i

TRAK Machine Tools

Southwestern Industries, Inc.

Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual

Table of Contents

Printer Model & Serial Number .............................................................................................................1

Buytrakparts.com Login Credentials .....................................................................................................1

1.0 Safety .....................................................................................................................................2

1.1 Safety Publications ...............................................................................................................2

1.2 Safety Labels & Notices as Used in this Manual ......................................................................2

1.3 Safety & Information Labels Used on the EVO-T and EVO22-T ................................................2

1.4 Safety Precautions................................................................................................................3

1.5 Safety Features ....................................................................................................................3

1.5.1. HARDWARE ..................................................................................................................3

1.5.2. SOFTWARE...................................................................................................................3

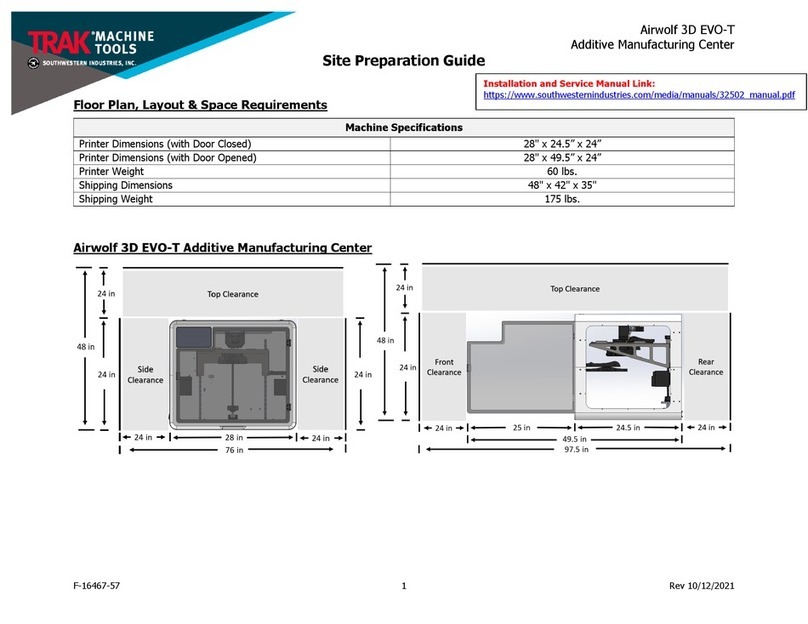

2.0 Site Prep & Requirements.........................................................................................................4

2.1 Printer Specifications ............................................................................................................4

2.2 Floor Plan, Layout & Space Requirements ..............................................................................5

2.2.1. EVO-T ..........................................................................................................................5

2.2.2. EVO22-T.......................................................................................................................6

3.0 Installation Process ..................................................................................................................7

3.1 Lifting, Moving, Uncrating, and Unpacking .............................................................................7

3.2 Packing List..........................................................................................................................9

3.3 Benchmark Part: Euclid Block ..............................................................................................10

3.4 Orientation, Controls & Functions ........................................................................................11

3.5Installation of Additional Components..................................................................................16

3.5.1. Top Cover ..................................................................................................................16

3.5.2. Install Glass onto bed..................................................................................................16

3.5.3. Connecting the Cables, Powering ON ...........................................................................17

3.6 LCD Overview ....................................................................................................................18

3.6.1. Home Menu................................................................................................................18

3.6.2. Print Menu..................................................................................................................19

3.6.3. Preheat Menu .............................................................................................................20

3.6.4. Control Menu ..............................................................................................................21

3.6.5. Settings Menu.............................................................................................................22

3.7 Connectivity .......................................................................................................................25

3.7.1. Connect via Wi-Fi ........................................................................................................25

3.7.2. Connect via Ethernet...................................................................................................25

4.0 Printing .................................................................................................................................26

4.1 Pre-Printing Steps ..............................................................................................................27

4.1.1. Verify all printer maintenance & firmware is up to date .................................................27

4.1.2. Slice your file, and save on a USB Drive .......................................................................27

4.1.3. Verify material type, quantity, and nozzle configuration.................................................28

4.1.4. WolfBite .....................................................................................................................30

4.1.5. Material & Nozzle Change Procedures

(if needed)

.........................................................32

4.2 Printing..............................................................................................................................38

4.3 Post-Printing ......................................................................................................................38