Go to fetco.com for the latest versions of all information Page 5P185 MARCH 2019

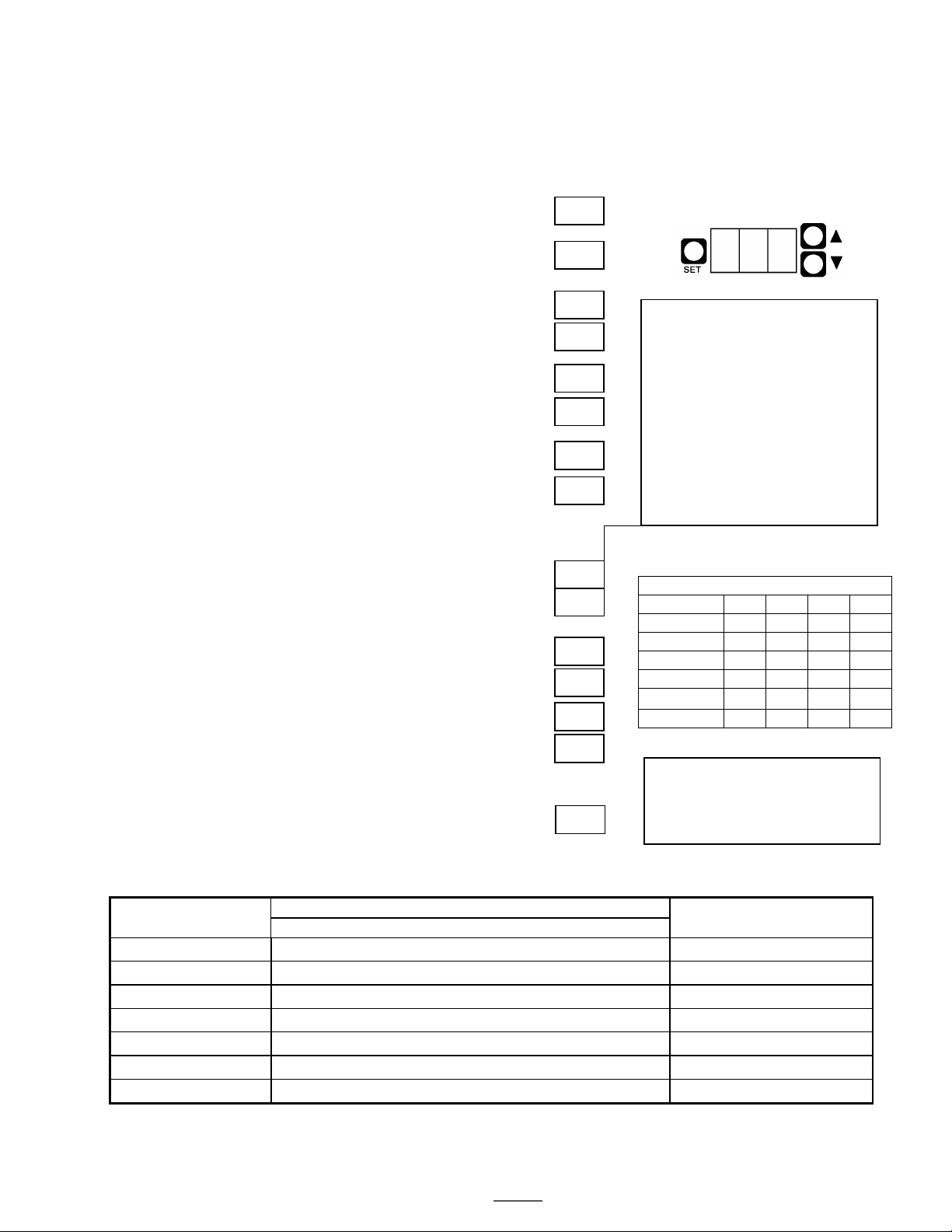

Programming Instructions

Software Version 1.2 and Above

(See Appendix A for units manufactured before August 2003)

Turn the power switch off.

Remove the lower cover.

Turn the power switch on.

The currently programmed model number will flash

briefly. (example: 12 = GR-1.2, 23 = GR-2.3)

Then, if the software default settings are currently

programmed, the display will read DEF. If not,

the display will be blank.

Hold SET for 5 seconds, until the display reads SET.

Release SET, the software version will be displayed.

(Example: 1.2, 1.3, etc.)

Press SET. The display will read TYP briefly,

followed by the currently programmed model number.

Press the UP and DOWN buttons until the correct model

number is displayed. (GR-1.2 = 12, GR-2.3 = 23, etc.)

Press SET. The display will read DEF.

Press SET to skip this section.

To reset the unit to factory default settings, hold SET for

5 seconds, until STO is displayed briefly. This will exit

programming mode. To re-enter programming mode, hold

SET for 5 seconds again.

Press SET.The display will read DLY briefly,

followed by the current motor delay setting in seconds.

(GR-2.2 & 2.3 only)

Press UP and DOWN to adjust.

Press SET.The first switch number will be displayed

briefly, followed by the current setting in seconds.

Example: LH1 = Left side small batch, 7.0 seconds

Press SET. The next switch number will be displayed

briefly, followed by the current setting.

Example: LH2 = Left side medium batch, 13.5 seconds.

Continue this way until all switches are programmed.

See the chart for switch designations.

Important! To save your changes and return to operating

mode, you must hold SET for 5 seconds until the display

reads STo.

Approximate grind times for medium size, average to dark roast beans.

Batch Size

Timer setting

Grind times are affected by conditions of the coffee beans such as: age, size, oily or dry, and degree of roast.

This sets the time that the motor

continues to run after the hopper

guillotine closes on GR-2 series

grinders. This delay ensures that

all beans have passed through

the grinding chamber,

preventing cross contamination

of different coffees.

The motor delay is added to the

end of the grind time setting.

Small – LH1/RH1 = 7 sec.

Med. – LH2/RH2 = 13.5 sec.

Large – LH3/RH3 = 20.0 sec.