After the screen shown above the initial screen will be displayed:

Warning! The electronic board will keep the settings it had

when the machine was switched off.

When the tank is in stand-by mode, the augers and the cooling system

are off. The augers and the gear motor can be turned on by pressing the

button. The screen will show

If you press the button, the screen will display as follows:

(where Y is a variable number between 2 and 5 for Cold Drink Mode,

which indicates the temperature in °C at which the product must be

prepared).

Using and you can increase or decrease the temperature of the

product. The recommended temperature is 4°C.

If you press the button, the screen will display as follows:

(where X is a variable number between 1 and 9 and indicates the

density of the slush). If you use the and buttons it is possible to

increase or decrease the slush density value.

Warning! If, when the electronic board is in Slush Mode, the product temperature is

greater than 5°C, the following screen will be:

This screen indicates that the calibration process is taking place. The

calibration process will take one minute to complete.

If you press the button (Cooling off - cold drink - slush) you can

switch the machine functioning modes alternatively. Each time you press

the button, the different screens of cold drink –slush and cooling off alternate. In this latter position

only the augers rotate and no other action is taken.

If you press the auger rotation key , the display will appear as

follows:

By holding the button for one second you will enter the

selection menu.

Please note that unless you give any further instruction to the electronic

board in more 10 seconds time, the display will automatically go back to

the initial screen.

This screen allows you to turn ON or OFF the light in the lid, by pressing

the and buttons of the electronic board.

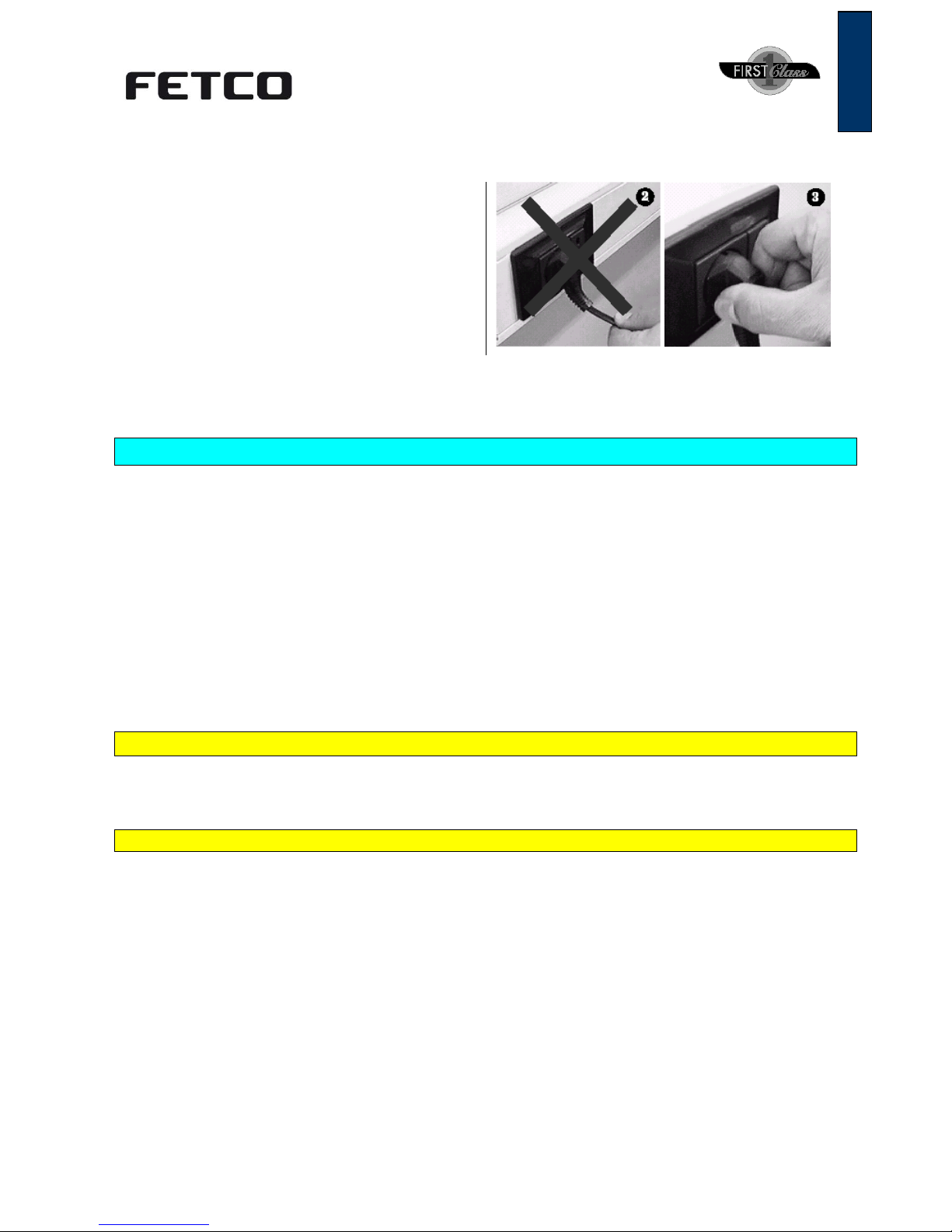

As you already know, for security reasons, when a tank is open, the

augers stop turning. However, the augers stop can be also caused by a malfunctioning of 1 and/or 2

contacts, or by the accidental lost of one of the contact during the

cleaning phase; in this case, it is possible to activate the electronic

bypass function. In this screen you can activate or deactivate the bypass

function by pressing the increase and decrease keys.

This screen allows you to turn ON or OFF the Low Level control function

(automatic decrease of slush’s density to no.1, when the level probe is

not covered with product for more than 20 minutes); you can do that by