22

ENGLISH

Original instructions

CONTENTS

1. Introduction..........................................22

2. Technical specification.........................22

3. Contents of packing .............................22

4. Features ................................................22

5 Safety instructions................................23

5.1 Specific safety instructions ..................23

5.2 Electrical safety....................................23

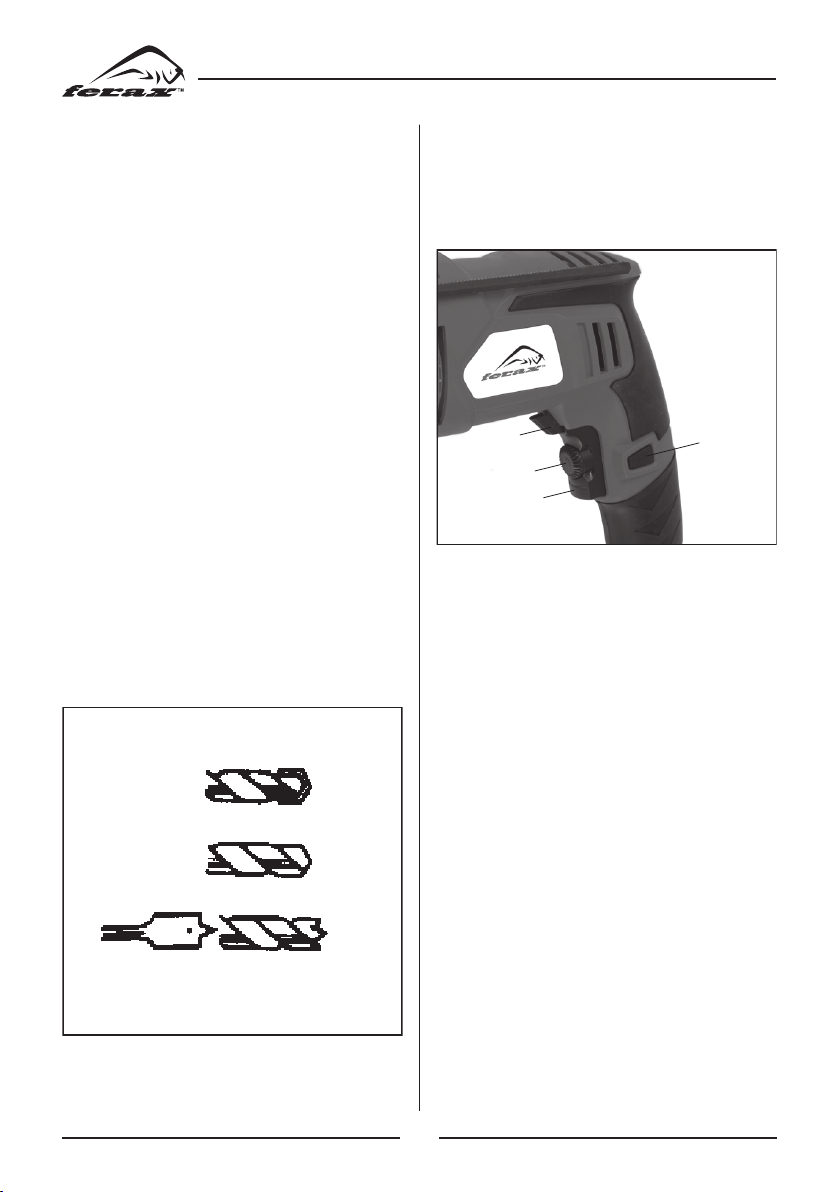

6 Assembly..............................................23

6.1 (Re)placing a drill ...............................23

6.2 Mounting the side handle.....................24

7 Use .......................................................24

7.1 Drills.....................................................24

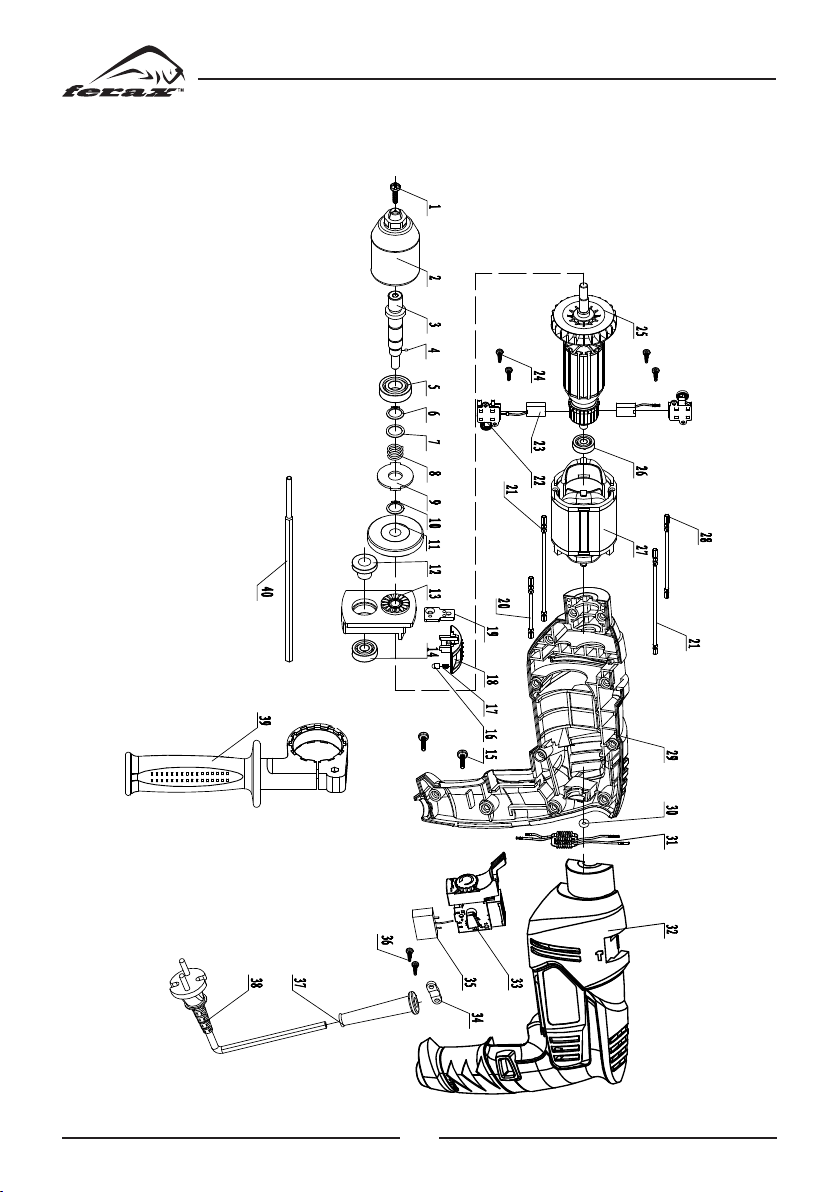

7.2 The On/Off switch.................................24

7.3 Switch-lock ..........................................24

7.4 Adjusting of the maximum rotation

speed.....................................................24

7.5 Switching the direction of rotation ......24

7.6 Switch for percussion drilling..............25

7.7 User tips ...............................................25

8 Service & maintenance ........................25

8.1 Maintenance.........................................25

8.2 Cleaning ...............................................25

8.3 Lubrication...........................................25

8.4 Faults....................................................25

8.5 Environment.........................................25

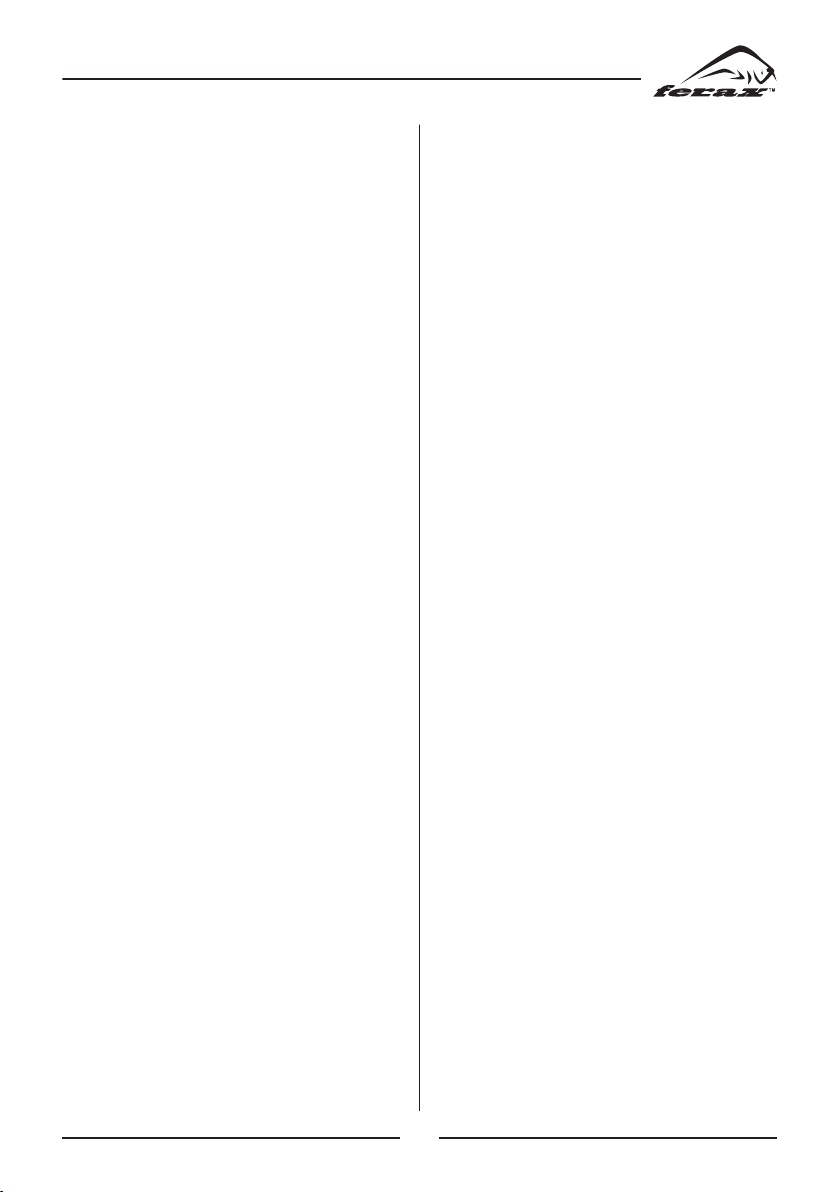

Spare parts list...............................................40

EC conformity declaration............................41

1. INTRODUCTION

Always read the instruction for elec-

trical products carefully before use. It

will help you understand your product

more easily and avoid unnecessary risks. Keep

this instruction manual in a safe place for

future use.

The machine is intended for impact drilling in

materials as brick and concrete. Besides it can

be used for drilling holes in wood, metal and

plastics.

2.

TECHNICAL SPECIFICATION

Voltage ....................................... V 230

Frequency................................. Hz 50

Input power............................... W 710

No load speed ...................... r/min 0-2300

Weight....................................... kg 2.2

Lpa (sound pressure)...........dB(A) 95.5+3

Lwa (sound power).............dB(A) 106.5+3

Vibration value

Impact drill into concrete....... m/s217.74

................................................ m/s2K=1.5

Drill into metal....................... m/s23.42

................................................ m/s2K=1.5

3.CONTENTS OF PACKING

1 Impact drill

1 Depth limiter

1 Chuck key

1 Auxiliary handle

1 Safety instructions

1 Instruction manual

1 Warranty card

4. FEATURES

1

3

2

4

7

5

8

6

Fig. 1

1. Drill dept limiter

2. Chuck

3. Switch for normal and percussion drilling

4. Side handle

5. Left/right switch

6. On/off switch with speed control