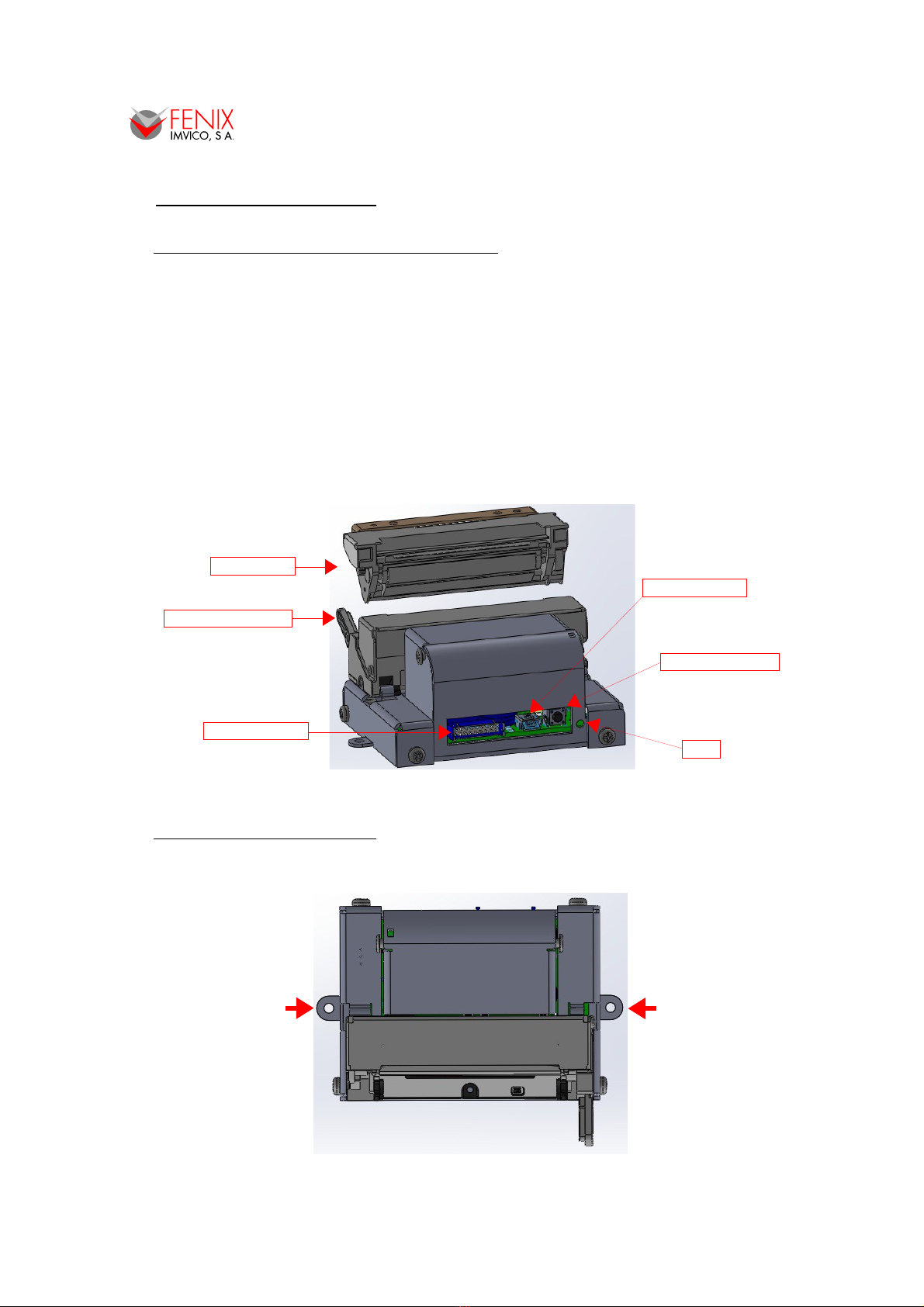

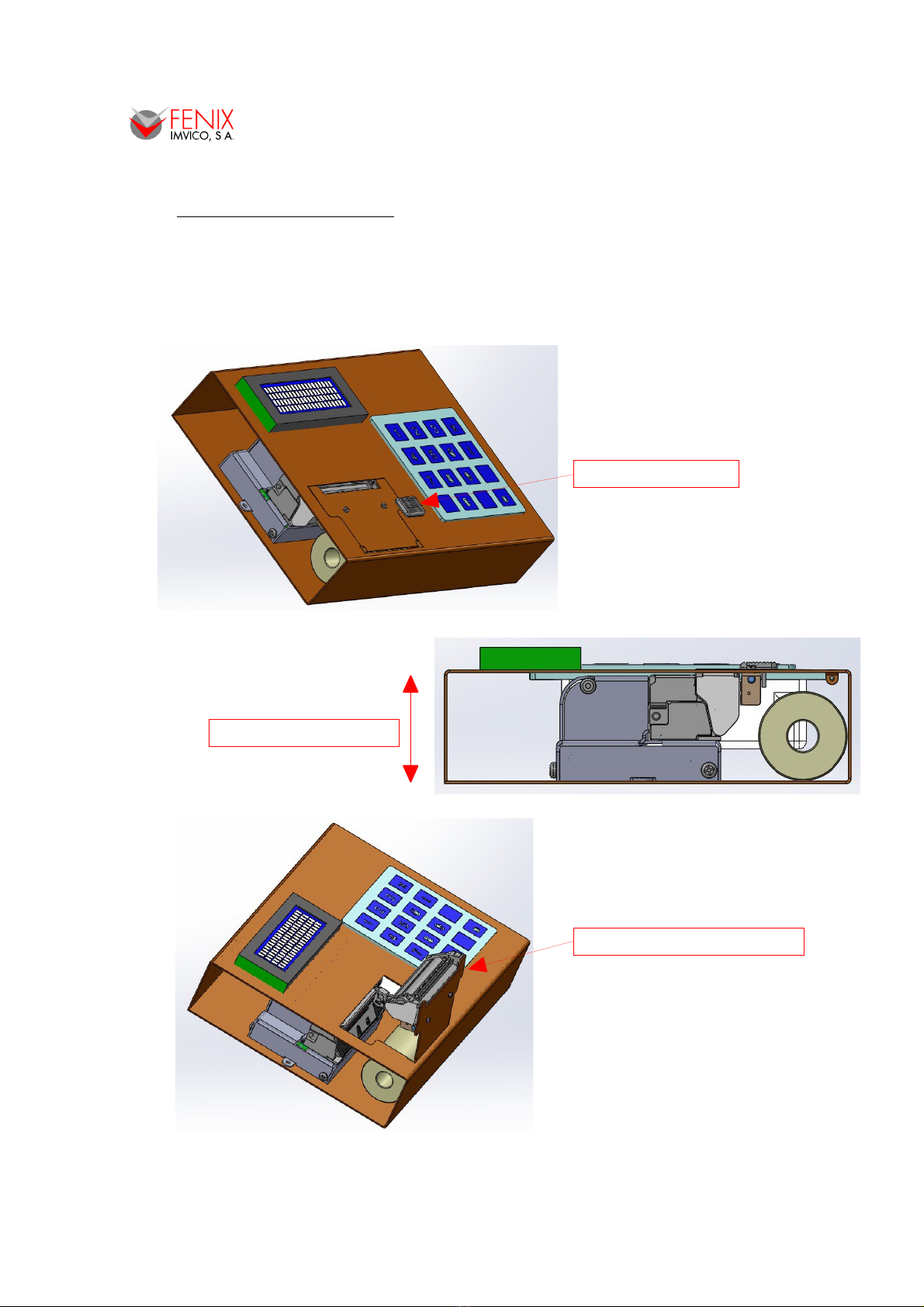

TS2000 PRINTERS OPERATION MANUAL

2 – IMPORTANT NOTES ON THERMAL PRINTER

HANDLING

In order to preserve the life of the printer, it is necessary to keep in mind some precautions on the

handling of the T 2000 printer. Please read carefully the following points in order to make a good use of

the printer.

2.1. SA FETY PRECAUTIONS

•Before using the printer, read carefully section - IN TALLATION.

•NEVER connect the external power supply with the wrong polarity. This could permanently

damage the printer.

•Turn off the printer immediately if it produces smoke, a strange smell or an unusual noise. Keeping

on using the printer could cause fire. Unplug the equipment immediately and contact your official

distributor.

•NEVER connect cables with different connectors from the ones mentioned in this manual. Failing

on doing so could permanently damage the printer.

•Use a power supply whose output voltage is within the specification range stated in this manual.

Over voltage can permanently damage the printer. Under voltage can cause malfunctions.

•NEVER wet T 2000 thermal printer with water or any other liquid. If any liquid is spilled inside the

equipment, unplug the power cable immediately and contact the technical service.

•Make sure the printer is on a steady, securely fixed surface. If the printer falls down, it could break

or damage.

•NEVER use the printer in high humidity or in locations with high risk of fire.

•NEVER place heavy objects on top of the printer and never lean on it.

•NEVER put any object inside of the printer, as it could cause hardware damage on it, such as

short-circuit, print head breaking or general failure of the printer.

•NEVER shake the printer.

•NEVER disassemble or modify the hardware of the printer.

•NEVER try to repair the printer. Please contact your official distributor in case of failure.

•As the printer contains electromagnets (inside of the motor), it should not be used in excessively

dirty environments or places with dust or metal particles.

•NEVER print without paper loaded or without the cover closed, as the thermal print head life can

be highly shortened.

•NEVER pull the paper out when the cover is closed. Use the paper advance button instead.

•Avoid touching accessible parts with metallic objects, such as screwdrivers or tweezers, the print

head thermal elements as well as the electronic printed circuit. They are delicate parts.

•NEVER touch with bare hands the areas around the print head and the motor surface as they

become very hot during and just after printing; wait 15 seconds after printing to let them cool down.

•NEVER touch the surfaces of the print head thermal elements or the electronic printed circuit, as

dust and dirt can stick to their surface and cause damage by electrostatic discharge. Moreover,

some electronic components can get very hot during operation.

•The thermal paper contains Na+, K+ and Cl- ions that can cause harm to the print head elements.

Therefore, use only the specified paper.

•If the printer has not been used for long period of time and the paper was loaded, the paper could

become deformed by the drive roller pressure. It is recommended to make it advance at least 30

mm before printing again.

•For safety reasons, unplug the printer if it is not going to be used over a long period of time.

•Do not print contin o sly (witho t stopping) for more than 6 min tes.

4/58