J<KLG<C<:KI@:8C D8@EK<E8E:< J<IM@:< G8IKJFG<I8K@FEJJ8=<KP@EKIF;L:K@FE

LJ<K?<HL@:B>L@;<G8><C89<CJKFJ<8I:?FLK@E=FID8K@FE=8JK

:fek\ekj

@EKIF;L:K@FE%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%)

Woodstock Technical Support .................. 2

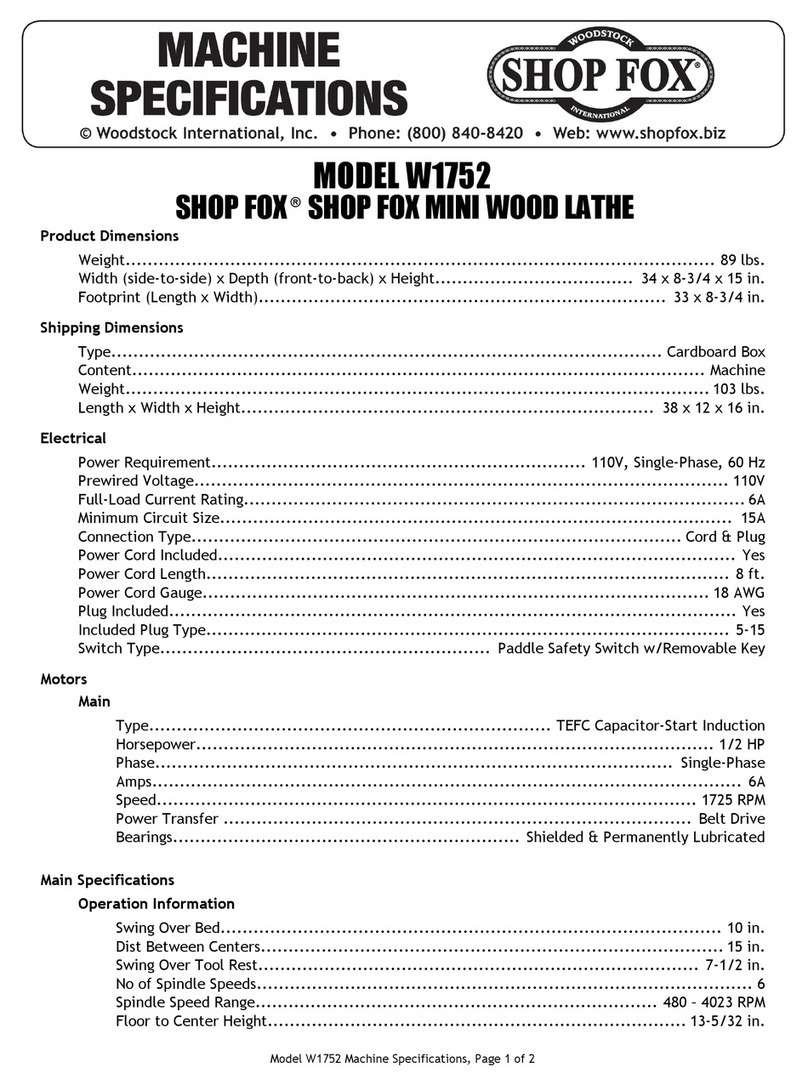

Specifications ..................................... 2

Controls and Features ........................... 3

J8=<KP%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%+

Standard Machinery Safety ..................... 4

Additional Safety for Lathe/Mills.............. 6

Avoiding Potential Injuries...................... 7

<C<:KI@:8C%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%/

220V Operation ................................... 8

Extension Cords .................................. 8

Grounding ......................................... 8

J<KLG%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%0

Inventory .......................................... 9

Cleaning Machine............................... 10

Machine Placement ............................ 10

Uncrating and Lifting .......................... 11

Test Run and Break-In ......................... 12

C8K?<FG<I8K@FEJ%%%%%%%%%%%%%%%%%%%%%%%%%%%%% (*

General .......................................... 13

Power Supply.................................... 13

Chuck & Faceplate Mounting................. 14

Replacing Jaws ................................. 15

Using Four-Jaw Chuck ......................... 16

Using Faceplate ................................ 17

Using Tailstock .................................. 18

Drilling with Tailstock ......................... 18

Tailstock Alignment ............................ 19

Using Centers ................................... 21

Using Steady Rest .............................. 22

Using Follow Rest .............................. 22

Setting Compound Slide....................... 23

Using Tool Post.................................. 23

Using Manual Feed ............................. 23

Setting RPM ..................................... 24

Setting Power Feed Rate...................... 25

Threading Setup ................................ 26

Change Gear Chart............................. 27

D@CC@E>FG<I8K@FEJ%%%%%%%%%%%%%%%%%%%%%%%%%%% )/

Installing Tools.................................. 28

Removing Tools ................................. 28

Headstock Positioning ......................... 29

Quill Travel ...................................... 29

Table Travel ..................................... 30

Start Up & Spindle Break-in Procedures.... 30

Setting RPM ..................................... 31

D8@EK<E8E:<%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% *)

General Maintenance .......................... 32

General Cleaning ............................... 32

General Lubrication............................ 32

Adjusting/Replacing .......................... 33

V-Belt............................................. 33

J<IM@:<%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% *+

Cross Slide Backlash ........................... 34

Slide & Half-Nut Adjustments ................ 34

Electrical Safety Instructions................. 35

Electrical Component Index .................. 36

Electrical Connections ....................... 37

Wiring Diagram ................................. 39

Troubleshooting................................. 40

G8IKJ%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% +)

Lathe Change Gear Housing Diagram ....... 43

(0000 Series Parts) ............................. 43

Thread Dial Diagram........................... 45

(1000 Series Parts) ............................. 45

Leadscrew Gearbox Diagram ................. 47

(2000 Series Parts) ............................. 47

Compound Slide & Tool Post Diagram....... 49

(2500 Series Parts) ............................. 49

Bed Diagram .................................... 51

(3000 Series Parts) ............................. 51

Steady & Follow Rest Diagram ............... 53

(3500 Series Parts) ............................. 53

Apron Diagram.................................. 54

(4000 Series Parts) ............................. 54

Tailstock Diagram .............................. 56

(5000 Series Parts) ............................. 56

Mill Column Diagram........................... 57

(6000 Series Parts) ............................. 57

Headstock Diagram ............................ 58

(7000 Series Parts) ............................. 58

Accessories & Labels Diagram................ 60

(8000 Series Parts) ............................. 60

Main Wiring Box Diagram ..................... 62

(9000 Series Parts) ............................. 62

Warranty Registration ......................... 63

N8II8EKP%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% -,