FERREX 708345 User manual

708345

650W PAINT SPRAYER

Read all safety warnings and all instructions

thoroughly before operating this product.

Ensure you keep your manual in a

safe place for future reference.

IM ed 6; 03/2022

Product

Info

QR codes take you where you want to go

quicky and easily

Whether you require product information, spare parts or accessories,

details on warranties or aftersales service, or if you want to watch

a product demonstration video, our QR codes will take you there in

no time at all.

What is a QR code?

A QR-code (QR=Quick Response) is a type of matrix that can be read

with a smartphone camera and that contains a link to a website or

contact details, for example.

Advantage: You are not required to manually enter a website address

or contact details.

How it works

To scan the QR code, all you need is a smartphone with QR codes reader

software and an Internet connection*. This type of software can be

downloaded for free from your smartphone’s app store.

Try it out now

Just scan the QR code with your smartphone and

nd out more about the Aldi product you have

purchased*.

* Depending on your tarif you may be charged for the connection.

Product

Info

REGISTER YOUR PURCHASE AT www.aldi.com.au/en/about-aldi/product-registration/ TO KEEP UP-TO-DATE WITH IMPORTANT PRODUCT INFORMATION.

The product is guaranteed to be free from defects in workmanship and parts for a period of 36 months from the

date of purchase. Defects that occur within this warranty period, under normal use and care, will be repaired,

replaced or refunded at our discretion. The benets conferred by this warranty are in addition to all rights and

remedies in respect of the product that the consumer has under the Competition and Consumer Act 2010 and

similar state and territory laws.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

Warranty details

AFTER SALES SUPPORT

(toll free)

MODEL No.: PRG650G •03/2022 • 708345

3

650W Paint Sprayer

Contents

Pack contents /parts 2

Description of symbols 3

General safety instructions 4

Additional safety instructions for your paint sprayer

6

Parts list 7

Assembly 9

Operation 11

On/o switch 11

Take the paint sprayer out of the paint sprayer holder 11

Trigger 11

Assemble the shoulder strap 11

Adjustment of the paint sprayer 12

Adjustment of the rate of ow 12

Spray technology 13

Work stoppages 13

Maintenance 14

Troubleshooting 15

Warranty 16

Environmental protection 16

What your 3 year warranty means 16

Service Support 18

Technical specications 18

Accessories and after sales parts 19

Pack contents / parts

Congratulations on the purchase of your FERREX® 650W Paint Sprayer. When

you open your packaging, rst remove all items and check there are no parts

damaged or missing. If you nd anything wrong, do not operate the product

until the parts have been replaced or the fault has been rectied. Failure to

do so could result in serious personal injury.

Intended use of the 650W Paint Sprayer

NOTE: This product is for private domestic DIY use only.

It is not suitable for commercial, industrial or trade use.

Use the 650W Paint Sprayer only for intended applications including

spraying non-ammable and non-hazardous paints and varnishes.

The Paint Sprayer should not be used for spraying of ammable liquids. Do

not use the Paint Sprayer for food, pharmacy or other purposes that are not

mentioned in the manual.

This user manual contains important information on how to use the 650W

Paint Sprayer. Read this user manual carefully, in particular the safety

instructions, before using the product. Failure to follow this user manual may

lead to severe injuries or product damage.

Keep this user manual for further reference.

IMPORTANT INFORMATION.

NOTE: First time users or inexperienced operators pay particular attention

to the operation of the 650W Paint Sprayer, including details of starting and

stopping and correct use of the 650W Paint Sprayer on pages 11-13, as well

as the maintenance instructions on page 14-16.

Contents of carton

2

1 x 650W Paint Sprayer

1 x 1.8m High ex hose

1 x Viscosity Cup/ Filler

1 x Nozzle Cleaning Needle

1 x Shoulder Strap

1 x 800ml Paint Pot

1 x Instruction Manual

1 x Warranty Card

The instruction manual or rating plate on your product may show symbols.

These represent important information about the product or instructions

on its use.

3

Read the instructions

Warning

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Warning: Do not direct the jet at persons, animals and

electrical equipment.

Double insulation

Conforms to relevant standards for electrical safety and

electromagnetic compatibility.

36 36 Months Warranty Period.

Box

The box is recyclable at the kerbside.

Description of symbols

General safety instructions

4

WARNING: Read all safety warnings, instructions, illustrations and

specications provided with this power tool. Failure to follow the

warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces the

risk of electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the inuence of drugs, alcohol or medication.

A moment of

inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the o-position

before connecting to power source and/or battery pack, picking up

or carrying the tool. Carrying power tools with your nger on the switch or

energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of these devices can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to

become complacent and ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the rate

for which it was designed.

b)

Do not use the power tool if the switch does not turn it on and o. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

5

parts, breakage of parts and any other condition that may aect the

power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations dierent from

those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and

grease. Slippery handles and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

5) Service

a) Have your power tool serviced by a qualied repair person using only

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

6) Recommendation

a) Recommendation that the tool always be used with a residual current

device having a rated residual current of 30 mA or less.

Additional safety instructions for your paint sprayer

1. Beware of high pressure at the nozzle and toxic sprays, it can cause

severe skin damage. Never allow any part of the body to come in

contact with the spray.

2. Recommendation that the tool always be supplied via a residual current

device with a rated residual current of 30mA or less.

3. Do not use guns for spraying ammable materials.

4. Do not clean guns with ammable solvents.

5. Warning! Be aware of any hazard presented by the material being

sprayed and consult the markings on the Paint pot or the information

supplied by the manufacturer of the material to be sprayed.

6. Do not spray any material where the hazard is not known.

7. Use appropriate personal protective equipment, such as dust mask,

protective clothing.

6

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

1. Trigger

2. Flow rate adjustment dial

3. Paint sprayer

4. 1.8m High ex hose

5. On / O switch

6. Paint sprayer holder

7. Paint pot

8. Cup collar

9. Air cap

10. Nozzle

11. Cap collar

12. Viscosity cup

13. Shoulder strap

14. Nozzle cleaning needle

15. Power cord

16. Shoulder strap connection points

17. Paint draw tube

Parts list

5

4

23

14

4

6

4

7

4

8

4

4

12

4

13

4

14

15

16

17

16

910 11

7

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

5

4

23

14

4

6

4

7

4

8

4

4

12

4

13

4

14

15

16

17

16

910 11

8

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

Assembly

WARNING: Ensure the product is disconnected from the mains

power supply before attempting any assembly.

1. Suitable coating materials

Solvent-based and water-based paints, nishes, primers, two-component

paints, varnishes, automotive topcoats, stains and wood preservatives.

2. Unsuitable coating materials

Wall colors (dispersion), etc., alkali and acidic paints.

A

3. Preparedness the coating material

Measuring the viscosity using the viscosity

cup(12). (See Fig. A)

1) Stir the coating material well before starting to

measure.

2) Fill the viscosity cup (12) with coating material

(100 cm3).

3) Lift viscosity cup (12) and measure the time

in seconds, until the coating material nishes

dripping.

4) These are called run-DIN-seconds (DIN-s).

Coating material viscosity DIN-s

Solvent-based paints 15-50

Primers 25-50

Pickling undiluted

2 Combination paints 20-50

Varnishes 15-40

Waterborne paints 20-40

Automotive topcoats 20-40

Wood protection center l undiluted

9

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

1

2

B1.

4. Connect the 1.8m high ex

hose to the tool

1) Insert the 1.8m high ex hose (4) end to

the guide at side of device rmly. Then turn

the 1.8m High ex hose (4) counterclockwise

until it clicks into place. (See Fig. B1)

2) Insert the other end of the 1.8m high ex

hose (4) to the spray gun connector side

rmly. Then turn the 1.8m high ex hose (4)

counterclockwise until it clicks into place. (See

Fig. B2)

B2.

1

2

5. Assembly of the paint draw

tube

1) Unscrew the paint pot (7) of the paint

sprayer (3).

2) Assemble the paint draw tube (17)

correctly depending on your requirement to

increase the paint uptake in the paint pot (7)

as much as possible.

Spraying with underlying objects

- rotate the paint draw tube (17) forward. (See

Fig. C1)

Note: Don’t tilt it at a large angle.

Spray job with overhead objects

- rotate the paint draw tube (17) backwards.

(See Fig. C2)

Note: Don’t tilt it at a large angle.

3) Place a protective sheet or something

similar under the paint pot (7) . Pour the

prepared coating material into the paint pot

(7).

4) Screw the paint pot (7) back into the

paint

sprayer

, and tighten it.

C2.

C1.

10

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

Operation

WARNING: Ensure that the paint

sprayer is always facing away from

the operator when in use.

Note: It is recommended that the tool

always be used via a residual current device

with a rated residual current of 30mA or less.

1. On/o switch

To start the paint sprayer, press the protective

cover over the on/o switch (5) indicated by

the mark “0”.

To stop the paint sprayer, press the protective

cover over the on / o switch (5) indicated by

the mark “I”. (See Fig. D)

2. Taking the paint sprayer out of

the paint sprayer holder

This paint sprayer is equipped with a 1.8m

high ex hose (4). The paint sprayer (3) can be

taken out of the sprayer holder (6) to make

work more convenient. (See Fig. E)

3. Trigger

Depress the trigger (1) to begin spraying.

(See Fig. F)

4. Assembling the shoulder strap

There are two shoulder strap connection

points (16) on the paint sprayer holder (6).

Connect one of the clips on the shoulder

strap (13) to each point. (See Fig. G)

D

E

F

G.

11

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

5. Adjustment of the paint sprayer

WARNING: Never change the setting of the air cap (9) when

pulling the trigger (1).

WARNING: Ensure the product is disconnected from the mains

power supply before attempting any assembly.

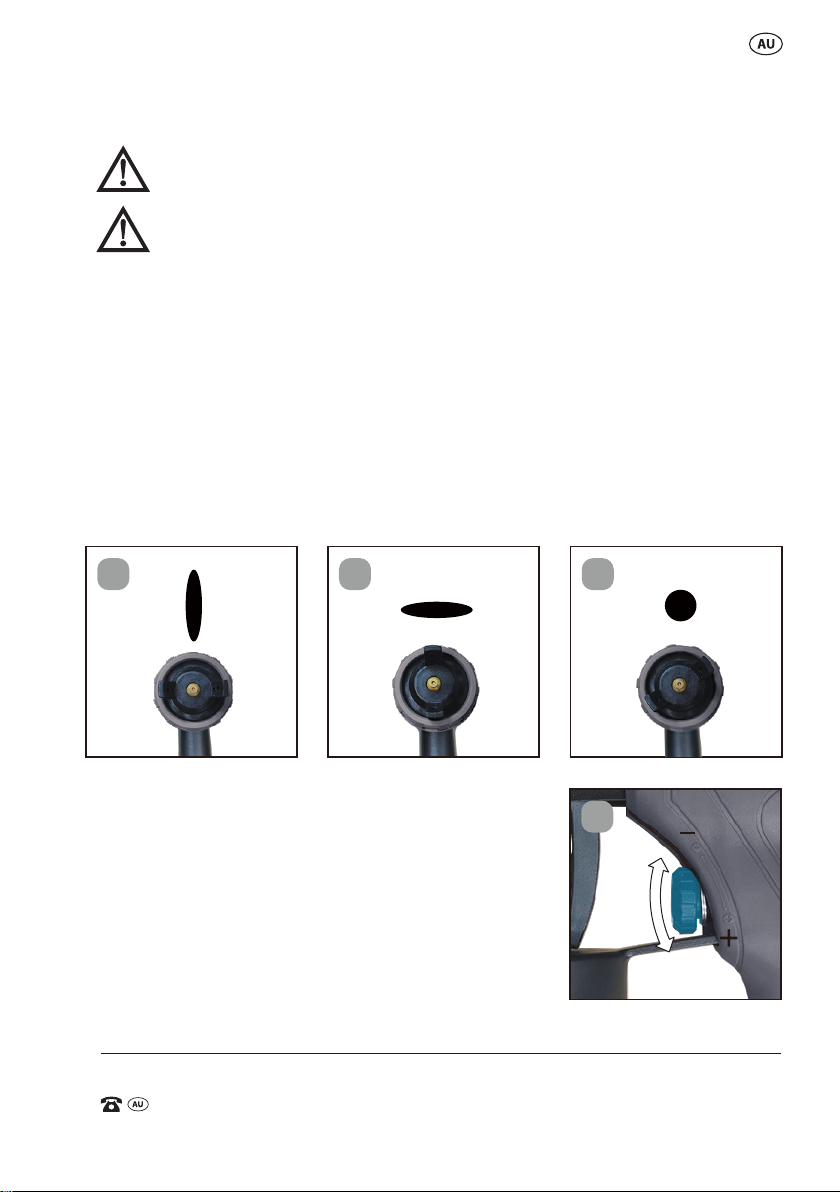

Selection spray patterns

1) Unscrew the cap collar (11).

2) Setting the position of air cap (9) to the desired requirement:

The Horizontal position (a) of air cap (9) = the spraying shape is vertical: for

vertical surface. (See Fig. H1)

The vertical position (b) of air cap (9) = the spraying shape is horizontal: for

horizontal surface. (See Fig. H2)

The oblique position (c) of air cap (9) = the spraying shape is circular: for

corners, edges and others. (See Fig. H3)

3) Screw the Cap collar and tighten it.

H1.

a

H2.

b

H3.

c

6. Flow rate adjustment

The ow volume of the material is adjusted by

turning the ow rate adjustment dial (2). (See Fig. I)

“ + ” Rotate anticlockwise: reduce the rate of ow

“ - ” Rotate clockwise : increase the rate of ow

I

12

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

8. Work stoppages

1) Switch o the paint sprayer by pressing on

the “O” on the on / o switch (5).

2) Return the paint sprayer (3) to the paint

sprayer holder (6).

7. Spray technology

1) The intended surface should be smooth and clean. And the surface must

be pretreated and dust-free.

2) Surfaces not to be sprayed should be covered with tape and newspaper.

3) It is important to perform a test on cardboard or a similar surface spray

sample to nd the right paint sprayersetting for your required paint job.

Correct directional length

Hold the paint sprayer at straight distance of about 5 -15 cm from the object

being sprayed. (See Fig. J1)

Incorrect

Do not spray as showing in Fig. J2. This will cause overspray and make the

surface spray uneven.

J1.

5-15cm

J2.

J3.

9

10

Note: It is necessary to clean the nozzle (10) and

air cap (9), to avoid buildup. Both parts can be

cleaned with solvents or water. (See Fig. J3)

Clean both parts after each use.

13

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

Maintenance

Remove the plug from the socket before carrying out any adjustment,

servicing or maintenance.

If the supply cord is damaged, a special cord or assembly available from the

manufacturer or its service agent must replace it.

Always remember to disconnect the plug from the socket before cleaning

the paint sprayer (3) or paint pot (7), it is essential that the paint sprayer (3) is

cleaned thoroughly after every use.

Failure to clean it will almost certainly result in blockages and it may not

operate when you next come to use it.

1) Switch o the paint sprayer. Press the trigger (1), so that the coating

material in the paint sprayer passes back into the paint pot (7).

2) Unscrew the paint pot (7). Empty the remaining coating material.

3) Clean paint pot (7) and paint draw tube with a brush.

4) Screw the paint pot (7). Always keep paint pot (7) seal free of paint residue

and check for damage.

5) Clean paint sprayer (3) and paint pot (7) exterior with a cloth soaked in

solvent and water.

Note: Never clean the nozzle (10) or 1.8m high ex hose (4) in the paint

sprayer (3) with sharp metal objects.

6) Warranty is void if the paint sprayer has not been cleaned and maintained

after each use.

14

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

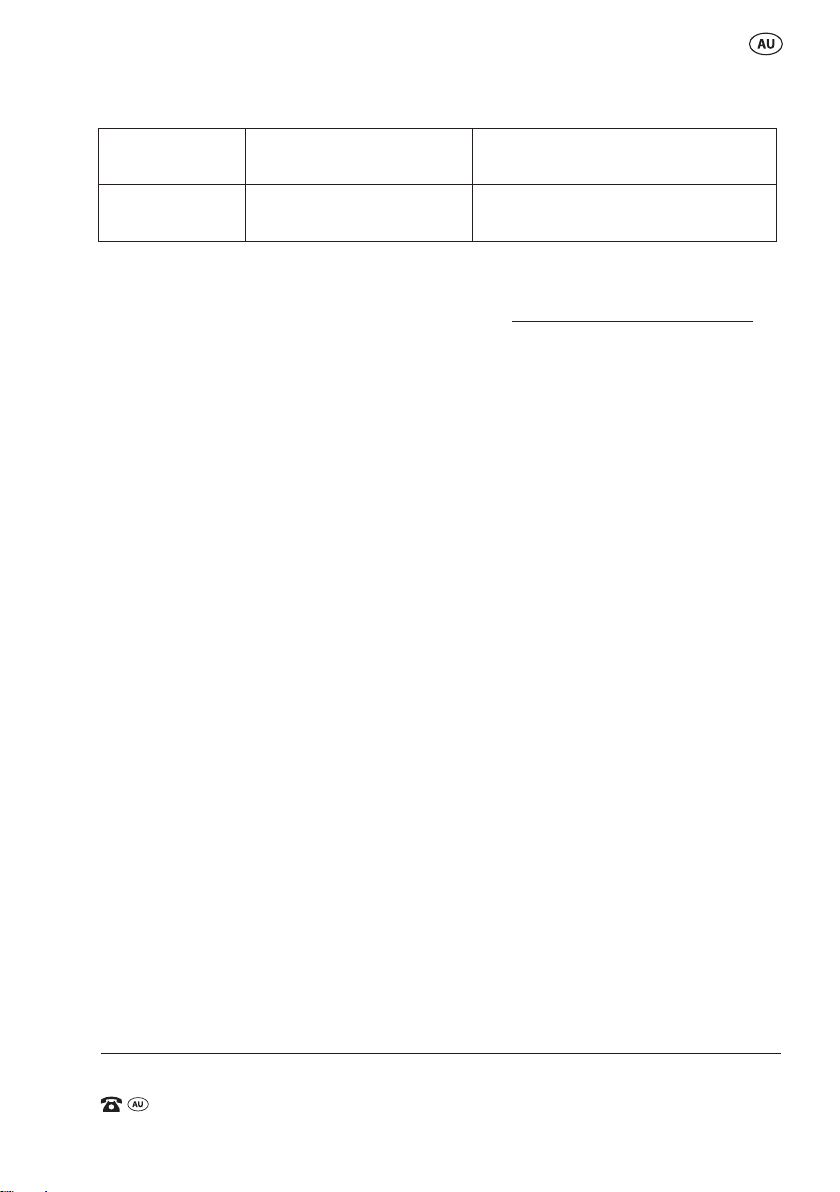

Toubleshooting

Problem Cause Remedy

No coating

material come

out from

nozzle (10)

Nozzle (10) clogged Clean

Paint draw tube (17)

clogged

Clean

Small holes on the paint

draw tube (17) pipe

clogged

Clean

Flow setting is at min

level

Rotate the ow rate adjustment

dial (2) clockwise

Paint draw tube (17)

loose

Tighten the paint draw tube (17)

Paint pot (7) loose Tighten the paint pot (7)

The viscosity is too high Dilute accordingly

Dripping

coating

material at

nozzle (10)

Nozzle (10) loose Tighten nozzle (10)

Worn nozzle Replace

Coating material

accumulated at air cap

(9) and nozzle (10)

Use the nozzle cleaning needle

(14) to clear the nozzle (10) and

the cap collar (11).

Spray too thick The viscosity is too high Dilution

Flow setting is at max

level

Rotate the ow rate adjustment

dial (2) anticlockwise

Too little pressure in the

paint pot (7)

Tighten the paint pot (7)

15

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

For further inquiries or issues associated with your 650W Paint Sprayer, call our

Customer Service on 1300 889 028 or email us at info.aldi@positecgroup.com

16

Spray unstable Too little coating

material in paint pot (7)

Add more coating material

Drips in spray Flow setting is at max

level

Rotate the ow rate adjustment

dial (2) anticlockwise

MODEL No.: PRG650G • 03/2022 • 708345

AFTER SALES SUPPORT

(toll free)

650 W Paint Sprayer

17

Warranty

Your new FERREX® 650W Paint Sprayer will more than satisfy your

expectations. It has been manufactured under stringent FERREX®. Quality

standards to meet superior performance criteria.

You will nd your new 650W Paint Sprayer easy and safe to operate, and, with

proper care, it will give you many years of dependable service.

CAUTION. Carefully read through this entire instruction manual before using

your new FERREX® 650W Paint Sprayer.

Take special care to heed the Cautions and Warnings.

Your FERREX® 650W Paint Sprayer has many features that will make your job

faster and easier. Safety, performance, and dependability have been given

top priority in the development of this FERREX® 650W Paint Sprayer, making

it easy to maintain and operate.

Use only FERREX® replacement parts for your product.

Non-conforming parts or modications made to parts will void your

warranty.

Environmental protection

Recycle unwanted materials instead of disposing of them as

waste. All tools, hoses and packaging should be sorted, taken to

the local recycling centre and disposed of in an environmentally

safe way.

What your 3 year warranty means

Great care has gone into the manufacture of this product and it should

therefore provide you with years of good service when used properly.

In the event of product failure within its intended use over the course of

Table of contents

Other FERREX Paint Sprayer manuals