. Remove the

fixing foam .

Take out accessory box from fixing

foam .

Take out the printer from the package.

Unpacking

Connect the power supply and press

the power button on right side of the

printer. During printer initialization.

Platform will go to the top position.

Printer Setup

5

5

Remove resin tank .

Remove the foam for fixing.

5

6

1

1

1

1

3

4

5

6

4

4.2

The resin material is a mixture, and it is likely to form a small amount of sediment after

placing for long time. Please shake the bottle well before adding to the resin tank.

You can also add resin during printing without pausing.

Resin level should be at between the minimum and maximum.

Please keep the cover closed during printing to ensure the print quality

Note:

Printer Setup

Install the Printer

(There are four positioning slot)

6

5

Put clean resin tank into the position.

Lock the buckles for platform.

6

Bolt the resin tank to the printer temporarily

for operating, if the buckle is damaged

and the replacement is not available at

the moment.

5

6

DO NOT remove the screen protector.

Screen Protector

4

4.3

The resin material is a mixture, and it is likely to form a small amount of sediment after

placing for long time. Please shake the bottle well before adding to the resin tank.

You can also add resin during printing without pausing.

Resin level should be at between the minimum and maximum.

Please keep the cover closed during printing to ensure the print quality

Note:

Shake The Bottle

Printer Setup

Add Material

Printer is ready to print!

7

Use scraper to stir resin in the tank to avoid sediment.

Wear gloves

5

4.3 Add Material

The resin material is a mixture, and it is likely to

form a small amount of sediment after placing

for long time. Please shake the bottle well

before adding to the resin tank.l

Ins ert cl ean bu ild pl a tfor m and fix i t.

5

6

15

(There are four positioning slot)

7

Put c lean r esin t ank in t o the po siti on.

Lock the buckles for platform.

7

6

2

You can also add resin during printing without pausing.

Resin level should be at between the minimum and maximum.

Please keep the cover closed during printing to ensure the print quality

Note:

Shake The Bottle

FabWare is the operating software for the printer, which controls the printer operation and

some manual settings can be done by user.

Queue page shows the pending files to be

printed and also the history files.

And customer can import the file by the

flash drive button if flash drive that stores

the sliced file is inserted.

Queue

The home page shows the printer status

. Idle, printing or printer finished.

Also the build environment info is

displayedfor reference. On the bottom

right side we can see the resin tank

setting of material and layers printed

by this resin tank.

Home

The settings page are all the software and

hardware settings of the printers.

Customer can setup the language or

network, manual control of axis etc.

Settings

If you see that the printer is not activated. Please insert the flash drive in the accessory

box and activate. The activation steps are explained in <Quick start guide>

Note:

FabWare

8

5

5.1 Connecting to Network

If you see that the printer is not activated. Please insert the flash drive in the accessory

box and activate. The activation steps are explained in <Quick start guide>

Note:

5.1.1

Take out the printer from the package.

23

Remove the package and place the printer

on the table. Remove the fixing foam .

1Take out accessory box from fixing foam .

2 1

Connect the Ethernet cable to the

network port .

Go to the FabWare. Go to settings and then choose Network Settings.

17

8

7

8

2

4

3Enable LAN Network

LAN network settings, you can choose auto way or manual way:

Auto Way: Enable Auto IP/DNS Configuration (enabled by default).

Manual Way: Disable Auto IP/DNS Configuration and configure manually.

5.1.2

Wireless Network

Under Network Settings, enable the

Wireless Network.

Select available network in the dropdown

list.

1

2

FabWare

If you want to send the print file after slicing through network. Then you need to connect

the printer to the network first, to LAN network or wireless network.

LAN Network

Note: Choose the same network AccuWare connected. Or it’s not possible to send sliced file.

9

There are two ways of updating FabWare. Online and Offline.

Open About Printer. Update Software.

Select Network Update.

Insert the flash drive with the downloaded software to apply the offline update.

Open Update Software.

Select Flash Drive Update.

Choose the downloaded software

Click Next to update FabWare.

Reboot printer.

5

5.2

5.2.1 Online Update

1 2

3

5.2.2

Offline Update

Choose the same network AccuWare connected. Or it’s not possible to send sliced file.

1

2

4Click Update to update the software

or material profile.

5Reboot

When new FabWare versions is available, a prompted window will indicate user to

update. You can choose update directly.

When material match error found with sliced file, you can try to update the material

profile. Which must be updated online.

3

4

5

FabWare

FabWare Update

10

6.1 Workflow

Print

6

6.2 Resin Tank Setting

The FabWare displays the current

material setting for the resin tank

and the layers have been printed

with the current resin tank. You

can click on the setting to change

the setting.

You can choose the brand and

material for the current print or just

to choose others to set for other

materials.

FabWare will check the setting of the resin tank and compare it with the setting of sliced file.

Please change the setting accordingly if an error of mismatch of setting detected.

print setup post processing

IPA 95%

IPA 95%

POST

PROCESSING

IMPORT

PRINT FILE

PRINTING

SETUP

AccuWare

Detailed information please refer to .AccuWare User Manual

POST

PROCESSING

IMPORT

PRINT FILE

PRINTING

SETUP

AccuWare

11

6.3 Platform level (Optional)

Print

6

Level Platform

Level Platform

Procedure:

Activation success. Click “Confirm ”to finish.

Shake well before pouring material into resin tank.

Note that resin level should be between the

indicator lines of minimum and maximum.

* Note : You can also add resin during printing without pausing.

Add Material

Find the“ AccuWare_3.1.X.XXX_release_install.exe”

located in the flash drive, and install.

Installation of Software

11

10

11

Platform level is crucial to successful print.Please install the clean platform and

remove the resin tank before the level process.

If A4 paper cannot be pulled out, the

printing platform leveling is basically

successful.

If not, move the platform down with

different step distance. Until it is

ready. Try small steps to avoid

damage to the screen.

3

3

4

In the control panel, find “Settings---

Hardware Settings---Motor Settings

---move to Zero Position” and tap.

Wait for the build platform to move

to the bottom and try to pull out A4

paper.

2

2

Lastly, tighten the four screws on the

printing platform in a diagonal order

and click OK to complete the leveling

of the printing platform.

4

4

First, place a piece of A4 paper on the

LCD screen,please make sure that

the A4 paper is clean and has no

excessive wrinkle.

1

Loosen four screws on the build

platform to ensure that the build

platform can be moved freely.

1

Moved freely

12

6.4 Clean Resin Tank (Optional)

Print

6

Clean Resin tank is a function that can be used after a print failure. To clean some residue the

failed print left in the resin tank.

On the FabWare main interface, tap

resin tank area to enter the Resin

Tank Information.

Click on Cure Resin close to proceed.

2

Select curing time and tap Next.

Change the curing time if the default

time is not sufficient.

3

After curing materials, remove the

cured material with resin tank cleaner.

DO NOT use sharp tools or it may

damage the film and lead to material

leakage.

4

6.4.1. Local Printing

Step 1 Choose to enter the printing queue. Which will show the pending jobs and history jobs

Step 2 Select a print job.

Select files to be printed

Step 3 Tap Print to Confirm printing

Tap Print

If there is a mismatch error detected, Please change the material setting by taping the button.

Modify printing brand and type

Step 4 Confirm printing prompts and tap Next.

Printing prompts

Tap to enter the Clean up the residue. Then select curing time and cure models. See 5.3 (Optional) Clean Resin Tank.

Step 5 Tap Next to start printing process.

Analyze and print model data file

Step 6 After finishing printing:

Tap OK to finish.

Finish printing

4

1

1

Place the resin tank cleaner in the

corner.

13

Print

6

3

3

4

Tap Print to Confirm printing.

If there is a mismatch error detected, Please change the material setting by

taping the button.

Confirm printing prompts and tap .

4

Tap to enter the Clean up the

residue. Then select curing time and

cure models.

See 6.3 Clean Resin Tank (Optional).

Print

2

6.5 Choose printing file

To ensure the model printing quality, keep the chamber door closed

when the Printer is printing or just finished printing. Do not touch the

model, resin tank, build platform or any other Printer parts.

Files can be sent to the printer with flash drive or through network.

6.5.1 Local Printing

Choose the print file stored in the printer to start printing in the queue.

2

1

2Select a print job.

Choose to enter the printing

queue. Which will show the pending

jobs and history jobs.

Next

14

Print

6

1

2

3

4

5

6

Insert the USB flash drive with sliced files into the Printer.

On FabWare main interface, tap to enter the printing interface.

Tap to enter the USB flash drive.

Select files to be printed.

Path for the saved sliced file:

This PC/Documents/3DDlpDocuments3/DlpGenerateOut/"Folder

(with corresponding Printer serial number)"

The Printer recognizes FAT32 format only.

7

Confirm printing prompts and tap Next.

Tap Next to start printing process.

After finishing printing,tap to finish.

Ok

6.5.2 Flash Drive Printing

5

6

6After finishing printing,tap

to finish.

Ok

5Tap to start printing process.

Next

6.5.1 Local Printing

15

Print

6

6.6

In the printing page, you can check the printing progress as well as pausing and cancelling

the current printing.

Printing Status

Name

1

2

3

4

5

6

Print detail

Print layer

Time

Percentage bar

Pause

Cancel

Tap to return to the previous step.

Printed layers/Total layers.

Time elapsed/Total time

Printing progress

Tap to pause the printing and tap again to resume.

Tap to cancel printing.

Description

1

2

3

4

5 6

16

Other manuals for AccuFab-L4D

1

Table of contents

Other Shining 3D 3D Printer manuals

Shining 3D

Shining 3D AccuFab-D1s User manual

Shining 3D

Shining 3D einstart-c User manual

Shining 3D

Shining 3D Transcan-C User manual

Shining 3D

Shining 3D Einstart User manual

Shining 3D

Shining 3D AccuFab-D1s User manual

Shining 3D

Shining 3D einstart-c User manual

Shining 3D

Shining 3D AccuFab L4D User manual

Shining 3D

Shining 3D einstart-c User manual

Shining 3D

Shining 3D EinScan-SE User manual

Shining 3D

Shining 3D AccuFab-L4D User manual