FG Modellsport 68500 User guide

Please thoroughly keep this construction

manual for your spare parts orders!

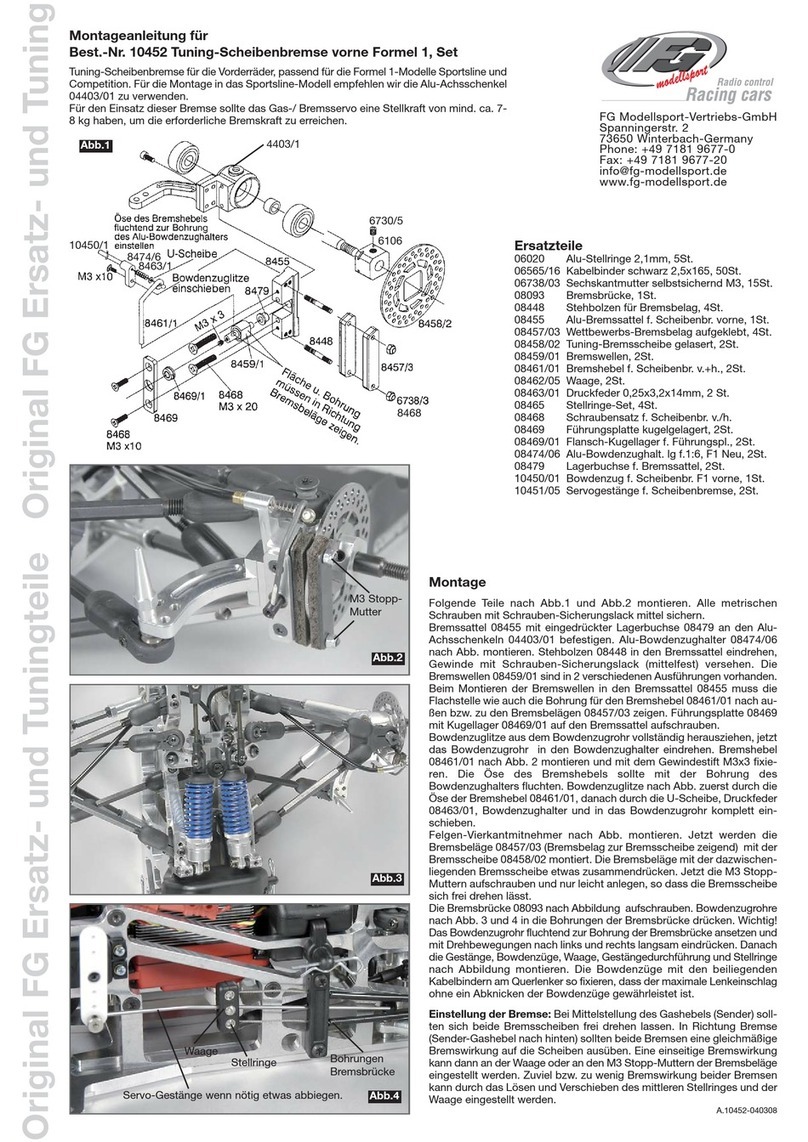

Mounting instruction for

conversion kit Monster models 2WD/RTR to 4WD

Item N°. 68500

Mounting instruction for

conversion kit Marder 2WD/RTR to 4WD

Item N°. 68501

Mounting instruction for

conversion kit Baja Buggy 2WD/RTR to 4WD

Item N°. 68502 A.68500-68502-D-200309

FG Modellsport GmbH

Spanningerstr. 2

73650 Winterbach-Germany

Phone: +49 7181 9677-0

Fax: +49 7181 9677-20

www.fg-modellsport.de

Monster models

Baja Buggy

Marder

The handling with fuels requires circumspective and careful hand-

ling. Imperatively observe the security advices.

-Refuel only if the engine is switched off!

-Take off the body.

-Thoroughly clean the area around the fuels nipple.

-Remove the fuel filler cap and carefully fill in the fuel mixture.

-Smoking or any kind of open fire is not admitted.

-Fuels might contain solvent-like substances. Avoid contact with skin

and eyes. Wear gloves for refueling. Do not inhale fuel vapors.

-Do not spill any fuel. If you have spilled fuel immediately clean the

engine and the model.

-Make sure that no fuel will get into the soils (environmental protecti-

on). Use an appropriate mat.

-Do not refuel in enclosed rooms. Fuel vapors accumulate at the soil

(risk of explosion).

-Transport and store fuels only in admitted and labeled canisters. Keep

fuel out of the range of children.

-The operator is responsible for any damages caused to third persons

in the operating range of the model, respectively of the engine, if they

are injured or in case of property damage.

-The model must only be passed on to persons who are familiar with

this model and its operation, always provide the operating manual.

-Persons with implanted heart pacemakers must not work on running

engines and on live parts of the ignition system when the engine is

being started.

-The engine must neither be started nor operated in enclosed rooms

(without sufficient ventilation).

-When starting the engine, avoid inhaling the exhausts.

-The model must neither be started nor operated without air filter or

without exhaust system.

-Before every start perform a functional check of the safety-relevant

parts.

-The throttle rods must always return automatically to the idle position.

-Any cleaning, maintenance and repair works must only be performed

with the engine being switched off. The engine and silencers are get-

ting very hot. In particular do not touch the silencer.

Comments regarding the construction manual:

Before starting the assembly please see through this construction

manual. This way you will get an overview of the whole execution.

Please check by means of the parts or bag list if the construction kit is

complete and also check the weight of the individual bags for the posi-

tions. Only this way you may be sure that all parts which you need for

the assembly are available. If a part is missing, please immediately

contact your specialized dealer.

Contents

Position 1-2: Front and rear differential gear

Position 3-7: Belt drive, belt stretcher, chassis structure

Position 8-15: Rear axle

Position 14-15: Front and rear shock absorber

Position 16-26: Front axle, front bumper

Position 30-36a: Engine, clutch, gear, air filter, tank

Position 37-43: RC-plate, receiver box, servo saver

Position 44-46: Roll cage, throttle rods

Position 47-50: Body mounts, side plates, roll cage parts

Position 52-56: Body trimmings

As 4WD models have raised steering forces compared

to 2WD models we recommend to use only servos with

metal gear for steering.

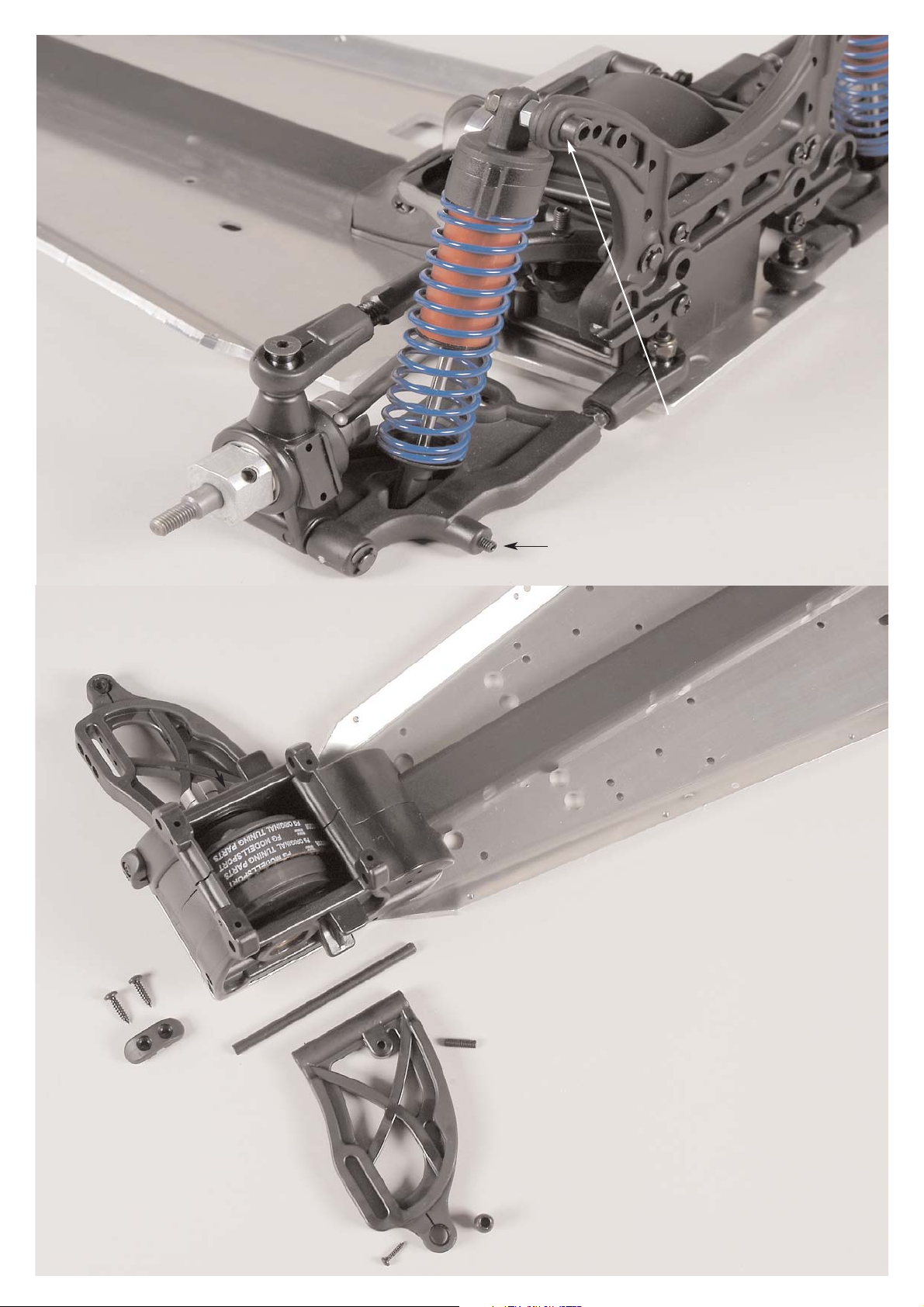

Mounting of the rear differential gear

1. Press the ball bearing 12x28x8 on the differential housing.

2. Insert the differential bevel gearwheels in the differential housing as

pictured in position 1. When using the FG mounting tool Item N°.

08505 the inserting of the bevel gearwheels will be eased considerably.

3. Lubricate the diff. driving axles slightly with grease and push them in

the diff. housing.

4. Mount the diff. bevel gear axle. If the bevel gear axle resperctively

the driving axles can only be pushed in severely or if it is impossible to

push them in at any position, you have to disassemble the bevel

gearwheels again and insert them once more.

5. Lubricate the gearwheels slightly with multipurpose grease, e.g. Item N°.

06501.

6. Now press the parts on the diff. housing as described in position 1

and in the given sequence: Steel gearwheel 48 teeth ( consider moun-

ting direction of the slant), rear plastic gear disk 42 teeth, plastic stop

disk right. Fix the complete unit with the M4x40 countersunk screws

and stop nuts M4 (impress the M4 stop nuts in the plastic stop disk

right and use the screw retention high-strength).

Mounting of the front differential gear

1. For mounting of the front differential gear you have to disassemble

the differential from your 2WD model, remove diff. bushing and steel

gearwheel 48 teeth.

2. Now mount the parts on the diff. housing as described in position 2

and in the given sequence: Front plastic stop disk left (consider moun-

ting direction of the slant), front plastic toothed belt wheel 42 teeth, pla-

stic stop disk right. Fix the complete unit with the M4x40 countersunk

screws and the stop nuts M4 (impress the M4 stop nuts in the plastic

stop disk right and use the screw retention high-strength).

3. Push the bearing shafts 6x50mm centrally in the deflection roller

16mm and in the 12-teeth toothed belt wheel.

Toothed belt

wheel 12 teeth

Bearing

shaft 6x50

Bearing

shaft 6x50

Deflection roller

16mm

Front plastic

stop disk

right

Front plastic

toothed belt

wheel 42 teeth

Front

differential

Rear

differential

Right plastic

stop disk

Position 1

Parts are in

bag B

Position 2

Parts are in

bag C

Differential

Diff. driving axle

Ball bearing

12x28x8

Ball bearing

12x28x8

Screw

M4x40

Differential

housing

Differential

housing

Differential

housing

Diff. bevel

gear axle

Diff. bevel gearwheel B

Diff. bevel

gearwheel A

Steel gearwheel

48 teeth

Rear plastic gear

disk 42 teeth

Plastic stop

disk right

Plastic stop

disk right

Slant to the

inside

Slant to the

inside

Ball diff.

driving axle

Screw

M4x40

Steel gearwheel

48 Zähne

Rear plastic gear

disk 42 teeth

Stop nut M4

Stop nut M4

Stop nut M4

All metric screws need to be secured with thread lock fluid.

Reusable parts from your 2WD model have to be checked carefully on their condition, defective and worn parts

should be replaced.

Inserting of the diff.

bevel gearwheels or

of the complete

package is much

easier if you use the

FG mounting tool

08505.

Screw

M4x40 Slant to the

outside

Lubricate

slightly

When mounting pay attention that the clo-

sed side of the lower belt channel faces

upwards. The teeth of the toothed belt are

not allowed to touch each other.

Toothed belt

Rear axle mount

left

Rear axle mount

right

Upper part belt

channel

Lower part belt

channel

Position 5

Parts are in

bag B+C

1. Put the toothed belt around the rear differential gear

as described in position 5.

2. Press the left and right rear axle mounts on the ball

bearings of the rear differential gear as pictured.

3. Put the left and right rear axle mounts on the alloy

chassis and fix them with the 4,2x16 countersunk

screws on the chassis.

1. Place the lower part of the belt channel (with the closed side facing

upwards) on the bottom part of the toothed belt. Then push the top part

of the belt channel in the bottom part. Now insert the complete belt

channel in the opening of the front axle housing (see position 5a). Make

sure that the toothed belt is running smoothly.

2. Fix the belt channel from underneath to the alloy chassis using the

4,2x16 countersunk screws.

Toothed belt wheel

12 teeth

Front axle

housing left

Front axle

housing right

Toothed belt

Deflection roller

16mm

Front differential

mounted

Position 3

Parts are in

bag C

1. Impress ball bearings 6x16x6 in both front

axle housings left and right.

2. Mount front differential gear, deflection roller

16mm, toothed belt wheel 12 teeth in the left

front axle housing as described in position 3.

3. Now put the toothed belt on the front dif-

ferential gear, also deflection roller 16mm,

toothed belt wheel with 12 teeth as descri-

bed in position 3.

4. Press the right front axle housing on the front diffe-

rential gear, also deflection roller 16mm and the toot-

hed belt wheel with 12 teeth (position 4).

5. Put the complete front axle housing on

the alloy chassis and fasten it using the

4,2x16 countersunk screws.

Front axle

housing left

Front axle

housing right

Alloy chassis

Front differential

gear

Countersunk

screw M4,2x16

Countersunk

screw M4,2x16

Position 4

Parts are in

bag C

Alloy chassis

Upper part

belt channel

Lower part belt

channel

Screw

4,2x16

Position 5a

Parts are in

bag B+C

Toothed belt

Front axle hou-

sing left

Front axle

housing

right

Countersunk

screw M4,2x16

Alloy chassis

Stretching pulley

housing mounted

Belt channel mounted

Position 7

Parts are in bag B

Countersunk

screw 4,2x16

Screw

M4x14

Disk Ø4,3

Stretching pulley

housing left

Fitting position for

toothed belt

wheel 42 teeth

Fitting position for

toothed belt wheel

40 teeth

Stretching pul-

ley housing

right

Collar

Plastic

bearing seat

Ball bearing

10x19x7

Bearing shaft

for stretching

pulley housing

Position 6

Parts are in

bag B

2. Push the bearing shaft for the stretching pulley

housing centrically in the 3 ball bearings 10x19x7.

1. Impress the plastic bearing seat

with inbound collar (pay attention to

fitting position) in the left and right

stretching pulley housing as descri-

bed in position 6.

3. Impress the bearing shaft which is equipped with

ball bearings in the bearing seat of the left and

right stretching pulley housing and fix it with

M4x14 pan-head screws and Ø4,3 disks.

1. Place the mounted stretching pulley housing ob toot-

hed belt and belt channel as described in position 7

and fix it on the alloy chassis using the 4,2x16 counter-

sunk screws. For this purpose, slightly move the belt.

2. When the assembly is performed, turn the belt in run-

ning direction. Make sure the belt is easily rotatable.

All metric screws need to be secured with thread lock fluid.

Tipp: The position of the front bearing seat is made for

the front plastic toothed belt wheel with 42 teeth. The

position of the rear bearing seat is made for the front

plastic toothed belt wheel with 40 teeth.

Fix the belt channel from underneath to the alloy

chassis with the 4,2x16 countersunk screws.

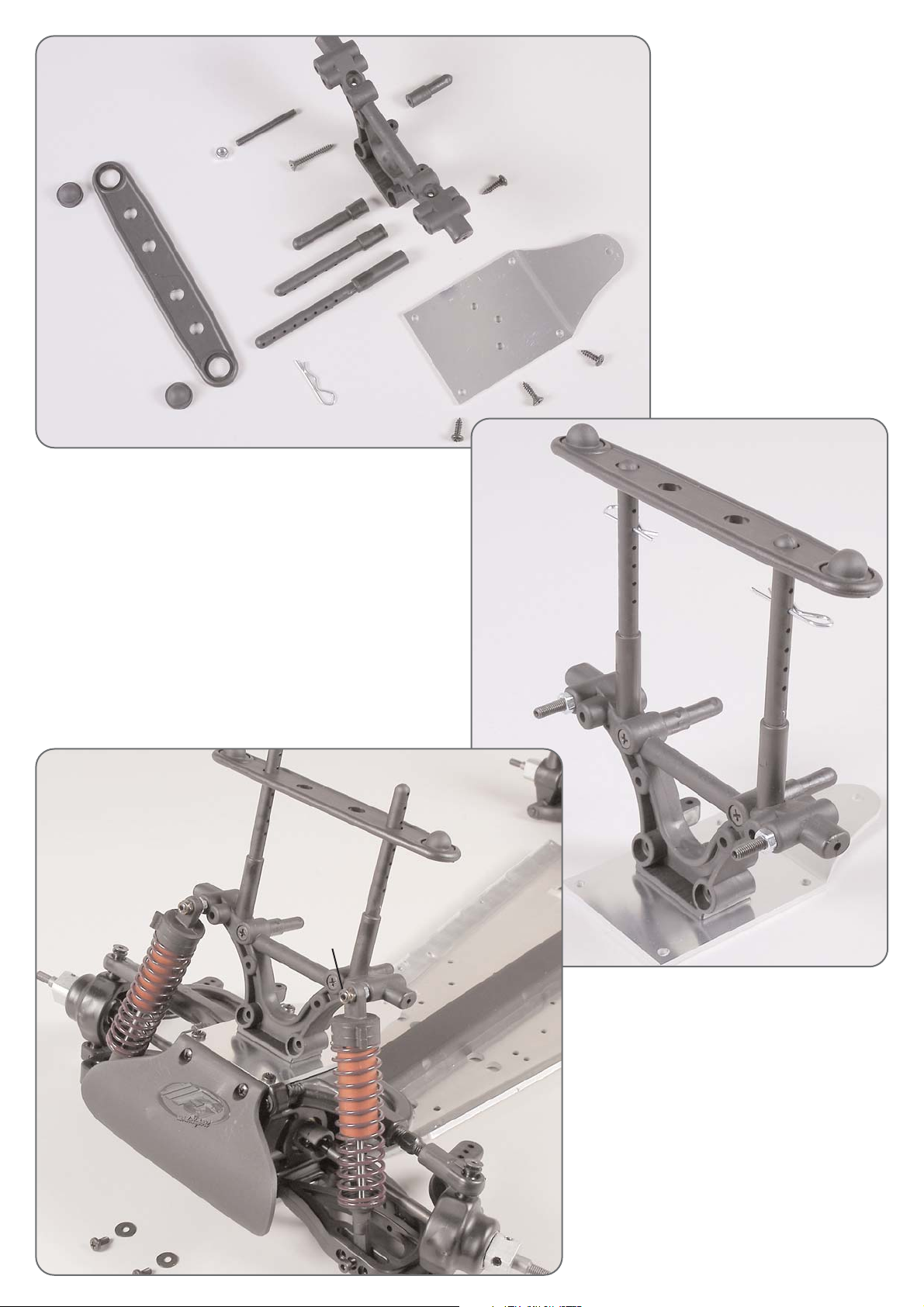

1. Push the rear axle cover between the left

and right rear axle mounts and fix it with the

alloy connection brace, M4x20 pan-head

screw and disk Ø4,3.

2. Disassemble the rear lower wishbone with

stabilizer from your 2WD model (stabilizer

only in Monster/Stadium models).

3. Fix the rear lower wishbones to the front

ball-and-socket joints using M5x30 counter-

sunk screws and 4 disks Ø5,3 (between ball-

and-socket joints and alloy chassis), then fix

all with M5 stop nuts to the alloy chassis.

Now fasten the rear ball-and-socket joints

with M5x25 countersunk screws and M5

stop nuts to the alloy chassis. Make sure the

mounted wishbones can be moved easily up

and down.

Alloy chassis

approx. 38mm

approx. 37,5mm

Screw

M5x25

Screw

M5x30

Screw

M4x20

Disk Ø5,3

Disk

Ø4,3

Rear lower

wishbone

Alloy connec-

tion brace

Stabilizer

5mm

Rear axle cover

Plastic brace for

stabilizer only for

Monster/Stadium

Ball-and-

socket joint

Adjusting screw

r/l 32mm

Stop nut M5

Position 8

Parts are in

bag D

All metric screws need to be secured with thread lock fluid.

Rear axle mount

right

Rear axle mount

left

Position 9

Parts are in

bag D

4. Impress the stabilizer 5mm (only for Monster/Stadium

models) in the plastic braces for stabilizer.

Adjust the setting screws

corresponding to your

existing model.

Stabilizer 5mm only in

Monster/Stadium version

Retaining

washer Ø5

Rear lower

wishbone pin

Rear driving

shaft

Disk Ø4,3

Rear damper

plate 4WD

Rear axle

mount left

Rear upright

left

Screw

4,2x9,5

Screw

4,2x22

Rear lower

wishbone

1. Mount the 4WD damper plate rear to the left and right

rear axle mounts using 4,2x22 pan-head screws.

2. Push the stabilizer (only Monster/Stadium models) into

the rear damper plate and fasten it with 4,2x9,5 pan-head

screws and disks Ø4,3.

3. Disassemble rear uprights, rear driving shafts and rear

lower wishbone pins from your existing 2WD model and

impress them in the rear lower wishbones as described in

position 10+11. Secure the wishbone pins with Ø5 retai-

ning washers.

Position 10

Parts are in

bag D

Position 11

Parts are in bag D

Adjusting clips

Retaining

washer Ø5

Rear upper

wishbone pin

Headless pin

M5x25

Left upright

Rear damper

plate

Rear wishbone

thread rod

M10/M8 84mm

Rear upper

wishbone

Ball-and-socket joint

Screw

M5x35

Baustufe 14

Teile sind in

Beutel

Position 12

Parts are in

bag D

Steel ball

10x13

Disk Ø5,3

Make sure the driving shaft has not

more than 2-3mm clearance in horizon-

tal position. Adjust the adjusting screws

of the rear axle correspondingly.

According to the toe-in

adjustment the upper

wishbone needs to be shim-

med by adjusting clips.

approx. 77mm

approx. 6mm

1. Disassemble the rear upper wishbone pin and the

ball-and-socket joint with steel ball from your existing

2WD model.

2. Screw the rear wishbone thread rods M10/M8 84mm into

the rear upper wishbones and in the ball-and-socket joints

to the size of approx. 77mm.

3. Fix the completely mounted rear upper wishbones at

the rear axle mounts by using wishbone pins, then

mount the rear damper plate. Secure the wishbone pins

with Ø5 retaining washers.

4. Push two adjusting clips each in the rear upper

wishbone pins in the front between rear axle mounts

and rear upper wishbones, then push one adjusting

clip each in the rear upper wishbone pins in the rear

between rear damper plate and rear upper wishbones.

5. Fix the ball-and-socket joints with steel

ball (steel ball collar must face the upright)

at the uprights using M5x35 countersunk

screws and disks Ø5,3, see position 12+13.

6. Screw M5x25 headless pins from above

into the rear upper wishbones (rebound stop

travel).

Disk

Ø5,3

Screw

M5x35

Position 13

Parts are in

bag D

Make sure the rear wishbones

can be moved easily up and

down.

O-ring

4x2

Damper fixing

short

Lower shock

absorber locking B

Lower shock

absorber locking A

Damper piston

rod long

Mounting of rear shock absorbers Marder/Baja

1. Mount o-rings 13x2,5 on the top of shock absorber locking M5 and lower

shock absorber locking A (position 14/14a).

2. Push retaining washer Ø3,2 in the first slot of the long damper piston

rod, then mount the damper piston with the recess facing towards the

retaining washer and fix it with a second retaining washer Ø3,2 (position

14b).

3. Press the lower shock absorber locking B (with the flat side facing the

damper piston), two o-rings 4x2 and upper shock absorber locking A

(with the thread facing the damper piston) on the long damper piston

rods.

4. Screw the short damper fixing on the thread of the long damper piston

rod until the thread is no longer visible. Now press it in the shock absor-

bers housing and screw it tight (position 14b).

5. Pull out the damper piston rod completely and fill the shock absorber

housing with oil to the start of thread. Now slide the damper piston rod

slowly several times in and out the shock absorber housing so that the

air bubbles in the oil will come upwards. If no longer air bubbles appear,

push the damper piston rod slowly into the shock absorber housing until

there are only approx. 5mm visible of the piston rod (position 14c). Then

screw the upper shock absorber lockings M5 on the shock absorber

housings (position 14d).

6. Mount one narrow and one wide damper collet each and a blue dam-

per pressure spring on the shock absorber housings and secure them

with the spring collars (Position 14e).

Mounting of front shock absorbers Marder/Baja

1. Dismount the rear shock absorbers from your existing 2WD model and

disassemble damper pressure springs, spring collar, damper fixings and

damper collets.

2. Screw the short damper fixings on the thread of the damper piston

rods until the thread is no longer visible.

6. Mount two narrow damper collets and a violet damper pressure spring

on the shock absorber housings, secure them with the spring collars

(position 14e).

Monster/Stadium

Retaining

washer Ø3,2

Mounting of shock absorbers Monster/Stadium

1. Mount the o-rings 13x2,5 on the upper shock absorber lockings M5 (positi-

on 14).

2. Dismount four shock absorbers from your existing 2WD model ans disas-

semble damper pressure springs, spring collar, damper fixings and damper

collets.

3. Screw two long and short damper fixings each on the thread of the

damper piston rod until the thread is no longer visible.

4. Dismount the upper shock absorber lockings M4, remove the oil from

the shock absorbers.

5. Pull out the damper piston rod completely and fill the shock absorber

housing with oil to the start of thread (position 14c). Now slide the dam-

per piston rod slowly several times in and out the shock absorber hou-

sing so that the air bubbles in the oil will come upwards. If no longer air

bubbles appear, push the damper piston rod slowly into the shock absor-

ber housing until there are only approx. 5mm visible of the piston rod.

Then screw the upper shock absorber lockings M5 on the shock absor-

ber housings (position 14d).

6. Mount each two narrow damper collets, one violet damper pressure

spring on the shock absorber housings with the long damper fixings and

secure with spring collars. Now mount each two wide damper collets,

one blue damper pressure spring on the shock absorber housings with

the short damper fixings and secure with spring collars (position 14f).

Rear damper

mounted

Rear damper

mounted

Front damper

mounted

Front damper

mounted

Hint: Slightly lubricate the o-rings with

silicone oil when mounting. If you use

the FG mounting tool 06853 + 06854,

the mounting of the shock absorbers

will be eased considerably.

Position 14

Parts are in

bag E

Position 14f

Position 14d

Parts are in

bag E

Position 14e

Position 14c

Parts are in

bag E

Position 14b

Parts are in

bag E

Position 14a

Parts are in

bag E

Mount o-ring 13x2,5

on the top shock

absorber locking.

Mount o-ring 13x2,5

on the lower shock

absorber locking.

Fill up with oil

to the start of

thread.

Damper piston

Push the piston

rod in, then

unscrew the

shock absorber

locking at the

top.

Marder/Baja

Screw

2,9x13

Screw

4,2x16

Guide for

stabilizer

Headless

pin

M5x16

Steel ball

Front lower

wishbone pin

Front lower

wishbone

Position 16

Parts are in

bag F

Hint: In order to withdraw the front lower wishbone

pins, screw an M4 screw into the threaded hole of

the front lower wishbone pins.

A clearance of the steel ball in the front lower

wishbone can be adjusted with the 2,9x13 screw.

Screw

M5x25

Nut

M5

Rear shock absor-

ber mounted

Stop

nut M5

Position 15

Parts are in

bag E

Rear damper

plate

Screw M5x25 cylinder screws into the rear

damper plate and counter with M5 nuts,

then fix the top of the shock absorber with

M5 stop nuts. Don’t tighten the stop nut.

All metric screws need to be secured

with thread lock fluid.

Front axle

housing left

Front axle

housing

right

Mount the rear shock absorbers to the rear

lower wishbones by using M4x30 headless

pins.

1. Screw the headless pin M5x16 from the

bottom into the front lower wishbone until

approx. 2mm thread are visible.

2. Disassemble the steel balls from the front axle of your exi-

sting 2WD model and push them into the front lower wishbo-

nes, then screw in the 2,9x13 pan-head screws.

3. Insert the front lower wishbones in the front axle housings, then

push the front lower wishbone pins with threaded hole towards

the front in the front axle housings and press them through the

pre-assembled front lower wishbones. Make sure the wishbones

can be moved easily up and down.

4. Impress the stabilizer guide as

locking device for the front lower

wishbone pins into the left and right

front axle housings and fix it using

4,2x16 pan-head screws.

Front lower

wishbone

Diff. dri-

ving axle

Adjusting

clips

Headless

pin

M5x25

Headless pin

M6x6

Front upper

wishbone

Front wishbone

thread rod

M10/M8 66mm

Front upper

wishbone

pin

Disk

Ø5,3

Disk

Ø5,3

Disk

Ø5,3

Disk

Ø8,4

Screw

M5x30

Screw

M5x30 Square wheel

driver 14mm

Front dri-

ving shaft

Front

driving

axle

Position 18

Parts are in

bag F

Steel

ball

1. Impress mounting nuts for front uprights from the

inside into the left and right uprights.

2. Push the ball bearing 17x26x7 from the inside into

the left and right upright.

3. Disassemble the ball bearing 8x22x7 from the

upright of your existing 2WD model and push it into the

front upright 4WD.

Position 17

Parts are in

bag F

Position 19

Parts are in

bag F

Front axle

housing

Front upright

4WD left

Front upright

left

Front upright

4WD left

Front upright

4WD right

Fixing nut for

front upright

Fixing nut for

front upright

Ball bearing

17x26x7

Ball bearing

8x22x7

Screw

M5x30

approx. 7,5mm

approx.19,5mm

Disk

Ø5,3

Make sure the driving shaft has not more than 2mm

clearance in horizontal position. Corresponding to the

adjustment of the upper wishbone (camber) you have

to mount or dismount enclosed steel disk Ø8,4 bet-

ween diff. axle and ball bearing.

1. Screw the front wishbone thread rods M10/M8

66mm into the front upper wishbones, then turn

the ball-and-socket joints on the front wishbone

thread rods M10/M8 66mm.

2. Dismount the steel balls from your existing

2WD model and press them into the ball-and-

socket joints.

3. Press the front upper wishbone pins through

the pre-assembled front upper wishbones into the

front axle housings as described in position 19.

Fix the front upper wishbone pins with Ø5 retai-

ning washers.

4. Withdraw the diff. driving axles from the front

differential and press them with disk Ø8,4 in the

front differential again.

5. Push the front driving axles into the pre-assem-

bled left and right uprights. Dismount square

wheel driver from your existing 2WD model and

mount it on the faces of the front driving axles

with the crank facing the bearing.

Ball-and-socket joint

Disk

Ø5,3

Mount the left and right

uprights to the lower wishbo-

nes and to the ball-and-socket

joints of the upper withbones

using Ø5,3 disks between

steel ball, screw and uprights.

At the same time mount the

driving shaft between front

driving axle and diff. driving

axle.

Retaining

washer Ø5

Impress four adjusting clips each in the

front between front axle housing and front

upper wishbones into the front upper

wishbone pins.

Screw the M5x25 headless

pins from above into the

front upper wishbones.

approx..49,5mm

Marder/Baja Buggy Position 23

Parts are in

bag G

Stop

nut M4

Disk

Ø4,3

Front bumper

Screw

M4x8

Screw

4,2x16

Screw M4x14

Marder

Baja Buggy

Baja Buggy

Position 20

Parts are in

bag G

Position 21

Parts are in

bag G

Position 22

Parts are in

bag G

Baja Buggy Position 20+21

1. Fix the front shock mount 4WD to

the reinforcing plate for the front axle

by using M4x16 countersunk screws,

Ø4,3 disks and M4 stop nuts.

Disassemble countersunk screw

M4x25 and M4 nut from the shock

mount of your existing 2WD model and

mount them at the front shock mount

4WD.

2. Mount the plastic fixing plate with

brake guide rail and alloy distances

between brake guide rail and reinfor-

cing plate to the reinforcing plate for

the front axle using M4x30 cylinder

screws, disks Ø4,3 and M4 stop nuts.

Marder Position 22

1. Fix front shock mount 4WD to the reinforcing plate

for the front axle using M4x16 countersunk screws,

disks Ø4,3 and M4 stop nuts.

Dismount countersunk screw M4x25 and M4 nut from

the shock mount of your existing 2WD model and

mount them in the 4WD shock mount.

2. Cover the rear bore holes of the reinforcing plate for

the front axle with an adhesive tape to prevent a con-

tamination of the gearwheel drive.

Marder/ Baja Buggy Position 23

1. Fix the assembled reinforcing plate for the front

axle on the front axle carriers using 4,2x13 pan-head

screws.

2. Mount the front shock absorbers at the front lower

wishbones using M4x14 cylinder screws, then fix the

top of the shock absorber with M4 stop nuts.

3. Assemble the front bumper with M4x8 pan-head

screws and Ø4,3 disks to the alloy chassis and with

4,2x16 pan-head screws at the front axle carriers.

Stop nut M4

Stop nut M4

Adhesive

tape

Reinforcing plate

for front axle

Plastic fixing

plate

Alloy

distance

Nut

M4

Nut

M4

Front shock

mount 4WD

Brake

guide

rail

Disk

Ø4,3

Disk

Ø4,3

Disk

Ø4,3

Screw

4,2x13

Screw

4,2x13

Screw

4,2x13

Screw

M4x16

Stop nut

M4

Reinforcing brace

for front axle

Front shock

mount 4WD

Disk

Ø4,3

Screw

M4x16

Screw

M4x25

Screw

M4x25

Screw

M4x30

Monster/Stadium

Monster/Stadium

Monster/Stadium

Position 24

Parts are in

bag G

Position 25

Parts are in

bag G

Position 26

Parts are in

bag G

Monster/Stadium Position 26

1. Fix the assembled reinforcing plate for front axle

on the front axle carrier using 4,2x13 pan-head

screws.

2. Mount the front shock absorbers to the front lower

wishbones with M4x14 cylinder screws, then fix the

shock absorbers at the top with M5 stop nuts.

3. Assemble the front bumper at the alloy chassis

using M4x8 pan-head screws and disks Ø4,3, then fix

it with 4,2x16 pan-head screws at the front axle car-

riers.

Stop

nut M5

Front bumper

Disk

Ø4,3

Screw

4,2x13

Screw

4,2x13

Screw

4,2x16

Screw

4,2x16

Screw

4,2x32

Screw

M4x8

Screw

4,2x16

Screw M4x14

Front shock

mount 4WD

Reinforcing plate for

front axle

Body support

Body mount short,

80mm, adjustable

Body clip

Dampening rubber

for body support

Nut M5

Headless pin

M5x45

Plastic part for

reinforcing plate

Monster/Stadium Position 24-25

1. Mount front shock mount 4WD to the reinforcing plate for front axle

using 4,2x16 countersunk screws.

2. Dismount the plastic parts for reinforcing brace from the shock mount of

your existing 2WD model and fix them to the front shock mount 4WD by

using 4,2x32 countersunk screws (position 25).

3. Screw the headless pins M5x45 from the front into the front shock

mount 4WD until they are flush with the rear side of the shock mount.

Then counter the headless pins witrh M5 nuts.

4. Disassemble the adjustable body mounts from the shock mount of

your existing 2WD model and mount them to the front shock mount

4WD by using 4,2x16 pan-head screws.

5. Fix the body clips in the adjustable body mounts as described in position

25 and press on the body support. Use the body clips and the body sup-

port from your existing 2WD model.

Screw

4,2x32

Nut M5

Headless

pin M5x45

Plastic

mount

Position 30

Parts are in

bag H

Position 31a

Parts are in

bag H

Position 30b

Parts are in

bag H

Position30c

Parts are in

bag H

Position 30d

Parts are in

bag H

Position 31

Parts are in

bag H

1. Disassemble the complete engine from your existing 2WD model.

Remove muffler, airfilter, gearplate and clutch. Make sure no dirt gets in the outlet port of the engi-

ne.

2. Dismount the clutch spring by twisting the clutch blocks.

3. Mount new clutch spring as described in position 30a-30c.

4. Now disperse the clutch blocks slightly until the clutch blocks lay straight parallel again, positi-

on 30b.

5. Push the clutch blocks on top of each other by using tongs or a vice, until they lock. Position

30c.

6. Push the shaft washers on the dowel screws for the clutch blocks and press them into the

clutch blocks from the side with the arrows (engine running direction). Fix them on the clutch

block carrier using 6x15x1 disks. Position 30d and 31.

7. Disassemble steel fixing plates and ball bearing 10x19x7 from the existing 2WD parts and

mount them to the large plastic mount 4WD.

8. Now mount the large plastic engine mount 4WD with the long and short steel fixing plates on

the engine using 4,2x13 pan-head screws as described in position 31.

Hint: If you use the FG piston punching pin Item N°. 08542 the mounting of the clutch will be con-

siderably simplified.

Clutch blocks

Clutch spring

Dowel screw for

clutch blocks

Plastic engine

mount large

4WD

Shaft washer

Driving direction

Disk

6x15x1

Screw

4,2x13

Screw

4,2x13

Steel fixing plate long

Steel fixing plate short

Ball bearing

10x19x7

1. Cover the outlet port of the engine

with an adhesive tape.

2. Saw off the housing part

with an metal hand saw, see

also illustration in position 31.

All metric screws need to be secured

with thread lock fluid.

Position 33

Parts are in

bag I

Steel gearwheel

15 teeth only for

Monster models

Headless

pin

M5x5

Headless

pin

M5x5

Brake

square

Clutch bell

Plastic

gearwheel

Gear

shaft

4WD

Retaining

washer Ø7

Retaining

washer Ø7

Gear

plate

Shim ring

10x16x1

Position 32

Parts are in

bag I

3. Push the gear shaft 4WD through the ball bearing of the large

plastic engine mount 4WD and re-assemble the gear plate at the

clutch flange using M6x40 cylinder screws and Ø6,4 disks.

4. Press steel gearwheel 14 teeth on the gear shaft 4WD as pic-

tured and fix it on the surfaces of the gear shaft 4WD using

M5x5 headless pins, secure with M6x16 countersunk screw and

use a high-strength screw retention (Position 32+34).

Plastic engine

mount large

4WD Gearwheel

cover gear

Clutchl flange

Basic

body

Filter cover

Screw

4,2x13

Screw

4,2x13

Screw

4,2x13

O-ring for airfilter

adapter

Airfilter

adapter

Foam filter Screw

4,2x16

Screw

M6x40

Screw

M6x16

Steel

gearwheel

14 teeth

Headless

pin

M5x5

Gear

shaft

4WD

Disk

Ø6,4

1. Remove the adhesive

tape from the outlet port of

the engine and re-assemble

muffler with muffler gasket

from your existing 2WD

model.

Mount the gearwheel cover at the large plastic

engine mount 4WD using 4,2x13 pan-head

screws as described in position 32+34.

Insert the o-ring for the airfilter

adapter in the basic body and

fasten it to the airfilter adapter

using 4,2x13 countersunk screws.

Press the oiled foam filter of your

existing 2WD model on the basic

body and fix it with filter cover and

4,2x16 countersunk screw.

Gear

plate

Hint: Rinse the existing foam filter (if it is dirty) with rinsing water,

let it dry and oil it again. To oil the foam filter knead it in a plastic

bag with FG filter oil Item N°. 06441 repeatedly.

2. Remove retaining washer Ø7 of the gear shaft from the plastic

gearwheel. Dismount headless pin M5x5 of the brake square and pull

out the 2WD geart shaft from the gear plate. Then press the 4WD

gear shaft through the brake square, gear plate, shim ring 1x16x1

and plastic gearwheel and secure it with retaining washer Ø7. Mount

brake square backlash-free on the surface of the gear shaft 4WD

using the headless pin M5x5.

Only for Monster models:

Dismount steel geawheel 16 teeth.

Mount steel gearwheel 15 teeth on the clutch bell and

secure with Ø7 retaining washer.

Tighten the steel gearwheel 15 teeth backlash-free on the

surfaces of the clutch bell using headless pins M5x5.

Position 34

Parts are in

bag I

Make sure that driving gearwheels, driving shafts

a.s.o. can be turned easily without any resistance.

Screw

4,2x32

Disk Ø4,3

Rear axle

mount left

Alloy connec-

ting brace

Plastic engi-

ne mount

large 4WD

Position 35

Parts are in

bag I

Position 36

Parts are in

bag I

1. Insert the complete engine in the

alloy chassis and fasten it with

4,2x32 pan-head screw and disk

Ø4,3 through the rear axle mount.

Do not tighten the 4,2x32 pan-head

screw yet, see also position 36a.

2. Fix the pre-assembled engine

using 4,2x16 countersunk screws

and engine fixing disks from

underneath on the alloy chassis.

Screw

4,2x32

Disk

Ø4,3

Screw

4,2x16

Screw

4,2x16

Screw

4,2x16

Alloy chassis

Tank mount

Tank complete

Tank base

Engine fixing

disk

5. Tighten the 4,2x32 pan-head

screws after setting the engine fixing

screws tight.

6. Install the fuel pipes as pictured,

shorten them if necessary.

3. Dismount tank from your existing 2WD

model. Fix the tank (tank cap facing the right

side) with tank mount on the tank base using

4,2x16 countersunk screws (longer side of tank

base must face the right side).

4. Mount the tank assembled on tank base on

the alloy chassis using 4,2x16 countersunk

screws.

All metric screws need to be secured

with thread lock fluid.

Position 36a

Parts are in

bag I

Screw

2,9x13

Plastic rc-plate

4WD

Battery mount with

receiver battery

Flexible aerial

Receiver

box

Body clip

Bolt for bat-

tery mount

Collar disk for

rc-plate 4WD

Steering servo

Gas/brake

servo

All metric screws need to be secured

with thread lock fluid.

Position 37

Parts are in

bag J

Position 38

Parts are in

bag J

Position 39

Parts are in

bag J

Position 40

Parts are in

bag J

Servo

arm

1. Dismount the rc-plate from your existing 2WD

model, remove battery mount, servos and receiver

box.

2. Mount the throttle/brake servo and the stee-

ring servo in the plastic rc-plate 4WD as descri-

bed in position 37.

3. Fix the receiver box to the plastic rc-plate

4WD using 2,9x13 pan-head screws, connect

the servo cables, battery cables to the receiver

again and check the function. Now stow the

receiver and the rest of the servo cables in the

receiver box, lead the aerial cable of the receiver

in the flexible aerial.

4. Press the collar disk for the 4WD rc-plate into

the plastic rc-plate 4WD.

5. Mount the bolts for the battery mounts to the

plastic rc-plate 4WD using 2,9x13 pan-head

screws. Fix the battery mount with receiver bat-

tery with body clips to the bolts.

6. Now press the servo arm back on the steering

servo as described in position 38 and fix it with

enclosed screw. The servo arm should be in a

90-degree position to the steering servo at neu-

tral position of the radio control, change the

position of the servo arm correspondingly.

Screw

2,9x13

Screw

2,9x13

Receiver

box

Plastic rc-plate

4WD

Servo saver

axle

Track rod

mounted

Joint

ball

Servo rods

mounted

Servo saver

mounted

Rods M4x51

Tension sleeve for

servo saver

Servo

saver

Part B

Servo

saver

Part A

Servo

saver

spring

Nut M10 for

servo saver

Screw

M5x10

Screw

M4x20

Screw

2,9x19

Stop nut

M4

Ball bearing

7mm

Steel ball

7mm

Collar disk for

rc-plate 4WD

6. Dismount the servo rods from your existing 2WD model

and remove the ball-and-socket joints from the linkage.

7. Screw the ball-and-socket joints 7mm on the rods M4x51

and press the steel balls 7mm into the ball-and-socket joints.

8. Fix the servo rods (collar of the steel ball must face the

servo saver) at the inner hole of the servo saver using 2,9x19

pan-head screws as pictured.

4. Disassemble the track

rods of your existing 2WD

model.

5. Mount the track rods

(collar of the joint ball

must face the servo saver)

to the servo saver by

using M4x20 cylinder

screws and M4 stop nuts. 1. Impress the tension sleeve for servo saver

from above through servo saver part B and

servo saver part A.

2. Mount the servo saver spring with the

M10 nut on the thread of the tension slee-

ve and check on free movement.

3. Lubricate the servo saver axle slightly

and press it from the top into the tension

sleeve for servo saver. Secure the servo

saver axle with an M5x10 pan-head

screw. Use screw retention lacquer.

Hint: Fill the bottom part of the receiver box

with some foam to protect the receiver

against vibrations.

approx. 108mm

3. Switch on the remote control system, set the trimming of

the steering to central position. Adjust the servo saver in

centre to the chassis. First mount one servo rod to the

servo arm of the steering servo using a 2,9x16 pan-head

screw, then mount the second servo rod. Both servo rods

should be adjusted in the same length. You should be able

to mount both servo rods easily and without any resistance

to the servo arm of the steering servo using 2,9x16 pan-

head screws, position 41-43.

4. Mount the track rods to the front uprights by using M4x20

cylinder screws, Ø4,3 disks and M4 stop nuts as described

in position 43.

Position 41

Parts are in

bag J

Position 42

Parts are in

bag J

Position 43

Parts are in

bag J

Screw

2,9x16

Steering servo

Servo rods

Alloy chassis

Plastic rc-plate 4WD

Plastic rc-

plate 4WD

Servo

saver

Servo

saver

Screw

4,2x16

Screw

M4x20

Screw

M4x20

Stop nut

M4

Stop nut

M4

Screw

4,2x16

Disk

Ø4,3

Disk

Ø4,3

Screw

M5x16

Screw

M5x16

Disk

Ø5,3

Disk

Ø5,3

Track rod

Track rod

Front upright

left

Front upright

left

Front axle

stiffening

Front axle

stiffening

All metric screws need to be secured with thread lock fluid.

1. Mount the plastic rc-plate 4WD underneath the front axle stif-

fening to the alloy chassis using 4,2x16 countersunk screws.

2. Now mount the servo saver underneath the plastic rc-plate

4WD by using M5x16 pan-head screw and Ø5,3 disk as pictu-

red. Use screw retention lacquer.

Dirt, but also longer downtimes can

affect the function and free move-

ment of the servo saver. Therefore we

recommend to spray some penetra-

ting oil between tension sleeve and

servo saver part A+B. Then press ser-

vo saver part A downwards against

the spring and check the function. If it

does not function smoothly you have

to dismount and clean the part.

A stiff servo saver can cause a servo

damage.

1. Mount the throttle rods to the carburetor arm using

collets and M3x3 headless pins as described in positi-

on 45. Keep some clearance between the collets and

the carburetor arm. Make sure the carburetor arm can

be easily moved and does not jam.

2. Push the M3x25 pan-head screw from the bottom

into the servo arm as described in position 46 and

secure it with an M3 nut. Screw on two M3 stop nuts

as distance. Switch on the remote control system and

set the trimming for throttle/brake in central position.

Press the servo arm on the the servo as pictured in

position 46 and fix it with enclosed screw.

3. Push the collet, pressure spring, throttle pivot post

and collet on the throttle rods. In doing so, press the

throttle pivot post on the M3x25 pan-head screw and

secure it with an M3 stop nut. Fix the collets using

M3x3 headless pins. See position 46.

Switch on the remote control system. Set the servo for

throttle/brake in central position. Now clamp the collet

to the throttle pivot post using an M3x3 headless pin.

Set the transmitter to full throttle position and check if

the carburetor arm opens completely.

Tipp: Do not tighten the M3 stop nut at the throttle

pivot post. The throttle pivot post and the throttle rods

must run smoothly, move easily and should neither

touch nor clamp in any position.

Throttle rods

Brake rods

Collet

Collet

Headless

pin M3x3

Headless

pin M3x3

Carburetor

arm

Position 44

Parts are in

bag K

Position 46

Parts are in

bag K

Steering servo

Throttle rods

Brake rods

Pressure spring

Throttle/brake

servo

Servo

arm

Nut

M3

Stop

nut M3

Stop

nut M3

Collet

Collet

Headless pin

M3x3

Headless

pin

M3x3

Screw

M3x25

Throttle pivot

post

Position 45

Parts are in

bag K

Position 48

Baustufe 50

Teile sind in

Beutel

Baja

Dämpferplatte

hinten 4WD

Roll bar

Screw

M4x8

Screw

M4x8

Alloy chassis

Schraube

4,2x13

Auspuffrohr

Screw

4,2x32

Schraube

4,2x22

Plastic brace

long

Kunststoff

strebe kurz

Spoilerhalter

Alloy side

plate left

Side body

mount

Alloy side

plate right

Halterung für

Auspuffrohr

Screw

4,2x16

Disk

Ø4,3

Scheibe

Ø4,3

Plastic

bush

4/6x5mm

Schraube

M6x75

Allloy distance

10x34

Disk Ø6,4

Cylinder screw

M6x75

Position 47

Parts are in

bag K

Screw

2,9x9,5

Screw

2,9x9,5

Screw

2,9x9,5

Alloy chassis Screw

4,2x16

Reinforcing brace

Plastic part for

reinforcing brace

Plastic part for

reinforcing brace

Reinforcing brace

Roll bar

Screw

4,2x32

3. Mount the roll bar to the alloy chassis

using 4,2x16 countersunk screws.

1. Dismount roll bar and reinforcing brace from your existing 2WD

model.

2. Mount the plastic parts for the reinforcing braces at the roll bar

again using 4,2x32 pan-head screws as pictured. Push the reinforcing

braces into the plastic parts for the braces at the front shock mount

and fix them using 2,9x9,5 pan-head screws.

Monster/Stadium models

Monster/Stadium models

1. Disassemble the left and right alloy side plates from your existing 2WD model and mount them to

the alloy chassis using M4x8 pan-head screws. Fix the left and right alloy side plates to the front

shock mount using 4,2x16 pan-head screws, Ø4,3 disks and plastic bushes 4/6x5.

2. Fasten the left alloy side plate with M6x75 cylinder screw, Ø6,4 disk and alloy distance 10x34.

3. Fasten the right alloy side plate with M4x45 cylinder screw, Ø4,3 disk and alloy distance 8x27.

4. Dismount the complete rear spoiler mount from your existing 2WD model and fix it at the rear shock

mount 4WD by using M4x20 cylinder screws and M4 stop nuts. Spoiler mount and rear body mounts

can differ for Hummer, Jeep and Beetle Pro models.

5. Mount the long plastic braces with 4,2x32 pan-head screws and roll bar.

If necessary file the side plates here slightly to

make sure the track rods do not pile while

steering. Treat the other side in the same way.

If necessary file the boring to a long slot.

Treat the other side in the same way. Mount exhaust pipe from your

existing 2WD model.

Table of contents

Other FG Modellsport Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price GEO TRAX K3115 user manual

Fancy Foam Models

Fancy Foam Models IndoorDepron001 Assembly instructions

Jamara

Jamara Tiger Moth Instruction

Mattel

Mattel Roll Cage Tyco RC user guide

Thames & Kosmos

Thames & Kosmos DIG IT! DINOS GIANT DINOSAUR SKELETON KIT manual

PalPlay

PalPlay The House of Fun M780 Assembly instructions