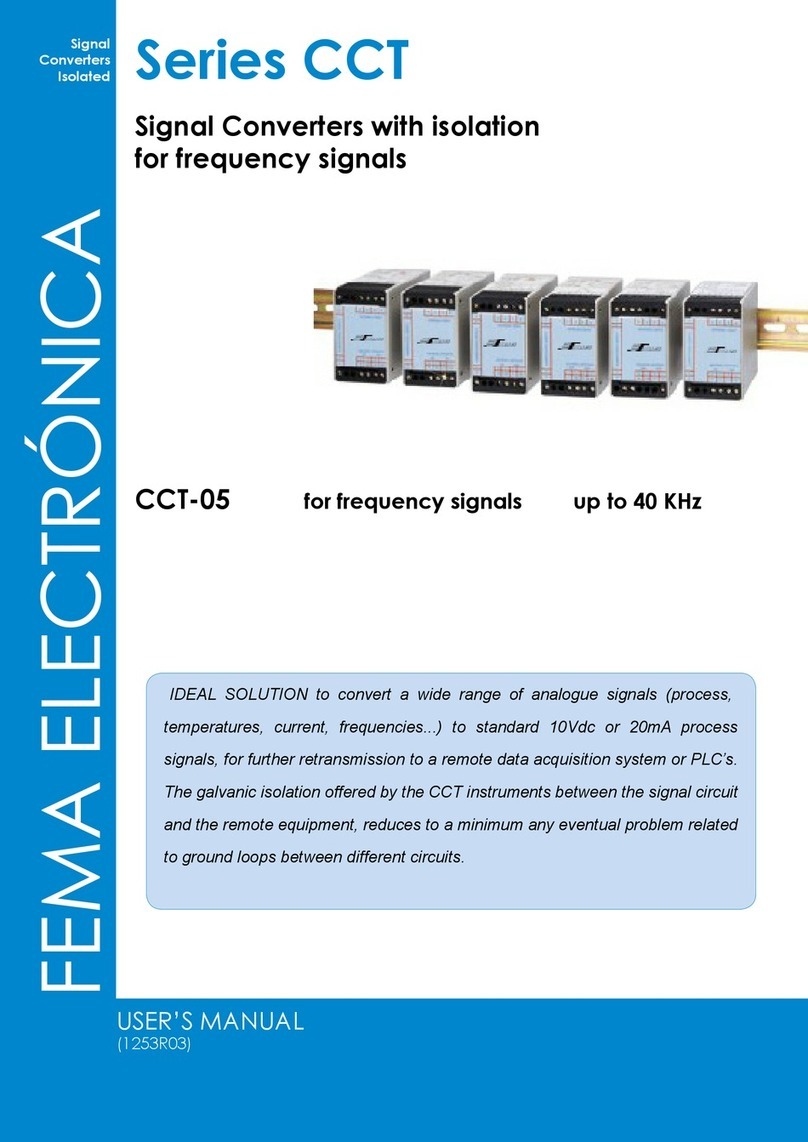

Fema Electronica ASGARD CCT Series User manual

36/96 rev.0911/03

CONVERTER-TRANSMITER .- Series CCT

CCT- 20 .- for PT100 Signals

CCT- 90 .- Potentiometer Signals

CCT- 95 .- Resistance Signals

P.I. Santiga Altimira 14 (Talleres 14, Nave 2) E08210-BARBERÀDELVALLÈS(SPAIN)

2.- ADJUST AND CALIBRATION PROCEDURE

1.- Open the housing to access the instrument internal circuits

2.- Select apropriate jumpers on boards ME, MP and MS

3.- Connectsignalgeneratortosignalinput terminals

Connect multimeter to signal output terminals

4.- Power up the instrument as indicated on the label

5.- Generatethesignallevellow

OperatepotentiometerP1onME until indication shows desired signal output low level

6.- Generatethesignallevelhigh

Operate potentiometer P2 on ME until indication shows desired signal output low level

7.- Repeat steps 6 to 9 in order to correct deviations and check adjust

Weight 270gr.

WireCrossection 4 mm2maximum

HousingandCover IP-40

Terminals IP-20

HousingandCover Polycarbonate, Light Grey, RAL 7032, UL 94 V-1

Terminals Polycarbonate,DarkGrey,UL94 V-2

Mounting StandardDINrail(DIN46277,DINEN50022)

(35 x 7,5mm) (1,38 x 0,3") .

1.- COMMON TECHNICAL SPECIFICATIONS

Output 0/20mA ó 4/20mA RL< 600 Ohms max. 22 mA ±3%

Output 0/10 Vdc RL> 1000 Ohms max. 11 V ±3%

ResponseTime ≤250 mSec

GalvanicIsolation 2 KVeff. 50 Hz/1 min (between all circuits)

IsolationTest 4 KVeff. 50 Hz/1min

Accuracy Class < 0,2forCCT-20,CCT-90andCCT-95

Ripple ≤0,5 %

Pass Band 1,5 Hz (-3 dB)

StorageTemperature -30 to +80 °C (-22 to +176 ºF)

WorkingTemperature -10 to +60 °C (+14 to +140 ºF)

TemperatureCoef. ≤0,015 %/ °C

PowerSupply Seelabeloninstrument

Consumption <1,5 VA

MECHANICALDIMENSIONSinmm(inches)

45

(1,771")

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

H i

+--

75

(2,952")

110

(4,33")

36

(1,417")

6.- INPUT SIGNAL MODULE

TheMEmoduletogetherwithMPmodule,allowconfigurationofdifferentinputsignalranges,andcalibratetheinstrument.On

theMEarelocated the potentiometersandjumpersforZero and Gainadjustment.OnMPmodulesare locatedthejumpers

forsignalinputconfiguration.

Jumper1.- ClosedforGrossPositive Offset

Jumper2.-ClosedforGrossNegativeOffset

JumperA.-ClosedforFineNegativeOffset

JumperB.-ClosedforMaximumGAIN

JumperC.-ClosedforMiddleGAIN

Jumper B y C .- Open for Minimum GAIN

Note : jumpers 1,2,A,B and C normally OPEN

P1 .- ZeroAdjustPotentiometer

P2 .- GainAdjustPotentiometer

OnSolderSide

1

2P2

P1

ABC

Power Supply connected on terminals 1

and 7. It is recommended the following

connection, including protection fuse and

mains switch.

POWER FUSE

230 Vac 50 mA

115 Vac 100 mA

48 Vac 150 mA

24 Vac 300 mA

24 Vdc 300 mA

4.- POWER SUPPLY CONNECTIONS POWER

FUSE

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+

--

MAINS

SWITCH

NOTE .- The current loop generated by

the CCT is ACTIVE. The CCT powers

the current loop. Do NOT connect the

output loop to elements which are also

active. This will damage both elements.

5.- OUTPUT SIGNAL .- SELECTION AND CONNECTIONS

InstrumentCCTallows outputs in voltage and

current. Only one of this outputs is active at

thesametime.Isispossibletoreconfigure the

instrumenttoanyoftheindicatedoutputsignals

below, plus the 4/20 mA and 0/10 Vdc signals

allowedbydefault.

Resistances in Ohms

OUTPUT R18 R24 R25

0/5mA - - - 100 - - -

0/10mA - - - 49,9 - - -

1/5mA 100K 124 - - -

0/20mA - - - - - - 24,9

NOTE : ‘- - -‘ resistance NOT installed

Resistances in KOhms

OUTPUT R29 R30 R31 R32

±10Vdc 49,9 - - - 200 - - -

0/1Vdc - - - - - - 11 100

0/5Vdc - - - - - - 100 100

1/5Vdc - - - 100 66,5 100

NOTE : ‘- - -‘ resistance NOT installed

MSMODULE

Jumper E and F Closed .- Outputs 4/20 mA

JumperE and F Opens.- Other Outputs

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+

--

Voltage Signal

Output

Current Signal

Output +-

+-

R29

R30

E F R24 R25

R31 R32

R18

C

A

B

3.- ACCESS TO INTERNAL CIRCUITS

1.-Witha flat screwdriver, force thefront cover ands walls towardsAandB,untilfixations ‘3’ are free.

2.-Take the instrument from points ‘2’ ‚ and extract it pulling towards C, until the internal circuits appear.

3.-Internalcircuitsareconnectedwiththehelpofpinsandallowaccesstopotentiometersansjumpersforrangeadjustment.

4.- When introducing back the housing, check position of front cover (Terminals 1 and 7 separated from the others) and

introduce it in the correct guides.

ME .- Signal Input Module

MS .- Signal Output Module

MA.- Power Module

MP .- Personalizer Module

ME MS

MA

MP

9.- MODEL 95 .- RANGES, JUMPERS, CONNECTIONS

The CCT converter can be configured in order to adequate the input and output signal ranges to the final application.2 Wire

measuringtechnique.Doesnotapplyautomaticcompensationofthemeasurewireresistances.Maximumadmisible resistance

is 1 MOhm

RANGE 0/200Ohms 0/2KOhms 0/20KOhms 0/200KOhms

MPJumpersClosed 5 6 7 None

MEJumpersClosed A,B,C OPEN

MinimumInputSpan 10% of Full Scale used

Minimum Input Span.- Minimum range at input in order to have a maximum output range in 0/10 Vdc

or 4/20 mA.

7.- MODEL 20 .- RANGES, JUMPERS, CONNECTIONS

The CCT converter can be configured in order to adequate the input and output signal ranges to the final application. For

thermorresitancePT100/RTDsignals,accordingtoDIN 43760, for 2 and3wirestechniques.

RANGE 0/100ºC 0/200ºC 0/300ºC 0/400ºC 0/500ºC 0/600ºC

MEJumpersClosed B C C Ninguno Ninguno Ninguno

MinimumInputSpan 50ºC 50ºC 50ºC 50ºC 50ºC 50ºC

CurrentthroughSensor < 1mA

SensorBreakDetection Outputsignagoeslower than the minimumoutput signal (<4mA for example)

Minimum Input Span.- Minimum range at input in order to have a maximum output range in 0/10 Vdc or 4/20 mA.

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+--

PT-100

2 wire

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+--

PT-100

3 wire

In 2 wire technique connections

the automatic compensation of the

measure wire resistenace is not

activated.

Personalizer Module

MP-90

7 6 5

8.- MODEL 90.- RANGES, JUMPERS, CONNECTIONS

The CCT converter can be configured in order to adequate the input and output signal ranges to the final application.Accepts

potentiometrictypesignals.Potentiometervaluesbetween100Ohmsand1MOhm.Bydefault,unitsareconfiguredat0/100%

of the potentiometer range,aAlthough it is possible to adjust only a part ot the potentiometer range.

RANGE 0/100%

MEJumpersClosed A,B,C OPEN

TerminalConnections 3,4 and 5

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+

--

Potentiometer

OUTPUTS / SALIDAS

mA Vdc

INPUT / ENTRADA

SUPPLY / ALIMENTACION

3 4 5 6

9 10 11 12

7

1

+

Lo

Hi

+

--

Resistencia

Manufacturer: FEMA ELECTRÓNICA, S.A.

Address: Centro Industrial Santiga

c\ Altimira, 14 (Talleres 14 - Nave 2)

E-08210 - Barberà del Vallès (ESPAÑA)

Products Covered SERIES:CCT MODELS : 20, 90, 95

We declare that the above referrenced instruments comply with the valid rules and regulations detailed below :

IMMUNITY: EN 50082-1 (1992)

CEI 801-2: UNE 20801-2-94 (Nivel 2)

CEI 801-3: UNE 20801-3-94 (Nivel 3)

CEI 801-4: UNE 20801-4-94 (Nivel 3)

EMISSION: UNE 50081-1 (1992)

EN55022:ClaseB/CISPR22

EN 60204-1 and prEN 60204-1 CHAP. 12, 13Electrical security

prescriptions.

UNE21352-76:CEI359-71Operatingqualityexpressionsforelectronic

equipments.

UNE 20652-80: CEI 284-68Behaviour rules inherent to the handling

of electronic equipments and other similar technics.

REGULATIONS:

EUROPEANDIRECTIVEFORLOW VOLTAGED73/23/CEE AMENDED

BY D93/68/CEE. Equipments powered from 50 to 1000 Vac. and /or from

75 to 1500 Vdc.

EUROPEANDIRECTIVE FOR THESAFETY D92/59/CEE.

ELECTROTECHNICALREGULATION FORLOW VOLTAGE(RBT)ITC

21, ITC 29, ITC 35. Equipments with power supply lower than 50 Vac

and/or 75 Vdc.

EUROPEANDIRECTIVE FORELECTROMAGNETICCOMPATIBILITY

D89/336/CEE AMENDED BY D93/68/CEE, ACCORDING TO RD1950/

1995 (01/12). Francisco Guàrdia

Quality Manager

Barberà del Vallès, 1998

DECLARATION OF CONFORMITY

INCLUDE THE FOLLOWING INFORMATION.-

Serial Number : ______________________________

Signal Input / Signal Output:____________________

Power Supply : ________________________

Provided by: ____________________________

Description of defective encountered :

13.- WARRANTY

FEMA ELECTRÓNICA, S.A. warrants this product free of defects in workmanship for ONE (1) year from the date of shipment. This Warranty

is VOID if the unit shows evidence of damages as a result of misapplication, accident, misuse or if the product had been tampered or repaired

by personnel or companies without the official authorization of FEMA ELECTRÓNICA, S.A. This Warranty is VOID also for damages caused by

defective or inappropriate applications. In case of malfunction return the unit to the manufacturer for evaluation. Within the warranty period, and

after examination, and if the unit is found to be deffective and covered by this warranty, the unit will be repaired or replaced.

LIMITATION OF LIABILITY : FEMA ELECTRÓNICA, S.A. shall not be responsible for any damage or loss to other equipment however caused,

which may be experienced as a result of the installation or use of this product. The liability shall not exceed the purchase price paid of the product

upon which liability is based. In no event shall FEMA ELECTRÓNICA, S.A. be liable for consequential, incidental or special damages.

SHIPMENTS FOR REPAIR.- Send free of charges and apropriately packed, to the following address :

FEMAELECTRÓNICA, S.A.

REPAIRS

Pol.Ind.Santiga (Altimira 14, Talleres 14, Nave 2)

Apartado de Correos 49

E-08210 BARBERÀ DEL VALLÈS (ESPAÑA)

EXCITATION VOLTAGE.- The model CCT-32 supply the Excitation voltage for

sensors, through the terminals 3 & 5. Do not connect these terminals to other

external power supply, permanent damages may result to the unit.

SIGNAL WIRING.- Certain considerations must be given when install the signal

input wires. If the wires are longs can act like an antenna and introduce the

electrical noise to the unit, therefore: Do not install the signal input wires in the

same conduit with power lines, heaters, solenoids, SCR controls etc...and

always far from these elements. When shielded wires are used, leave

unconnected the shield on the transmitter side and connect the other end of the

shield to the ground terminal of the machine.

SAFETYCONSIDERATIONS

PRESCRIPTIONS.- Before starting any operation of adjustment, replace-

ment, maintenance or repair, the unit must be disconnected from any kind of

powersupply.Keeptheunit clean , toassure goodfunctioning andperformance.

Topreventelectrical or fire hazard,donot expose theunitto excessive moisture.

Do not operate the unit in the presence of flammable gases

or fumes, such an environment constitutes a definite safety

hazard.Theunit is designedto be mounted ina metal panel.

If the unit shows signs of damage, or is not able to show the

expected measures, or has been stored in a bad conditions

or a protection failure can occur, then do not attempt to operate and keep the

unit out of service.

IN CASE OF FIRE

1.- Disconnect the unit from the power supply.

2.- Give the alarm according to the local rules.

3.- Switch off all the air conditioning devices.

4.- Attack the fire with carbonic snow, do not use water

in any case.

WARNING : In closed areas do not use systems with vaporized liquids.

11.- PRELIMINARY NOTES

INSTALLATION.-PRECAUTIONS

Theinstallation and useof this unitmust be doneby qualified

personnel. The unit has not AC (mains) switch, neither

internal protection fuse. it will be in operation as soon as

powerisconnected.Theinstallationmustincorporateanexternalmainsswitch

with a protection fuse in the power line

Power : 230 Vac Fuse 50 mA

Power : 115 Vac Fuse 100 mA

Power : 24 Vdc Fuse 300 mA

Add the appropriate devices to the installation in order to protect the operator

and system when using the unit to control a machine or process where injury

to personnel or damage to equipment may occur as a result of failure of the

unit. SAFETY PRESCRIPTIONS.- This unit has been designed and

tested under EN-61010-1 rules and is delivered in good condition.

This operator's manual contains useful information for electrical

connections. Do not make wiring signal changes or connections

when power is applied to the unit. Make signal connections before

power is applied and, is reconnection is required, disconnect the AC (mains)

power before such wiring is attempted. Install the unit in a places with a good

ventilation to avoid the excessive heating. And far from electrical noise

source or magnetic field generators such as power relays, electrical motors,

speed controls etc... The unit cannot be installed in open places. Do not use

until the installation is finished.

POWER SUPPLY.- The power supply must be connected to the adequate

terminals (see the connection instructions). The characteristics of the power

supplyareshowedontheside label. Please makesurethattheunitis correctly

connected to a power supply of the correct voltage and frequency. Do not

use other power supply otherwise permanent damage may be caused to the

unit. Do not connect the unit to power sources heavily loaded or to circuits

whichpowerloads in cycle ON-OFForto circuits whichpowerinductive loads.

WARNING.- If the power supply is dc voltage, be careful with the polarity

indicated for each terminal.

This manual suits for next models

3

Table of contents

Other Fema Electronica Transmitter manuals

Popular Transmitter manuals by other brands

Vega

Vega VEGABAR 81 operating instructions

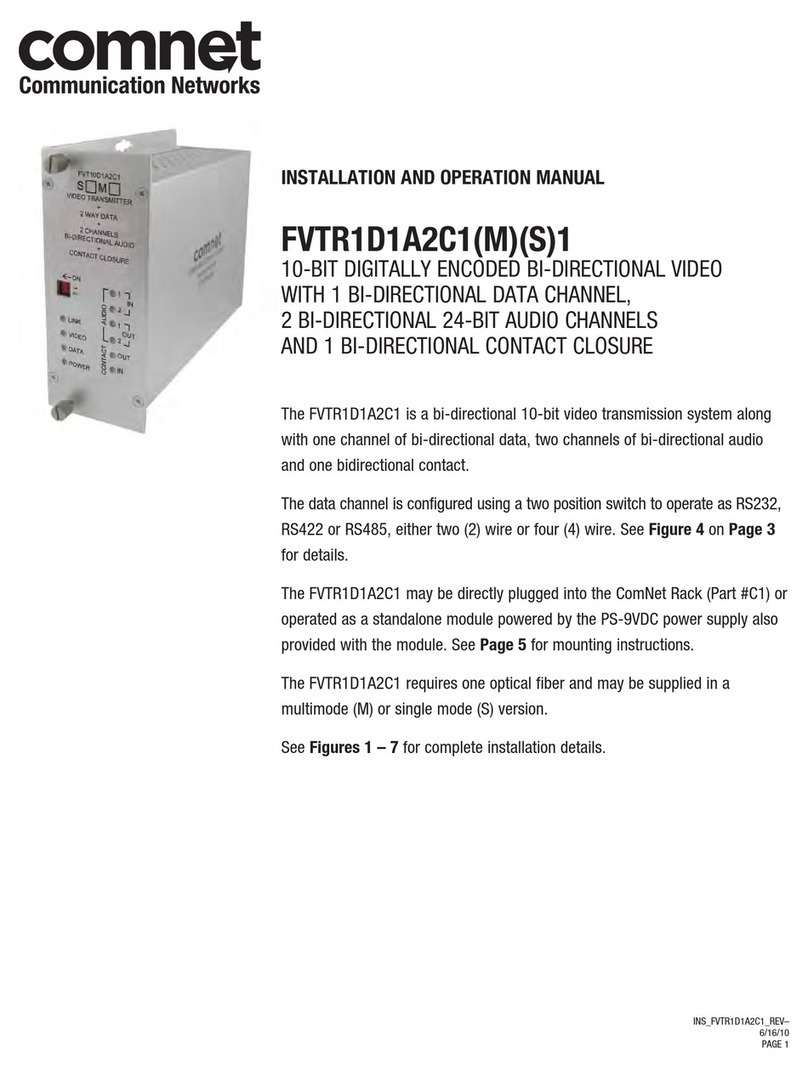

Comnet

Comnet FVTR1D1A2C1M1 Installation and operation manual

aci

aci ACI/DP Series Installation and operation instructions

Evikon

Evikon PluraSens E2658-O3 user manual

Sennheiser

Sennheiser BT T100 user manual

Dwyer Instruments

Dwyer Instruments GSTA Series Installation and operating instructions

CAME

CAME TOP Series quick start guide

Siel

Siel EXC-GT Series User and maintenance manual

Teslink

Teslink WPT171AT Installation information for customers & installers

Clarion

Clarion DGL373 owner's manual

Shure

Shure AXIENT AXT100 user manual

Becker

Becker B-Tronic VarioControl VC3201B Assembly and operation instructions