Fenwal F1H-RYW1K Administrator Guide

Page 1

F1H-RYW1K

Operation Instruction Manual

ES1417 K0

Thank you for purchasing this product

In this manual, we have shown the important notice in

order for you to use the device just and the method of

handling this system

In additional to you read this manual well before the

utilization, understanding well, and use

After you read, in the place where it seen with it is seen

with anytime, please to be sure to keep

730110 K0

2

ES1417

Page

Table of contents

1. Safety Instructions................................................................................................................................ 3

2. Name and Function of each section........................................................................................................ 4

3. Install.................................................................................................................................................. 5

4. Specification...................................................................................................................................... 8

5. Maintenance and Inspection................................................................................................................ 10

6. Disposal ............................................................................................................................................ 13

7. Support.............................................................................................................................................. 13

730110 K0

3

ES1417

Page

Safety Instructions

・This smoke detector has the ability to transfer information outputs and alarm status indicators to detect

smoke.

・Before the using, read this chapter and use correctly.

・The contents which it occurs when you handle erroneously are divided in two of “warning” and “caution”.

This division states clearly the size and impendence of the harm and the damage.

・Please keep below rules for safety.

・Guarantee

[A term of a guarantee]

In regard to the guarantee of this product, the designated payment of the order main thing after the paying

1 years you guarantee first only the breakdown which occurs in the normal busy condition which you

follow the instruction manual.

[Guarantee range]

In regard to the breakdown which it occurs in this product with the criticism of payment person side

during the above-mentioned guarantee period, it does returns repair in the responsibility of payment

person side. However, when it corresponds next, you exclude from the object of this guarantee.

1) Fire, earthquake and the damage by wind and flood, breakdown and the loss by the thunderbolt

and other natural disasters etc.

2) After the shipping, transporting and moving and falling etc at your corporation, breakdown and

the loss with inadequate handling.

3) When cause of breakdown due to the reason other than the payment item.

4) Error in regard to use of the consumer, breakdown and the loss with repairing, remodeling other

than our company and error connecting.

Furthermore, the guarantee referred to here being something which means the guarantee of the payment

item single unit, pardons the damage which is induced by the breakdown of the payment item.

The Warning symbol is used to indicate situations and conditions that can cause

operator serious injury and/or equipment damage.

The Caution symbol is used to indicate situations and conditions that can cause

operator injury and/or equipment damage.

!

Warning

・Do not disassemble a detector. It causes trouble.

・Do not remove a detector, Fire can not be detected.

・Do not use detector which have impacted. And also do not paint or cover a

detector.

・Do not soak a detector in water, and do not put a detector into water. It causes

electric shock.

・Do not use the method that not listed in this manual, It causes trouble.

・This system only tells the outbreak of a fire. This system is not Fire prevention

systems. And Fire extinguishing system.

・Do not use at the place where it exceeds environmental specification. It causes

trouble.

・Do not put heat source under the detector.

Caution

!

!

Warning

Caution

!

730110 K0

4

ES1417

Page

1. Name and Function of each section

Detector

Mounting Base

State Indication LED

・Normal supervision:10 seconds interval

・Alarm mode:1 seconds interval

・Trouble mode:Off (not blinking)

Power Supply &

Signal output connector

Guide of installation

Insert Terminal 3, 4

Smoke Air flow

Insert Terminal 1, 2

730110 K0

5

ES1417

Page

2. Install

2.1. Install of Smoke Detector

Smoke detectors should be installed in order to detect following place.

・The flow of smoke into position

・Fans forced to inhale position

When you use smoke detector in a fast wind speed, it is necessary that the smoke is ongoing around

detector. Please be careful.State Indication LED Address number should be placed below or sideways

・The smoke detector detects a scattered light by smoke particles optically.

And that detects a large amount of dust and steam too.

Please install correct location.

・Do not use at the place where it exceeds environmental specification. It

causes trouble.

・Do not install wrong location. The smoke detector cannot detect a smoke.

・Be sure to install the detector away from sources of electrical noise such as

high voltage and high current switches.

・煙検知器は光学的に煙の粒子による散乱光を検出しており、煙ではなく

ても埃や水蒸気の粒子等が多量に発生する環境で使用されると、誤作動

の原因となります。

・使用環境温度、湿度は仕様値内でご使用下さい。

・誤った位置に取り付けると火災による煙を正常に感知できず、誤動作の

原因になります。

・誤動作を防止する為に検知器を高電圧スイッチや大電流スイッチなどの

ノイズ源を近づけないで下さい。

[Isolation from electric noise source such as power line]

The signal conductor which is connected to the detector, please wires over 20cm

separating from the power line.

Case it is not possible, please pass in the metallic conduit which the power line is

grounded.

[モーターなどの動力線電気的ノイズ源からの隔離]

モーターなどの動力線は検知器から 20cm 以上離して敷設して下さい。20cm

以上離す事ができない場合は、動力線を D種接地(第 3種接地)された金属

管の中に通して下さい。

・Do not disassemble a detector. It causes trouble.

・Do not remove a detector, Fire can not be detected.

・Do not use detector which have impacted. And also do not paint or cover a

detector.

・Do not wiring while power is on. It causes electric shock and detector troubles.

Caution

!

Caution

!

!

Warning

F1H-RYW1K

F1H-RYW1K

730110 K0

6

ES1417

Page

2.2. Method of installation

(1)Names of parts mounting base is as follows.

(2)Please install a Mounting Base to “install holes”with two screws M3 which is more than 15mm

length.

(3)Please put both insert guides together, and insert Terminal and Attachment of Detector into Mounting

Base.And Turn a Detector Clockwise until make a sound with "a snick".

・Incorrect loading of the equipments can cause a malfunction, failure or drop.

・Tighten the screw in the specified torque range. (torque 0.5N・m: Reference

value)

・Under tightening can cause a drop, short circuit or malfunction.

・Over tightening can cause a drop, short circuit or malfunction due to damage to

the screw or he equipments and malfunction and fire.

・Put Insert guides, Detector Terminal andAttachment together correctly.

It causes trouble.

・Do not turning a detector too much.Also do not make a lack of insertion.

・Do not remove a detector, Fire can not be detected.

・Do not use detector which have impacted. And also do not paint or cover a

detector.

!

Warning

!

Warning

730110 K0

7

ES1417

Page

(4)Please insert the connector cable into the output connector.

・The connectors are polarized. Please make suitable polar insertion. And please

ensure that no loose insert. Loose or Force inserts failure can cause a fire.

・Please do not pull the connector strongly. It causes damage.

・Output relay is PhotoMOS relay. Insulation Test under DC24V between Relay

and Relay, Relay and Power supply.

・Do not place obstacle as wiring etc. near the slit of the detector. It will disturb

inflow of smoke.

・Please provide a dedicated power supply as much as possible.

・This Detector does not have over voltage protection device. Before using,

Please add an external over current circuit breaker.

・Smoke detectors are detecting light scattered by smoke particles in the optical.

When used in an environment that generated a large amount of water vapor and

particles of dust and smoke can not cause false alarms.

!

Warning

Caution

!

730110 K0

8

ES1417

Page

3. Specification

(1)

Name

:

Photoelectric Smoke Detector

(2)

Type

:

F1H-RYW1K- xx xx x

①Sensitivity

②Type of Output

③Length of cable

Standard setting F1H-RYW1K-R3BB2

Sensitivity 0.3%/m, Alarm Output B, Trouble Output B, Cable length 2m.

①Sensitivity:0.3%/m~0.9%/m,1%/m,2%/m,3%/m(Value = R3~R9、01,02,03)

Standard Setting is 0.3%/m.(Value=R3)

②Type of Output:Type of Alarm & Trouble Output

Standard Setting is Alarm=B,Trouble=B.

(Value = BB)

③Length of cable:Cable Length 0=None,2=2m,5=5m。

Standard Setting is 2m. (Value = 2)

3.1. Electrical Specification

(1)

Rated Current

:

DC 30mA

(2)

Range of

Operating Voltage

:

DC10.0V~DC30.0V

Acceptable ripple voltage 300mVp-p

Power supply with connector cable.(See bellow(6))

(3)

Sensitivity

:

Depend on Type of Product. 0.3%/m(Nominal)

(4)

State Indication

LED

:

RED LED

State of LED

Normal mode

10 seconds interval

Alarm mode

1 seconds interval

Trouble mode

Off (not blinking)

Alarm will override trouble.

(5)

Output

:

Alarm, Trouble Relay Output

Capacity of Relay DC24V,0.5A Resistance loading

State depends on Type of relay.

Type

Contact

Normal

mode

Alarm

mode

Trouble

mode

Power

OFF

AA

Alarm

Open

Close

Open

Open

Trouble

Open

Open

Close

Open

AB

Alarm

Open

Close

Open

Open

Trouble

Close

Close

Open

Open

BA

Alarm

Close

Open

Close

Open

Trouble

Open

Open

Close

Open

BB

(Standard)

Alarm

Close

Open

Close

Open

Trouble

Close

Close

Open

Open

・State of output will be normal about a second after power supply.

・Output relay is PhotoMOS relay.

・On resistance Max.0.7Ω.Off state leakage current 1μA.

・Insulation Test under DC24V between Relay and Relay, Relay and

Power supply.

730110 K0

9

ES1417

Page

(6)

Connector Cable

of Power supply &

Output

:

Connector cable included.

Connector:JST SHR-06V 6pin

Cable:Temperature rating 80℃,Voltage rating 300V,AWG#28, UL1061

Length:Depend on Type of Product. Standard is 2m..

Connection Details

Pin №& Color

Power

Operating Voltage

6

Blue

-

5

White

Alarm

3

Orange

-

4

Orange

Trouble

1

Brown

-

2

Brown

(7)

Alarm

Restoration

:

Auto Restoration:When smoke disappear Automatically.

(8)

Self Check

:

Dirty, Deterioration

(9)

Automatic test

function

:

Automatically sensitivity correction is carried out once a day to

check sensitivity change of optical instruments by

environmental and annual deterioration. The detector becomes

trouble condition before exceeding correctable limit.

3.2. Mechanical Specification

(1)

External

:

Φ28×H57mm(Installation Base 10mm is contained)

(2)

Mass

:

Approx 25g(Installation Base is contained)

(3)

Main Material

:

ABS resins

3.3. Environmental Specification

(1)

Operating

Temperature

Range

:

-10℃~60℃

(2)

Storage

Temperature

Range

:

-20℃~75℃

(3)

Operating

Humidity Range

:

30~85%RH Non condensing

(4)

Storage

Humidity Range

:

5~95%RH Non condensing

(5)

Resistance to

corrosion

:

No tolerance to acid and alkaline.

Use the detector in an environment that meets the general specifications

contained in this manual. Otherwise it causes trouble and erroneous operation.

Working temperature and humidity will affect the life span of equipment.

Please consider derating and use.

!

Warning

Caution

!

730110 K0

10

ES1417

Page

4. Maintenance and Inspection

4.1. Daily Inspection

№

Item

Object

Content

Method

Judgment

Criteria

Treatment

1

Installation

Common

Securely locked?

Move the

detector to

check.

The detector must

be installed

securely.

Retighten the

screws on the

base with proper

torque.

Obstacle near the

inlet of detector?

Check

Visually

Obstacle must not

be present.

Removed.

2

Appearance

Common

Adhesion of dirt

and foreign

matter?

Check

Visually

Dirt and foreign

matter must not

be present.

Removed and

Clean.

Damages?

Check

Visually

Damages must

not be present.

Change the

detector.

3

Wiring

Common

Damages or

Breakages?

Check

Visually

Damages must

not be present.

Change the

connector cable.

Adhesion of dirt

and foreign

matter on the

connector?

Check

Visually

Dirt and foreign

matter must not

be present.

Removed and

Clean.

Looseness of

connectors

Move the

wire to

check.

Connectors must

not be loose

Change the

connector cable.

4

Behavior

Normal

supervision

Detector

State Indication

LED

Check

Visually

Blink 10 seconds

interval.

Check the State

Indication LED

behavior.

・Please do not touch the terminal while the unit is energized. It may get an electric

shock.

・Please do the cleaning and the increase tightening of the screw after the power

supply off. If not the power supply off, it may get an electric shock.

・Do not soak a detector in water, and do not put a detector into water.

・Under tightening can cause a drop, malfunction.

・Over tightening can cause a drop, malfunction due to damage to the screw or

equipments and malfunction.

・Please use the dry cloth or wring the water out tightly cloth for the cleaning.

・After Cleaning, Do not leave a foreign substance such as sawdust or wiring debris

on a detector. Such debris could cause erroneous operation.

・Do not clean with a solvent such as a ph-balanced detergent, Bleach, Benzene,

Thinner, Alcohol. It causes the detector surface is damaged.

!

Warning

Caution

!

730110 K0

11

ES1417

Page

4.2. Periodic Inspection

The items that must be inspected one or two times every 6 months to 1 year are listed below.

When the equipment is moved or modified, or layout of the wiring is changed, also perform this

inspection.

Do not needs to check smoke detect function with real smoke such as Tobacco, incense, etc. Because

this smoke detector has self check functions.

№

Item

Object

Content

Method

Judgment

Criteria

Treatment

1

Operating Temperature

Common

Used within the

specification?

Measure

with a

thermometer.

0℃~50℃

Meets the

specification.

2

Operating Humidity

Common

Used within the

specification?

Measure

with a

hygrometer.

30~85%RH Non

condensing

Meets the

specification.

3

Atmosphere

Common

IS there volatile

or corrosive

gas?

Measure

corrosive

gas.

No tolerance to

acid and alkaline.

Meets the

specification.

4

Power Supply Voltage

Common

Used within the

Power Supply

Voltage

specification?

Measure a

Power

Supply

voltage.

DC10.0V ~

DC30.0V

Meets the

specification.

5

Ripple Voltage

Common

Used within the

Ripple Voltage

specification?

Measure a

ripple

voltage.

300mVp-p

Meets the

specification.

6

Installation

Common

Securely

locked?

Move the

detector to

check.

The detector must

be installed

securely.

Retighten the

screws on the

base with proper

torque.

Obstacle near

the inlet of

detector?

Check

Visually

Obstacle must not

be present.

Removed.

7

Appearance

Common

Adhesion of dirt

and foreign

matter?

Check

Visually

Dirt and foreign

matter must not

be present.

Removed and

Clean.

Damages?

Check

Visually

Damages must

not be present.

Change the

detector.

8

Wiring

Common

Damages or

Breakages?

Check

Visually

Damages must

not be present.

Change the

connector cable.

Adhesion of dirt

and foreign

matter on the

connector?

Check

Visually

Dirt and foreign

matter must not

be present.

Removed and

Clean.

Looseness of

connectors

Move the

wire to

check.

Connectors must

not be loose

Change the

connector cable.

9

Behavior

Normal

supervision

Detector

State Indication

LED

Check

Visually

Blink 10 seconds

interval.

Check the State

Indication LED

behavior.

・Please do not touch the terminal while the unit is energized. It may get an electric

shock.

・Please do the cleaning and the increase tightening of the screw after the power

supply off. If not the power supply off, it may get an electric shock.

・Do not soak a detector in water, and do not put a detector into water.

!

Warning

730110 K0

12

ES1417

Page

・Under tightening can cause a drop, malfunction.

・Over tightening can cause a drop, malfunction due to damage to the screw or

equipments and malfunction.

・Please use the dry cloth or wring the water out tightly cloth for the cleaning.

・After Cleaning, Do not leave a foreign substance such as sawdust or wiring debris

on a detector. Such debris could cause erroneous operation.

・Do not clean with a solvent such as a ph-balanced detergent, Bleach, Benzene,

Thinner, Alcohol. It causes the detector surface is damaged.

Caution

!

730110 K0

13

ES1417

Page

5. Disposal

This product is as general industrial waste disposal.

Disposal methods are specific criteria depending on each municipality.

6. Support

Please inquire about this product to Fenwal Controls of Japan Co., Ltd. Tokyo headquarters.

Fenwal Controls of Japan Co., Ltd.

1-5-10 Iidabashi Chiyoda Tokyo, 102-0072 Japan

Tokyo headquarters: +81-3-3237-3565

警告

注意

警告

警告

警告

警告

注意

警告

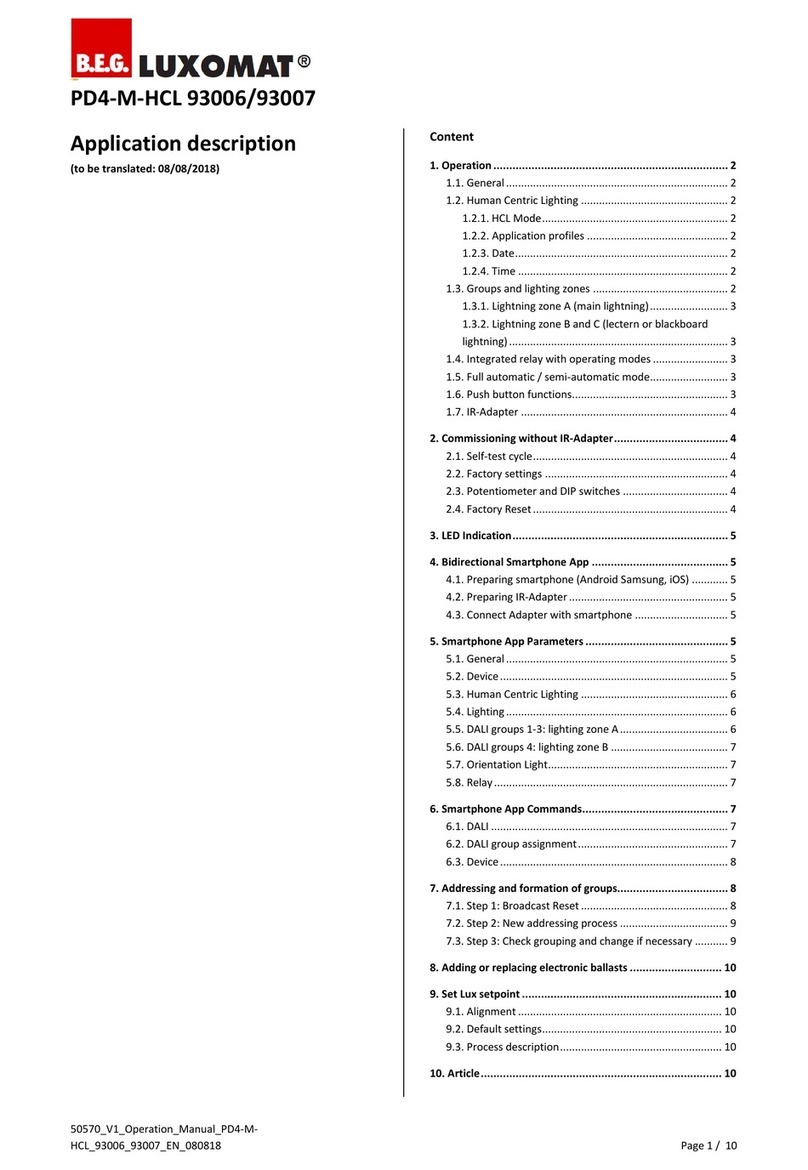

Table of contents

Other Fenwal Security Sensor manuals

Popular Security Sensor manuals by other brands

Interlogix

Interlogix SB Series installation manual

Steren

Steren SEG-060 instruction manual

Interlogix

Interlogix TVK-600 Configuration manual

AVE

AVE LUCE AMICA instruction manual

Adixen

Adixen ASM 182 TD PLUS user manual

Capital Safety

Capital Safety DBI SALA PROTECTA EN361 Instructions for use and maintenance

steute

steute HS Si 4 Extreme Series Mounting and wiring instructions

System Sensor

System Sensor ECO1005ABL Installation and maintenance instructions

Lunos

Lunos 9/IBE installation manual

Diablo Controls

Diablo Controls DSP-40S Product profile

Takex

Takex PA-5312E instruction manual

GE

GE H-10 Operation and service