Ferrari ZEUS User manual

“ZEUS” CORKER

OPERATION AND MAINTENANCE MANUAL

PATENTED

2

PRESENTATION / TABLE OF CONTENTS

Presentation

Dear Customer,

Thank you for choosing FERRARI GROUP SRL.

Please read the instructions in this manual carefully. The proper use and

maintenance of this corker will help to ensure that it reaches its maximum

life expectancy as well as keep the warranty valid.

Please store this manual in a safe place and consult it before proceeding

with any operation, format change, or cleaning task.

Table of contents

Introduction _

Warranty _ 3

Usage conditions and limitations _____ _4

Technical specifications and Kit ________5

Preliminary operations _ 7

Configuration for 8 -12 liter bottles ________________ 8

Configuration for 5 liter bottles ________ 10

How to restore initial configuration 10

How to adjust the pin for standard corks __ 12

Operation ______ _______ 13

Maintenance 14

Storage and demolition _______ 15

Overview table 1 _______ 16

Overview table 2 17

Exploded view drawing 18

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

3

INTRODUCTION

WARRANTY

Introduction

Please read this manual carefully before using the corker.

To get the maximum performance, reliability, and durability of the corker, it is

important that you follow these instructions carefully.

This manual is an integral part of the corker and must be carefully stored by the

user.

This manual must accompany the corker if it is sold to a new user.

Notwithstanding the main technical and safety features of this product, in a

continuing effort to improve production, the manufacturer reserves the right to make

changes without notice in order to improve its products.

IMPORTANT! Follow all instructions marked with this symbol very carefully

as they include information on important safety regulations.

Warranty

FERRARI GROUP SRL warrants the corker described in this manual for a period of

5 YEARS starting from the date of delivery. Within this period, the manufacturer

agrees to repair or replace faulty parts, provided that the corker has been properly

used in compliance with the instructions included in this operation and maintenance

manual.

The warranty will be voided for the following:

1. Poor maintenance and misuse of the corker

2. The use of non-original spare parts;

3. Tampering by persons not authorized by FERRARI GROUP SRL.

The spare parts replaced under warranty must be returned (on request)

The warranty does not cover parts of the corker that are subject to wear.

FERRARI GROUP SRL shall not be held liable for general malfunctions or

failures caused by improper use or interventions and/or modifications

performed by unauthorized external persons.

4

USAGE CONDITIONS AND LIMITATIONS

Usage conditions and limitations

The Zeus corker is a manual corking machine and has been designed to

cork bottles only with corks made of cork or synthetic material. The

maximum dimensions of both corks and bottles are specified in the

“Overview table 1” on page 16.

FERRARI GROUP s.r.l. shall not be held liable for injuries to persons/animals, or

damages to property or the corker arising from improper use.

DO NOT REMOVE TEMPORARY GUARDS ON MOVING PARTS

This symbol indicates that it is forbidden to remove safety guards

and devices except if set-up adjustments are necessary.

SAFETY GLOVES MUST BE WORN This symbol indicates

that safety gloves must be worn when corking or during any

other maintenance or handling operation.

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

5

Technical specifications and Kit

The overview table below provides an overview of the technical data specifications

for the “Zeus” corker.

The corker is furnished with the following equipment:

N.3 numbered bottle mouth adaptors;

N.1 cork pushing pin ø15 mm, h 55 mm;

N.1 cork pushing pin ø15 mm, h 40 mm for mushroom corks;

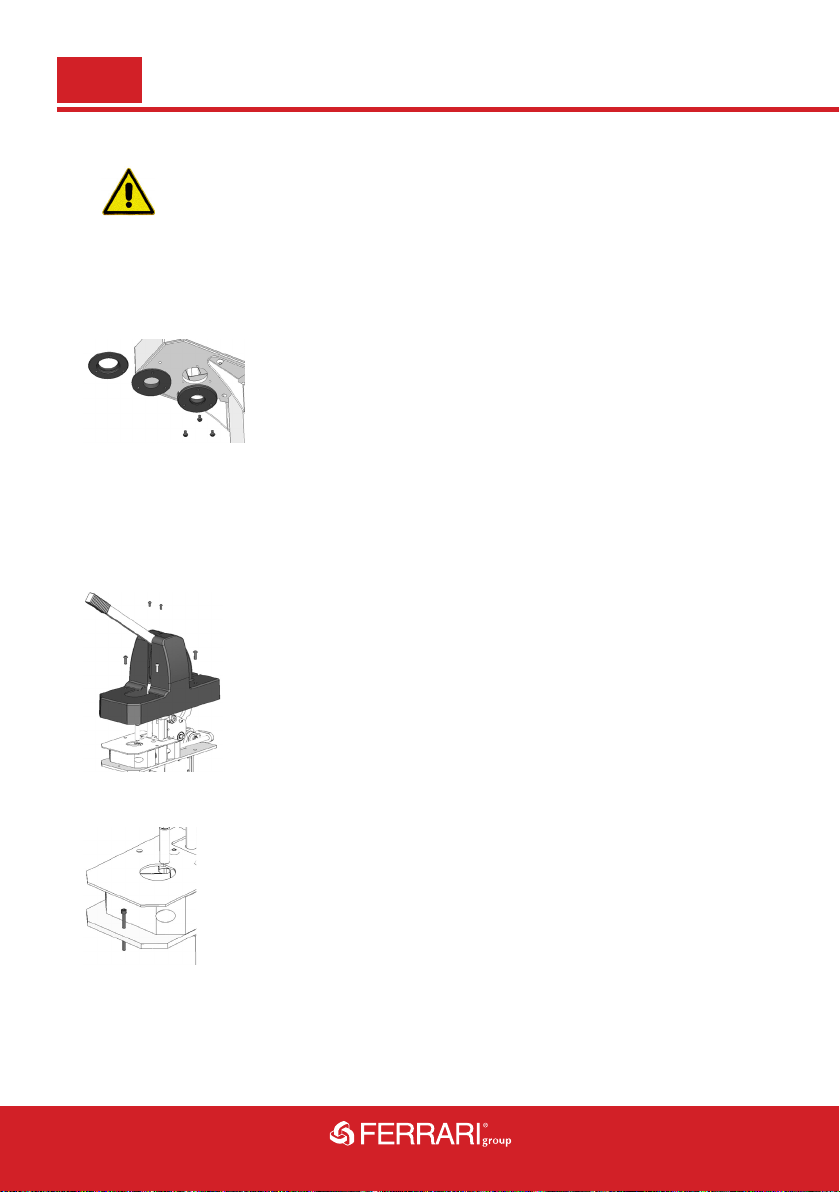

N.1 kit for large bottles (see picture on the right) consisting of:

N.2 5 mm spacers (A photo)

N.1 centering plate (B photo)

N.1 eccentric cork pushing pin, ø19 mm h 55mm (C photo)

N.1 eccentric cork pushing pin, ø19 mm, h 40 mm,

for mushroom corks (D photo)

N.1 extension rod for bottle height adjustments (E photo)

N.1 Prism lock pin (F photo)

The “overview table 1” includes bottle and cork measurements for the correct

use of the parts included with the corker.

The “preliminary operations” section covers the procedures for assembling the

parts listed above.

Weight Material Length

Width

Height

Volume

(kg) (mm) (mm) (mm) (m3)

43 -Stainless Steel

-Hardened Steel 550 700 1400 0,54

TECHNICAL SPECIFICATIONS AND KIT

(foto A)

(foto C) (foto E)

(foto F)

6

TECHNICAL SPECIFICATIONS AND KIT

Technical specifications and Kit

The base of the “Zeus” corker consists of 4 adjustable feet with non-slip rubber which

are also suitable for uneven floors.

The machine can be transported manually as has 2 wheels and a handle for pulling it.

Watch out for bumps, holes, objects, and material when moving the machine to

prevent it from tipping over.

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

7

PRELIMINARY OPERATIONS

Preliminary operations

When you receive the corker, check that the machine and its accessories match

the list on page 5. Make sure that the product has not been damaged during

transport.

The machine is delivered ready to cork 3 liter bottles with 55 mm

long and ø15 mm plunger and the n.2 bottle mouth adaptor (for

cork measurement see “overview table 1”.

If specifically requested, the corker can also be calibrated for a different sized bottle.

For all other types of bottles follow the operations listed below.

To adjust the height of the platform simply screw or unscrew the black

adjustment knob located on the lower front right hand side. If necessary, mount

the extension rod provided with the machine (see “overview table 2”).

Adjustment

knob

Extension rod

for platform

extender

Preliminary operations

When you receive the corker, check that the machine and its accessories match

the list on page 5. Make sure that the product has not been damaged during

transport.

The machine is delivered ready to cork 3 liter bottles with 55 mm

long and ø15 mm plunger and the n.2 bottle mouth adaptor (for

cork measurement see “overview table 1”.

If specifically requested, the corker can also be calibrated for a different sized bottle.

For all other types of bottles follow the operations listed below.

To adjust the height of the platform simply screw or unscrew the black

adjustment knob located on the lower front right hand side. If necessary, mount

the extension rod provided with the machine (see “overview table 2”).

Adjustment

knob

Extension rod

for platform

extender

Preliminary operations

When you receive the corker, check that the machine and its accessories match

the list on page 5. Make sure that the product has not been damaged during

transport.

The machine is delivered ready to cork 3 liter bottles with 55 mm

long and ø15 mm plunger and the n.2 bottle mouth adaptor (for

cork measurement see “overview table 1”.

If specifically requested, the corker can also be calibrated for a different sized bottle.

For all other types of bottles follow the operations listed below.

To adjust the height of the platform simply screw or unscrew the black

adjustment knob located on the lower front right hand side. If necessary, mount

the extension rod provided with the machine (see “overview table 2”).

Adjustment

knob

Extension rod

for platform

extender

8

PRELIMINARY OPERATIONS

Preliminary operations

Configuration for 8 -12 liter bottles

Follow the instructions below to assemble the kit for large bottles:

1) Remove the end part of the corking lever.

2) Unscrew the 6 setscrews of the clear safety guard

3) Now remove the safety guard

4) Insert the prism lock pin.

5) Loosen the 2 screws (see picture)

6) Insert the 2 5mm spacers included in the kit for large bottles

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

9

PRELIMINARY OPERATIONS

Preliminary operations

7) Replace the screws and firmly tighten them

8) Unscrew the 2 nuts and remove the 15 mm diameter

plunger (see picture)

9) Insert and screw in the 19 mm diameter plunger (for

champagne corks use the 40 mm long pin, otherwise select

the 55 mm long plunger) with the centering template

included in the kit for big bottles (see picture)

10) Once adjustments are complete, tighten the 2 nuts

11) Check that the plunger is centered on the centering

hole when it goes down.

Position the cork in the bottle by screwing or unscrewing the

plunger (see picture)

12) Remove the centering template

13) Remove the prism lock pin.

14) Put the safety guard back on

10

PRELIMINARY OPERATIONS

Preliminary operations

CAUTION The 19 mm eccentric plunger must always be mounted

with the kit, in order not to damage the 4 prisms

Configuration for 5 liter bottles

Follow the same procedure explained in the previous

paragraph. In addition, mount adaptor n. 3 on the machine

(as indicated in table n.1)

How to restore the initial configuration (0.75 –1.5 –3 liter bottles)

Follow the procedure below to restore the machine to the standard version:

1) Remove the end part of the corking lever.

2) Unscrew the 6 setscrews of the safety guard (see picture)

3) Now remove the safety guard

4) Insert the prism lock pin as shown in the picture

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

11

PRELIMINARY OPERATIONS

Preliminary operations

5) Loosen the 2 screws shown in the picture

6) Remove the 2 5mm spacers shown in the picture

7) Put the 2 screws back in

8) Unscrew the 2 nuts and remove the 19 mm diameter plunger

9) Screw the 15 mm diameter pin back in (for champagne

head corks use the 40mm long pin, otherwise select the 55mm

long pin) with the 2 lock nuts, adjusting the height desired for the

cork.

10) Mount adaptor n.1 or n.2 depending on the mouth of the

bottle that you would like to cork (see overview table n.1)

IMPORTANT: The 3 adaptors are suitable for most mouth sizes of off-the-

shelf bottles. However, check that the adaptor is the appropriate size before

proceeding to corking operations (if it is not compatible, please contact the

technical office of FERRARI GROUP SRL and they will be able to produce a

part to meet your requirements)

The 15 mm diameter plunger does not require the centering

template

12

PRELIMINARY OPERATIONS

Preliminary operations

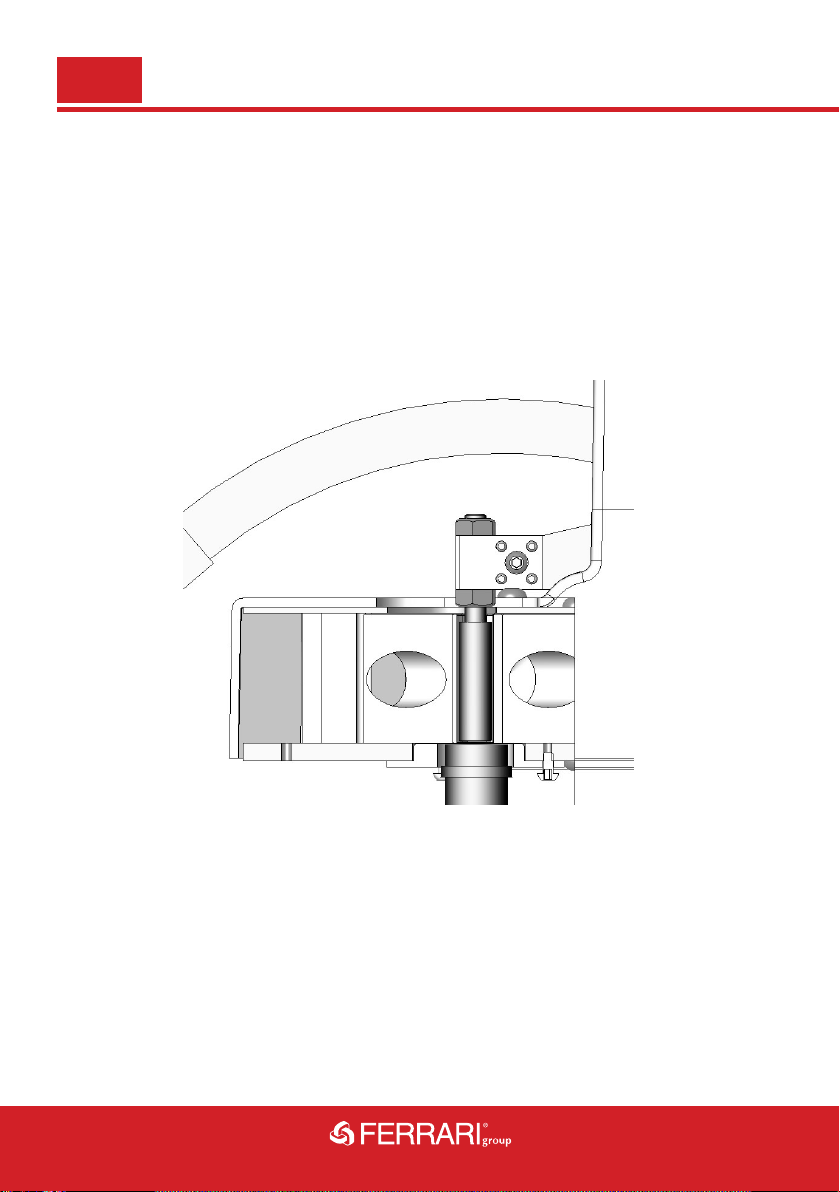

How to adjust the pin for standard corks

For successful bottle corking, i.e. so that the cork is flush with the bottle, you

must adjust the 55 mm long pin (ø19 or ø15 as required) so that when the

lever is in the horizontal corking position, the pin is flush with the lower end of

the prisms (see the illustration below).

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

13

OPERATION

NO

Operation

1. Position the corking lever in a vertical position

2. Press the pedal with your foot to lift and lower the

platform

3. Place the bottle on the platform

4. Release the pedal carefully until the upper mouth of

the bottle reaches the mouth adaptor of the machine

(see picture)

5. Put a cork in the opening at the top

6. Pull down on the corking lever and cork the bottle

7. Make sure that the cork is completely inserted in the bottle and

complete the cycle

8. Bring the corking lever back to the initial position

9. Press the up-down pedal with your foot

10. Remove the bottle

11. Release the pedal

CAUTION: Press the up-down pedal only when the lever is in the

vertical position; failure to do so may cause permanent damage to

the locking clutch.

YES NO

YES

14

MAINTENANCE

Maintenance

•To keep the machine in perfect working condition it is very important that you

clean off any dust on the cork,

•Use a brush or compressed air to remove any cork residue that may

accumulate in the moving seat of the prisms,

•Keep the work area clean and free of any material that could obstruct

corking operations,

•Keep the surrounding area clean; in particular, make sure that the area is

free from oil and grease or other materials that could make the floor slippery,

•Use lithium grease to lubricate the gear shafts,

•Use grease or neutral food grade Teflon solids or spray to lubricate internal

head movements (prisms, gibs) coming into contact with corks.

Check that:

-All safety guards have been properly mounted and closed.

Once a year:

-Check that all screws and bolts are properly tightened on the machine.

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

15

STORAGE AND DEMOLITION

Storage and Demolition

If the machine is kept in storage for an extended period of time, store it in an area

protected from rain and wind and, if possible, in a dry area.

Do not expose the machine to temperatures that are less than -10°C or greater than

+ 60°C.

It is forbidden to leave the machine or parts of the machine on

structures that have not been especially designed for it.

Do not leave material or tools on the machine.

Machine Disposal

Any waste resulting from dismantling the machine must be disposed of in an eco-

friendly manner, thus avoiding ground, air, and water pollution.

In any case, you must comply with all local laws in force on waste disposal.

We would like to remind you that waste is defined as any type of substance or

object which the holder disposes of or is required to dispose of (Legislative Decree

n.22 of 5 February 1997 and Legislative Decree n. 389 of 8 November 1997).

Waste resulting from the dismantling of the machine is classified as special waste.

Demolition Materials

These are non-hazardous special waste that can be recovered, in accordance

Ministerial Decree 5 February 1998

•Ferrous materials, aluminum, stainless steel, copper;

•Plastic materials;

•Electronic cards;

•Electric conductors.

Information on proper waste management

Ferrous materials: As this type of material can be recycled (secondary raw

materials) it should be delivered to the appropriate authorized collection center.

Plastic materials; Recycling is permitted, if provided.

This type of material should be disposed of in urban waste type landfills.

Incineration is permitted in facilities equipped with post combustion and dust control

systems before release into the environment

16

OVERVIEW TABLE 1

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

17

OVERVIEW TABLE 2

18

EXPLODED VIEW DRAWING

All the rights are reserved, inclusive those of translation. It is forbidden to reproduce completely or

in part this publication without the authorization of the FERRARI GROUP s.r.l.

19

EXPLODED VIEW DRAWING

Via Europa, 11 - 43022 Basilicagoiano - Parma (Italy)

Tel. + 39.0521.687125 - Fax +39.0521.687101

E-mail: info@ferrarigroup.com Web: www.ferrarigroup.com

Table of contents