FG Modellsport Leopard 4 Competition User manual

E.67000_e_011210

Please thoroughly keep this construction manual for spare parts orders!

FG Modellsport GmbH

Spanningerstr. 2

73650 Winterbach-Germany

Phone: +49 7181 9677-0

Fax: +49 7181 9677-20

www.fg-modellsport.de

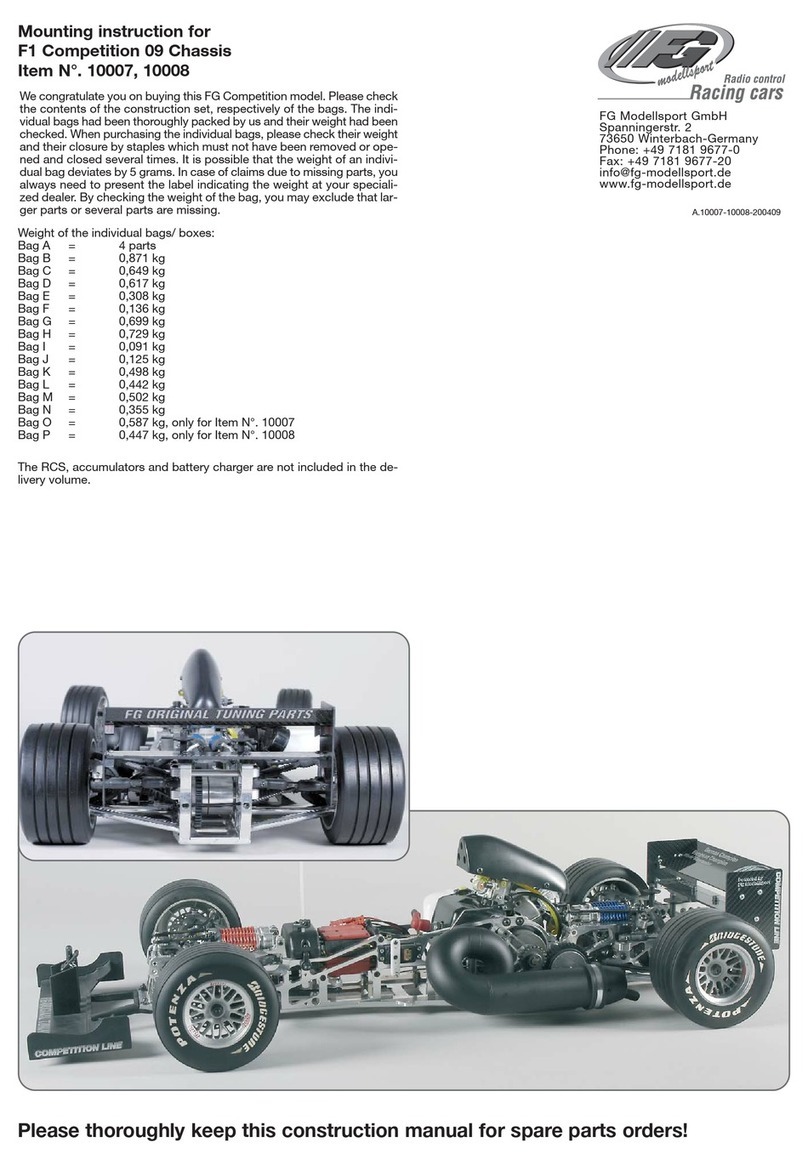

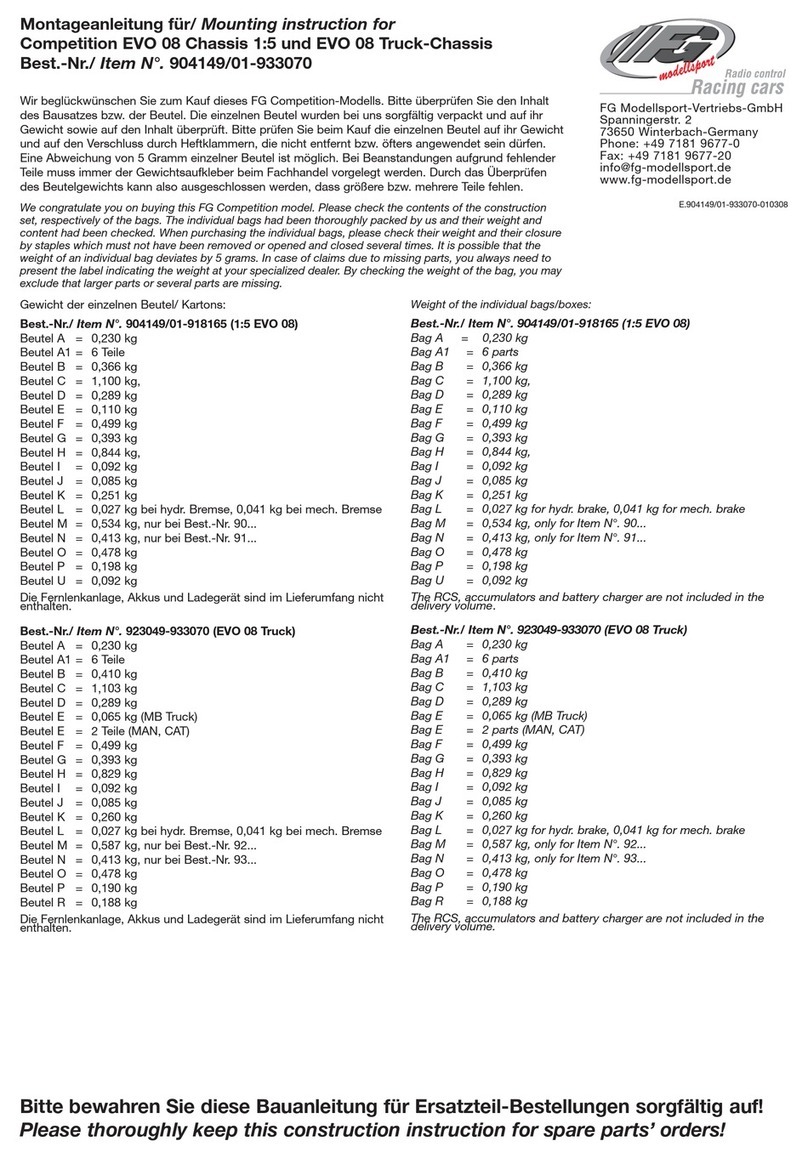

We congratulate you on buying this FG Competition model. Please check the contents of the construction set,

respectively of the bags. The individual bags have been thoroughly packed by us and their weight and content

has been checked. When purchasing the individual bags, please check their weight and their closure by staples

which must not have been removed or opened and closed several times. It is possible that the weight of an in-

dividual bag deviates by 5 grams. In case of claims due to missing parts, you always need to present the label

indicating the weight at your specialized dealer. By checking the weight of the bag, you may exclude that larger

parts or several parts are missing.

Mounting instruction for 4WD Off-Road Buggy

Leopard 4 Competition, Item N°. 67000

Weight of the individual bags/ boxes:

Item N°. 67000

Bag A = 0,158 kg

Bag B = 1,265 kg

Bag C = 0,791 kg

Bag D = 0,685 kg

Bag E = 0,743 kg

Bag F = 0,887 kg

Bag G = 0,210 kg

Bag H = 0,442 kg

Bag I = 0,388 kg

Bag J = 0,078 kg

Bag K = 0,332 kg

Bag L = 0,362 kg

Bag M = 0,303 kg

Bag N = 0,029 kg

Bag O = 0,390 - 0,400 kg

Bag Q = 0,382 kg

The RCS, accumulators and battery charger are not included in the

delivery volume.

The handling with fuels requires circumspective and ca-

reful handling. Imperatively observe the security advices.

- Refuel only if the engine is switched off!

- Take off the body.

- Thoroughly clean the area around the fuels nipple.

- Remove the fuel filler cap and carefully fill in the fuel mixture.

- Smoking or any kind of open fire is not admitted.

- Fuels might contain solvent-like substances. Avoid contact with skin and

eyes. Wear gloves for refueling. Do not inhale fuel vapors.

- Do not spill any fuel. If you have spilled fuel immediately clean the engi-

ne and the model.

- Make sure that no fuel will get into the soils (environmental protection).

Use an appropriate mat.

- Do not refuel in enclosed rooms. Fuel vapors accumulate at the soil (risk

of explosion).

- Transport and store fuels only in admitted and labeled canisters. Keep

fuel out of the range of children.

- The operator is responsible for any damages caused to third persons in

the operating range of the model, respectively of the engine, if they are

injured or in case of property damage.

- The model must only be passed on to persons who are familiar with this

model and its operation, always provide the operating manual.

- Persons with implanted heart pacemakers must not work on running en-

gines and on live parts of the ignition system when the engine is being

started.

- The engine must neither be started nor operated in enclosed rooms (wi-

thout sufficient ventilation).

- When starting the engine, avoid inhaling the exhausts.

- The model must neither be started nor operated without air filter or wi-

thout exhaust system.

- Before every start perform a functional check of the safety-relevant parts.

- The throttle rods must always return automatically to the idle position.

- Any cleaning, maintenance and repair works must only be performed

with the engine being switched off. The engine and silencers are getting

very hot. In particular do not touch the silencer.

Comments regarding the construction manual:

Before starting the assembly please see through this construction manu-

al. This way you will get an overview of the whole execution.

Please check by means of the parts or bag list if the construction kit is com-

plete and also check the weight of the individual bags for the positions.

Only this way you may be sure that all parts which you need for the as-

sembly are available. If a part is missing, please immediately contact your

specialized dealer.

Table of contents

Position 1-3: Front and rear differential gear

Position 4-8: Belt drive, belt tensioner

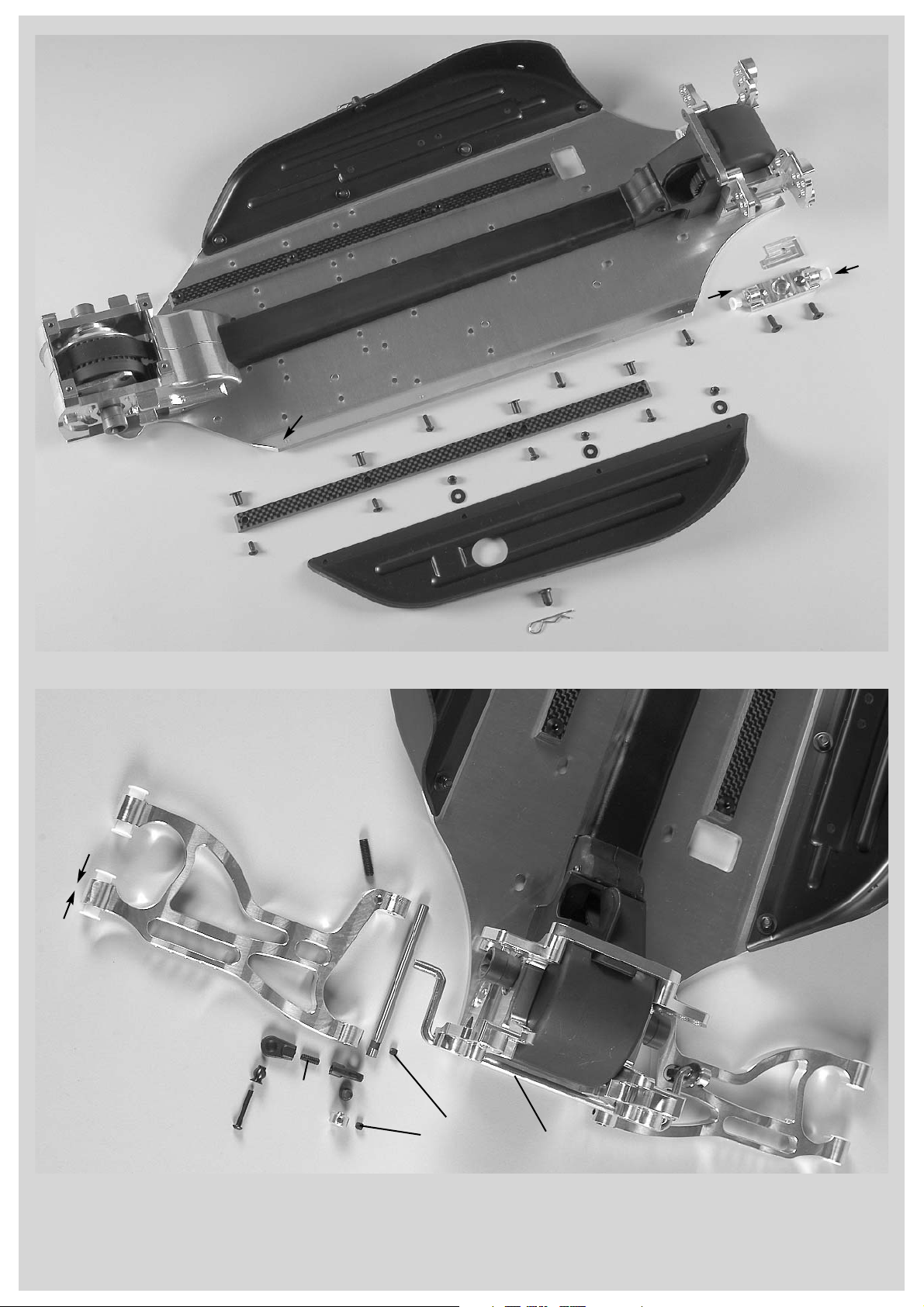

Position 9: CFRP chassis stiffening, ABS splash guards

Position 10-13: Rear axle

Position 14: Shock absorbers

Position 15: Shock mount, spoiler mount, rear damper protection

Position 16-21: Engine, air filter, gear, fuel tank

Position 22-25: Starter rope ,roll bar, tuning pipe

Position 26-32: Servos, receiver box, servo saver

Position 33-35: Wishbones, stabilizer, front uprights

Position 36-37: Front axle plate, front bumper

Position 38-39: Throttle rods

Position 40-45: Hydraulic brake system

Warranty conditions for engines:

FG Modellsport assumes no liability for defects if the engine has been modified by installation of parts of foreign

origin or if engine parts for tuning purposes were worked on or were modified and the damage stands in causal

interrelationship with the modification. Further the liability for defects of power-increased engines is excluded. In

this case also the compensation liability is excluded.

All metric screws need to be secured with thread lock fluid.

Inserting of the diff.

bevel gear wheels or

of the complete pack-

age becomes much

easier if you use the

FG mounting tool Item

N°. 08505.

Alum. differential gear 4-fold self-locking

Diff. bevel

gear B

Axial bearing

5x12x4

Pressure

disk

Diff. bevel gear

self-locking

Friction

disk

Adjusting

screw for self-

locking diff.

Spacer

disk

Buffer

plate

Steel

bush

8x12x5

Needle

bearing

Shim ring

5x17x0,1

Diff. bevel

wheel axle

Position 1

Parts are in

bag C

Position 2

Parts are in

bag C

1. Insert diff. bevel gears B and self-locking bevel gears together with

friction disks and buffer plates in the alum. differential housing as shown

in position 1. Now lubricate both ball diff. driving axles and diff. bevel

wheel axle slightly with some grease and impress them into the alum.

differential housing. The borings of the differential housing must be in

true alignment with the borings of the diff. bevel gears. If you notice a

misalignment of the borings, take the complete package out of the diffe-

rential housing and replace the diff. bevel gears one tooth offset. Then

mount the complete package back into the diff. housing.

2. Press out the diff. bevel wheel axle slightly and push a spacer disk

between diff. bevel gear B and alum. diff. housing. Mount the second

spacer disk in the same way.

3. Press out the diff. bevel wheel axle approx. to the half. Now mount 1x

axial bearing, then both pressure disks with cone against each other to

the centre and finally the second axial bearing. Impress the diff. bevel

wheel axle completely back into the alum. diff. housing. Turn the ball diff.

driving axles and check the differential gear on smooth running. Too

much tooth clearance can be balanced with the enclosed shim rings

5x17x0,1, fix them between alum. diff. housing and spacer disks.

4. Mount the spacer disks to the alum. diff. housing using M4x8 coun-

tersunk screws, use screw retention lacquer.

5. Apply some multi-purpose grease (f.e. Item N°. 06501) on the diffe-

rential bevel gears and insert the o-ring small and large in the provided

groove of the alum. differential housing.

6. Press the front left plastic spacer disk, the front plastic toothed belt

wheel 42 teeth and right alum. spacer disk on the alum. diff. housing as

described in position 1. Fix the complete unit with the M4x40 counter-

sunk screws, use high-strength screw retention lacquer.

7. Screw the adjusting screws for the self-locking differential equally into

the right alum. spacer disk until they touch the pressure disks, use

medium screw retention lacquer.

8. Impress the bearing shafts

6x50mm into the guide pulley

16mm and centric into the too-

thed belt wheel 12 teeth.

Screw

M4x40

Screw

M4x40

Right alum.

spacer disk

Adjusting screw for self-

locking differential

Alum.

differential

housing

Screw buffer plates to

the alum. differential hou-

sing using M4x8 counter-

sunk screws.

Toothed belt

wheel 12 teeth

Bearing

shaft 6x50

Bearing shaft

6x50

Guide pulley

16mm

Front left plastic

spacer disk

Plastic toothed

belt wheel front

42 teeth

Ball diff. dri-

ving axle

Ball diff.

driving axle

Ball bearing

15x28x7

O-ring

small

O-ring

large

Front drive

Hint: The barrier effect of a self-locking differential gear is caused by the torque which is generated when the bevel gears press on the friction

disk respectively the spacer disk and are slowed down by the higher friction. This differential gear can be additionally locked mechanically

through the adjusting screws in the right alum. spacer disk, therefore screw them in in clockwise direction. To lock this differential mechanically,

turn in both adjusting screws symmetrically in clockwise direction. You achieve a lower barrier effect if you unscrew them anticlockwise.

Position 3

Parts are in

bag B

Rear differential

Ball diff.

driving axle

Ball bearing

15x28x7

Screw

M4x40

Needle bea-

ring f. Diff.

Bronze

bush

Alum. differential

housing

Diff. bevel

wheel axle

O-rings

Shim ring

5x17x0,1

Shim rings

8x20x0,1

Diff. bevel gear B

Diff. bevel gear A

Steel gearwheel

48 teeth

Rear plastic tooth

wheel 42 teeth

Right alum.

spacer disk

Rear drive

Slope to the inside

Ball diff. driving

axle

Ball bearing

15x28x7

Screw

M4x40

Alum. differential

housing

Steel gearwheel 48

teeth

Rear plastic tooth

wheel 42 teeth

Right alum.

spacer disk

1. Insert the diff. bevel gears A and B in the alum. diff. housing as des-

cribed in position 3.

2. Lubricate the ball diff. driving axles slightly with some grease and

push it in the diff. housing.

3. Mount the diff. bevel gear axle. If the bevel gear axle respectively the

driving axles can only be pushed in severely or if it cannot be pushed in

at any position, you have to dismantle the bevel gearwheels again. Then

insert them again.

4. If the gearwheels have too much clearance, correct it using the enclo-

sed shim rings. Please make sure that the gearwheel clearance had not

been set too close.

5. Lubricate the diff. bevel gears slightly with multipurpose grease, e.g. Item

N°. 06501.

6. Press the parts on the alum. diff. housing as described in position 3

and in the given sequence: O-ring large, O-ring small, steel gearwheel

48 teeth, rear plastic gear disk 42 teeth, right alum. spacer disk. Fasten

the complete unit using the M4x40 countersunk screws (use the screw

retention high-strength).

Inserting of the diff.

bevel gear wheels or of

the complete package

becomes much easier

if you use the FG

mounting tool Item N°.

08505.

Toothed belt wheel

12 teeth

Left alum.

front axle

housing

Ball bearing

6x16x6

Toothed belt

Guide pulley

16mm

Front differential

mounted

1. Press the front differential gear, 16mm

guide pulley, toothed belt wheel 12 teeth into

the left alum. front axle housing as described

in position 4.

2. Now place the toothed belt as illustrated

on the front differential gear, 16mm guide

pulley, toothed belt wheel 12 teeth as shown

in position 4.

Position 4

Parts are in

bag B+C

Belt pulley

housing right

Plastic bearing seat

1. Press the right alum. front axle

housing on the front differential

gear, guide pulley 16mm, toothed

belt wheel 12 t (as pictured in

position 4).

2. Place the complete alum. front

axle housing on the alum. chassis

and fix it using M4x14 counter-

sunk screws.

Position 5

Parts are in

bag C

Position 6

Parts are in

bag B

Position 7

Parts are in

bag B

Position 8

Parts are in

bag B

All metric screws need to be secured with thread lock fluid.

Alum. front

axle hou-

sing left

Alum. front

axle hou-

sing right

Toothed belt

Alum. chassis

Front

differential

gear

Screw

M4x14

Toothed belt

Alum. chassis

Rear

differential

gear

Alum. rear axle

mount left

Alum. rear

axle mount

right

Top part

belt channel

Bottom part

belt channel

Screw

M5x14

Screw

4,2x16

Screw

4,2x16

1. Place the toothed belt on the rear differential gear as

pictured in position 6.

2. Press the left and right alum. rear axle mounts on

the ball bearing of the rear differential gear as shown in

position 6.

3. Place the left and right alum. rear axle mounts on

the alum. chassis and fix them using M5x14 counter-

sunk screws.

4. Lay the bottom part of the belt channel on the bot-

tom part of the toothed belt as described in position 6.

Now press the top part into the bottom part of the belt

channel. Push the complete belt channel into the ope-

ning of the alum. front axle housing. Make sure the

toothed belt is running smoothly.

5. Fix the belt channel from

underneath to the alum. chassis

using the 4,2x16 countersunk

screws.

Mount the closed side of the lower belt chan-

nel facing upwards. The teeth of the toothed

belt are not allowed to touch each other.

Screw

M4x14

Disk Ø4,3

Belt pulley

housing left

Mounting position

for toothed belt

wheel 42 teeth

Mounting posi-

tion toothed belt

wheel 40 teeth

Collar

Ball bearing

10x19x7

Bearing shaft

for belt pulley

housing

1. Impress the plastic bearing

seat with inbound collar (pay

attention to fitting position) in

the left and right belt pulley

housing as described in posi-

tion 7.

2. Push the bearing shaft for the belt pulley hou-

sing centrically in the 3 ball bearings 10x19x7.

3. Impress the bearing shaft which is equipped with

ball bearings in the bearing seat of the left and

right belt pulley housing and fix it with M4x14

pan-head screws and Ø4,3 disks.

Hint: The position of the front bearing seat is made for

the front plastic toothed belt wheel with 42 teeth. The

position of the rear bearing seat is made for the front

plastic toothed belt wheel with 40 teeth.

1. Place the mounted belt pulley housing on toothed

belt and belt channel as described in position 8 and fix

it on the alum. chassis using the 4,2x16 countersunk

screws. For this purpose, slightly move the belt.

2. When the assembly is performed, turn the belt in run-

ning direction. Make sure the belt is easily rotatable.

Rear axle cover

3. Press the rear axle cover

between the alum. rear axle

mounts and fix it with alum.

connecting brace, M4x20 pan-

head screw and Ø4,3 disk.

Screw

M4x20

Disk Ø4,3

Alum.

connection

brace

Alum. rear

axle mount

right

Alum. rear

axle mount

left

Alum. chassis

Position 9

Parts are in

bag A+B

Position 10

Parts are in

bag B+D

Alum. rear

axle mount

right

Alum. rear

axle mount

left

Alum. chassis

Screw

M5x14

Alum. adju-

sting key 2°

Alum. wish-

bone fixing

2°, left

Guide bush

with collar

Impress

guide bushes

Screw

M4x10

Screw

M4x10

Body clip

Body bolt

Screw

M4x12

Screw

M4x12

ABS splash guard

CFRP chas-

sis stiffening

Insert bush for

chassis stiffening

Disk Ø4,3

Stop

nut M4

1. Press the M4x12 pan head screws from underneath into the

alum. chassis and fix the le/ri ABS splash guard using Ø4,3 disks

and stop nuts M4. Do not fasten the front left ABS splash guard.

2. Press the body bolts from the inside into the ABS

splash guard and fix with some superglue, then

clip on the body clip.

Do not fasten the front

left ABS splash guard.

3. Press the insert bushes for the chassis stiffening

from the top into the CFRP chassis stiffenings, then

mount them from below to the alum. chassis using M4x10

countersunk screws. Left and right CFRP chassis stiffenings are dif-

ferent, pay attention to the borings.

4. Impress the guide bushes with col-

lar into the le/ri alum. wishbone

fixings 2° and mount them together

with alum. adjusting key 2° and

M5x14 countersunk screws to the left

and right rear axle mounts.

Screw

M3x20

Guide bush

with collar

Rear lower

alum. wish-

bone

Headless

pin M5x20

Headless

pin M4x4

Headless

pin M4x14

Impress

guide bushes

Stabilizer

5mm

Steel ball

7mm

Ball

joint

7mm

Steel ball

Ø7 x 5mm

Alum.

collet

5mm

1. Press the guide bushes

with collar from the inside

and outside into the rear

lower alum. wishbones.

All metric screws need to be secured with thread lock fluid.

4. Screw the 7mm ball joints on the M4x14 headless pins until they are in contact and until they are 90° twisted. Impress a steel ball 7mm and

steel ball Ø7x5mm each one side of the ball joints 7mm.

5. Press the ball joints 7mm with the side of the steel ball Ø7x5mm on each side of the 5mm stabilizer and fix them using the 5mm alum. retai-

ning collar (collar facing the ball joint) and the headless pin M4x4.

6. Mount the ball joints 7mm with the side of the steel ball 7mm to the rear lower alum. wishbones (with the collar of the steel ball facing bak-

kwards) using M3x20 pan head screws. Impress the 5mm stabilizer into the alum. rear axle mounts.

2. Screw the headless pin

M5x20 centrically using screw

retention from the top into the

rear lower alum. wishbones.

3. Fix the rear lower alum. wishbones with wishbone pins

6x85mm to the alum. wishbone fixings 2° left/right, groove

and thread must face backwards. Make sure the mounted

wishbones can be moved easily up and down.

Hint: To withdraw the rear

lower wishbone pins

6x85mm screw an M4

screw into the tap hole

of the wishbone pins

6x85mm and pull them out.

Wishbone pin 6x85

Apply lubri-

cating grease

Slightly lubricate the

ball driving shaft

Protection bellow

Protection bellow

Ball diff. axle

Ball driving

axle

Distance

disks

Balls for

driving shaft

Position 11

Parts are in

bag D

Position 12

Parts are in

bag D

Position 13

Parts are in

bag D

All metric screws need to be secured with thread lock fluid.

Mounting of the ball driving shafts

Stick the distance disks into the round recess of the ball

driving axles as well as in the ball diff. axle using some

multipurpose grease. Mount the protection bellows to the

ball driving shafts according to the illustration. Slightly gre-

ase the ball area when mounting the protection bellow.

Apply some lubricating grease on the ball holes of the dri-

ving shafts and impress the balls. The balls will be held by

the lubricating grease and this way the driving shaft can be

mounted more easily. Now push the complete ball driving

shaft into the differential axle and driving axle. Push the

protection bellows over the ball diff. axles and driving

axles.

Adjusting clips

Use high-strength

screw retention

Adjust rear upper wishbo-

nes to approx. 72 mm

Rear lower

alum. wish-

bone

Headless

pin M4x4

Alum. square

wheel driver

9,5mm/M6

Balls

for

driving

shaft

Adjusting clips

Securing

disk Ø5

Securing

disk Ø5

Wishbone

pin 6x65

Wishbone

pin 6x63

Ball driving

axle

Ball driving

shaft

Distance

disk

Wheel nut

Headless

pin M6x6

Headless

pin M3x3

Alum.

upright

left

Screw

M5x25 Screw

2,9x13

Screw

2,9x13

Adjusting screw

ri./le. M7x110

Ball joint

10mm M7

Alum. ball

retaining

collar

Ø10x15

Alum. joint

ball Ø10x13

Ball diff.

driving axle

1. Press the ball driving axles of the premounted ball driving set

(position 11) into the alum. uprights equipped with ball bearings and

fix the alum. square wheel driver 9,5mm/M6 (shoulder facing the ball

bearing) on the areas of the ball driving axles (use high-strength

screw retention).

2. Push the alum. uprights and wishbone pins 6x65mm into the rear

lower alum. wishbones as shown in position 12. Secure the wishbo-

ne pins with Ø5 securing disks.

3. Press each one adjusting clip front and rear between the alum.

uprights and rear lower alum. wishbones on the wishbone pins,

secure the alum. uprights with M3x3 headless pins. Check the alum.

uprights on free movement.

4. Screw the ball joints 10mm M7 on the adjusting screws ri/le M7x110mm, impress alum. joint ball Ø10x13 and alum. ball retaining collar

Ø10x15 each one side of the ball joint 10mm M7, then screw the 2,9x13 pan head screws into the ball joints 10mm M7 and adjust the ball clea-

rance (position 12).

5. Mount the wishbone pins 6x63mm (with the side of the alum. ball retaining collar Ø10x15, collar in driving direction) through the premounted

upper wishbones, now mount the alum. rear axle mounts ri/le into the lower inside boring and secure them using Ø5 securing disks and M4x4

headless pin.

6. Fix the premounted upper wishbones through the alum. joint ball Ø10x13 (collar facing the alum. upright) using M5x25 pan head screws to the

alum. uprights le/ri.

Position 14

Parts are

in bag E

Position 14a

Parts are in

bag E

O-ring

Ø22x1,5

Plastic bush

Ø5/Ø7x6,5

Plastic

bush

Ø4,5/Ø7x4

Plastic guiding

disk

Volume

control

Ø20 Plastic damper

piston

Upper alum.

shock absor-

ber seal

Plastic

adjusting

ring

Lower alum.

shock absor-

ber seal

Lower alum.

shock absor-

ber seal

Lower alum.

shock absor-

ber seal, pre-

mounted

Gasket Ø4,5

Lower shock

fastening,

reinforced

Threaded

piston rod,

short + long Threaded

piston rod,

short + long

Pliers Item N°.

06854

O-ring

Ø24x1,5

O-ring

Ø20x1,5

Position 14d

Parts are in

bag E

Position 14c

Parts are in

bag E

Position 14b

Parts are in

bag E

Upper alum.

shock absor-

ber seal

Disk

Ø3,2

Stop nut

M3

Lower alum.

shock absor-

ber seal, pre-

mounted,

short + long

Alum. shock

absorber

housing

short + long

Shock absor-

ber oil 1000

Shock absorber

long, mounted

Shock absorber

short, mounted

Plastic adju-

sting ring

Plastic

adjusting

ring

Plastic spring

guide

Damper

pressure

spring

orange

2,4x40

Damper

pressure

spring

orange

2,4x105

Damper

pressure

spring red

2,4x105

Alum. spring

plate

1. Press plastic bush Ø5/Ø7x6,5 into the upper alum. shock absorber seals as shown in position 14 and insert the o-ring Ø22x1,5 in the groove.

2. Insert o-ring Ø24x1,5 in the groove of the plastic adjusting rings.

3. Mount the o-ring Ø20x1,5 into the groove of the lower alum. shock absorber seals.

4. Screw the lower reinforced shock fastenings on the thread of the threaded piston rods short and long until the thread can not be seen anymo-

re. Make sure you do not damage the piston rod. Therefore we recommend to use the pliers Item N°. 06854.

5. Impress the plastic bushes Ø4,5/Ø7x4 and gaskets Ø4,5 into the lower alum. shock absorber seals, then press the volume control Ø20 on the

plastic guiding disks and impress into the lower alum. shock absorber seals (see position 14a).

6. Push the threaded piston rods short and long carefully and with some shock absorber oil through the premounted alum. shock absorber seals

as shown in position 14b, then mount the plastic damper piston with disk Ø3,2 and stop nut M3. Do not tighten the stop nuts M3 too firm, make

sure the plastic damper pistons can still be moved.

7. Screw the plastic adjusting

rings with some oil on the alum.

shock absorber housing short and

long as shown in position 14c.

8. Fix the assembled alum. shock

absorber seals with short piston

rod into the short shock absorber

housing.

Fix the assembled alum. shock

absorber seals with long piston

rod into the long shock absorber

housing.

9. Fill the shock absorbers with

shock absorber oil up to the top

and move the piston rod carefully

several times in and out so that

the air bubbles in the oil come

upwards. As soon as no air bub-

bles appear anymore, pull the

piston rod completely out and lock

the shock absorbers with the

upper alum. shock absorber seals.

10. Mount the orange damper

pressure spring 2,4x40, the plastic

spring guide and red damper pres-

sure spring 2,4x105 on the long

rear shock absorbers and secure

them with the alum. spring plates

as shown in position 14d. Fix the

orange damper pressure spring

2,4x105 on the short front shock

absorbers and secure it using the

alum. spring plates.

Screw

M5x40

Engine

Alum. engine

mount small

Stop

nut M5

Stop

nut M5

Headless

pin M5x20

Screw for carrier

M6x14 with disk

Carrier for

clutch shoes

Engine flan-

ge for engine

quick

fastening

1. Mount the small alum. engine mount to the engine using

M5x40 pan head screws and counter with M5 stop nuts.

For this purpose the original screws of the engine have to

be removed.

2. Apply screw retention lacquer on the four headless pins

M5x20 and screw them into the engine housing until they

poke out of the housing approx. 9mm.

3. Press the engine flange for the engine quick fastening

(with the cutout facing the cylinder) on the housing or

respectively the headless pins and fix it using M5 stop

nuts.

4. Fix the carrier for the clutch shoes to the engine using

an M6x14 hexagon screw with pressed on disk.

Hint: If the FG piston stop pin Item N°. 08542 is used, the

assembling of the clutch shoe carrier will be considerably

simplified.

Position 15

Parts are in

bag B,E+M

Position 16

Parts are in

bag H

All metric screws need to be secured with thread lock fluid.

Screw

M4x20

Screw

M5x25

Screw

M4x14

Screw

M5x10

Screw

4,2x32

Mount for

pull start

Rear shock

absorber

mounted

Rear CFRP

damper pro-

tection

Screw

M4x18

Disk Ø4,3

Disk Ø5,3

Stop nut

M5

Body clip

Plastic brace

Ø10x80

Adjusting part

spoiler mount

Spoiler

mount

1. Fix the rear alum. damper plate

to the le/ri alum. rear axle mounts

using M4x18 pan head screws

and disks Ø4,3 ( Mount the cut-

out of the alum. shock mount in

driving direction).

2. Mount the rear assembled lower

shock absorbers to the rear lower

alum. wishbones (medium threa-

ded hole) using M4x20 pan head

screws. Screw M5x25 pan head

screws in the outer threaded holes

of the alum. damper plate rear,

then fix the shock absorbers at the

top using disks Ø5,3 and stop

nuts M5.

3. Mount the rear CFRP damper

protection to the le/ri alum. rear

axle mount using M4x18 pan head

screws and disks Ø4,3 on both

sides of the rear CFRP damper

protection.

4. Fix the spoiler mount at the rear

alum. damper plate using M4x14

cylinder head screws, mount the

plastic brace Ø10x80mm and the

adjusting parts spoiler mount in

between using 4,2x32 pan head

screws as shown in position 15.

Clip the body clips on the adju-

sting parts spoiler mount.

5. Assemble the mount for the pull

start to the rear alum. damper

plate using M5x10 pan head

screws as shown in position 15.

Rear alum.

damper

plate

Position 17

Parts are in

bag H+J

Position 18

Parts are in

bag I

Screw

M5x16

Screw

4,2x13

Screw

4,2x13

Screw

4,2x16

Engine

Manifold

Silencer gasket

O-ring for

air filter

adapter

Air filter

adapter

Filter cover

Foam filter

Basic

body

Clutch

shoes

Clutch spring

Set screw for clutch shoes

Shaft washer

Driving direction

Disk

6x15x1

Screw

M6x10

Screw

M5x14

Screw

M4x14

Screw

M4x14

Screw

M6x10

Screw

M6x16

Screw

M4x10

Screw

M5x10

Steel gearwheel

14 teeth

Headless

pin M5x5

Headless

pin M5x5

Headless pin

M6x6

Tuning gear

shaft

Pre-filter

for intake

air filter

longer

shaft flats

Steel

gearwheel

46 teeth

Set screw

10x16x1

Alum.

gear

plate

Alum.

gear flange

engine mount

Set screw

10x16x1

Steel

gearwheel

18 teeth

Alum.

gearwheel

adapter

Tuning

clutch bell

Engine flange

for engine

quick

fastening

2. Press the oiled foam filter on the basic body and fix it with the filter

cover and a 4,2x16 countersunk screw.

3. Mount the manifold to the engine using M5x16 pan head screws and

silencer gasket.

Hint: The enclosed foam filter is ready-to-use and oiled. If at a later point

of time a filter is required which is ready-to-use, please proceed as fol-

lows: in order to oil the foam filter place the filter together with some FG

filter oil for foam filter Item N°. 06441 in a plastic bag and press together

to rub it in.

2. Impress the tuning clutch bell with

two set screws 10x16x1 in the alum.

gear plate as shown in position 18,

now mount set screw 10x16x1 and

steel gearwheel 18 teeth on the flats

of the tuning clutch bell using M5x5

headless pins, secure with M6x10

pan head screw.

3. Assemble the alum. gear plate at

the alum. gear flange-engine mount

using M4x14 cylinder head screws.

Screw M5x14 pan head screw into

the alum. gear flange-engine mount,

but do not tighten yet.

4. Press the tuning gear shaft at the

side with the longer shaft flats flush

into the alum. gearwheel adapter and

secure with M6x6 headless pins and

M6x10 pan head screws.

5. Mount steel gearwheel 46 teeth to

the alum. gearwheel adapter using

M5x10 pan head screws.

6. Press the tuning gear shaft through

the ball bearings of the alum. gear

plate and alum. gear flange-engine

mount.

7. Press the steel gearwheel 14 teeth

on the tuning gear shaft as shown in

position 18 and fix it using M5x5

headless pins on the flats of the

tuning gear shaft, secure with M6x16

countersunk screw. Use high-strength

screw retention.

8. Plug the complete gear unit on the

engine flange for engine quick faste-

ning.

Disk Ø4,3

Gearwheel

cover

Optional accessory

1. Pull the pre-filter for

the intake air filter over

the completely moun-

ted air filter, pull it

together with the lace

and fix it with a tie.

9. Fix the gearwheel

cover to the alum.

gearflange-engine

mount using an

M4x10 pan head

screw and Ø4,3 disk.

4. Kupplungsfeder in die Kupplungsbacken einhängen und Kupplungsbacken nach Abbildung aufeinander schieben (werksseitig vormontiert).

5. Place the shaft washers on the set screws for the clutch shoes and push them from the side with the arrows (running direction of the engine)

into the clutch shoes, then fix it on the clutch shoe carrier using 6x15x1 disks.

Hint: If the FG piston stop pin Item N°. 08542 is used, the assembling of the clutch will be considerably simplified.

1. Insert the o-ring

for the air filter adap-

ter in the basic body

and fix it to the air fil-

ter adapter using

4,2x13 countersunk

screws.

Position 19

Parts are in

bag H+K

Position 20

Parts are in

bag I

All metric screws need to be secured with thread lock fluid.

Screw

M4x14

Screw

4,2x16

Screw

4,2x16

Lower tank mount

Engine

fixing disk

Screw

M4x25

Disk

Ø4,3

Screw

M4x6

1. Insert the premounted engine in the alum. chassis as illustrated in position 13 and fix it

using an M4x25 pan head screw and disk Ø4,3 through the left alum. rear axle mount, also

fix it with the alum. connecting brace at the alum. gear flange-engine mount. Just apply the

M4x25 pan head screw, do not tighten yet (see also position 20).

2. Mount the pre-assembled engine in the alum. chassis using M4x14 countersunk screws

and engine fixing disks.

3. Fix the tank on the lower tank mount using M4x6 countersunk screws as shwon in posi-

tion 19, use medium screw retention.

4. Mount the pre-assembled tank with lower tank mount

on the alum. chassis using 4,2x16 countersunk screws.

Tank complete

Screw

M5x14

Alum. gear flan-

ge-engine mount

2. Tighten the M5x14 pan

head screw at the alum.

gear flange-engine mount.

Screw

M4x25

Disk

Ø4,3

Alum. rear

axle mount

left

Alum. con-

nencting

brace

1. Tighten the M4x25 pan

head screw after tightening

the engine fixing screws.

Position 21

Parts are in

bag K

Position 22

Parts are in

bag B

Position 23

Parts are in

bag M

Install fuel hoses as illustrated and

shorten if necessary.

Return

hose

Intake hose

Venting hose

Screw

4,2x22

Screw

4,2x22

Screw

4,2x22

Screw

M4x25

Screw

4,2x13

Screw

4,2x32

Plug pro-

tection

Plastic

brace long

Plastic

brace short

Alum.

distance

Ø10x70

Plastic brace

Ø10x60

Body

mount

Roll bar

short

Headless pin

M5x30

Headless pin

M4x20

Alum.

damper

plate rear

Body clip

Alum. chassis

1. Screw M4x20 headless pins centric into

the short roll bar and screw the alum.

distances Ø10x70mm on top, then mount

the complete roll bar through the CFRP

chassis stiffening to the alum. chassis

using M4x25 countersunk screws.

2. Screw M5x30 headless pins centric into

the plastic braces Ø10x60 as shown in

position 23, then screw on the long plastic

braces.

3. Fix the body mounts from the bottom at

the long plastic braces into the front boring

using 4,2x22 countersunk screws and

press the body clips on. Mount the long

pre-assembled plastic braces to the rear

alum. damper plate and to the short front

roll bar using 4,2x22 and 4,2x32 pan head

screws as shown in position 23.

4. Fix the short plastic brace to the long

plastic brace using 4,2x22 pan head

screws as illustrated in position 23.

5. Assemble the plug protection at the long

plastic braces using 4,2x13 countersunk

screws.

Clip the rope star-

ter in the holder

Position 24

Parts are in

bag O

Position 25

Parts are in

bag O

All metric screws need to be secured with thread lock fluid.

Alum. chassis

Fixing wire

for silencer

Fixing wire

for silencer

Manifold

Exhaust hose

Hose clamp

FG Steel-Power

Tuning pipe

FG Steel-Power

Tuning pipe

Screw M4x14

Disk Ø4,3

Stop nut M4

Screw M4x10

Disk Ø4,3

Alum.

distance

Ø8x37,5

Headless

pin M5x5

Headless

pin M5x5

Heat one end of the exhaust hose slightly

with a lighter and press it on the FG Steel-

Power Tuning pipe as shown in position 24,

then fix it using a hose clamp.

Heat up the exhaust hose once again and

press it with the second hose clamp on the

manifold, then fasten it.

1. Fix the alum. distance Ø8x37,5 to the alum. chassis using M4x14

countersunk screw. Bend the fixing wire for the FG Steel-Power

Tuning pipe as illustrated in position 25 and fasten it at the alum.

distance Ø8x37,5 using M4x10 pan head screw and disk Ø4,3.

2. Bend the second fixing wire for the FG Steel-Power Tuning pipe as

illustrated in position 25 and fix it at the alum. chassis in the front left

side by using M4x14 pan head screw, disk Ø4,3 and stop nut M4.

Clamp the fixing wire using an M5x5 headless pin. Adjust and fix the

Tuning pipe with both fixing wires in a way that the pipe does not

touch other parts.

1. Mount the adjustable body mounts on the alum. chassis

using 4,2x16 countersunk screws. Mount 2,9x9,5 pan head

screws in the second boring from the top of the adjustable

body mounts, press the o-rings Ø6x3 on and secure the

alum. battery holding brace with body clips.

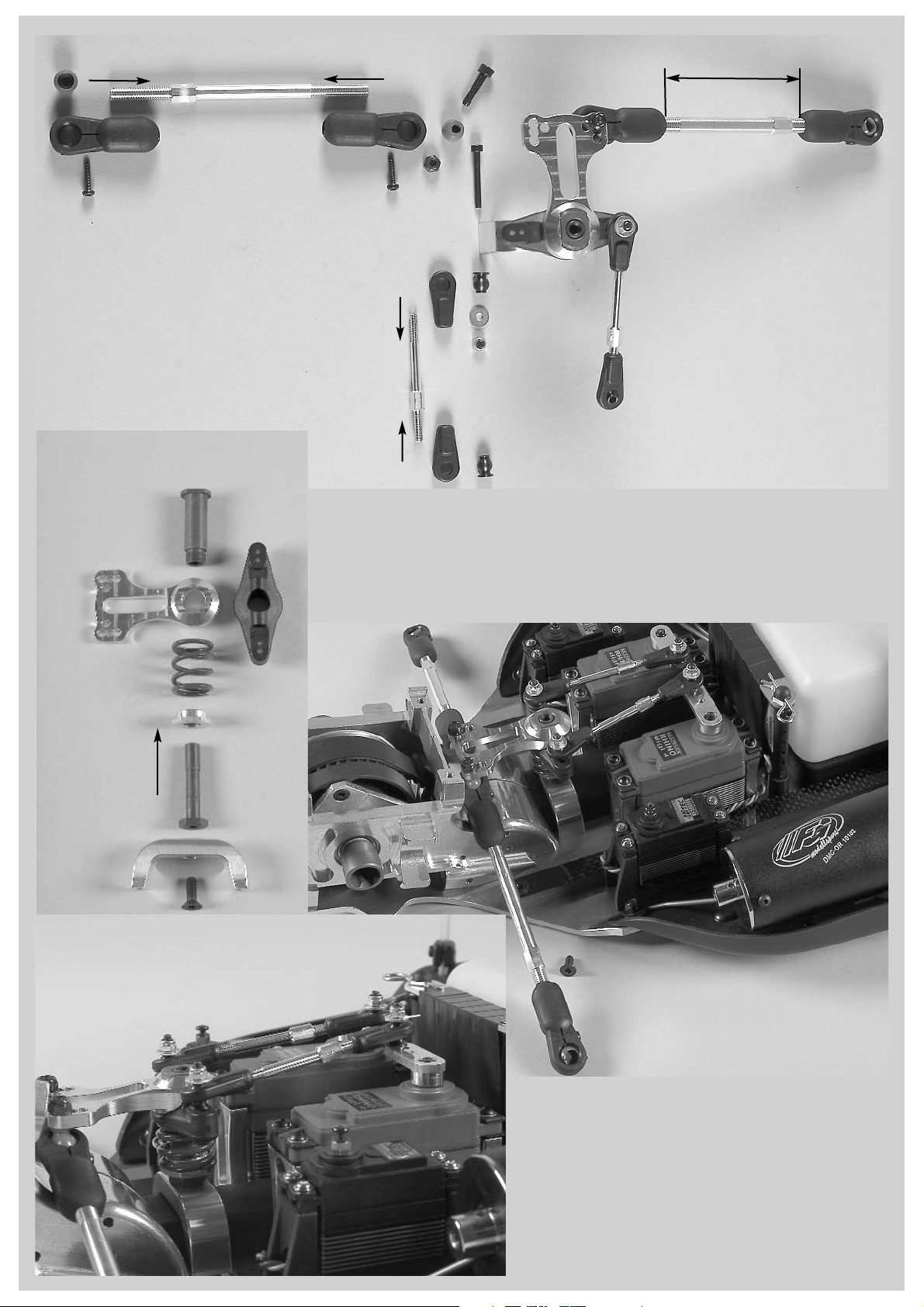

Position 26

Parts are in

bag L

Position 27

Parts are in

bag L

Position 28

Parts are in

bag L

All metric screws need to be secured with thread lock fluid.

Screw

M3x16

Disk Ø3,2

Distanzbolzen

Ø8x28

Before you start mounting the remote control components, please

also thoroughly read the enclosed RC manual and deal with trans-

mitter, receiver and servos. Charge the receiver and transmitter bat-

teries and check the parts on their function.

Alum. servo

mount

Screw

4,2x13 Screw

4,2x13

Screw

4,2x16 Screw

4,2x16

Screw

4,2x16

Screw

M4x10

Screw

M4x10

Disk

Ø4,3

Plastic servo

mount small

Brake

servo

Steering servo

Steering servo

Throttle/brake

servo

Screw

2,9x9,5

Screw

2,9x19

Aerial tubing

Aerial mount

Receiver box

Alum. chassis

2. Mount distance bolts Ø8x28mm to the right ABS

splash guard using 4,2x13 pan head screws and

disks Ø4,3 as shown in position 26.

3. Fix the small plastic servo mount to the alum.

chassis using 4,2x16 countersunk screws. Mount

the throttle/brake servo and brake servo into the

small plastic servo mounts using the enclosed

fixing rubber bushings and screws as shown in

position 26.

4. Fix the alum. servo mount to the alum. chassis

using M4x10 countersunk screws. Mount the stee-

ring servos into the alum. servo mounts using the

enclosed fixing rubber bushings, M3x16 pan head

screws and disks Ø3,2 as shown in position 26.

5. Assemble the receiver battery to the alum. bat-

tery brace using insulating tape as illustrated in

position 27.

6. Fix the aerial mount at the top part of the recei-

ver box using a 2,9x19 pan head screw as shown

in position 28. Press the aerial tubing into the aerial

mount and clamp it using a 2,9x9,5 pan head

screw.

7. Press the bottom part of the receiver box on the

distance bolts Ø8x28mm. Connect the servo cable,

battery cable a.s.o. to the receiver and check on

function.

8. To lead the cables through you have to drill a

hole of approx. Ø8mm at a suitable place of the

receiver box top.

9. Store receiver and the rest of the cables in the

receiver box, push thew aerial cable of the receiver

into the aerial tubing.

10. Place an o-ring between the receiver box bot-

tom and receiver box top for sealing.

11. Screw the receiver box on the distance bolts

Ø8x28mm using 4,2x16 pan head screws.

ABS splash

guard

Alum. bat-

tery holding

brace

Receiver battery

Due to the constricted space

conditions we recommend to

use the FG Mini Racing pack

06543/01 for the receiver/

servo power supply. Additio-

nally the FG receiver cable

Item N°. 06547/02 or FG recei-

ver cable with switch FG/JR

Item N°. 06551 is required.

Hint: Cover the bottom part of the receiver box with some foam in order to protect the

receiver against vibrations.

Screw

4,2x16

Adjustable body

mount

Screw

2,9x9,5

O-ring

Ø6x3

Body clip

Position 29

Parts are in

bag L

Position 30

Parts are in

bag L

Position 31

Parts are in

bag L

Position 32

Parts are in

bag L

Disk Ø3,2

1. Screw the ball joints 10mm M7 on the adjusting screws

ri/le M7x110mm as shown in position 30 and impress the

alum. joint balls in the ball joints 10mm M7, screw 2,9x13

pan head screws into the ball joints 10mm M7 and adjust

the ball clearance. Fix the mounted track rods to the pre-

assembled servo saver (collar of the alum. joint ball must

face the mounted servo saver, see illustration) using M4x16

cylinder head screws and stop nuts M4.

Servo saver

axle

Tension sleeve

for servo saver

Alum. servo

saver strap Alum. servo

saver strap

Alum. servo

saver, Part B

Servo

saver

Part A

Servo

saver

spring

Nut M10 for

servo saver

Screw

M5x16

Alum. joint ball

Alum.

joint

ball

Ball joint

7mm

Ball joint

7mm

Steering rods

ri./le., M4x56

Adjusting screw

ri./le. M7x110

Steel ball

7mm

Steel ball

7mm

Steering rods

mounted

Track rod

mounted

Servo saver

mounted

Screw

M4x16

Screw

M3x25

Screw

2,9x13

Screw

2,9x13 Stop

nut M4

Stop

nut M3

Ball joint

10mm M7

Ball joint

10mm M7

1. Impress the tension sleeve for servo saver from the top through alum. servo saver part B and servo

saver part A as shown in position 29.

2. Mount the servo saver spring with nut M10 for servo saver on the thread of the tension sleeve

for servo saver as shown in position 29 and check servo saver on smooth running.

3. Lubricate the servo saver axle slightly and press it from the bottom into the tension sleeve as

shown in position 29.

4. Fix the alum. servo saver strap at the servo saver axle using an M5x16 countersunk screw.

Adjust track rod to

approx. 71 mm

2. Screw ball joints 7mm on the track

rods ri/le M4x56mm and impress

steel balls 7mm into the ball joints.

3. Screw M3x25 pan head screws

from the bottom into the inner

borings of the mounted servo saver

as shown in position 30. Fix the stee-

ring rods to the mounted servo saver

(the collar of the steel ball 7mm must

face the servo saver) using disks

Ø3,2 and stop nuts M3 on the M3x25

pan head screws

2. First mount an assembled steering rod (collar of the ball

must face towards the servo arm) to the servo arm using

M3x18 pan head screw, disk Ø3,2 and stop nut M3 as shown

in position 32. Press the servo arm on the toothing of the stee-

ring servo as illustrated in position 32 and fix it with enclosed

screw. The servo arm should be mounted in 90° position to the

steering servo, it may be necessary to shorten it depending on

the version. Now fix the second assembled steering rod to the

second servo arm in the same way, both steering rods must

have the identical length, make sure you are able to press the

servo arm easily and without any resistance on the toothing of

the steering servo.

Screw

M4x10

Alum. chassis

Servo arm

Screw M3x18

Disk Ø3,2

Stop nut M3

Steering rods

mounted

Servo saver

mounted

Mount the pre-assembled servo saver

with alum. servo saver strap on the alum.

chassis as illustrated in position 31 using

M4x10 countersunk screws.

1. Switch the remote control

on and set the trimming of the

steering to mid-position.

Screw M4x12

Screw

4,2x22

Alum. stee-

ring lever

Plastic stee-

ring stop

shortened

Alu-Achsschenkel

vorne links

Front right

alum. uprights

Ball bearing

15x28x7

Ball bearing

17x26x7

Mount the alum. steering lever to the front alum.

uprights right/left using M4x12 cylinder head screws as

shown in position 34. Fix the plastic steering stop shor-

tened to the alum. steering levers using 4,2x22 pan

head screws.

Position 33

Parts are in

bag F

Position 34

Parts are in

bag F

Position 35

Parts are in

bag F

All metric screws need to be secured with thread lock fluid.

Screw

M4x16

Screw M3x18

Headless pin

M3x3

Stabilizer

mount front

Collet 4mm

Steel ball Ø7 x5mm, Ø4

Stabilizer

4mm front

Headless pin M4x14

Steel ball 7mm

Ball joint 7mm

Screw

M3x6

Headless

pin M5x16

Wishbone pin 6x106

Ball bush

Front lower

alum.

wishbone

Alum. front

axle housing

Alum. front

axle housing

Guide bush

with collar

1. Secure the impressed ball

bushes in the front lower alum.

wishbones with M3x6 pan head

screws.

2. Press the guide bushes with

collar into the front lower alum.

wishbones.

3. Screw the M5x16 headless

pins centric from below into the

front lower alum. wishbones as

shown in position 33 (use screw

retention).

4. Screw ball joints 7mm on the M4x14 headless pins until they are in contact and 90°

distorted. Impress each one steel ball 7mm and steel ball Ø7x5mm, Ø4 in one side of

the ball joints 7mm.

5. Press the ball joint 7mm (steel ball side Ø7x5mm, Ø4) on each one end of the front

stabilizer 4mm and fasten with collet 4mm and headless pin M3x3.

6. Mount the ball joint 7mm (steel ball side 7mm) to the front lower alum. wishbones

(collar of the steel ball must face forwards) using M3x18 pan head screws.

7. Impress the front stabilizer mount with front stabilizer 4mm into the alum. front axle

carrier as shown in position 33 and fix with M4x16 pan head screws.

Hint: To remove the front lower wishbone pins 6x106mm screw an M4 screw into the

threaded hole of the wishbone pin 6x106mm and pull it out.

Screw

M4x12

Screw

M4x20

Screw

4,2x22

Alum.

steering

lever

Nut M4

Plastic

steering

stop

shortened

Front alum.

upright

Front lower

alum. wishbone

Securing

disk Ø5

Adjusting

clips

Headless

pin M6x6

Headless

pin M5x20

Front upper

plastic

wishbone

Wishbone

thread rod

M10/M8x108

Wishbone pin 6x87

Screw

Ø5,3

Disk

Ø5,3

Screw

M5x25

Screw

M5x25

Wheel nut

Ball

joint

for M8

Cardan

joint for

front axle

Alum.

joint ball

Ø5/10x15mm

Taper

disk

Alum.

square

wheel driver

9,5mm/M6

Hint: Always mount the

taper disks with the thinner

side facing the ball

bush.

Track rod

Place the front lower alum. wishbones in the alum.

front axle housing as shown in position 33 and impress

the wishbone pins 6x106mm (threaded hole must face for-

wards) into the alum. front axle housing and front lower alum. wishbones. Make

sure the wishbones can be moved easily up and down.

Tipp: The front alum. uprights on the right and left

side are the same, according to the position of alum.

steering lever and plastic steering stops they have to

be built differently.

Protection

bellow

Balls for

driving

shaft

Distance

disk

Ball

diff.

driving

axle 6. Impress the cardan joint driving shafts in the pre-

assembled alum. uprights left and right and mount alum.

square wheel driver 9,5mm/M6 (offset facing the bearing)

with M6x6 headless pins on the flats of the cardan joints

for front axle. Use high-strength screw retention.

7. Fix the le/ri alum. uprights to the lower alum. wishbones

with two disks Ø5,3 between taper disk and alum.

uprights by using M5x25 countersunk screws.

8. Mount the alum. le/ri uprights to the assembled upper

plastic wishbones with a disk Ø5,3 between alum. joint

ball Ø5/10x15mm and alum. uprights using M5x25 pan

head screws.

9. Mount the track rods (collar of the alum. joint ball must

face the alum. steering lever) into the second thread hole

from the top using two M4 nuts.

1. Screw the wishbone

thread rods M10/M8x108

into the front upper

plastic wishbone, then

screw the ball joints for

M8 on the wishbone thre-

ad rods M10/M8x108mm

and impress the alum. joint

ball Ø5/10x15mm into the

ball joints for M8.

2. Press the wishbone pins 6x87mm through the pre-assembled front upper

plastic wishbones into the alum. front axle housing as shown in position 35 and

secure with Ø5 securing disks.

3. Press each four adjusting clips in the front between alum. front axle housing

and front upper plastic wishbones on the wishbone pins 6x87mm.

4. Screw M5x25 headless pins from the top into the front upper plastic wishbo-

nes.

5. Mount ball diff. driving axle, protection bellow, distance disk and

balls for driving shaft on the cardan joint for front axle in the same

way as the ball driving shafts at the rear axle (see mounting instruc-

tion, position 11) and impress into the front differential.

Position 36

Parts are in

bag G

Position 38

Parts are in

bag N

Position 39

Parts are in

bag N

Screw

M5x14

Screw

M5x16

Screw

M4x10

Screw

M4x10

Screw

4,2x16

Front

alum.

damper

plate

Reinforcing

plate for front

axle

Adjustable body

mount 54mm,

support for body

mount,

body clip

5. Mount the front bumper to the alum. chassis using M4x8

pan head screws and Ø4,3 disks, also fix the bumper at the

alum. front axle housings using M4x14 pan head screws.

Screw

M4x14

Screw

M4x8

Disk Ø4,3

Disk

Ø5,3

Front damper

protection right

Front bumper

Screw

M5x25

Disk Ø5,3

Stop nut

M5

Front

alum.

damper

plate

Mount

the front

assembled

shock absor-

bers at the bottom

with M4x22 pan

head screws and

le/ri damper protection

into the outer thread

holes to the front lower

alum. wishbones as

illustrated in position 37.

Fix the le/ri damper

protection at the inner thread holes

to the front lower alum. wishbones.

Screw M5x25 pan head screws

into the second thread hole

from the outside of the front

alum. damper plate, then fasten

the top of the shock absorbers with Ø5,3 disks and

stop nuts M5.

1. Mount the support for body mount with body clip to the adjustable body mount 54mm and

fix it to the reinforcing plate for front axle as shown in position 36.

2. Fix the front alum. damper plate to the reinforcing plate for front axle using M5x14 counter-

sunk screws (see position 36).

3. Mount the assembled reinforcing plate for front axle on the alum. front axle housings using

M4x10 pan head screws.

4. Now fix the reinforcing plate for front axle to the servo saver axle using M5x16 pan head

screw and disk Ø5,3.

Front

lower alum.

wishbone

Screw

M4x22

Front damper

protection

left

Adjust the front upper

wishbone to approx. 61mm

Throttle rods

Collet

Headless

pin M3x3

Carburetor

arm

Mount the throttle rods to the carburetor arm using

collets and M3x3 headless pins. Leave a slight clea-

rance between collets and carburetor arm. Pay atten-

tion that the carburetor arm is free movable.

Servo

arm

Nut

M3

Throttle/brake

servo

Throttle rods

Collet

Headless pin

M3x3

Collet

Headless pin

M3x3

Pressure spring

Push rod

grommet

Headless pin

M3x20

Stop nut M3

Distance

bush Ø5x20

Screw

M3x10

1. Mount the distance bush Ø5x20 to the

servo arm using an M3x10 pan head screw

as shown in position 39. Screw nut M3 on

the headless pin M3x20 and turn it into the

distance bush Ø5x20 until approx. 12mm are

left visible, now counter with M3 nut.

2. Push the collet, pressure spring, push rod

grommet and collet on the throttle rods, the-

reby press the push rod grommet on the

headless pin M3x20 and secure with an M3

stop nut. Fix the collets with M3x3 headless

pins. Switch on the remote control system.

Adjust servo for throttle/brake in neutral posi-

tion. Now clamp the collet at the push rod

grommet with an M3x3 headless pin. Adjust

transmitter at full throttle position and check

if the carburetor arm is set at full throttle

position, too.

Hint: Do not tighten the stop nut M3 at the

push rod grommet. Push rod grommet and

throttle rods must be free-moving, easy

movable and mustn’t touch or jam.

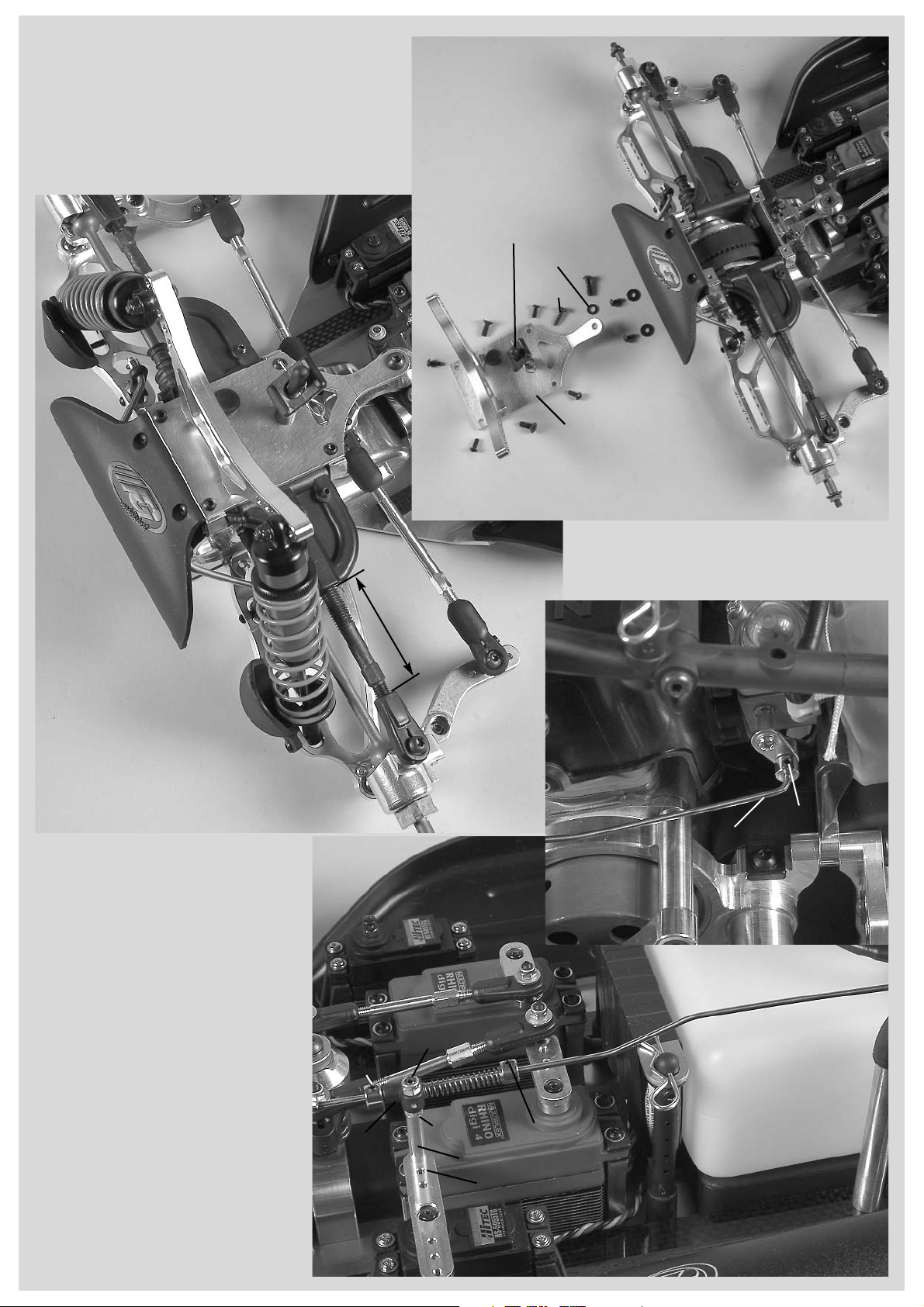

Position 37

Parts are in

bag E+G

Position 40

Parts are in

bag Q

Position 41

Parts are in

bag Q

Position 42

Parts are in

bag Q

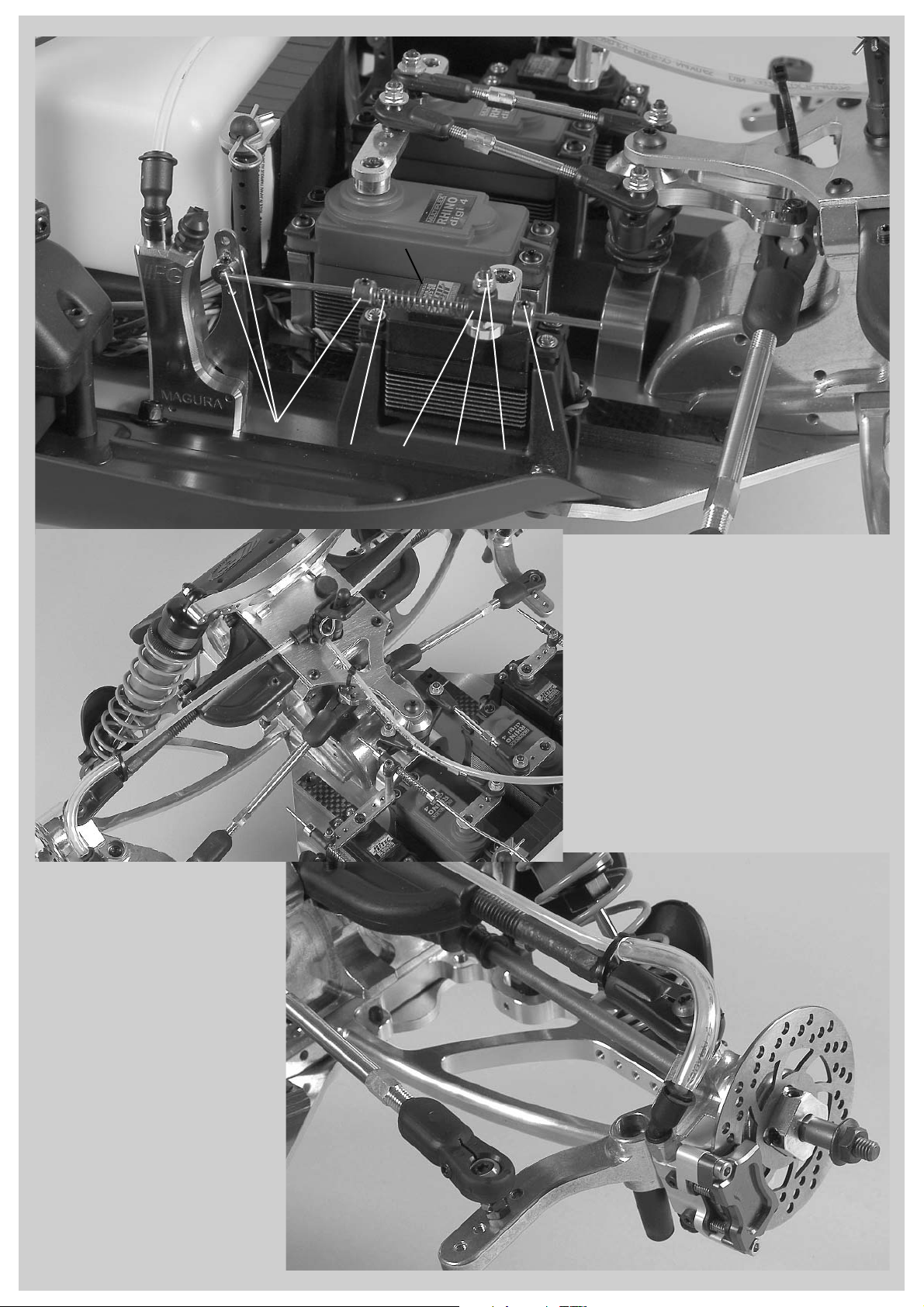

Front disk brake

The brake tube at the front

respectively the rear axle

must not be squeezed or

pulled by chassis compo-

nents during deflecting or

steering.

Brake disk

Cable clamp

Protective hose

Brake caliper Screw

M3x30

Brake tube

Brake tube

Angle

connection

T-piece

Front disk brake

Front disk brake

Protection

cap

Main brake

cylinder Pressure

spring

Push rod

grommet

Collet Collet

Brake rods

Brake servo Servo

arm

Screw

M3x18

Stop

nut M3

Brake tube to the

front wheels

Angle

connection

All metric screws need to be secured with screw

retention lacquer, pay attention to enclosed brake

manual.

1. Mount each one angle connection and one valve

each main brake cylinder as described in position 40

and 43. Do not tighten the valves too firm, otherwise

the valve seat might be damaged.

2. Mount the main brake cylinders on the chassis

plate for the front wheels (right driving direction)

respectively the rear wheels (left driving direction) as

shown in position 40 and 43.

3. Place the brake disks on the square wheel drivers,

then fasten the brake calipers at the uprights using

M3x30 screws. Now mount the angle connections

and the valves as described in position 42 and 45.

4. Arrange the brake tubes as illustrated.

Pay attention to the following when you

mount the brake tube: Shorten the brake

tube only with a sharp knife or the FG

cutting knife Item N°. 09449! Please

make sure that the brake tubes to front

respectively rear axle are long enough

and allow the full steering angle (frant

axle) respectively spring defection. Press

the brake tubes completely into the T-

pieces respectively angle connections.

Don’t lay the brake tubes too close at hot

vehicle components as exhaust manifold

or silencer.

Position 43

Parts are in

bag Q

Position 44

Parts are in

bag Q

Position 45

Parts are in

bag Q 5. Install the brake rods with pressure

spring and collets as described in position

40 and 43. Left side in driving direction for

the rear axle, right side for the front axle.

According to the mounting height and the

size of the servos the brake rods need to

be bent slightly towards the main brake

cylinder. Bend the brake rods according to

the circumstances. Nevertheless it should

run smoothly and should not touch

anywhere.

6. Fill and bleed the brake system. For fil-

ling and bleeding please refer to the enclo-

sed brake manual.

7. Place rubber protective caps on the val-

ves.

8. Impress securing rings into the angle

connections and T-pieces

The brake tube at the front respectively the rear ax-

le must not be squeezed or pulled by chassis com-

ponents during deflecting or steering.

Rear disk brake

Rear disk brake

Cable clamp

Cable clamp

Cable clamp

Protective hose

Brake disk

Brake caliper

Screw

M3x30

Brake tube

Protection

cap

Angle con-

nection

T-piece

Main brake

cylinder

Pressure spring

Push rod

grommet

Collet

Collet

Brake rods

Servo

arm

Screw

M3x18

Stop

nut M3

Angle con-

nection

Brake tube to

the rear wheels

Throttle/Brake servo

Exploded view for

Leopard 4 Competition, Item N°. 67000

8381

8381

8381

8381/1

8380/1

8380/4

8380/8

8380/8

8380/3

8380/7

8380/6

6920/6

6732/4 6350/1 6350 6349

6350

8381/1

8381/3

E.67000-290710

6067

8491

8496/1

8486/3

8500/1

6920/8 8500/3

8500/2

8493/5 6068

6067

6067

8491

8491

8496/1

8500/3

8500/2

8500/2

66258/7

8501/2

8501/2

8500/1

6920/8

8500/1

6920/8

8499/3

8499/3

8499/1

8499/1

6743

6743

6068 4fold self-locking

4fold self-locking

67284/1

66250

67275

66251

67284

67260

67260/7

66258/6

66258/7

67270

67228

67241

Front tire

glued

6912/16

6912/16

6920/10

6920/14

6920/14

6920/10

6924/18

6930/16

6930/20

1097/1

6929/14

67260/5

67302

67336

8514/8

67260/1

67267

68266

6029/8

6926/25

7475/1

67287

67287

7155

67265

67243

7154/1

6924/25

6924/18

6924/16

6922/16

68423/1

6013 4493/3

6932/20

6932/16

6738/4

6739/4

6734/5

6734/3

67240

69241

6926/25

6738/5

6734/5

6928/3

6738/3

6738/3

6914/9

6914/13

6925/22

6925/10

6925/16

10027/7

7475/2

7475/2

6113

66245

6732/5

6732/5

66270/4

6933/6

6107

7100

66244/1

66244/1

66245

66245

6926/16

68326

68325/1

68323

68324/1

67239

68327/1

6078/5

66270/1

66270/2

66271

6932/12

6916/22

6922/25

4429/2

6734/5

4466

6917/6

60230

6734/4

6925/8

6925/14

6922/14

67151

67151

6013 6012

6734/4

6734/4

6925/12 6925/12

4412

7080/2

7080/3

6069/2

6920/40

7102/5

66268

66257

66256

66254

66254

66255

68253

68252

67320/01

67330/1

67320/3

67320/5

67315

67320/11

67320/14

67320/15

6734/3

67320/12

6481/4

67320/4

67320/7

67320/9

67320/8

67320/10

67330/2

67320/02

67320/06 67302

67303

67312

6738/3

67320/13

66295/100

Shock absor-

ber oil 1000

67320 Alum.

shock absorber

long, Ø24, 2pcs.

67330 Alum.

shock absorber

short, Ø24, 2pcs.

Other FG Modellsport Motorized Toy Car manuals