FERREX DM600VARIO User manual

AFTER SALES SUPPORT 702030

1300 855 831

MODEL:

DM600VARIO

3

YEAR

WARRANTY

AU

Made in China

FERREX®is a registered trademark of ALDI Stores

DISTRIBUTED BY:

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

AU

ALDI guarantees that our exclusive brand products are developed to our

stringent quality specifications. If you are not entirely satisfied with this

product, please return it to the nearest ALDI store within 60 days from the

date of purchase, for a full refund or replacement, or take advantage of our

after sales support by calling the supplier’s Customer Service Hotline.

05/2023

User Manual

WOOD LATHE

DM600VARIO

Contents

Dok./Rev.-Nr. 702030_20220829

Overview ..................................................................................... 3

Package contents/part list .........................................................6

Explanation of Symbols .............................................................. 7

Introduction ................................................................................8

Layout ..........................................................................................9

Scope of delivery.........................................................................9

Intended use ..............................................................................10

Safety regulations...................................................................... 11

Attachment and operation........................................................17

Cleaning and maintenance........................................................21

Technical data ........................................................................... 22

Storage and transport .............................................................. 23

Disposal and recycling .............................................................. 23

Troubleshooting........................................................................ 24

Warranty Details........................................................................ 25

Repair and Refurbished Goods or Parts Notice ....................... 26

3

11 2 3 4 5 6 7 8 9 10

11

A

12

A

A

A13

14

21 4 3115

4

4

13

6

59

11

10

5

56

Package contents/part

list

1Motor unit, 1x

2Headstock drive centre, 1x

3Tool rest, 1x

4Tool support, 1x

5Centering pin, 1x

6Tailstock, 1x

7Machine bed, 1x

8Faceplate, 1x

9Wrench, 2x

10 Clamping lever tool rest, 1x

11 Fastening screws, 8 x

12 Warranty card

13 Instruction manual

Kapitelüberschrift

7

Explanation of Symbols

The use of symbols in this manual is intended to draw your attention to possible risks.

The safety symbols and the explanations that accompany them must be perfectly un-

derstood. The warnings in themselves do not remove the risks and cannot replace

correct actions for preventing accidents.

Warning! Potential danger to life, risk of injury or dam-

age to the tool when ignoring the instructions.

Before commissioning, read and observe the operating

instructions and safety instructions!

Wear safety goggles!

Wear hearing protection!

Do not wear long hair uncovered. Use a hair net.

Do not wear gloves.

Protection class II (double shielded)

Made in China

Complies with the Australian norms and standards.

336 Warranty period.

Warranty class.

Explanation of symbols

Kapitelüberschrift

8

Introduction

Congratulations on choosing to buy a FERREX®product.

All products brought to you by FERREX®are manufactured to the highest standards

of performance and safety, and as part of our philosophy of customer service and

satisfaction, are backed by our comprehensive 3 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

According to the applicable product liability law the manufacturer of this device is

not liable for damages which arise on or in connection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs by third party, non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation

of the device.

These operating instructions are intended to make it easier for you to get familiar

with your device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, properly

and economically with your machine and how to avoid dangers, save repair costs,

reduce downtime, and increase the reliability and working life of the machine.

In addition to the safety regulations contained herein, you must in any case comply

with the applicable regulations of your country with respect to the operation of the

machine.

Keep the operating instructions in a clear plastic folder to protect them from dirt and

humidity; store them near the machine. The instructions should be read and careful-

ly understood by each operator prior to using the machine. Only persons who have

been trained in the use of the machine and are aware of the related dangers and

risks should be allowed to use the machine. The local required minimum age must

be met.

In addition to the safety notes contained in these operating instructions and any

specific regulations in your country, the generally recognised technical rules for the

operation of identically constructed machines must be observed.

Introduction

Kapitelüberschrift

9

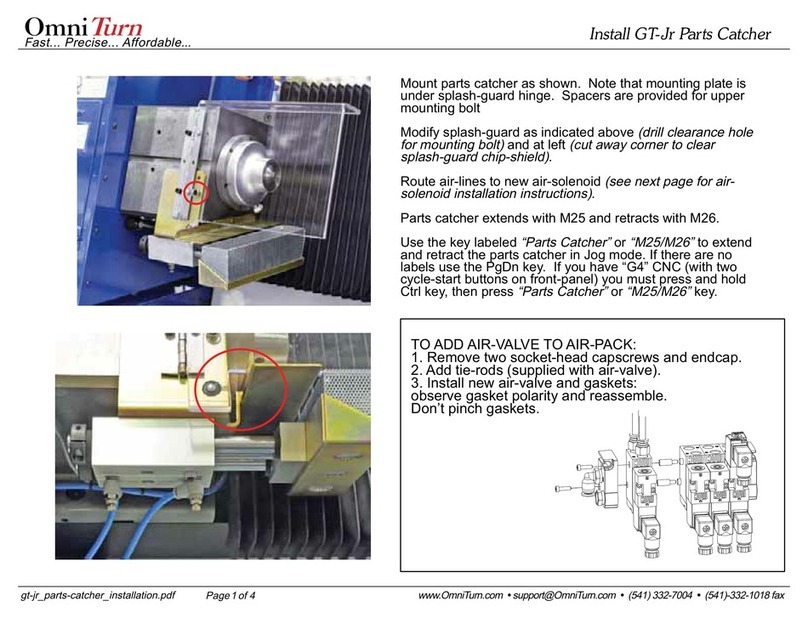

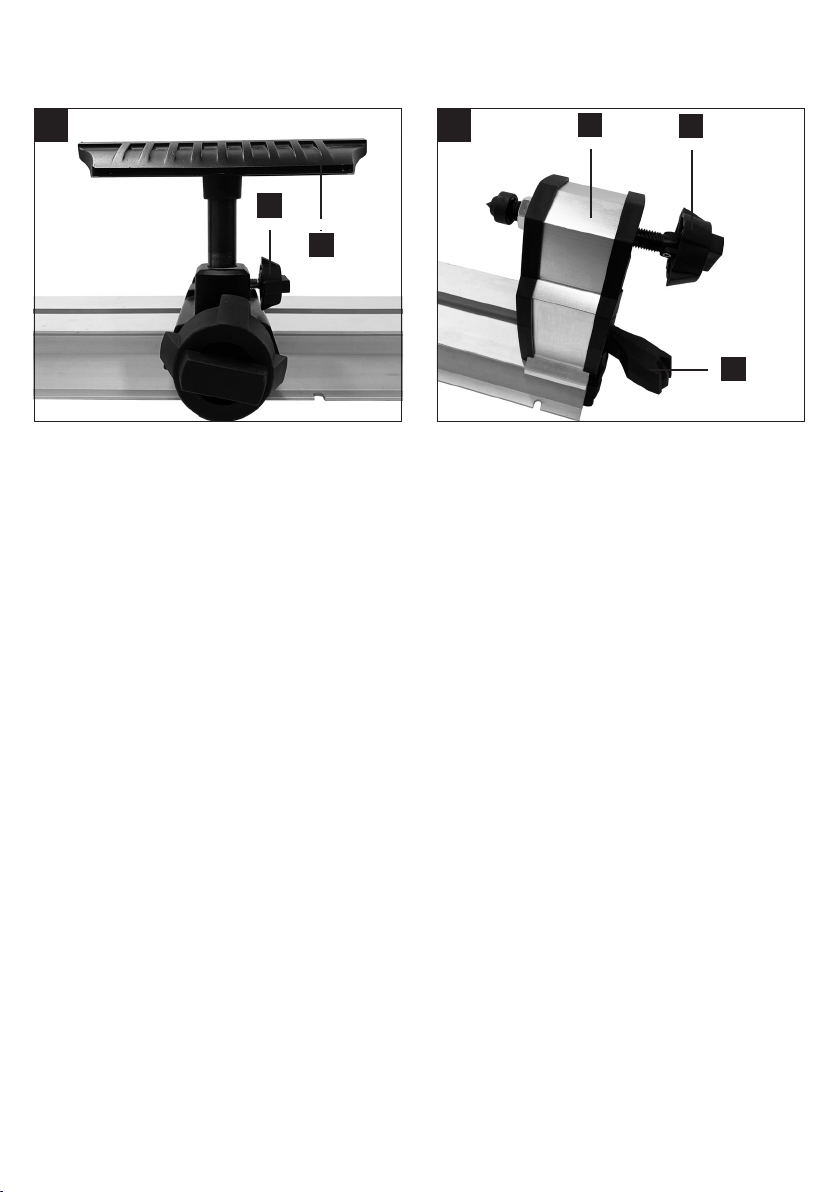

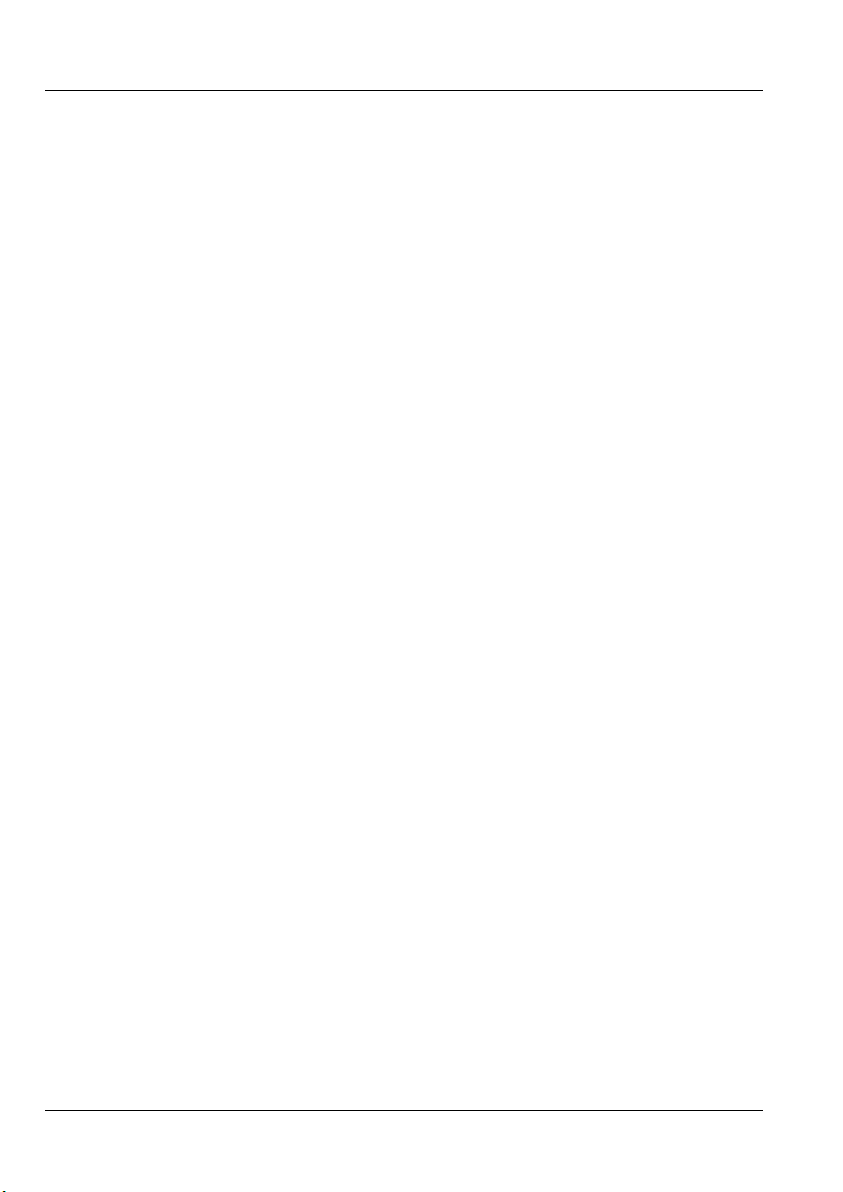

Layout (Fig. 1-5)

1. Motor unit

2. On/Off switch

3. Speed control

4. Headstock drive centre

5. Tool support

6. Tool rest

7. Centering pin

8. Counter nut

9. Tailstock

10. Handwheel

11. Clamping lever tailstock

12. Machine bed

13. Locking screw

14. Clamping lever for tool rest

15. Faceplate

A. Slotted hole

Scope of delivery

Motor unit 1x

Headstock drive centre 1x

Tool rest 1x

Tool support 1x

Centering pin 1x

Tailstock 1x

Machine bed 1x

Faceplate 1x

Wrench 2x

Clamping lever tool rest (pre-assembled) 1x

Fastening screws 8x

Warranty card 1x

Instruction manual 1x

Layout/Scope of delivery

Kapitelüberschrift

10

• Open the packaging and take out the equipment with care.

• Remove the packaging material.

• Check that all listed contents are present.

• Inspect the equipment and parts for any damage. Please contact the helpline if

anything is missing.

• If possible, keep the packaging until the end of the guarantee period.

• Read the operating instructions fully to familiarise yourself with the tool prior to

using it.

• Only use original accessories and spare parts. Spare parts are available by

contacting the helpline.

• Specify the part numbers when you contact the helpline.

m ATTENTION!

The device and packaging materials are not toys!

Children must not be allowed to play with plastic bags, film and small parts!

There is a risk of swallowing and suffocation!

Intended use

The machine is only designed for working on wood using a suitable turning tool.

The manufacturer’s safety, operation and maintenance instructions as well as the

technical data given in the calibrations and dimensions must be adhered to.

Relevant accident prevention regulations and other generally recognized safety and

technical rules must also be adhered to.

The machine may only be used, maintained or repaired by trained persons who are

familiar with the machine and have been informed about the dangers. Unauthorized

modifications of the machine exclude a liability of the manufacturer for damages re-

sulting from the modifications.

The machine is intended for use only with original spare parts and original tools from

the producer.

Any other use is considered to be not intended. The manufacturer excludes any liabil-

ity for resulting damages, the risk is exclusively borne by the user.

mPlease note that our equipment is designed for domestic DIY use, and has not

been designed for commercial, trade or industrial applications. Our warranty will be

voided if the equipment is used in commercial, trade or industrial businesses or for

equivalent purposes.

Scope of delivery/Intended use

Kapitelüberschrift

11

Safety regulations

General power tool safety warnings

mWARNING Read all safety warnings, instructions, illustrations

and specifications provided with this power tool. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed (ground-

ed) power tools. Unmodifiedplugs and matching outletswillreduce

risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water enter-

ing a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the

Safety regulations

Kapitelüberschrift

12

risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use re-

duces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use

a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock. It is recommended that the tool al-

ways be supplied via a residual current device having a rated residu-

al current of 30 mA or less.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as a dust mask, non-skid safety shoes,

hard hat or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentionalstarting. Ensuretheswitchisin theoff-po-

sition before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your fin-

ger on the switch or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the pow-

er tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situa-

tions.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair and clothing away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

Safety regulations

Kapitelüberschrift

13

used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you

to become complacent and ignore tool safety principles. A care-

less action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is dan-

gerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the

battery pack, if detachable, from the power tool before making

any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the pow-

er tool accidentally.

d) Store idle power tools out of the reach of children and do not al-

low persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools and accessories. Check for misalignment or

binding of moving parts, breakage of parts and any other condi-

tion that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are eas-

ier to control.

g) Use the power tool, accessories and tool bits etc. in accordance

with these instructions, taking into account the working condi-

tions and the work to be performed. Use of the power tool for op-

erations different from those intended could result in a hazardous

situation.

h) Keep handles and grasping surfaces dry, clean and free from oil

and grease. Slippery handles and grasping surfaces do not allow for

Safety regulations

Kapitelüberschrift

14

safe handling and control of the tool in unexpected situations.

5) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Operational Safety Instructions for the Wood Turning Lathe

• Familiarise yourself with the machine’s features and wood-turning

techniques before using the machine.

• Examine all workpieces for splits or knots. Glued joints must set com-

pletely before turning.

• Ensure that the workpiece is securely locked in position and all attach-

ments are secured.

• Before turning the machine ON ensure that the workpiece can rotate

freely by rotating it by hand.

• Keep your hands and fingers away from the rotating workpiece.

• Switch the machine OFF and wait until it has come to a full stop before

making any adjustments on the workpiece, tailstock, or tool rest.

• Maintenance, adjustment, calibration and cleaning may only be per-

formed with the motor turned off.

• The machine is designed for use with wood-turning chisels only.

• Always store away the wood-turning chisels safely before you leave

the workplace.

• Do not run the lathe without its covers and guards in place.

• Keep cutting tools sharp.

• Use the lowest speed when starting a new workpiece.

• Always stop the lathe at its slowest speed. If the lathe is run so fast

that it vibrates, there is a risk that the workpiece will be thrown or the

cutting tool jerked from your hands.

• Do not allow cutting tools to bite into the workpiece. The wood could

be split or thrown from the lathe.

• Always position the tool rest above the centre line of the lathe when

shaping a piece of stock.

• Before attaching a workpiece to the faceplate, always rough it out to

Safety regulations

Kapitelüberschrift

15

make it as round as possible. This minimizes the vibrations while the

piece is being turned. Always fasten the workpiece securely to the

faceplate. Failure to do so could result in the workpiece being thrown

away from the lathe.

• Use a brush or compressed air to remove wood shavings; never your

hands. The wood shavings will be sharp.

• The cutting tool must always be tight within the chuck and adjusted to

limit projection from the post. This will reduce the possibility of the tool

breaking or bending.

• Do not reach a cross the lathe while it is running.

• Only feed workpiece into a cutting tool against the direction of rota-

tion. The workpiece must always be rotating toward you.

• Do not leave the tool unattended when it is plugged into an electrical

outlet. Turn off the tool, and unplug it from its electrical outlet before

leaving.

• This product is not a toy. Keep it out of reach of children.

• Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contains chemicals known to cause can-

cer, birth defects or other reproductive harm. Some examples of these

chemicals are:

-Lead from lead-based paints

-Crystalline silica from bricks and cement or other masonry prod-

ucts

-Arsenic and chromium from chemically treated lumber

• Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equip-

ment ,such as those dust masks that are specially designed to filter out

microscopic particles.

• People with pacemakers should consult their physician(s) before use.

Electromagnetic fields inclose proximity to heart pacemaker could

cause pacemaker interference or pacemaker failure. In addition, peo-

ple with pacemakers should:

-Avoid operating alone.

• Properly maintain and inspect to avoid electrical shock.

• The warnings, precautions, and instructions discussed in this user

manual cannot cover all possible conditions and situations that may

Safety regulations

Kapitelüberschrift

16

occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must

be supplied by the operator.

Additional safety instructions for the use of faceplates

• Ensure that the faceplate is the appropriate size to support the work-

piece.

• Ensure that the workpiece is securely fastened to the faceplate.

• Rough cut the workpiece as close as possible to the final shape before

mounting onto a faceplate.

• Only use scraping chisels for faceplate turning. Cutting chisels can

easily be torn out of your hands.

• Pay attention that the woodturning chisel cannot interfere with the

holding screws at the finished dimensions of the workpiece.

Remaining hazards

The machine has been built using modern technology in accord-

ance with recognized safety rules. Some remaining hazards, how-

ever, may still exist.

• Only process selected woods without defects such as: Branch knots,

edge cracks, surface cracks. Wood with such defects is prone to splin-

tering and hazardous.

• Wood which is not correctly glued can explode when being processed

due to centrifugal force.

• Trim work piece to a rectangular shape, center and correctly secure

before processing. Unbalanced work pieces can be hazardous.

• Injuries can occur when feeding work pieces if tool supports are not

correctly adjusted or if turning tools are blunt. Sharp turning tools

which are free of defects are necessary for professional turning.

• Long hair and loose clothing can be hazardous when the work piece

is rotating. Wear personal protective gear such as a hair net and tight

fitting work clothes.

• Saw dust and wood chips can be hazardous. Wear personal protective

gear such as safety goggles and a dust mask.

• The use of incorrect or damaged mains cables can lead to injuries

caused by electricity.

• Even when all safety measures are taken, some remaining hazards

Safety regulations

Kapitelüberschrift

17

which are not yet evident may still be present.

• Remaining hazards can be minimized by following the instructions in

“Safety Precautions“, “Proper Use“ and in the entire operating manual.

• Before carrying out any adjustment or maintenance work, switch off

the device and disconnect the mains plug.

Exceptional and emergency situations

In case of an injury follow the following procedure:

Conduct a first-aid procedure adequate to the injury and summon qua-

lified medical attendance as quickly as possible. Protect the injured per-

son from further harm and calm them down.

If you seek help, state the following pieces of information:

1. Accident site ,

2. Accident type,

3. Number of injured persons,

4. Injury type(s)

Attachment and operation

mWarning! Risk of injury!

Prepare the workplace where you intend to place the electrical power tool. Provide

enough space to ensure safe and trouble-free operation. The power tool is designed

for working in enclosed rooms and has to be installed on level and firm ground.

mImportant! Pull out the power plug before carrying out any maintenance,

resetting or assembly work on the device!

Recommendation: Connect the appliance to a power socket with a residual current

circuit breaker of rated residual current no more than 30 mA.

Fixation of the machine (Fig. 1)

Before operation, the device must be screwed to a workbench, undercarriage or sim-

ilar. Use the slotted holes (A) and the delivered fastening screws for this purpose.

Installing the tool rest (Fig. 1; 4)

1. Plug the tool rest (6) into the hole in the tool support (5).

2. Fasten the tool rest (6) at the desired height using the locking screw (13).

Safety regulations/Attachment and operation

Kapitelüberschrift

18

Setting the tool rest (Fig. 1; 4)

1. The height of the tool rest (6) can be set by loosening the locking screw (13).

2. In order to set the length of the tool rest (6), loosen the clamping lever for tool rest

(14). The tool rest (6) must be driven as close as possible to the workpiece without

touching it.

3. Retighten the clamping lever for tool rest (14).

Adjustment of the tailstock (Fig. 1; 5)

1. Loosen the clamping lever (11) for the tailstock (9) in order to set the distance be-

tween the tailstock (9) and the headstock drive centre (4).

2. To adjust the clamping pressure use the handwheel (10) and secure it with the

counter nut (8).

Warning! Make sure that the tool rest (6) is tightened securely and cannot turn

in towards the workpiece.

Securing the workpiece on the headstock drive centre (Fig. 1)

1. Locate the centre of the workpiece by accurately drawing diagonal lines on each

end. The intersection point of these two lines will indicate the centre of the work-

piece.

2. At the end of the workpiece, produce an approx. 2mm deep saw cut along the

diagonal, in order to receive the headstock drive centre (4).

3. Use a wood mallet (not supplied) to drive the headstock drive centre (4) into the

point where the diagonal cuts across the end of the workpiece. Take care to pro-

tect the threaded end of the headstock drive centre (4) so that no object damages

the thread.

4. Cut the corners off the workpiece if the diameter of the ends is greater than 5 cm x

5 cm to make turning easier and safer.

5. Measure the combined total length of the workpiece with the headstock drive

centre (4) and centering pin (7) on each end.

6. Loosen the clamping lever for the tailstock (9) and set the distance between the

headstock drive centre (4) and the centering pin (7), such that a slightly greater

distance is obtained than the measured total length of the workpiece.

7. Tightly screw the headstock drive centre (4) with workpiece onto the centering

pin (7) by the hand wheel (10).

8. Once positioned fasten the counter nut (8) against the tail stock (9).

9. Set the tool support (5) with tool rest (6) approx. 3 mm away from the workpiece.

Caution: Before starting the machine test the setup by rotating the workpiece

by hand to ensure that there is enough clearance all the way around and that it

Attachment and operation

Table of contents