3Festo — DFST-50 ... 80-G2 — 2019-02

1 Further applicable documents..................................................................................... 4

2 Safety........................................................................................................................... 4

2.1 Safety instructions........................................................................................................ 4

2.2 Intended use................................................................................................................ 4

2.3 Foreseeable misuse...................................................................................................... 4

2.4 Training of qualified personnel..................................................................................... 4

3 Further information..................................................................................................... 5

4 Service..........................................................................................................................5

5 Product overview......................................................................................................... 5

5.1 Function....................................................................................................................... 5

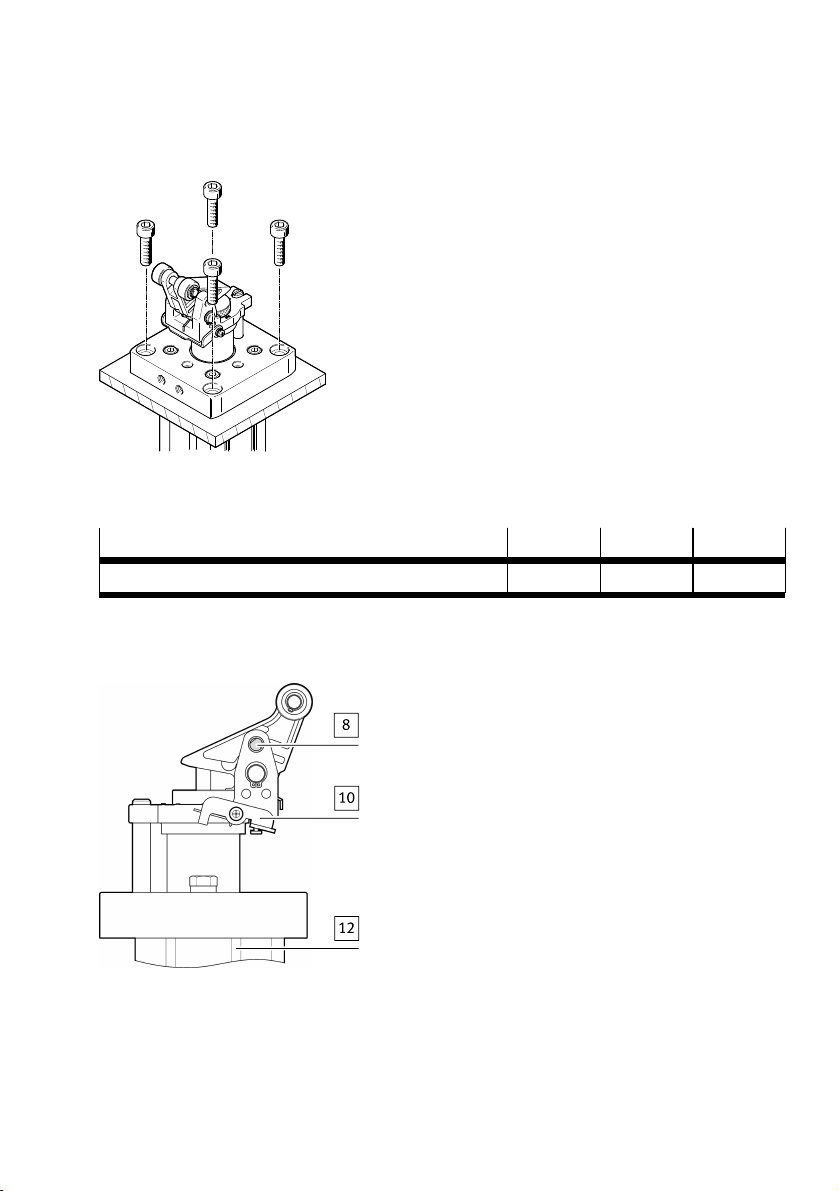

5.2 Design........................................................................................................................... 6

6 Mounting..................................................................................................................... 7

6.1 Preparation................................................................................................................... 7

6.2 Mounting...................................................................................................................... 9

6.3 Mounting accessories................................................................................................... 9

7 Pneumatic installation................................................................................................ 10

8 Commissioning............................................................................................................ 11

9 Maintenance................................................................................................................ 12

9.1 Cleaning....................................................................................................................... 12

9.2 Lubrication................................................................................................................... 13

9.3 Fault clearance............................................................................................................. 13

9.4 Repair............................................................................................................................14

10 Modification................................................................................................................ 14

11 Disposal........................................................................................................................14

12 Technical data............................................................................................................. 15

Table of contents