Figure 3: System Wiring

Figure 2: Flush Mount Units

Series 27020-0 and 27021-0

1. In order to function properly, the sensing shell of the unit must

remain free from paint, grease, oil, etc. Should such a build up

occur, DO NOT, under any circumstances, attempt to remove it.

Replace the unit.

2. Detectors mounted in an area subject to physical abuse or damage,

other than above, must be suitable protected without obstruction the

thermal airpath to the unit.

3. Do not install the unit where the shell would be physically

damaged by sand, grain, rocks, etc.

4. Any detector that has been involved in a fire, abused

or damaged must be replaced.

5. Consult the factory for special precautions necessary

for outdoor use or moist environments.

ANY OF THE ABOVE COULD CHANGE THE FACTORY

TEMPERATURE SETTING, WHICH MAY RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY OR DEATH.

IT IS POSSIBLE FOR A UNIT TO HAVE BEEN ABUSED OR

DAMAGED AND NOT DISPLAY ANY OUTWARD INDICATION OF

THE DAMAGE. ALL UNITS SHOULD BE TESTED PERIODICALLY

IN ACCORDANCE WITH NATIONAL FIRE PROTECTION

ASSOCIATION REQUIREMENTS (72e) OR THE AGENCY HAVING

LOCAL JURISDICTION.

WARNINGS

INSTALLATION (continued)

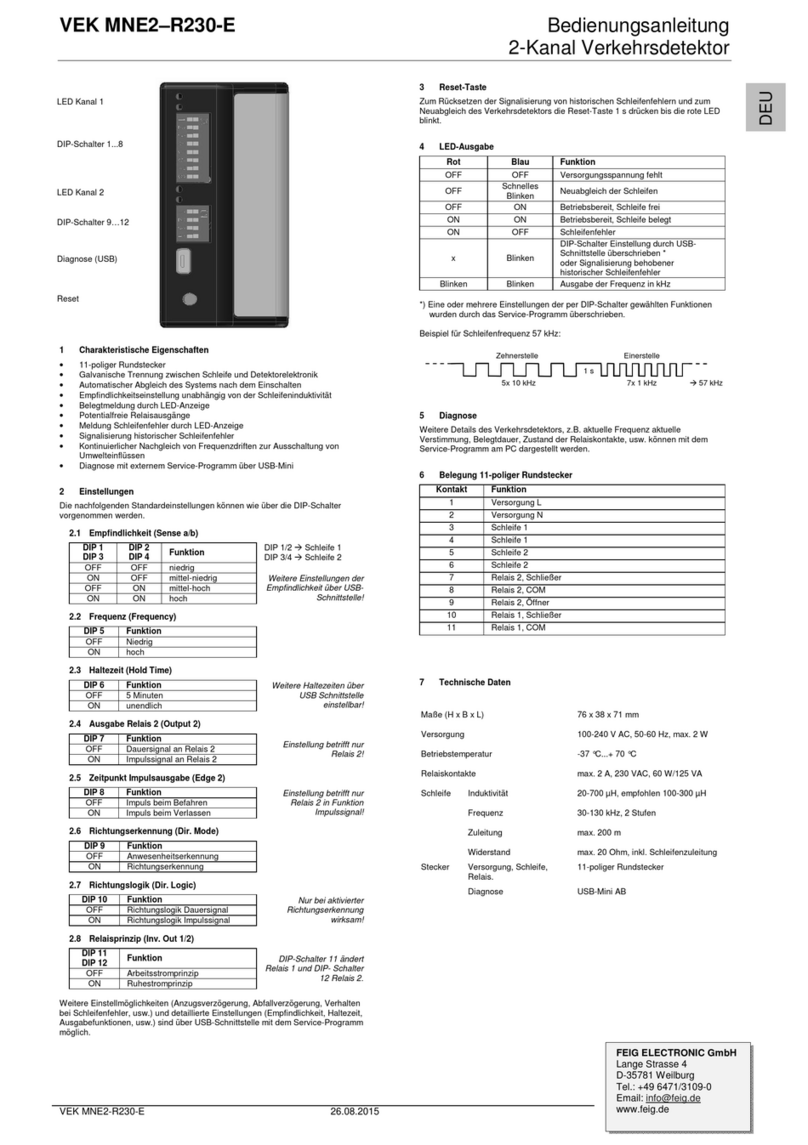

3. Run system wiring through rubber grommets and connect

to terminals on detector per Figure 3 observing applicable

electrical codes.

4. Mount detector to adaptor with two #8-32 screws supplied.

For optional outlet box mount, proceed as follows:

1. Bend the mounting brackets on the supplied adaptor to fit

standard 4-inch outlet box.

2. Mount adaptor to outlet box through two slotted holes in

adaptor mounting brackets. Adaptor may be rotated to

position detector.

3. Connect system wiring to terminals on detector per Figure 3

observing applicable electrical codes.

4. Mount detector to adaptor with two #8-32 screws supplied.

1. It is recommended that a standard 4-inch outlet box be

used to mount the detector. Care should be taken that a

neat 4-inch diameter hole be cut in ceiling to allow mounting

clearance for detector. An oversized or ragged hole may

show around the mounted unit.

2. Attach supplied flush mount adaptor to outlet box. Adaptor

may be rotated in screw slots to position detectors as desired.

3. Connect system wiring to terminals on detector per Figure 3

observing applicable electrical codes.

4. Mount detector to adaptor with two #8-32 screws supplied.

400 MAIN STREET, ASHLAND, MA 01721

TEL: (508) 881-2000 FAX: (508) 881-6729

www.fenwalcontrols.com

These instructions do not purport to cover all the details or variations in the equipment described,

nor do they provide for every possible contingency to be met in connection with installation,

operation and maintenance. All specifications are subject to change without notice. Should further

information be desired or should particular problems arise which are not covered sufficiently for

the purchaser’s purposes, the matter should be referred to KIDDE-FENWAL, Inc., Ashland,

Massachusetts.

Page 2 Horizontal DETECT-A-FIRE®Units 1-800-FENWAL-1 www.fenwalcontrols.com

© 2009 Kidde-Fenwal. All rights reserved. Printed in U.S.A. 06-L04104-001 3/26/2009

Fenwal is a registered trademark of Kidde-Fenwal, Inc.

®