3Festo — VABF-S4-...-CB-VH/VL-... — 2019-05

1 About this document................................................................................................... 5

2 Safety........................................................................................................................... 5

2.1 Intended use................................................................................................................ 5

2.2 General safety instructions........................................................................................... 5

3 Product overview......................................................................................................... 6

3.1 Design........................................................................................................................... 6

3.2 Product variants........................................................................................................... 7

3.3 Display components..................................................................................................... 8

4 Function........................................................................................................................9

4.1 Function overview........................................................................................................ 9

4.2 Operating modes.......................................................................................................... 9

4.2.1 Data record mode................................................................................................... 9

4.2.2 PLC mode................................................................................................................9

4.3 Switching functions...................................................................................................... 9

4.4 Vacuum generation...................................................................................................... 10

4.5 Control of the vacuum function..................................................................................... 10

4.6 Valve control................................................................................................................ 11

4.7 Power ejector pulse (VABF-...-AP)................................................................................. 11

4.8 Air saving function........................................................................................................ 12

4.9 Monitoring and diagnostics.......................................................................................... 13

4.9.1 Monitoring the process...........................................................................................13

4.10 Measured variables...................................................................................................... 14

4.11 Teach-in function.......................................................................................................... 14

4.12 Operating statuses of the vacuum generator................................................................ 16

4.13 Emergency-stop function.............................................................................................. 17

4.14 Error state..................................................................................................................... 17

5 Installation.................................................................................................................. 18

5.1 Pneumatic installation.................................................................................................. 18

6 Commissioning............................................................................................................ 20

6.1 Commissioning the vacuum generator......................................................................... 20

6.2 Configure ejector pulse................................................................................................. 20

7 Operation and use....................................................................................................... 21

7.1 Operating manual override........................................................................................... 21

7.2 Teach-in via FMT........................................................................................................... 23

7.2.1 Teach clock cycle.................................................................................................... 23

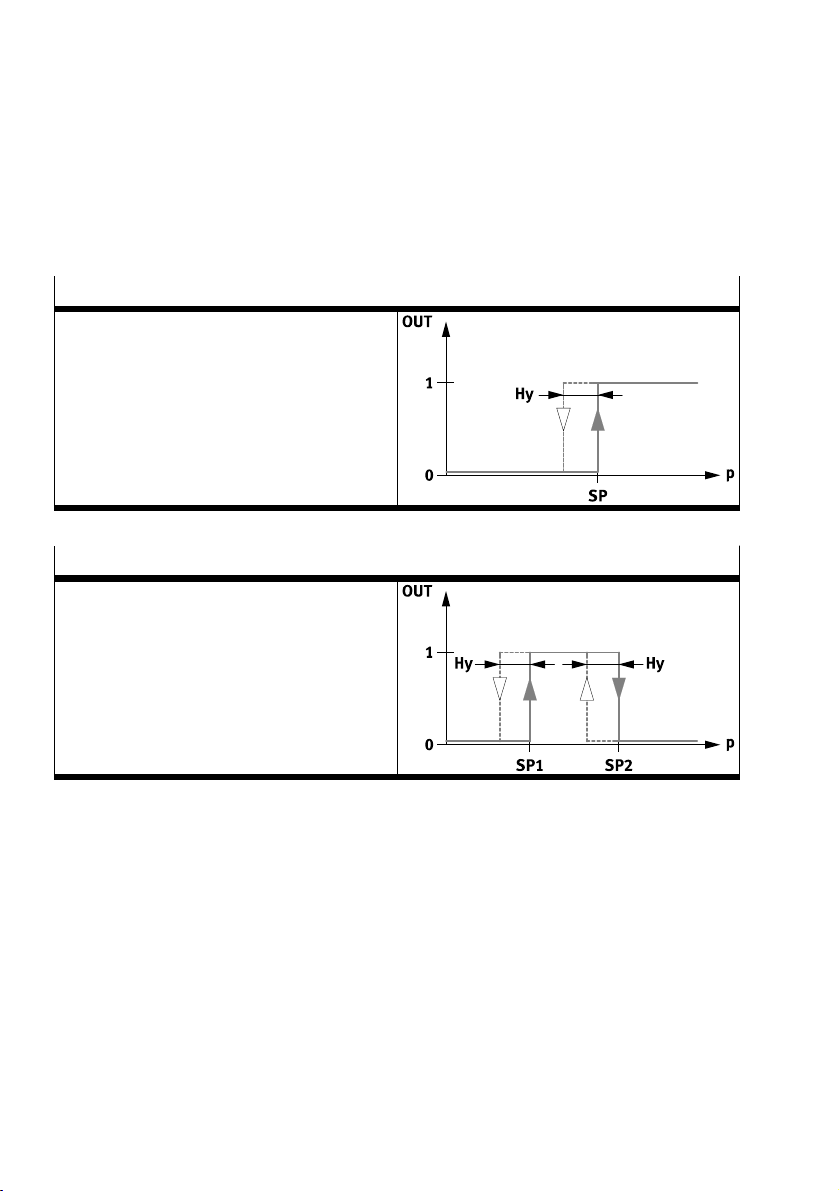

7.2.2 Teach-in threshold value comparator..................................................................... 24

7.2.3 Teach-in window comparator..................................................................................24

7.3 Restoring factory settings............................................................................................. 25

8 Parameter description................................................................................................. 25

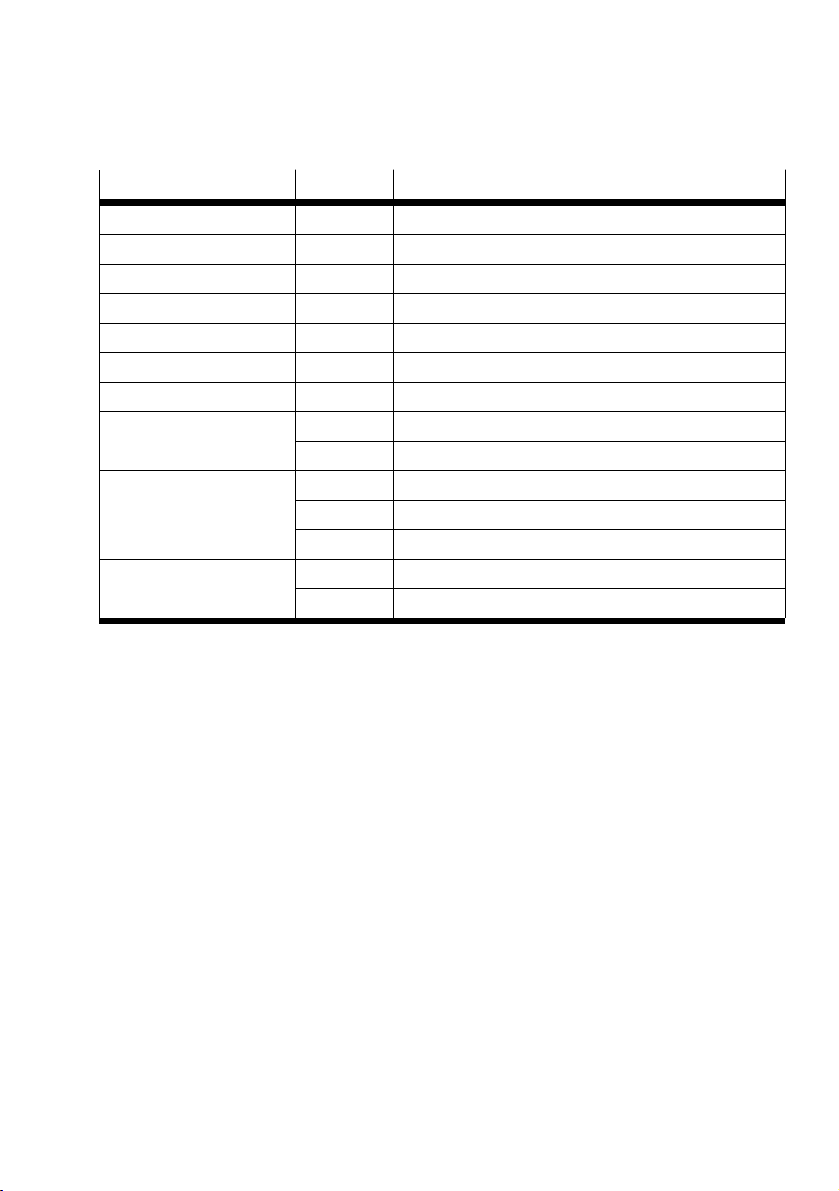

8.1 Module parameters...................................................................................................... 25

Table of contents