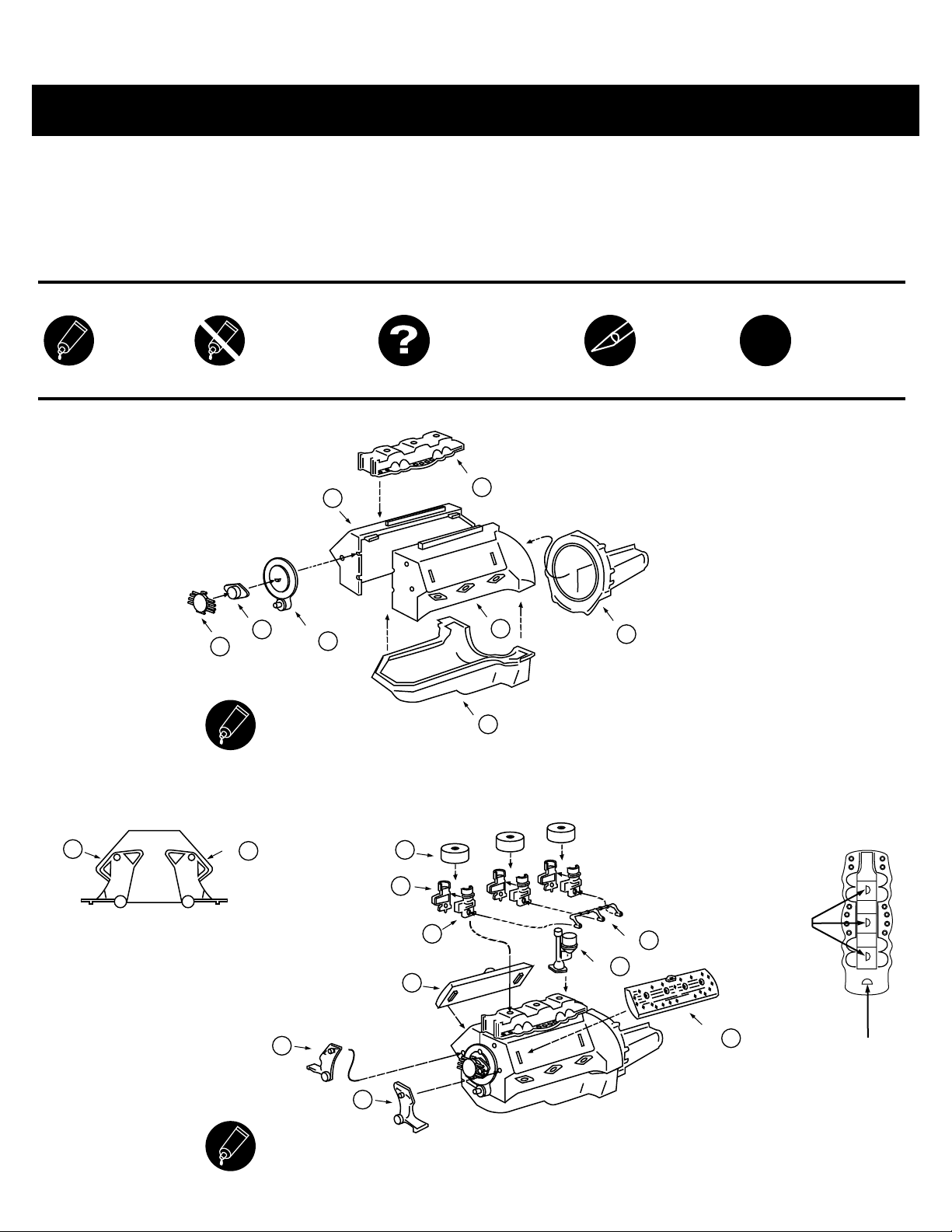

17

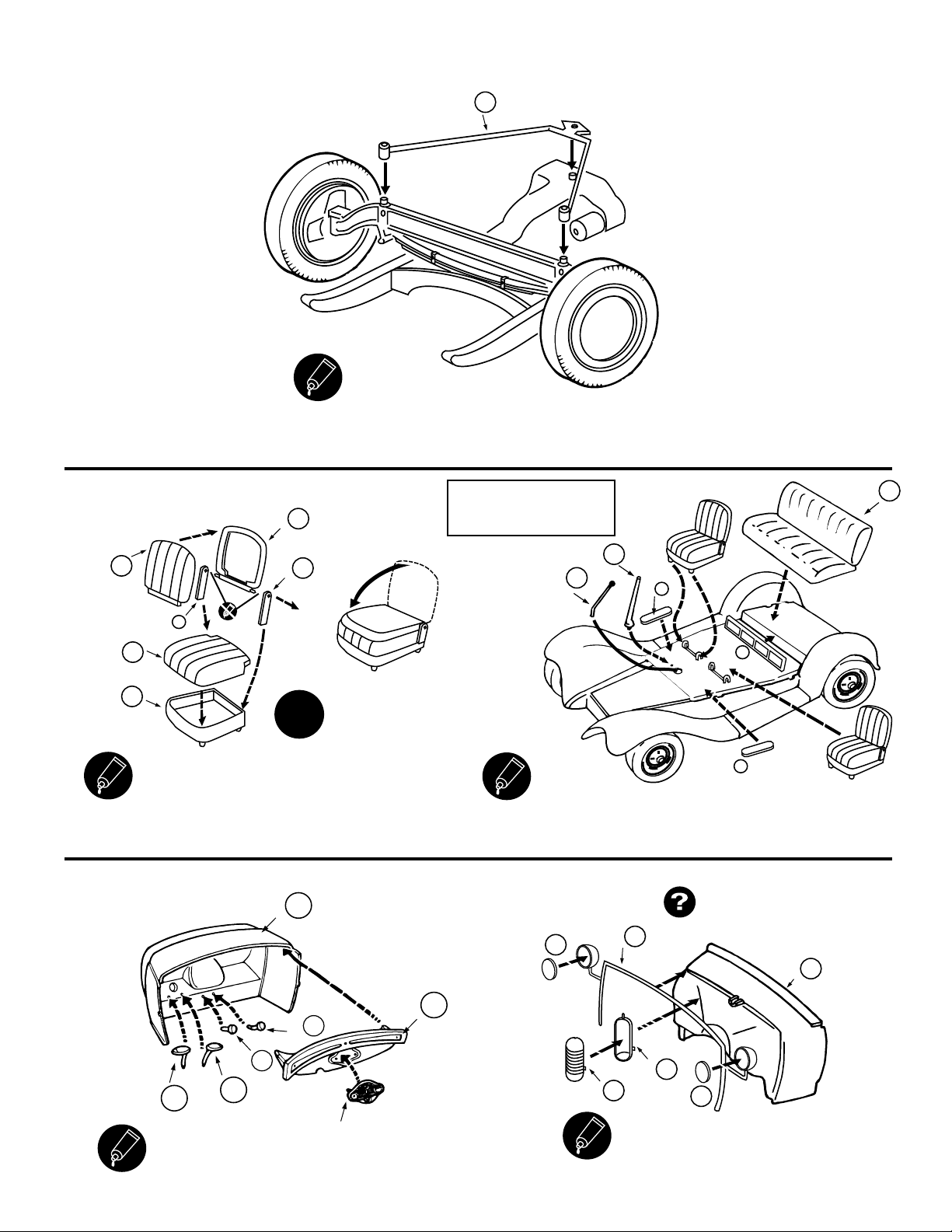

NOTE: All parts shown upside down.

Snap wheel assembly onto stubs.

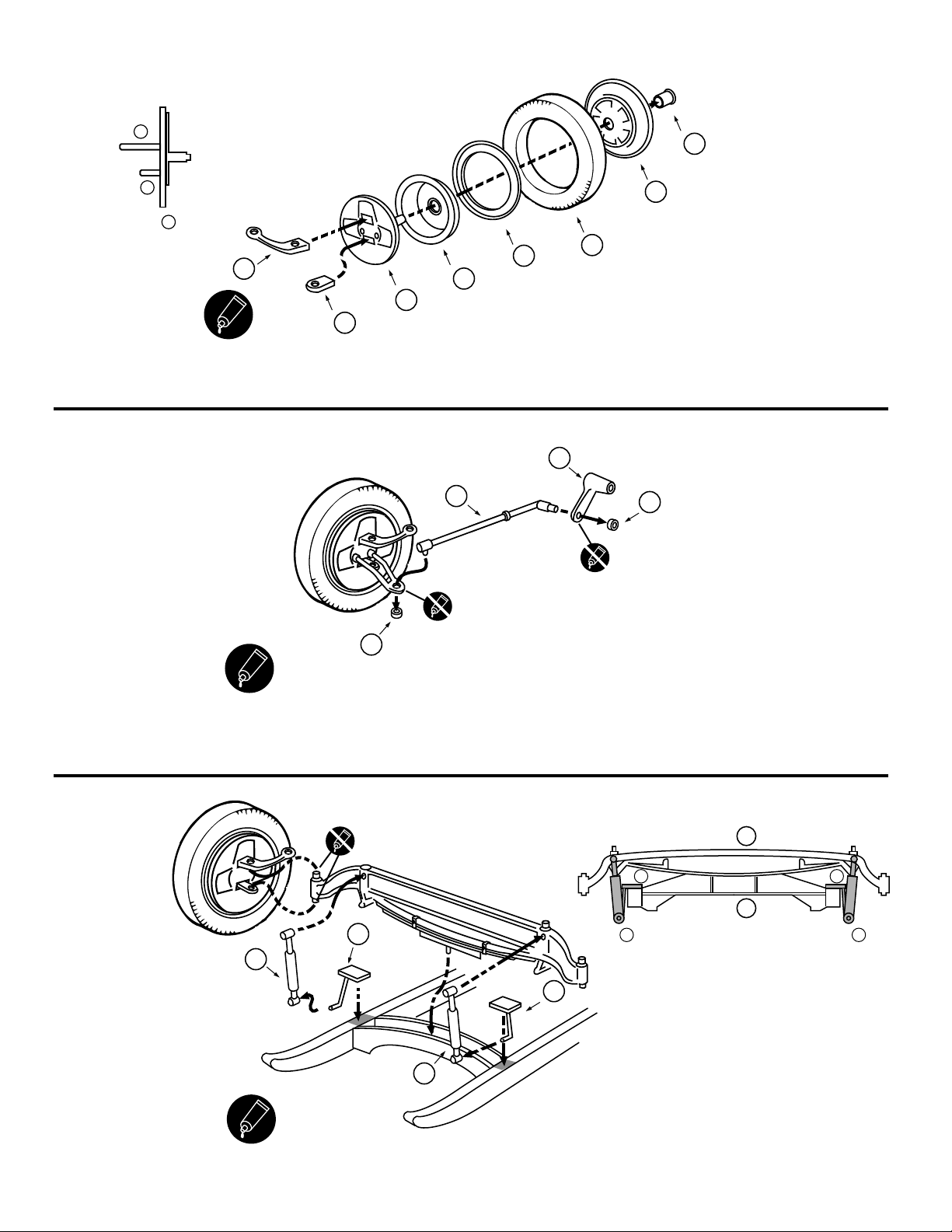

18

NOTE: All parts shown upside down. Front suspension parts not shown

for clarity. Pass end stubs of tie rod (33) through holes in steering arms

and glue caps (71) on ends.

71

Q

33

Q

71

Q

Be sure to test the fit

of parts Q(33/35) in the

respective holes in mating parts.

Non-glued parts should move

easily for proper movement

of operable features.

PLEASE NOTE

NOTE

If exhausts are installed in

upper position (exiting sides of engine compartment),

steering shaft must go between second &

third exhaust pipes on left side.

If installed in the downward

position (exiting under engine compartment)

some trimming of exhausts

may be required to clear

steering linkage.

Press fit

20

Turn model over.

Glue together steering box parts (47/48).

Press fit steering box to frame.

Press fit the steering link onto the shaft of part 47.

47

Q

48

Q

19

Cement floorboard D(1) to B (1). Cement fender B(3) in place.

NOTE

Some parts not shown

for clarity.

1

D

2

B

1

B

19

G

18

G

NOTE

Some parts not shown

for clarity.

Parts are shown upside down.

21

Cement battery parts F(22/26) together and glue to frame in position shown.

Cement fenders and floorboard assembly to frame. Cement engine

assembly in position, connecting to driveshaft. Glue exhausts in

your preferred position, then glue steering linkage in place.

26

F

22

F