FG Modellsport 10007 User guide

Mounting instruction for

F1 Competition 09 Chassis

Item N°. 10007, 10008

A.10007-10008-200409

FG Modellsport GmbH

Spanningerstr. 2

73650 Winterbach-Germany

Phone: +49 7181 9677-0

Fax: +49 7181 9677-20

www.fg-modellsport.de

Please thoroughly keep this construction manual for spare parts orders!

Weight of the individual bags/ boxes:

Bag A = 4 parts

Bag B = 0,871 kg

Bag C = 0,649 kg

Bag D = 0,617 kg

Bag E = 0,308 kg

Bag F = 0,136 kg

Bag G = 0,699 kg

Bag H = 0,729 kg

Bag I = 0,091 kg

Bag J = 0,125 kg

Bag K = 0,498 kg

Bag L = 0,442 kg

Bag M = 0,502 kg

Bag N = 0,355 kg

Bag O = 0,587 kg, only for Item N°. 10007

Bag P = 0,447 kg, only for Item N°. 10008

The RCS, accumulators and battery charger are not included in the de-

livery volume.

We congratulate you on buying this FG Competition model. Please check

the contents of the construction set, respectively of the bags. The indi-

vidual bags had been thoroughly packed by us and their weight had been

checked. When purchasing the individual bags, please check their weight

and their closure by staples which must not have been removed or ope-

ned and closed several times. It is possible that the weight of an indivi-

dual bag deviates by 5 grams. In case of claims due to missing parts, you

always need to present the label indicating the weight at your speciali-

zed dealer. By checking the weight of the bag, you may exclude that lar-

ger parts or several parts are missing.

The handling with fuels requires circumspective and ca-

reful handling. Imperatively observe the security advi-

ces.

- Refuel only if the engine is switched off!

- Take off the body.

- Thoroughly clean the area around the fuels nipple.

- Remove the fuel filler cap and carefully fill in the fuel mixture.

- Smoking or any kind of open fire is not admitted.

- Fuels might contain solvent-like substances. Avoid contact with skin and ey-

es. Wear gloves for refueling. Do not inhale fuel vapors.

- Do not spill any fuel. If you have spilled fuel immediately clean the engine

and the model.

- Make sure that no fuel will get into the soils (environmental protection). Use

an appropriate mat.

- Do not refuel in enclosed rooms. Fuel vapors accumulate at the soil (risk of

explosion).

- Transport and store fuels only in admitted and labeled canisters. Keep fuel

out of the range of children.

- The operator is responsible for any damages caused to third persons in the

operating range of the model, respectively of the engine, if they are injured

or in case of property damage.

- The model must only be passed on to persons who are familiar with this mo-

del and its operation, always provide the operating manual.

- Persons with implanted heart pacemakers must not work on running engi-

nes and on live parts of the ignition system when the engine is being star-

ted.

- The engine must neither be started nor operated in enclosed rooms (wi-

thout sufficient ventilation).

- When starting the engine, avoid inhaling the exhausts.

- The model must neither be started nor operated without air filter or without

exhaust system.

- Before every start perform a functional check of the safety-relevant parts.

- The throttle rods must always return automatically to the idle position.

- Any cleaning, maintenance and repair works must only be performed with

the engine being switched off. The engine and silencers are getting very

hot. In particular do not touch the silencer.

Comments regarding the construction manual:

Before starting the assembly please see through this construction manual.

This way you will get an overview of the whole execution.

Please check by means of the parts or bag list if the construction kit is com-

plete and also check the weight of the individual bags for the positions. Only

this way you may be sure that all parts which you need for the assembly are

available. If a part is missing, please immediately contact your specialized

dealer.

Table of contents

Position 1: Differential gear

Position 2-7: Rear axle, gearwheel drive

Position 8: Shock absorber

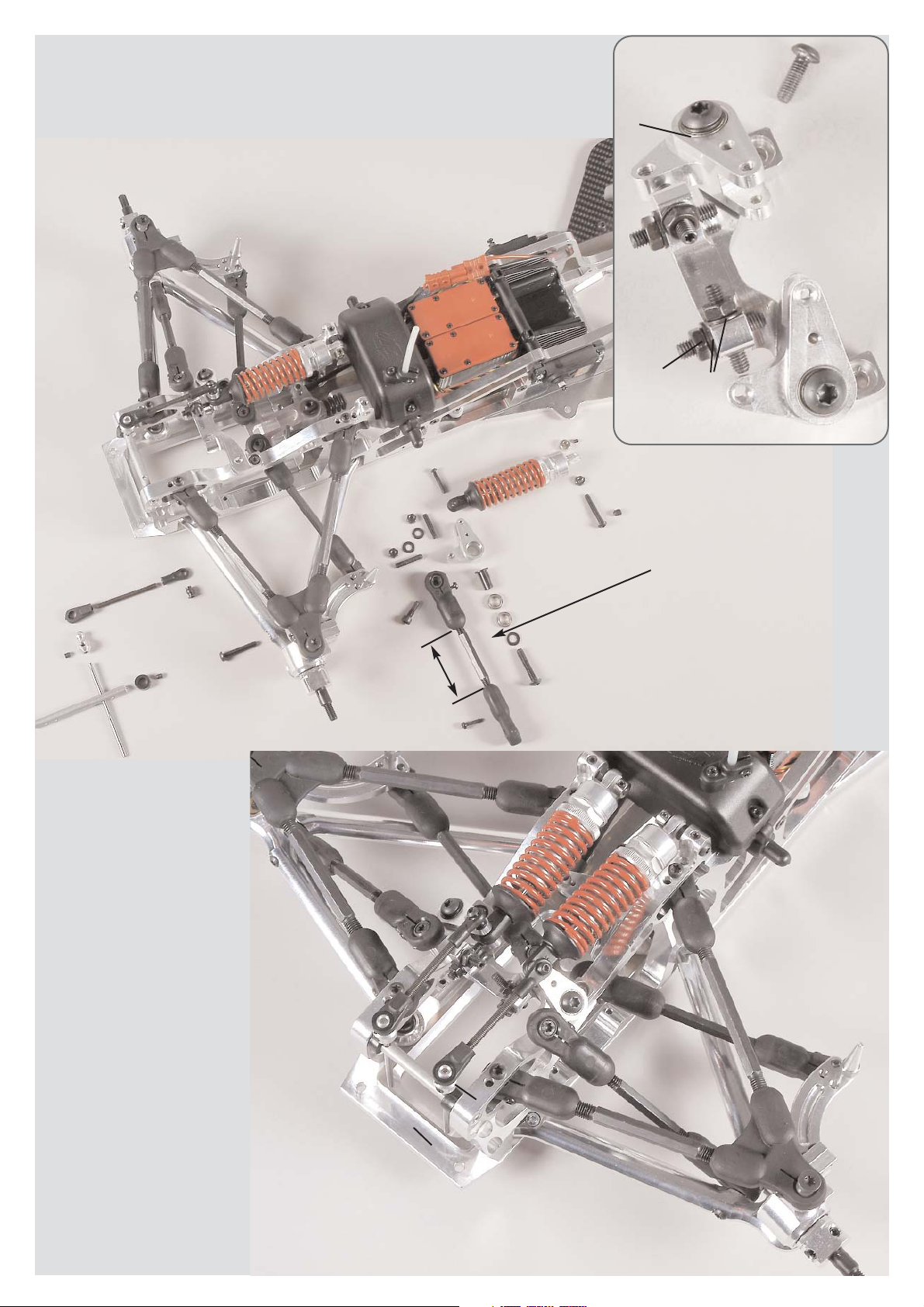

Position 9-10a: Assembly shock absorber, stabilizer - rear axle

Position 11-19a: Front axle

Position 14-17: Servos, receiver

Position 18-19a: Assembly shock absorber, stabilizer - front axle

Position 12-13: Servo saver, track rods, steering rods

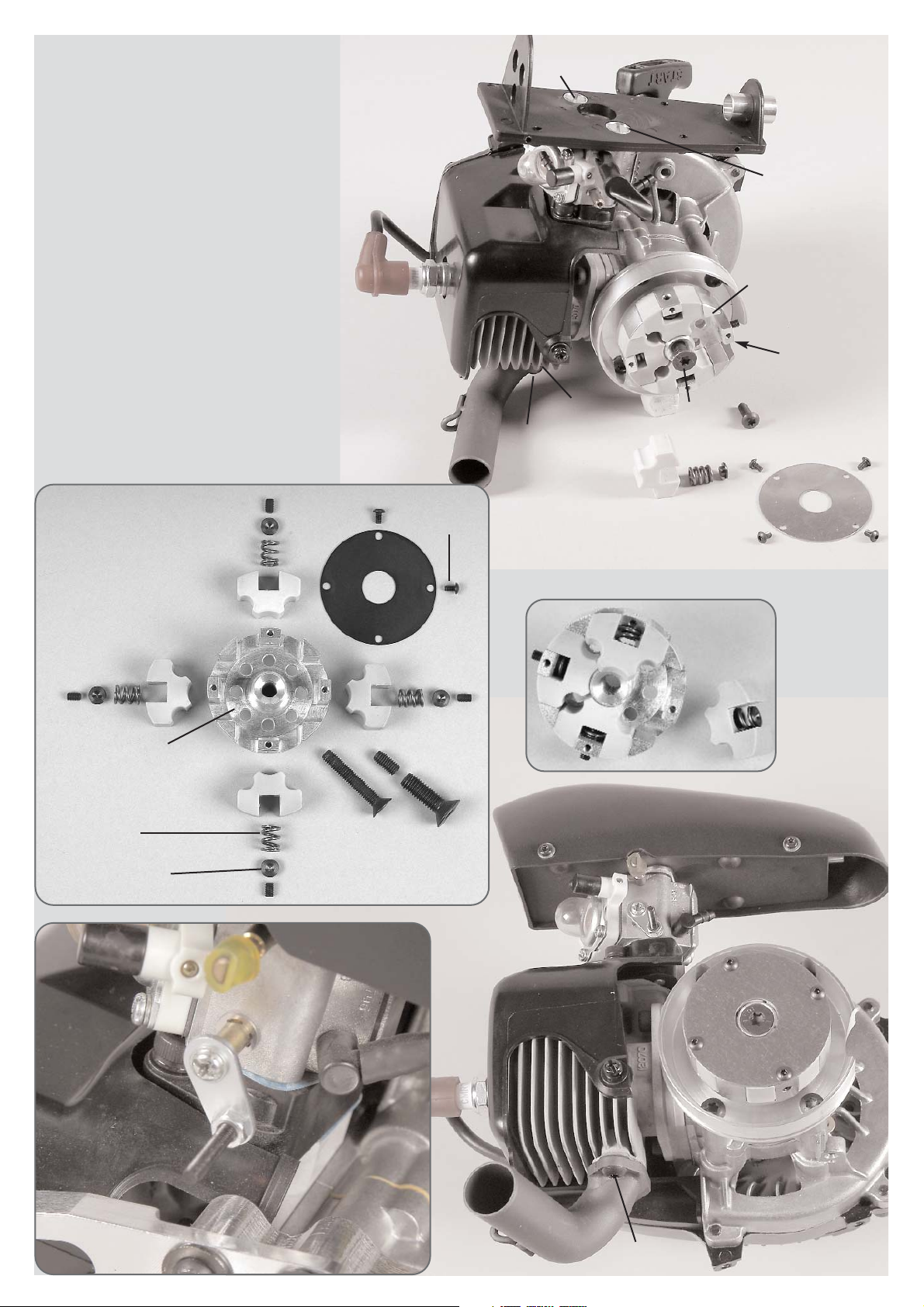

Position 19-23: Engine, manifold, airbox, clutch

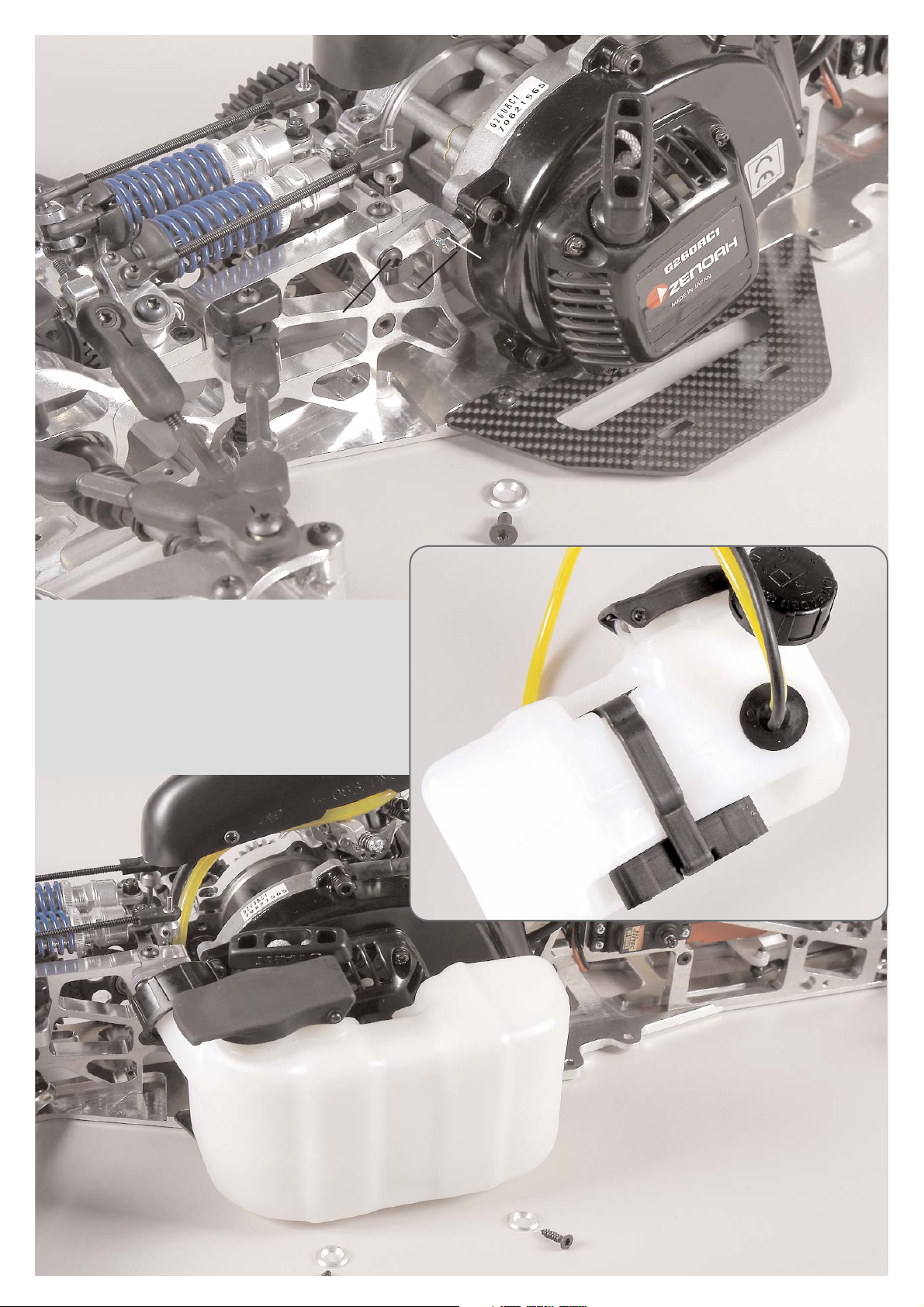

Position 23-24a: Engine assembly, tank

Position 25-25a: Tuning pipe

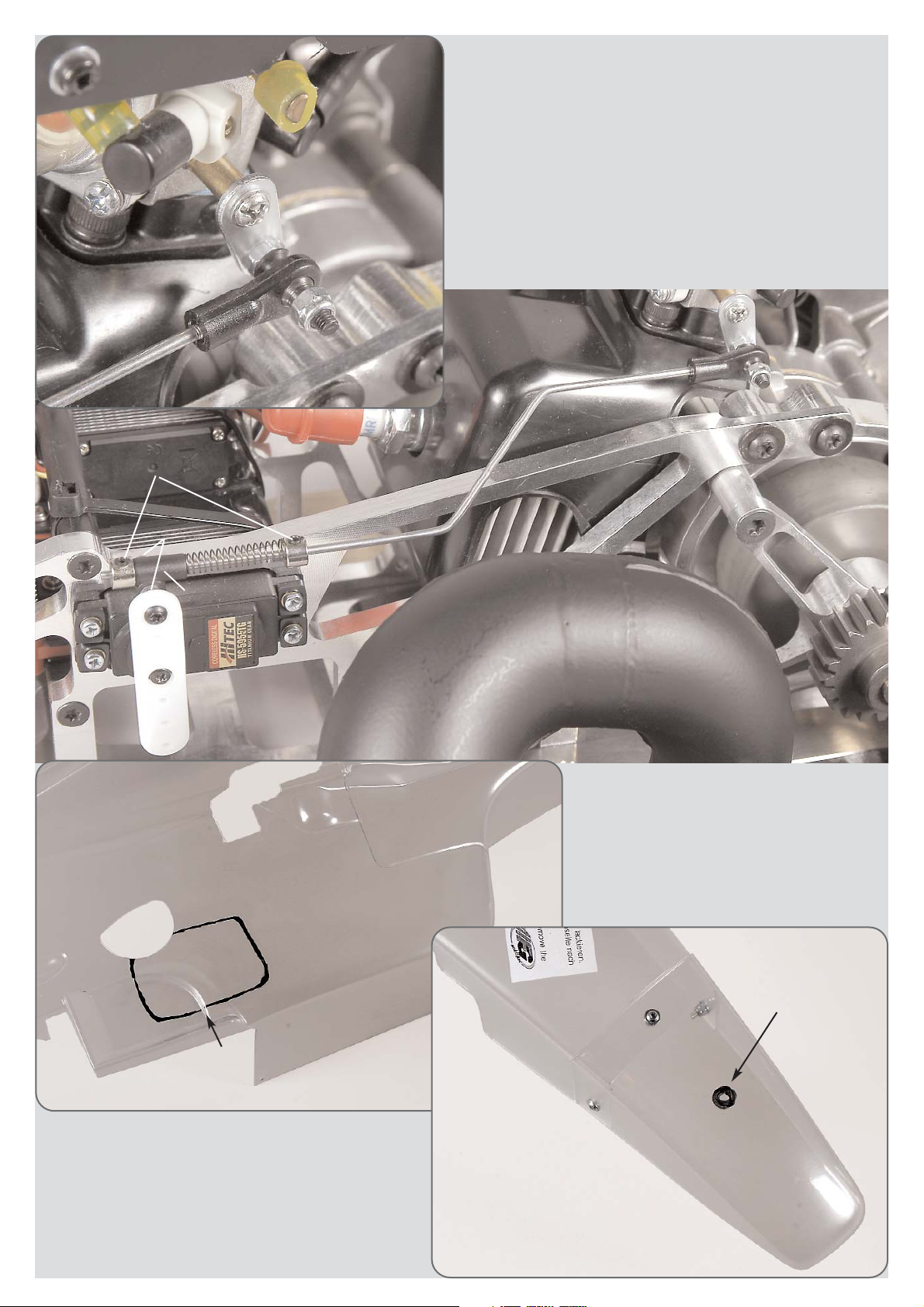

Position 18: Throttle rods

Position 28-29: Front spoiler, rear spoiler

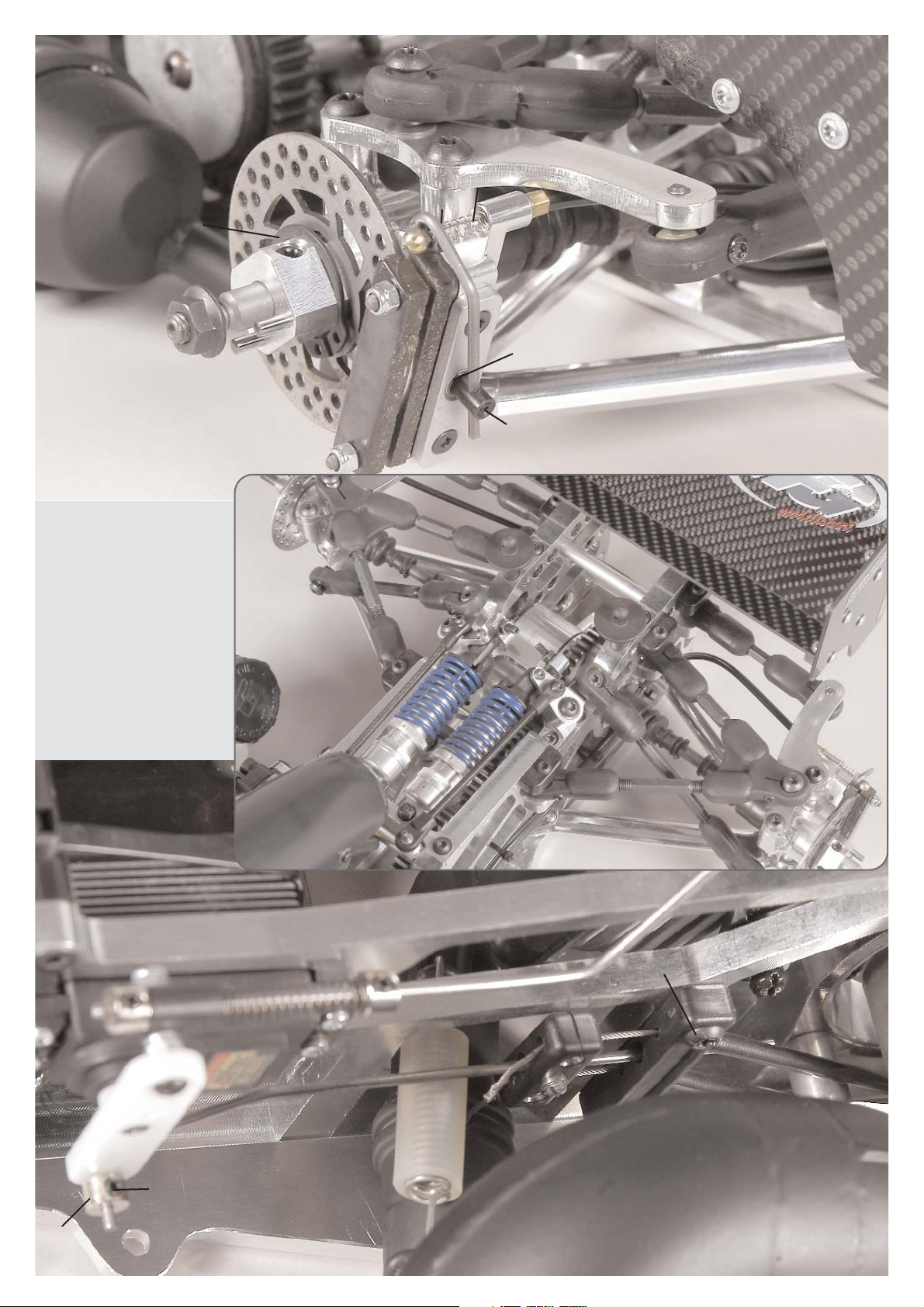

Position 30-31b: FG Magura hydr. brake system front and rear

Position 32-33b: Tuning disk brake front and rear

All metric screws need to be secured

with thread lock fluid.

7080/3

6069/2 8600/13

8600/3 8600/4

8602/1

8493 8600/11

8602/2

8600/13 8600/13

8602/2

8600/2

8600/13

8600/9

8600/10

8493

6924/20

6069/2

7080/3

6924/20

8600/8

6067

6068

8500/3

6067

8600/8

8600/11

8600/1

8600/11

8600/6

Steel gearwheel

large 48t.

Screw M4x8

Flat side

O-ring

Ball diff.

axle

Assembly

The flange bushes 8602/2, roller bearing 8602/1 as well as the rotary shaft se-

als 8600/6 and the ball bearing 8493 have professionally been mounted on

the alloy differential housing A/B by the manufacturers FG .

Now mount the steel gearwheel 48 teeth on the alloy differential housing A.

Check the internal and external fins on production birs, if necessary remove

them with an emery cloth. Do not bend the fins.

Now mount the set of fins according to illustration 1: Insert a differential ge-

arwheel with square on a differential bevel wheel axle. Then slide on the

square one after another in the following order 1x internal fin, 1x O-ring 14x1.5,

1x external fin, 1x internal fin, 1x O-ring 14x1.5, 1x external fin, 1x internal fin,

1x external fin. Grease the shim ring 8600/13 a little and put the differential

housing on the flange bush 8602/2. Now insert the whole package into the

differential housing A according to the illustration. Now push the differential

gearwheel with a screw driver with the fin package towards the housing and

carefully pull out the differential axle.

Push both bronze bushes 8600/8 from the inside to the outside into the bo-

rings of the differential housing, position 1a. Insert the differential gearwheels

B into the housing and push in the differential bevel differential gear axle

6068. Grease the 8mm shaft of the ball diff. axle 6069/2 plentifully and push

it from outside into the differential housing. The borings of the alloy diffe-

rential housing need to align with the borings of the differential gearwheels.

If the borings are offset, the gearwheels need to be disassembled and reas-

sembled once again displaced by one tooth until the parts can be easily tur-

ned. Mount the O-rings 3x1 and 42x1.5 according to the illustration.

Now join the two halves of the housing, check them for free movement and

assemble them using the two enclosed M3x20 screws.

Fill in about 15ml of the enclosed silicon oil into the boring of the alloy diffe-

rential housing B. Add about 5ml 2-stroke engine oil for better lubrication. Then

close the boring by means of the locking screw M8x1/ copper disk. You may

influence the locking effect by the number of fins by the viscosity of the fil-

led in oil as well as by the filling quantity.

When driving an overpressure is building up in the diff. housing. Therefore you

should unscrew the locking screw after a few laps of driving time in order to

release the overpressure.

Insert the fin package

into housing A.

O-ring 42x1,5

O-ring 3x1

Bronze bush

7x18x5

Position 1

Parts are in

bag C

Position 1b

Parts are in

bag C

Position 1a

Parts are in

bag C

Press the bearing shafts into the right alloy rear axle mounts

and mount the alloy cross bracing with M4x18 countersunk

screws to the left and right alloy rear axle mounts.

Before assembling, impress the alloy diff. bearings into the gui-

dings of the left and right alloy rear axle mounts and check if they

are running smoothly, it may be necessary to rework the gui-

dings a little with an emery cloth. Then press them on the ball

bearings of the pre-assembled differential and press them in

evenly (with the gearwheel in direction to the left alloy rear ax-

le mount) into the left and right alloy rear axle mounts. Mount the

alloy diff. bearings to the alloy rear axle mounts by using pan-he-

ad screws M5x14.

Insert the body supports in the left and right alloy diff. bearings,

align the borings for the body clips in driving direction and clamp

them by using headless pins M4x10.

Mount the complete gearwheel drive on the alloy chassis by

using M4x14 countersunk screws.

Hint: The left and right alloy diff. bearings are different, please pay

attention to the mounting direction. Make sure that the gearw-

heels are running smoothly. If this is not the case, look for the re-

ason and remedy the defect, mount it again, if necessary.

Position 2

Parts are in

bag A+B

CFRP chassis

right side part

Drivingdirection

Disk Ø 4,3

Screw 4x8

Stop nut

M5

Alloy chassis

Screw

5x25

Screw

5x30

Screw 3x6

Ball bush

Rear lower alloy

wishbone

CFRP chassis

left side part

Bevel

washer

Bevel

washer

Alloy bush

5x10x5,5

Position 3

Parts are in

bag C+D

Alloy rear axle

mount right

Ball bearing

8x16x5

Distance

bush

11x8x1

Ball bearing

8x16x5

Bearing

shaft

Gearwheeel

38 teeth

Distance

bush

11x8x6

Guide bush

Guide bush

Differential

mounted

Alu-Quer-

verstrebung

Alloy cross

bracing

Alloy rear axle

mount left

Screw

4x18 Screw 4x18

Screw

4x18

Headless

pin 4x10

Headless

pin 4x10

Alloy wish-

bone fixing

M4

Alloy wish-

bone fixing

M4

Plastic wish-

bone fixing

Ø4

Plastic wish-

bone fixing

Ø4

Screw

4,2x19

Screw

4,2x19

Left alloy

diff. bearing

Screw

5x14

Screw

5x14

Screw

5x14

Body support

Disk

Ø 5,3

Disk

Ø 5,3

Screw

5x14

Alloy chassis

Position 4

Parts are in

bag C+D

Alloy rear

axle mount

right

Alloy rear

axle mount

left

Screw

4x14

Screw the CFRP chassis side parts to the al-

loy chassis using M4x8 pan-head screws and

disks Ø4,3.

The CFRP chassis side parts left and right

differ, pay attention to the mounting direction.

Impress the ball bushes into the alloy

wishbones and secure them with M3x6

pan-head screws.

Mount the rear lower alloy wishbones to the front alloy chassis by using M5x25

countersunk screws, bevel washers and stop nuts M5. Fix the rear alloy wish-

bone by using M5x30 countersunk screws, alloy bushes 5x10x5,5 (between al-

loy chassis and bevel washer), bevel washers and stop nuts M5.

Mount the bevel washers always with the thinner side facing towards the ball bush.

Press the guide bushes into the alloy rear axle mounts.

Mount the lower alloy wishbone fixings M4 and the upper

plasic wishbone fixings Ø4 to the alloy rear axle mounts

by using M4x18 and 4,2x19 countersunk screws. Press

each 2 ball bearings 8x16x5 and a distance bush 11x8x1

into the gearwheels 38 teeth, then insert the bearing shafts

from the square side. Now press the bearings shafts with

the distance bushes 11x8x6 into the left alloy rear axle

mount and fix them by using M5x14 pan-head screws and

disks Ø5,3.

Push the distance disks into the round recess of the ball driving

axle as well as into the ball diff. axle. Mount the protection bellows to the ball dri-

veshafts according to the illustration. Lubricate the ball range a little when put-

ting on the protection bellow. Apply lubrication grease on the ball holes of the dri-

veshafts and press in the balls. The balls will be held by the lubrication grease

and this way the driveshaft can be mounted more easily. Now press the complete

ball driveshaft into the ball differential axle and the ball driving axle. Shift the pro-

tection bellows over the ball diff. axles and the ball driving axles.

Position 7

Parts are in

bag B

Driving

shaft

mounted

Left alloy

upright

Headless

pin 6x6

Wheel nut

M6

Square wheel

14 mm

Screw

4x12

Distance

bush

Ball bearing

8x22x7

Ball bearing

8x22x7

Pay attention

to the slant

Screw

5x16

Screw

5x16 Screw

5x20

Rear axle

plate left

Screw

5x20

Bevel

washer

Driving direction

Track rod

mounted

Screw

2,9x13

Screw

2,9x13

Rear upper

wishbone

left mounted

Screw

4x35

Screw

4x35

Ball diff. axle

Alloy rear axle

mount left

approx.

21,5mm

approx.

39mm

approx.

10,5mm

Hint: The left and right upper wishbones are different,

mounting direction of the steel ball with collar on the

alloy upright is showing to the bottom and the shorter

side faces the rear. The clearance of the balls in the

ball-and-socket joints can be adjusted with the help of

the screws 2.9x13. The left and right rear axle plates

differ, pay attention that the slant shows to the top when

assembling.

Apply

lubrication

grease.

Lubricate ball driveshaft a little.

Protection bellow

Ball diff. axle

Ball driving

axle

Distance

disks Balls for dri-

ving shaft

Position 5

Parts are in

bag B

1. Press the cylinder pins into the square wheel 14mm as

described in position 6, use high-strength screw reten-

tion.

Press the ball driving axles of the pre-assembled dri-

veshafts into the alloy uprights which are equipped with

ball bearings and then mount the square wheel driver

14mm with recess facing the ball bearing on the flat si-

de of the ball driving axle by using the headless pins

M6x6.

Mount the alloy upright between alloy upright and alloy

wishbones using a countersunk screw M5x20 and bevel

disk (thin side facing the ball bush). The left and right al-

loy uprights are different. The milled surface for the bra-

ke has to face the rear.

2. Mount 2,9x13 pan-head screws into all

plastic ball-and-socket joints.

Mount the pre-assembled upper wishbones

and track rods to the alloy rear axle mounts

using the pan-head screws M4x35.

Fix the rear axle plates with the slant showing

upwards to the alloy uprights by using M5x16

pan-head screws.

Mount the upper wishbones to the rear axle

plates using countersunk screws M5x20.

Mount the track rods to the rear axle plates

using cylinder screws M4x12.

Hint: The left and right track rods are diffe-

rent, pay attention to the balls in the ball-and-

socket joints, mount the ball with lowering

using the cylinder screw.

All metric screws need to be secured with thread lock fluid.

Position 6

Parts are in

bag B

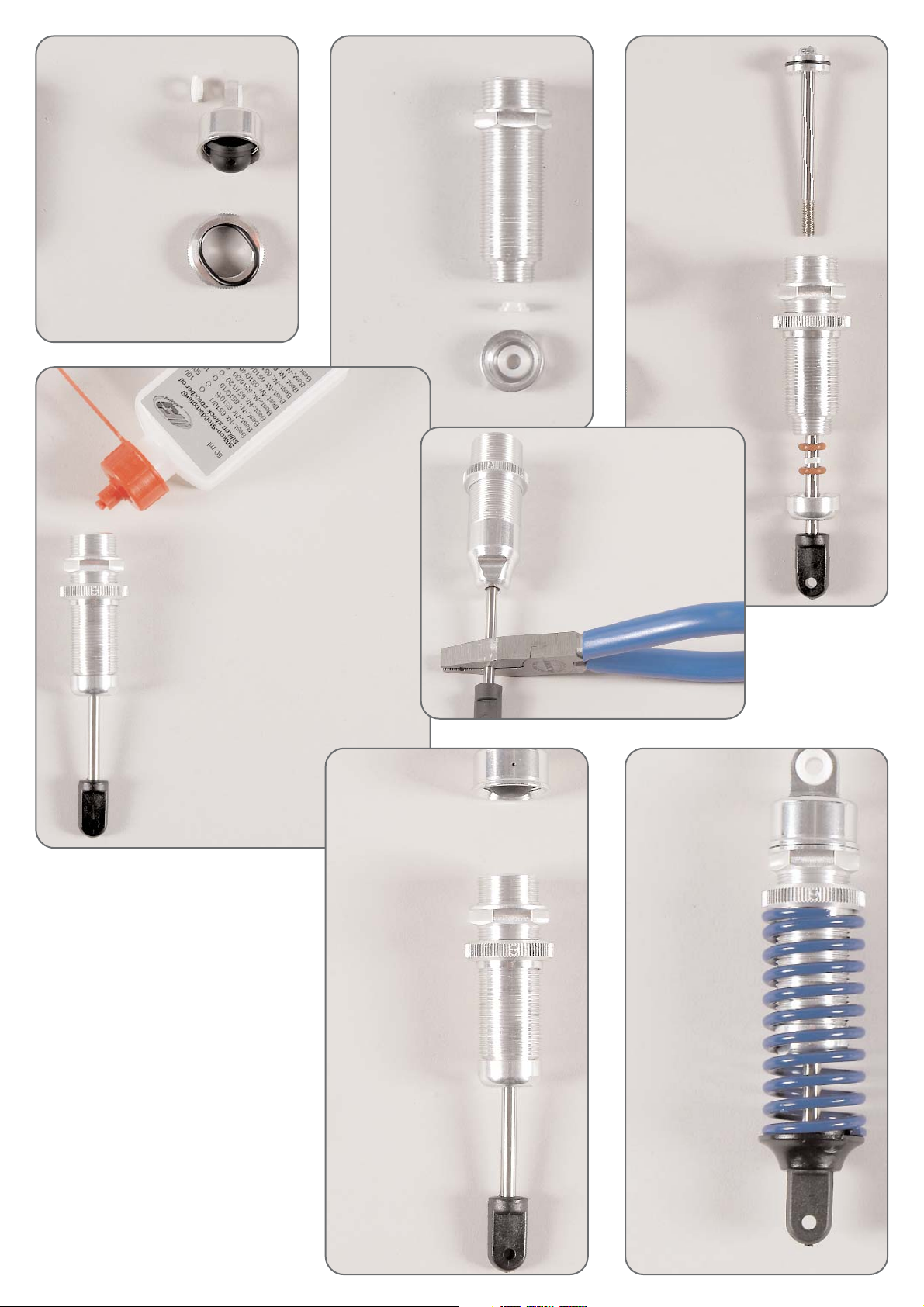

Position 8

Parts are in

bag E

Position 8a

Parts are in

bag E

Position 8b

Parts are in

bag E

Position 8e

Parts are in

bag E

Position 8c

Parts are in

bag E

Position 8d

Parts are in

bag E

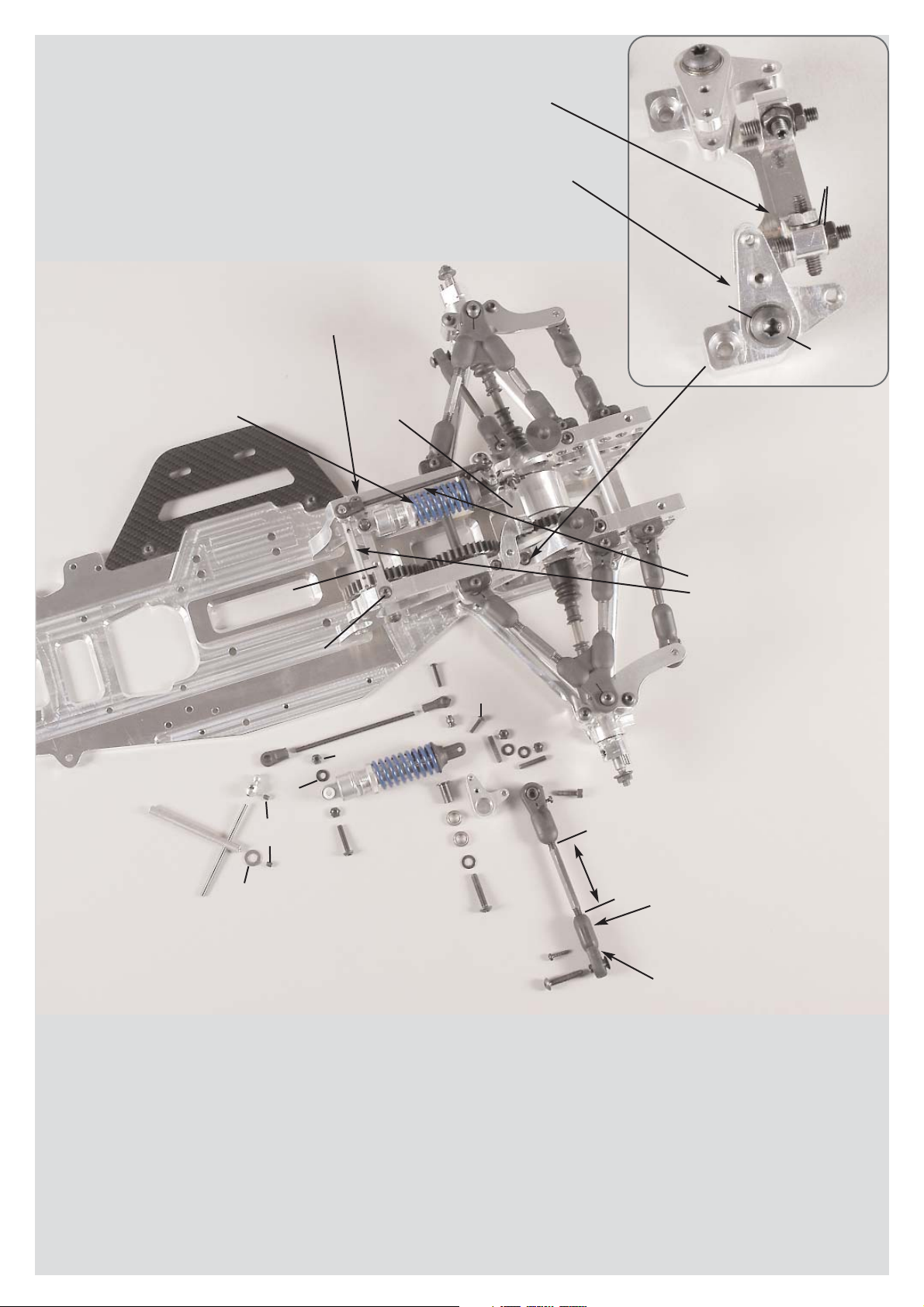

Disk

Ø 4,3

Disk Ø

4,3

Rear alloy

baffle

Screw

5x25

Disk

Ø 5,3

Ball bearing

7x11x3

Headless

pin 4x20

Headless

pin 4x20

Nut

M4

Alloy damper

reversing

Alloy dam-

per rever-

sing

Screw the ball-and-socket joints

6mm and 7mm on the rods to the

length of approc. 72mm, then

press the steel balls 6mm and ball

collets 7mm in the same direc-

tion into the ball-and-socket jo-

ints 6mm and 7mm.

Mount the stabilizer into the ball

collets 7mm with an excess

length of approx. 8mm by using a

headless pin M4x4.

Press the stabilizer shaft with

shim rings 6x12x1 between the

alloy rear axle mounts, insert the

two stabilizer rods in the stabilizer

shaft, connect the stabilizer rods

with the shim rings between the

alloy rear axle mounts and mount

them using headless pins M4x4.

Mount the ball-and-socket joint

with steel ball 6mm to the inside

of the damper reversings using

pan-head screws M3x16. Pay at-

tention to position 10a.

Screw

5x25

Push-Rod

mounted

Screw

2,9x13

approx.

53mm

Position 9

Parts are in

bag F

Position 10

Parts are in

bag F

Stabilizer

Stabilizer shaft

Ball collet

7mm

Ball joint

7mm

Linkage

Headless

pin 4x4

Shim ring

6x12x1

Screw

3x16

Stop

nut M4

Damper fixing

brace

Disk

Ø 4,3

Screw

4x12

Rear alloy

baffle

Screw

4x14

Disk

Ø 5,3

Screw

5x25

Ball bearing

7x11x3

Ball joint

6mm

Steel ball

6mm

Screw

4x20

Nut

M4

Screw

3x12

Bearing

bush

Nut

M4 Disk Ø

4,3

Assemble the M4x20 pan-head screws into

the damper fixing brace and secure them

with M4 nuts. Now mount the fixing brace

to the alloy rear axle mounts by using M4x12

pan-head screws and Ø4,3 disks.

Screw the M4x20 headless pins into the alloy baffle as pic-

tured and secure them by using Ø4,3 disks and M4 nuts.

Mount the alloy baffle to the alloy rear axle mounts using

M4x12 pan-head screws.

Press the ball bearing 7x11x3 into the alloy damper rever-

sing, insert the bearing bushes through the alloy damper re-

versings which are equipped with ball bearings and mount

them to the alloy baffle using M5x25 pan-head screws and

Ø5,3 disks.

Fix the rear dampers to the damper fixing bra-

ce by using Ø4,3 disks and M4 stop nuts.

Fix the front dampers from the outside at the

alloy damper reversings with M3x12 pan-head

screws.

Mount the 2,9x13 pan-head screws in-

to the plastic ball joints of the push-rods.

Fix the pre-assembled lower push-rod

with the collar of the steel ball to the re-

ar lower alloy wishbones by using

M5x25 pan-head screws.

Mount the pre-assembled upper push-

rod to the alloy damper reversings by

using M4x14 cylinder screws.

Hint: Left and right push-rods are diffe-

rent, pay attention to the balls in the ball

joints, mount the ball with lowering with

the cylinder screw. An arising clearance

in the ball joints can be adjusted with

the 2,9x13 screws.

All metric screws need to be secured with thread lock fluid.

Alloy servo saver A 04

ball-beared

Alloy servo saver B 04

ball-beared

Flange sleeve for

alloy servo saver

Servo saver spring

Servo saver axle

Countersunk screw M5x25

Securing disk 6mm

Shim ring 7x13x0,3

O-rings

Ball bearing 7x14x5

Ball bearing

7x11x3

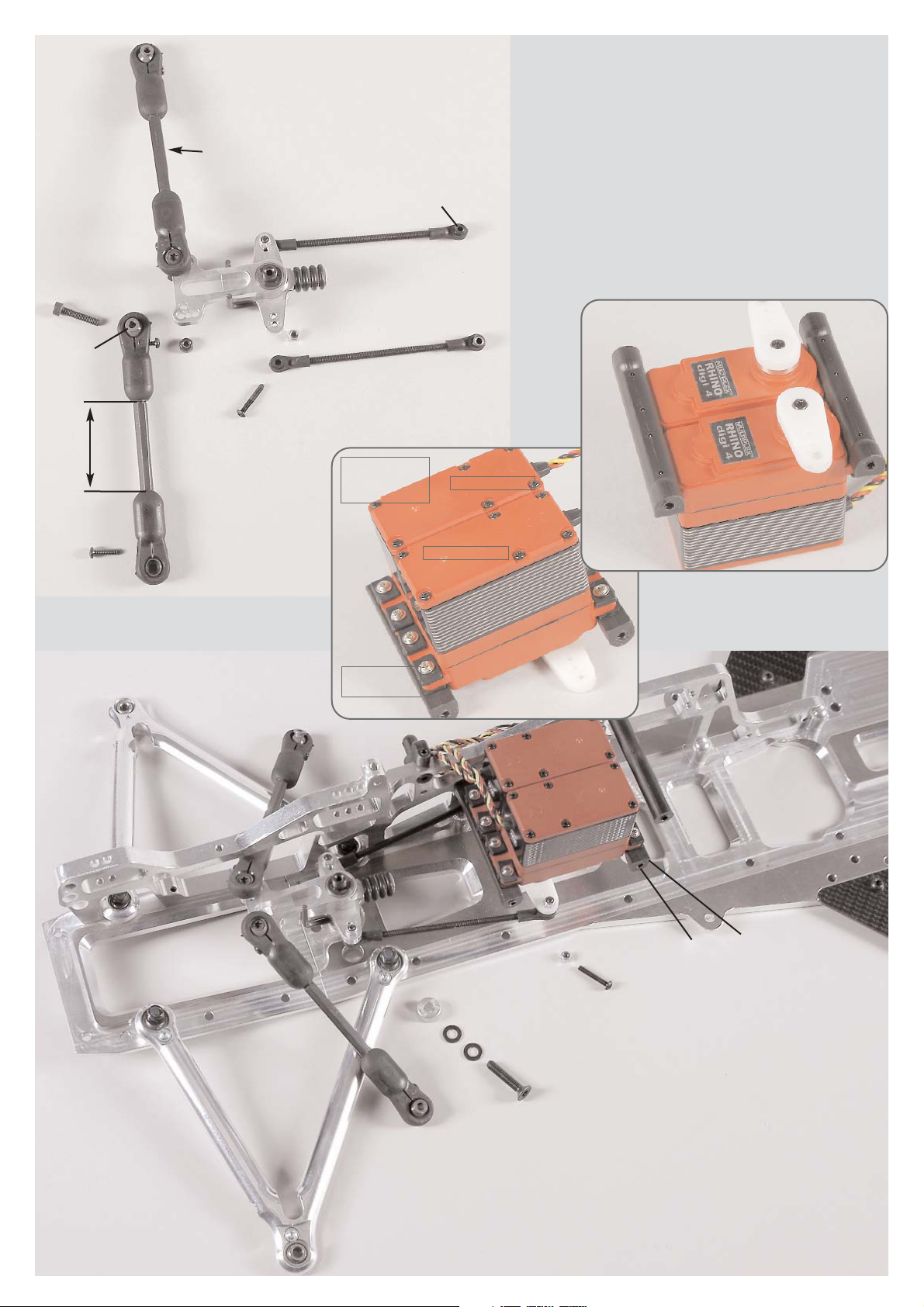

Position 12

Parts are in

bag H

approx. 8mm

approx. 72mm

Screw

4x14

Screw

4x14

Stop nut

M5

Screw

3x6

Screw

3x6

Bevel

disk

Bevel

disk

Front axle

carrier right

Alloy chassis

Alloy front

chassis

Position 11

Parts are in bags

G+A+H

Front lower alloy

wishbone left

Ball-type

nipple

Screw

5x25

Screw

5x25

Body mount

Screw

4,2x19

Position 10a

Parts are in

bag F

The stabilizer rod should be mounted pa-

rallel to the shock absorber.

Make sure the stabilizer 3mm projects ap-

prox. 8mm at the top. Please check if the

stabilizer does not contact any other parts

when deflecting.

Secure the ball-type nip-

ples which are moulded

in the alloy wishbones

using the binding head

screws M3x6.

Mount the front lower alloy wishbone with the shorter side facing the front to the

alloy chassis and the alloy front chassis by using M5x25 countersunk screws, be-

vel disks and M5 stop nuts. Mount bevel disks always with the thinner side facing

the ball-type nipple.

Fix the body mounts to the left and right front axle carriers using 4,2x19 countersunk

screws. Mount the right front axle carrier to alloy chassis and alloy front chassis

with M4x14 countersunk screws.

Push the ball bearing in the alloy servo saver parts A and B. Mount the

servo saver spring on the alloy servo saver part A, then mould the flan-

ge sleeve in the alloy servo saver part A. Press the servo saver axle

through the flange sleeve into the two servo saver parts and secure it

using the shim rings and the securing ring 6mm. Check if the servo sa-

ver is running smoothly, mount the o-rings on the servo saver.

Hint: You can adjust the effect of the servo saver with the number of the

used o-rings. The more o-rings, the harder is the effect of the servo sa-

ver.

All metric screws need to be secured

with thread lock fluid.

Servohebel

Screw

3x18

Screw

4x20

Screw

2,9x13

Ball joint

Ball joint

6mm

Alloy joint

ball

Track rod

mounted

Steering rods

mounted

Stop nut

M4

Stop nut

M3

Steel ball

6mm

Servo saver

mounted

Position 13

Parts are in

bag H

approx. 45mm

Front axle

carrier right

Screw

3x18

Screw

4,2x16

Screw

5x25

Distance

disk

Distance

bolt

Stop nut

M3

Steering servo

Steering servo

Servo fixing

brace

Steering rods

mounted

Disk Ø

5,3

Screw

4,2x19

Mount the assembled steering rods through the steel balls 6mm with

the collar facing the servo saver into the outer thread holes of the al-

loy servo saver by usin g M3x18 pan-head screws and secure them

with M3 stop nuts. Screw 2,9x13 pan-head screws into the plastic

ball-and-scket joints of the track rods.

Fix the mounted track rod into the front outer hole of the servo saver

by using M4x20 cylinder screws. The cylinder screw must go through

the alloy joint ball, the collar must face the alloy servo saver. Fasten

it all with M4 stop nuts.

Hint: The ball clearance can be adjusted with the 2,9x13 screws in the

ball-and-socket joints.

Steering servo

Steering servo

Servo fixing

brace

Position 14

Parts are in

bag H

Mount the steering servos with the enclosed fi-

xing rubber bushings and screws to the servo fi-

xing braces as described in position 14. Switch on

your RCS and bring the steering servos in neu-

tral position. The servo arms have to be shortened

slightly corresponding the type. For competition

we recommend to use alloy servo arms. Press the

servo arms on the servos as pictured and fix them

with the enclosed screws. Preferably the servo

arms should be in a 90° position to the servo.

Mount the servo fixing braces on the right front axle carrier by

using 4,2x16 countersunk screws.

Mount the distance bolt with a 4,2x19 countersunk screw to

the right front axle carrier.

Mount the servo saver with a M5x25 countersunk screw, Ø 5,3

disk and distance disk between servo saver and alloy chas-

sis in the rear hole of the alloy chassis.

Switch on the RCS, bring the trim of the steering into central

position. Align servo saver in centre of the chassis. First mount

one servo rod using M3x18 pan-head screw and M3 stop nut,

then the second in the same way. Adjust both servo rods in

the same length. You should be able to fix the servo rods ea-

sily and without any resistance on the servo arms of the stee-

ring servos.

Hint: Adjust both steering rods in the same length by turning

the ball-and-socket joints. Servo saver and servo arm should

be parallel.

Servo arm

Steering servo

Servo fixing

brace

Position 14

Parts are in

bag H

Position 15

Parts are in

bag H

Disk

Ø 4,3

Front axle

carrier left

Screw

4x14

Screw

4x14

Screw

4x14

Alloy battery

fixing brace F1

Drill the alloy battery

fixing brace F1 to

7mm if using the 3rd

receiver fixing.

Alloy

chassis

Screw

2,9x13

Receiver

battery

Body mount

Body clip

Dampening

rubber

Battery/

body bolt

Screw

2,9x9,5

Screw

2,9x19

Screw

2,9x16

Receiver box

Flexible aerial

Mount for flexible aerial

Stop

nut M4

Mount the left front axle carrier to the

alloy chassis and the alloy front chas-

sis using M4x14 countersunk screws .

Mount the servo mounting brace to the

left front axle carrier using 4.2x16

countersunk screws. Mount the dis-

tance bolt to the left front axle carrier

using a 4.2x19 countersunk screw.

Mount the throttle-brake servo and the

brake servo to the front axle carrier

using M2.5x12 pan-head screws.

Drill out the aerial hole by 3mm at the

lid of the receiver box and mount the

aerial mount to the lid of the receiver

box using a 2.9x19 pan-head screw.

Insert the flexible aerial through the fle-

xible aerial mount and clamp it with a

2.9x9.5 pan-head screw.

In order to lead-in the servo cables, cut

out a hole of a diameter of approx.

10mm at an appropriate position bet-

ween the lower and upper part of the

box.

Put the lower part of the box on the

body mounts. Connect all servo ca-

bles and battery cables to the receiver

and check if it is working properly. Le-

ad-in the aerial cable through the ho-

le of the upper part of the box and

through the flexible aerial. Now stow

the cable remnants of the servos in the

receiver box, mount the lower and up-

per part of the receiver box to the bo-

dy mounts using the 2.9x16 pan-head

screws.

Hint: Cover the lower part of the re-

ceiver box with some foam in order to

protect the receiver against vibrations.

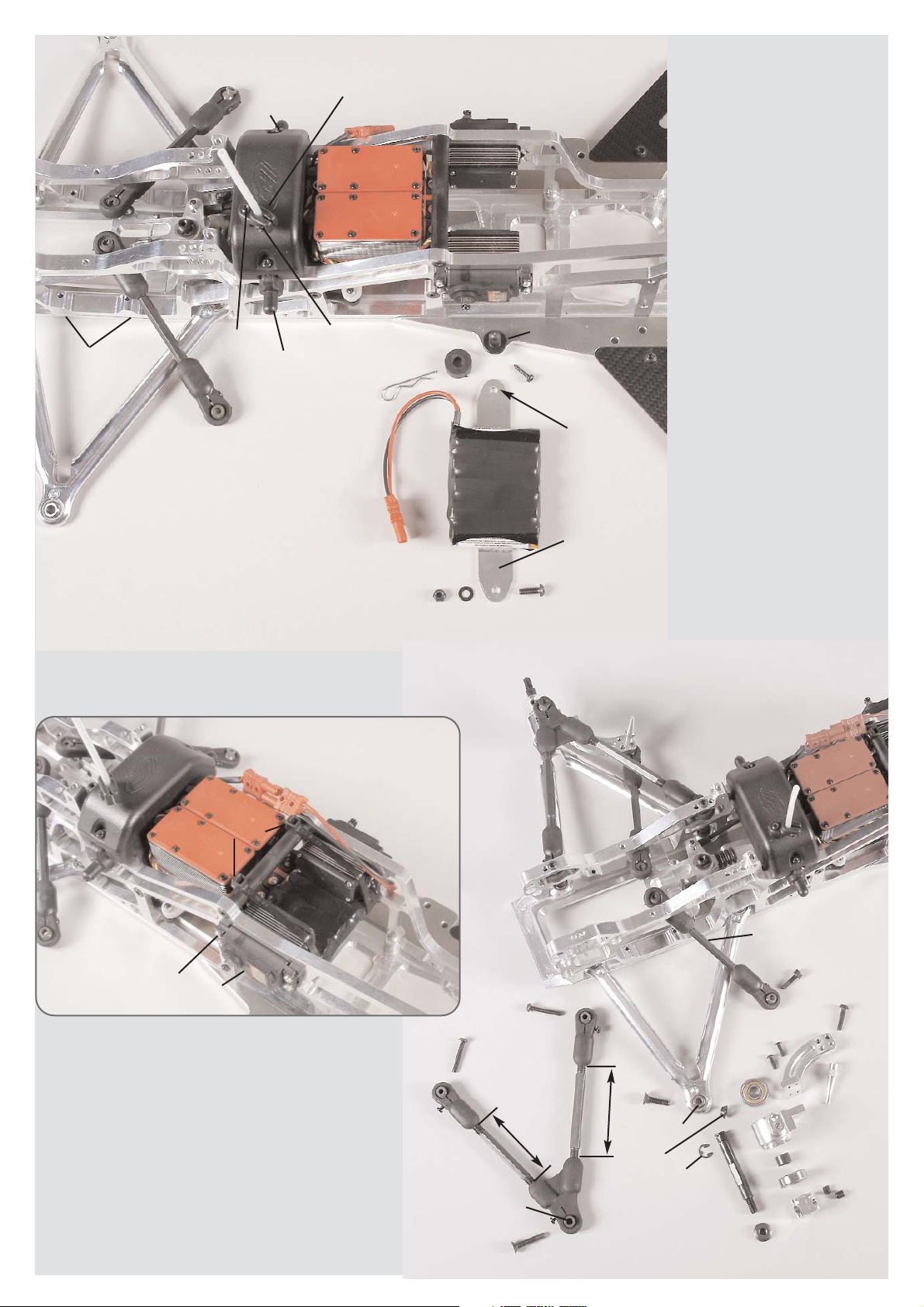

Position 16

Parts are in

bag I

Position 17

Parts are in

bag G+H

Track rod

mounted

Alloy

steering

stop

Wheel nut M6

approx. 71mm

approx. 62mm

Retaining

washer Ø 5

Driving

axle

Square

wheel

14mm

Alloy

steering

arm

Bevel

disk

Left alloy

uprights axi-

ally displaced

Distance

bush

Ball bearing

8x22x7

Front upper

wishbone

left mounted

Screw

5x25

Screw

3x10

Screw

4x14

Screw

4x18

Screw

5x20

Screw

2,9x13

Screw

4x25

Screw

4x25

Headless

pin 6x6

Front axle

carrier left

Ball

bush

Position 16a

Parts are in

bag I

Brake servo

Brake servo

Cable clip

Receiver

battery

Throttle-

brake servo

Throttle-

Brake servo

Screw

2,5x12

Push the securing disk in the 2nd groove of the driving axles, then in-

sert it in the alloy uprights equipped with ball bearings according to

the illustration position 17. Then, mount the square wheel driver 14mm

with recess facing the bearing on the flat side of the driving axle by

using M6x6 headless pins. Mount the alloy steering arm to the alloy

uprights using M3x10 pan-head screws. Mount the alloy uprights using

M5x20 countersunk screws and bevel disk (thin side facing the ball-ty-

pe nipple) between the alloy upright and the front lower alloy wishbo-

ne. Mount the pre-assembled upper wishbones to the front axle car-

riers using M4x25 pan-head screws. Mount the upper wishbones to

the outside of the alloy uprights using M5x25 countersunk screws. Fix

the alloy steering stops to the alloy steering arms (front outer thread bo-

ring) by using M4x18 pan-head screws. Mount the track rods to the al-

loy steering arms (rear inner thread boring) using M4x14 cylinder screws.

Hint: Pay attention to the mounting direction of the upper wishbones,

mount the shorter side facing the front. The front alloy uprights are axi-

ally displaced, mount the side with the two threaded holes facing the

top.

There are 3 possibilities to fasten the receiver battery:

1. Fix the receiver battery from the bottom to the throttle-brake servo

and brake servo using cable clips as illustrated in position 16a.

2. Fix the receiver battery with adhesive tape centred on the alloy bat-

tery fixing brace F1. Now mount the alloy battery fixing brace F1 under

the throttle/brake servo and brake servo on both sides of the alloy chas-

sis by using M4x14 pan-head screws, disks Ø 4,3 and M4 stop nuts.

3. Drill the fixing holes of the alloy battery fixing brace F1 on both sides

to 7mm and fix the receiver battery with adhesive tape centred on the

F1 fixing brace. Mount the battery/body bolts on both sides of the al-

loy chassis using 2,9x13 pan-head screws. Fix the alloy battery fixing

brace F1 on the battery/body bolts under the throttle/brake servo and

brake servo with dampening rubber and body clip.

Hint: The 3rd mounting version of the receiver battery enables a quick

changing of the receiver battery.

Ball bearing

7x11x3

Alloy dam-

per rever-

sing

Alloy

reversing

plate

Screw

4x12

Screw

5x25

Nut M4

Headless

pin 4x20

Disk

Ø 4,3

Push rod

mounted

ca.30,5mm

Collet

Headless

pin 3x3

Nut M4

Headless

pin

5x5

Screw

4x25

Bearing

bush

Disk Ø 5,3

Screw

5x25

ca. 45mm

Ball bearing

7x11x3

Alloy dam-

per rever-

sing

Screw

4x14

Screw

2,9x13

Screw

4x25

Distance

disk

Screw

3x20

Nut

M4

Disk

Ø 4,3

Headless

pin

4x20

Front axle

carrier right

Front axle

carrier left

Steel

ball

6mm

Ball

joint

6mm

Rods

4x43

Ball

joint

7mm

Ball

collet

7mm

Headless

pin

M4x4

Stabilizer 3mm

Stabilizer

shaft

Headless

pin

M4x4

Position 19

Parts are

bags E+J

Position 19a

Parts are in

bags E+J

Position 18

Parts are in

bags E+J

Mount 2,9x13 pan-head screws into the

plastic ball-and-socket joints of the push

rod. Fix the pre-asssembled push rod

at the bottom to the front lower alloy

wishbones using M4x25 pan-head

screws. Fix the pre-assembled push rod

at the top to the alloy damper reversings

using M4x14 cylinder screws.

Hint: Pay attentin to the balls in the ball-

and-socket joints, mount the ball with

lowering with the cylinder screw. The

clearance of the balls can be adjusted

with the 2,9x13 screws in the ball joints.

Screw M4x20 headless pins centrally in the alloy baffle and se-

cure it with disks Ø4.3 and M4 nuts. Mount the alloy baffle to

the front axle carrier by using M4x12 pan-head screws .

Mould the ball bearings 7x11x3 into the alloy reversing plate,

insert the bearing bushes through the alloy reversing plates

which are equipped with ball bearings and mount it to the al-

loy baffle using M5x25 pan-head screws and disks Ø5.3.

Screw the ball-and-socket joints 6mm and 7mm

on the rods to the length of approx. 30,5mm, then

push the steel balls 6mm and ball collets 7mm in

the same direction into the ball-and-socket joints

6mm and 7mm. Mount the stabilizer flush into

ball collets 7mm using a headless pin M4x4.

Press the stabilizer shaft with distance disks bet-

ween the front axle carriers, insert both stabilizer

rods 3mm in the stabilizer shaft, align the stabi-

lizer rods between the front axle carriers using

the distance disks and mount them with M4x4

headless pins. It may be necessary to grind the

distance disks slightly with an emery cloth. Mount

the ball-and-socket joint with steel balls 6mm,

M3x20 pan-head screws and damper mount of

the shock absorber through the outer hole to the

alloy damper reversing plates. Press M4x25 pan-

head screws into the front axle carriers and se-

cure with M4 nuts and M5x5 headless pins. Press

the shock absorbers onto the protruding threads,

then secure them with collets and M3x3 head-

less pins.

Hint: The stabilizer rods should be mounted pa-

rallel to the shock absorber.

Mount the alloy gear box flange to the alloy rear axle carriers using a

M6x14 pan-head screw and a disk Ø6.4 and mount it to the alloy

chassis using M4x14 countersunk screws and fastening disks. Put on

M4x14 pan-head screws with disks Ø4.3 throughout the front axle

carrier into the alloy gear box flange. Put on a M5x14 screw into the

alloy gear box flange.

Push the clutch bell in the clutch flange bearing which is equipped

with ball-and-socket joints, press on 4 shim rings 10x16x1 and steel

gearwheel with 21 teeth and mount it using M5x5 headless pins.

Mount the clutch flange bearing with M5x30 countersunk screws and

distances 5.1x10x16 between the alloy gear flange and the clutch

flange bearing.

Press 10x19x7 ball bearings on both sides into the alloy bearing bus-

hing, insert a distance bush 13x10x35 in between. Mount the alloy

bearing bush to the alloy gear flange using M5x14 pan-head screws.

Push the alloy gear carrier in the plastic gearwheel with 42 teeth and

press it on to the side of the gear shaft which has the shorter flat sur-

faces. Mount the alloy gear carrier to the surface of the gear shaft

using M5x6 headless pins, secure the plastic gearwheel with 42 teeth

using a spacer washer and a M6x10 pan-head screw.

Impress the gear shaft into the alloy bearing bush equipped with ball

bearings. Mount steel gearwheel 15 teeth using M5x5 headless pins

and secure it in the gear shaft using M6x10 pan-head screws.

Hint: Clutch bell and gear shaft should be almost axially without cle-

arance. Make sure that all gear wheels are correctly geared, check if

the complete unit is running smoothly while turning it.

Position 20a

Parts are in

bag K

Screw

5x30

Screw

5x14

Screw

6x10

Screw

6x10

Centre disk

Clutch bell

Gear shaft

Plastic

gearwheel

42 teeth

Headless

pin 5x5

Headless

pin

5x5

Headless

pin

5x6

Clutch flange

bearing

mounted with

ball bearing

10x22x6

Steel gearwheel

15 teeth

Alloy gear

carrier

Shim rings

10x16x1

Alloy gear

flange

Alloy

bearing

bush

Ball bearing

10x19x7

Distance bush

13x10x35

Distance

5,1x10x16

Steel

gearwheel

21 teeth

Position 20

Parts are in

bag K

Front axle

carrier left

Disk Ø4,3

Screw

4x14

Screw

4x14

Screw

4x14

Fixing disk

Fixing disk

Screw

5x14

Disk

Ø 6,4

Screw

6x14

10531/01

Clutch carrier 05 f. F1, 1 pce.

10530/02

Clutch blocks 05, 4 pcs.

10530/03

Cover disk, 1 pce.

10530/04

Spring guide, 4 pcs. 10530/05

Screw set

10530/05

Screw set

10530/05

Screw set

04416/02

10530/06

Clutch springs, 4 pcs.

To dismount the clutch from the

crankshaft remove the M6x25 coun-

tersunk screw, screw in the M6 he-

adless pin and screw the M8 coun-

tersunk screw against it.

Position 21a

Parts are in

bag L

Position 21

Parts are in

bag L

Fixing disk

11,4x8x5

Alloy engine

flange F1

Headless

pin 4x6

Clutch carrier

Cutout

Screw

5x14

Screw

3x5

Cover disk

Spring

guide

Clutch

spring

Clutch blocks

Screw

6x25

Manifold

Screw

5x16

Silencer gasket

Screw

5x55

Bottom

part inlet

silencer

Screw

5x16

Manifold

Silencer

gasket

Position 22

Parts are in

bag L

Position 22a

Parts are in

bag L

Screw

3x18

Nut M3

Screw

3x4

Fuel pipe

6mm

Carburet

or arm

Mount the manifold with silencer gasket and M5x16 pan-head screws

to the engine.

Mount the alloy engine flange to the engine using M5x14 pan-head

screws as illustrated.

In order to mount the clutch, please use the enclosed manual as an aid.

Mount the clutch blocks with clutch springs and spring guides into the

clutch carrier. Screw-in M4x6 headless pins, until they are fitted close-

ly to the spring guide, however, do not pretense the springs. Fasten the

cover disk using M3x5 pan-head screws. Mount the complete clutch to

the engine using an M6x25 countersunk screw.

Disassemble the original air filter and mount the lower part of the inlet

silencer using a fixing disk 11.4x8x5 and M5x55 countersunk screws.

In order to mount the inlet silencer, please use the enclosed manual as

an aid.

Press M3x18 pan-head screw into the carburetor arm

and secure with M3 nut. Mount the carburetor arm to the

carburetor using an M3x4 pan-head screw, use screw retention and

hold the carburetor arm with a pliers to make sure that the carburetor

arm does not turn the shaft against the stop and bends it.

Pull off the choke lever, cut approx. 6mm off from the yellow fuel pipe

of the tank and press the piece of pipe on the choke shaft instead of the

choke lever.

Hint: Screw-in the headless pin M4x6 with screw retention until it con-

tacts the spring guide. Through an equal screwing-in the spring power

will be increased and the clutch applies later.

Befestigungs-

scheibe

Position 24a

Parts are in

bag L

Position 23

Parts are in

bag L

Disk

Ø 5,3

Screw

5x14

Screw

5x14

Alloy

engine

mount

Screw

5x12

Fixing disk

Fuel hoses

Upper tank

mount

Lower tank

mount

Tank complete

Position 24

Parts are in

bag L

Disk

4,2x16

Tank with mount

assembled

Fixing disk

Mount the pre-assembled engine with manifold and air filter in-

to the chassis.Fix the engine with the M5x12 countersunk screws

and engine fixing disks to the chassis.

Mount the alloy engine mount to the engine and the alloy rear

axle carrier using M5x14 pan-head screws, M5x14 hexagon screw

and disks Ø5.3.

Hint: At first, only slightly tighten the engine screws and the

screws for the engine mount. Tighten all screws later when the

complete unit is mounted (in order to avoid warping).

Fix the tank mount complete to the tank as

described in position 24a.

Mount the complete tank at the tank mount

to the CFRP chassis side part using 4,2x16

countersunk screws and fixing disks.

Place the fuel hoses as illustrated on the

following pictures and shorten their length

accordingly. Carefully twist the angle con-

nection at the carburetor for the yellow fuel

hose.

Screw

4x16

Screw

5x14

Screw

4x14

Disk Ø 4,3

Holding strap

Silicone hose

Tension spring

Steel-Power Tuning pipe F1

Steel-Power Tuning pipe F1

Stop nut

M4

Position 25

Parts are in

bag M

Position 25a

Parts are in

bag M

Insert the o-rings into the groove of the Steel-Power Tuning

pipe F1 and moisten them with some 2-stroke oil, then push

the Steel-Power Tuning pipe F1 carefully on the manifold wi-

thout damaging the o-rings.

Press the silicone hose over the tension spring and fasten the

manifold and Steel-Power Tuning pipe F1 with the tension

spring.

Mount the holding strap for the Steel-Power Tuning pipe F1

to the CFRP chassis side part by using the M4x16 pan-head

screw, disks Ø4,3 and M4 stop nuts.

Tighten the M4x14 and M5x14 pan-head screws at the alloy

gear flange.

Position 26a

Parts are in

bag L

Position 26

Parts are in

bag L

Stop nut

M3

Stop nut

M3

Pressure spring

Collet

Collet

Servo

arm

Headless pin

3x3

Throttle pivot

post

Throttle rods

Throttle rods

Screw

3x18

Throttle-brake servo

Mount the ball-and-socket joint of the throttle rods with an M3 stop nut to

the carburetor arm. Make sure the carburetor arm can be moved easily.

Mount the servo arm with the screws which are enclosed in the servos.

Mount the M3x18 screw with the M3 stop nut through the servo arm of the

throttle-brake servos.

Push the collet, pressure spring, throttle pivot post and collet on the thrott-

le rods, press the throttle pivot post on the M3x18 screw in the same time

and mount it in the collets using M3 stop nuts and M3x3 headless pins.

Hint: Do not tighten the M3 stop nut which is on the throttle pivot post,

the throttle pivot post needs to be moved easily. Bend the throttle rods

according to the illustration, they need to run smoothly and should neit-

her touch nor clamp in any position.

Position 27

Position 27a

Cut a sparing for the snap closure of the tank

cap into the bodyshell by using a scissors or

a model knife.

Drill a hole with approx. 8mm

for the adjustable body mount.

Position 28

Parts are in

bag N

Position 29

Parts are in

bag N

Screw

4x18

Disk

Ø 4,3

Stop

nut M4

Screw

2,9x9,5

Screw

2,9x9,5

Screw

4,2x16

Mount for

front spoiler

Polyamide front spoiler

Body clip

Adjustable body

mount

Support for body

mount

CFRP side part

Screw

3x10

Alloy fixing

CFRP wing

top

CFRP wing

bottom

Disk

Ø 5,3

Screw

5x25

Dampening

rubber

Screw

3x10

Assemble the mount for front spoiler to the

polyamide front spoiler using 2.9x9.5 pan-

head screws.

Fix the adjustable body mount to the poly-

amide front spoiler using 4,2x16 countersunk

screws. Mount the support for the body

mount with a body clip.

Mount the polyamide front spoiler to the al-

loy front chassis using M4x18 pan-head

screws, disks Ø4.3 and M4 stop nuts.

Mount the CFRP lower wing to the alloy rear axle carrier with each

2 dampening rubbers between the CFRP lower wing and alloy re-

ar axle carrier using M5x25 pan-head screws and disks Ø5.3.

Mount the CFRP side parts to the lower and upper CFRP wing using

M3x10 pan-head screws and alloy fixings.

Position 30

Parts are in

bag O

Throttle-brake servo

Position 30a

Parts are in

bag O

Position 30b

Parts are in

bag O

Brake pipe

Screw

4x14

Main brake

cylinder

Collet

Headless

pin 3x3

Brake rods

Collet

Headless

pin 3x3

Servo

arm

Collet Throttle pivot

post

Pressure spring

Screw

3x20

Brake pipe

Brake pipe

Cable strap

Brake pipe

Brake disk

Brake caliper

Valve

Protective cap

Screw

3x30

Angle connection

Stop nut

M3

Snap ring for

square wheel

Mount the rear hydraulic brake as described in enclosed

manual. Bend the brake rods corresponding to the illus-

tration and the throttle pivot post. Make sure it is of easy

motion and it does not touch anything. For neutral posi-

tion of the RCS the brake must be released and the gas

must be in neutral gear.

Position 30 - 31 show the Formula 1 Competition 09 Item N°. 10007 with

the FG Magura hydraulic brake system.

007

Position 31

Parts are in

bag O

Brake servo

Servo

arm

Brake pipe

Stop nut

M3

Main brake

cylinder

Screw

4x14

Collet

Headless

pin 3x3

Headless

pin 3x3

Stellring

Brake

rods Pressure spring

Throttle pivot

post

Screw

3x20

Position 31a

Parts are in

bag O

Position 31b

Parts are in

bag O

Angle connection

Brake pipe

Screw

3x30

Protective cap

Valve

Brake caliper

Brake

disk

Snap ring for

square wheel

Mount the front hydraulic brake as described in enclosed

manual. Bend the brake rods corresponding to the illus-

tration and the throttle pivot post. Make sure it is of easy

motion and it does not touch anything. For neutral posi-

tion of the RCS the brake must be released.

Position 32

Parts are in

bag P

Position 32a

Parts are in

bag P

Disk

Ø 2,7

Brake

disk

Pressure spring

Bowden cable

Guiding

plate

Flange

bearing

Stud bolt

Brake shaft

Brake lever

Competition

brake lining

Headless

pin 3x3

Screw

3x10

Stop

nut M3

Alloy bow-

den cable

holder short

Mount the rear Tuning disk bra-

ke as described in enclosed ma-

nual. For neutral position of the

RCS the brake must be released

and the gas must be in neutral

gear.

Bend the servo rods correspon-

ding to the throttle pivot post.

Make sure it is of easy motion

and it does not touch anything.

Snap ring for

square wheel

Position 32b

Parts are in

bag P

Servo

arm

Throttle -

brake servo

Collet

Headless

pin 3x3

Servo rods

Balance

Bowden cable

Brake guide rail

Screw

4x14

Position 32 - 33 show the Formula 1 Competition 09 Item N°. 10008

with a mechanical brake system.

This manual suits for next models

1

Table of contents

Other FG Modellsport Motorized Toy Car manuals

Popular Motorized Toy Car manuals by other brands

MINICRAFT

MINICRAFT 11232 manual

Carson

Carson Stormracer Extreme 103013 RTR instruction manual

Tamiya

Tamiya Blazing Star manual

Fisher-Price

Fisher-Price Power Wheels C3493 Owner's manual with assembly instructions

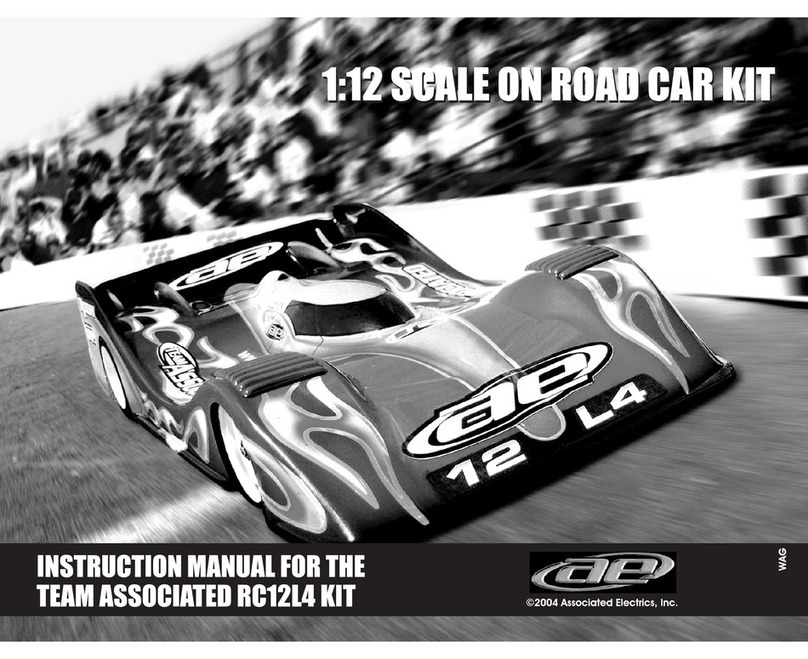

Associated Electrics

Associated Electrics RC12l4 Kit instruction manual

Jamara

Jamara Mercedes-AMG G63 instructions