Vacuum generator

OVEM−Ū−1P/1N

Festo AG & Co. KG

Postfach

D−73726 Esslingen

++49/711/347−0

www.festo.com

Operatinginstructions 754851

1007NH

Original: de

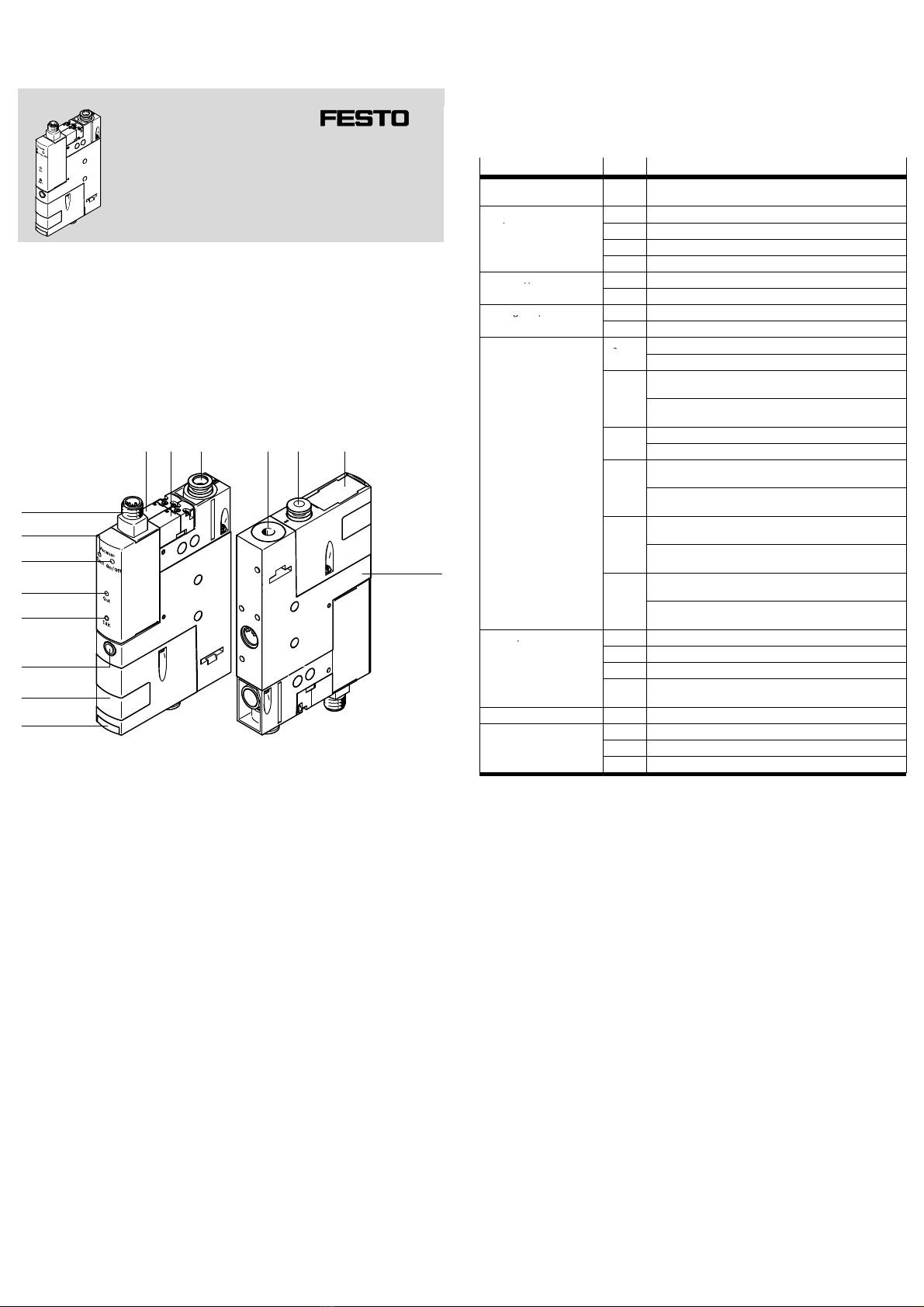

1 Product description

1.1 Overview

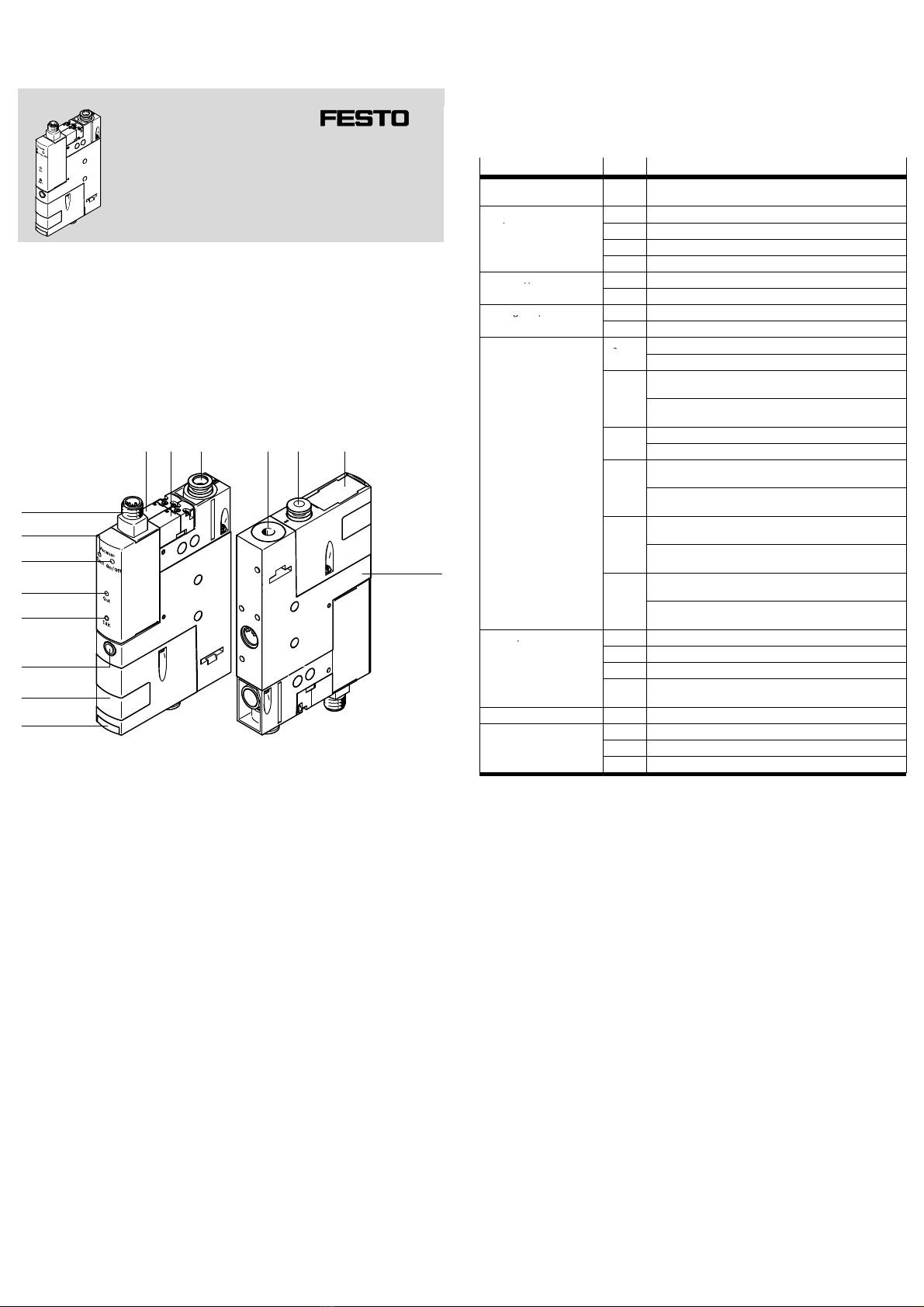

aJ

9

8

aD

2 3

aA

1

aB

aC

aE

7

4 5 6

1Solenoid valve, ejector pulse (E)

2Solenoid valve, vacuum

ON/OFF(V)

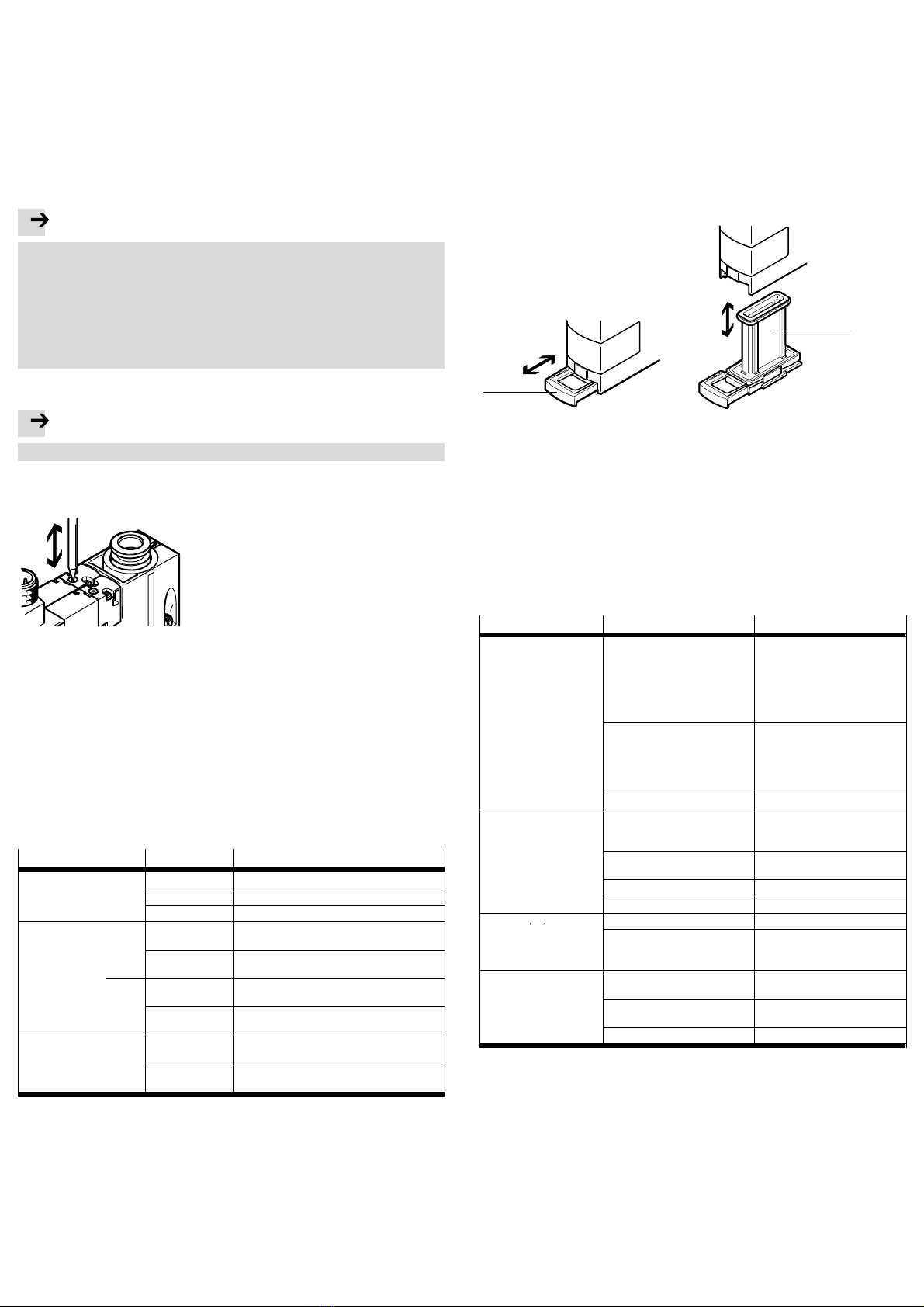

3Supply port

4Exhaust port/silencer

5Vacuum port

6Replaceable filter element

7Housing with mounting holes

8Slide for changing the filter

9Filter housing with inspection

window

aJ Flow control screw for adjusting

the intensity of the ejector pulse

aA EDIT button1)

aB LED for switching output Out1)

aC LED for switching input Vacuum

On/Off

aD LED for switching input Ejector

pulse

aE Plug for electrical connection

(M12)

1) LED and EDIT button not present on models without vacuum sensor

Fig.1 Operating elements and connections

1.2 Key features

Integrated solenoid valve for control of compressed air supply for vacuum gen

eration, available with two different switching functions: NC/NO

NC− de−energised when closed, meaning there is no vacuum generation when

the solenoid valve is in normal position (−CE,−CN)

NO− de−energised when open, meaning vacuum is generated when the sole

noid valve is in normal position (−OE, −ON)

Integrated solenoid valve for control of ejector pulse for rapid purging of vacuum

and safe set−down (−CE, −OE)

Flow control screw for controlling the ejector pulse (−CE, −OE)

Integrated vacuum sensor with switching output and Teach function (−1P, −1N)

Operating statuses of the solenoid valves displayed by LEDs

Solenoid valves can be operated with mechanical manual override

Filtering of the process air to protect the vacuum generator

Open, integrated silencer to reduce contamination of the vacuum generator

(−QO, −GO, −PO)

Various pneumatic connection alternatives (QS fitting: −QS, −QO, −PL, −PO;

female thread: −GN, −GO)

Electrical connection via M12 plug

Various output stages (05/07/10/14) vacuum types (H/L)

Anon−return valve prevents purging of vacuum if vacuum generation is inter

rupted (−CE, −OE)

Integrated protection against reverse polarity and overload protection for

switching output

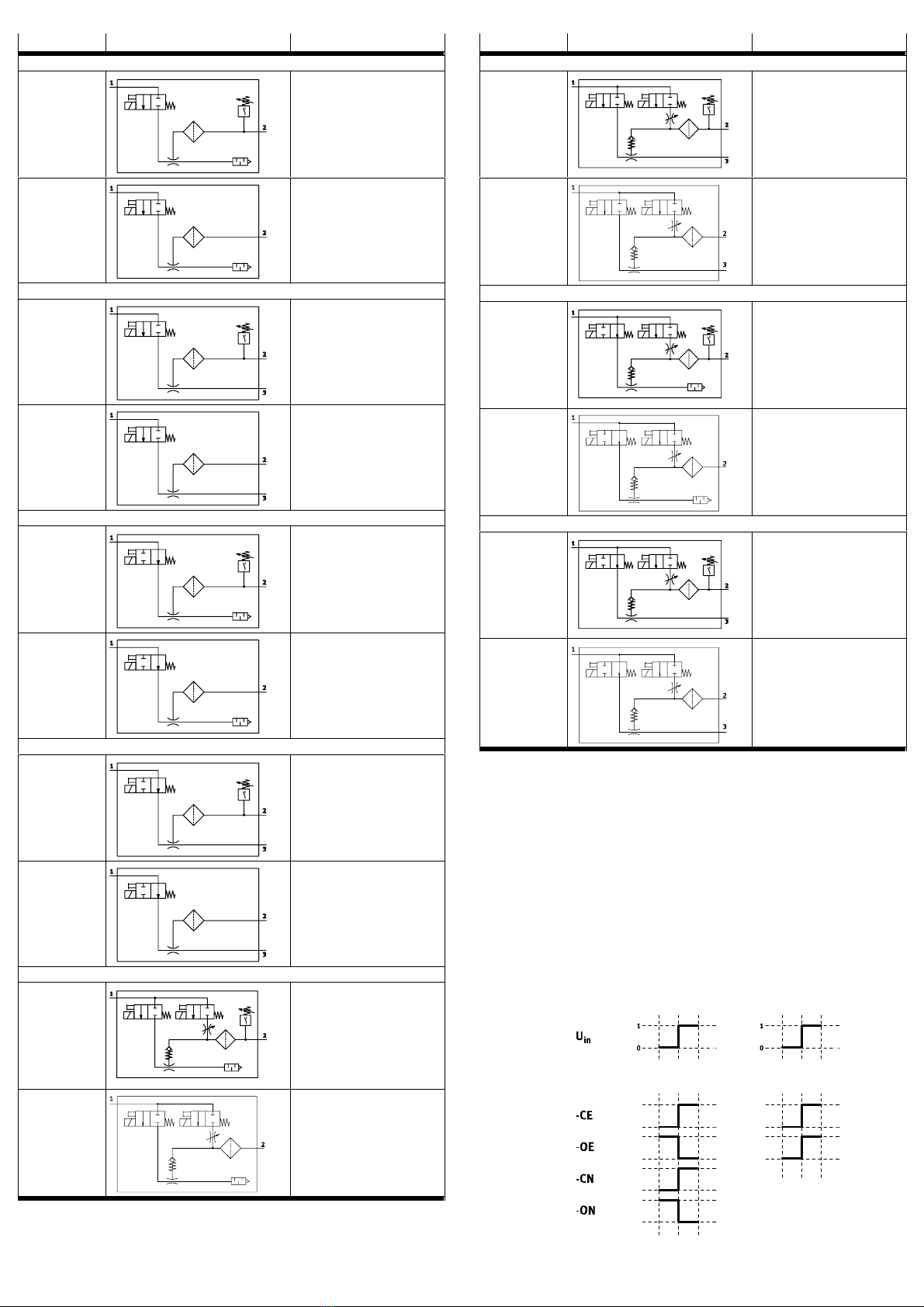

Features Type Design

Vacuum generator OVEM Vacuum generator with solenoid valve for vacuum

valveON/OFF and manual override

Nominal size of Laval

−05 0.45mm

nozzle −07 0.7mm

−10 0.95mm

−14 1.4mm

Vacuum type −H High vacuum

−L High suction capacity

Housing size/width −B 20mm wide, ISO standard

−BN 20mm wide, NPT

Pneumatic connections −QS All ports with QS fittings (−B−QS)

All ports with QS fittings in inch sizes (−BN−QS)

−QO Supply/vacuum port with QS fittings, exhaust port with

open silencer (−B−QO)

Supply/vacuum port with QS fittings in inch sizes, exhaust

port with open silencer (−BN−QO)

−GN All ports with female G thread (−B−GN)

All ports with female NPT thread (−BN−GN)

−GO Supply/vacuum port with female G threads, exhaust port

with open silencer (−B−GO)

Supply/vacuum port with female NPT threads, exhaust

port with open silencer (−BN−GO)

−PL Prepared for supply strip, vacuum port and exhaust port

with QS fittings (−B−PL)

Prepared for supply strip, vacuum port and exhaust port

with QS fittings in inch sizes (−BN−PL)

−PO Prepared for supply strip, vacuum port with QS fitting,

exhaust port with open silencer (−B−PO)

Prepared for supply strip, vacuum port with QS fitting in

inch size, exhaust port with open silencer (−BN−PO)

Normal position of the va −ON NO, normally open (vacuum generation)

cuum generator −OE NO, normally open (vacuum generation) with ejector pulse

−CN NC, normally closed (no vacuum generation)

−CE NC, normally closed (no vacuum generation) with ejector

pulse

Electrical connection −N Plug M12 (5−pin)

Vacuum sensor No vacuum sensor (PNP switching input)

−1P 1switching output PNP

−1N 1switching output NPN

Fig.2 Overview of variants

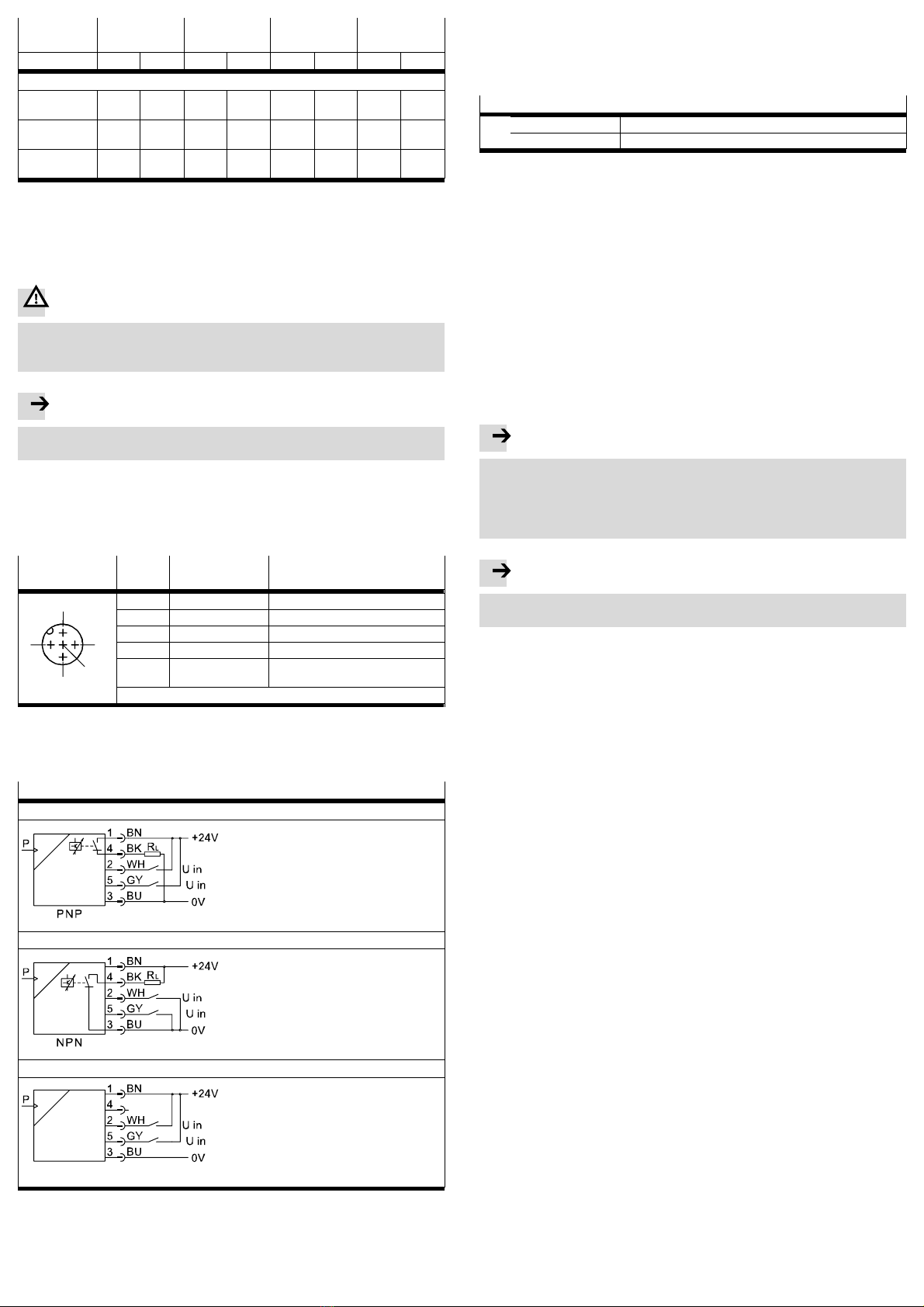

2 Function and application

The vacuum generator type OVEM is designed for generating a vacuum. The vac

uum generated is used together with a suction gripper to create a force that can

grip a workpiece so that it can be transported. The vacuum generator is available

with a variety of pneumatic and electric switching functions.

The taught setpoint value for the generated vacuum is monitored via an integrated

vacuum sensor (−1P, −1N). If the setpoint value is reached or if it is not reached due

to malfunctions (e.g.leakage, dropped workpiece), the vacuum sensor emits an

electrical signal and the Out LED indicates whether or not the setpoint was

reached.

The compressed air supply for vacuum generation is controlled by an integrated

solenoid valve. The solenoid valve can be supplied with two different switching

functions, NC and NO. The vacuum is generated as soon as compressed air is ap

plied to the vacuum generator and the electrical power supply is switched on

(NC: −CE, −CN) or off (NO: −OE, −ON) as defined by the switching function of the

solenoid valve2.

The integrated solenoid valve1can be used to control and generate an ejector

pulse to release the workpiece safely from the suction cup and to purge the vac

uum rapidly.