DSE Model 7560 ATS and Mains Controller Operators Manual

057-017 7560 OPERATING MANUAL ISSUE 10.2 10/02/09 AM 3

TABLE OF CONTENTS

Section Page

1

BIBLIOGRAPHY........................................................................................... 5

1.1

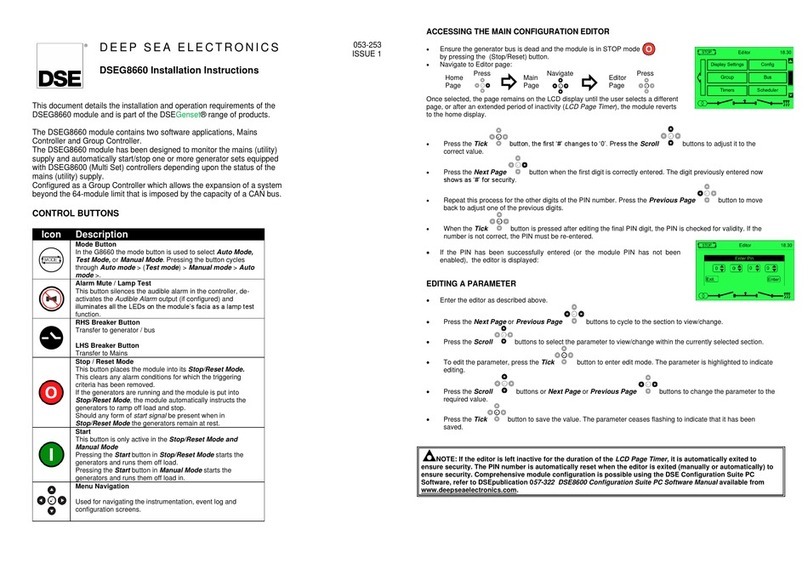

INSTALLATION INSTRUCTIONS.................................................................................5

1.2

TRAINING GUIDES.....................................................................................................5

1.3

MANUALS..................................................................................................................5

1.4

OTHER PUBLICATIONS.............................................................................................6

2

INTRODUCTION........................................................................................... 7

3

SPECIFICATIONS........................................................................................ 8

3.1

PART NUMBERING ....................................................................................................8

3.1.1

SHORT NAMES....................................................................................................8

3.2

POWER SUPPLY REQUIREMENTS............................................................................9

3.3

TERMINAL SPECIFICATION .......................................................................................9

3.4

GENERATOR VOLTAGE / FREQUENCY SENSING.....................................................9

3.5

INPUTS......................................................................................................................9

3.5.1

DIGITAL INPUTS..................................................................................................9

3.6

OUTPUTS................................................................................................................10

3.6.1

OUTPUTS A & B (FUEL AND START)..................................................................10

3.6.2

CONFIGURABLE OUTPUTS C & D (LOAD SWITCHING)......................................10

3.6.3

CONFIGURABLE OUTPUTS E, F & G..................................................................10

3.7

COMMUNICATION PORTS.......................................................................................10

3.8

ACCUMULATED INSTRUMENTATION......................................................................10

3.9

SOUNDER................................................................................................................11

3.10

DIMENSIONS AND MOUNTING .............................................................................11

3.10.1

FIXING CLIPS....................................................................................................12

3.10.2

CABLE TIE FIXING POINTS................................................................................13

3.10.3

SILICON SEALING GASKET...............................................................................13

3.11

APPLICABLE STANDARDS ...................................................................................14

4

INSTALLATION ......................................................................................... 15

4.1

USER CONNECTIONS..............................................................................................15

4.2

TERMINAL DESCRIPTION........................................................................................16

4.2.1

DC SUPPLY, FUEL AND START OUTPUTS, OUTPUTS E,F,G..............................16

4.2.2

MSCMAGNETIC PICKUP, CANAND EXPANSION................................................16

4.2.3

LOAD SWITCHING AND MAINS VOLTAGE SENSING..........................................17

4.2.4

BUS VOLTAGE SENSING...................................................................................17

4.2.5

MAINS AND BUS CURRENT TRANSFORMERS...................................................18

4.2.6

CONFIGURABLE DIGITAL INPUTS.....................................................................19

4.2.7

PC CONFIGURATIONINTERFACE CONNECTOR................................................20

4.2.8

EXPANSIONINTERFACE CONNECTOR..............................................................20

4.2.9

RS485 CONNECTOR..........................................................................................21

4.2.10

LED INDICATORS AND LOGO INSERT...............................................................22

4.3

TYPICAL WIRING DIAGRAMS...................................................................................23

4.3.1

SINGLE MAINS, MULTIPLE GENERATORS ........................................................24

4.3.2

DUAL MAINS, MULTIPLE GENERATORS............................................................25

4.3.3

MULTIPLE MAINS, MULTIPLE GENERATORS ....................................................26

5

OPERATION .............................................................................................. 27

5.1

CONTROL................................................................................................................27

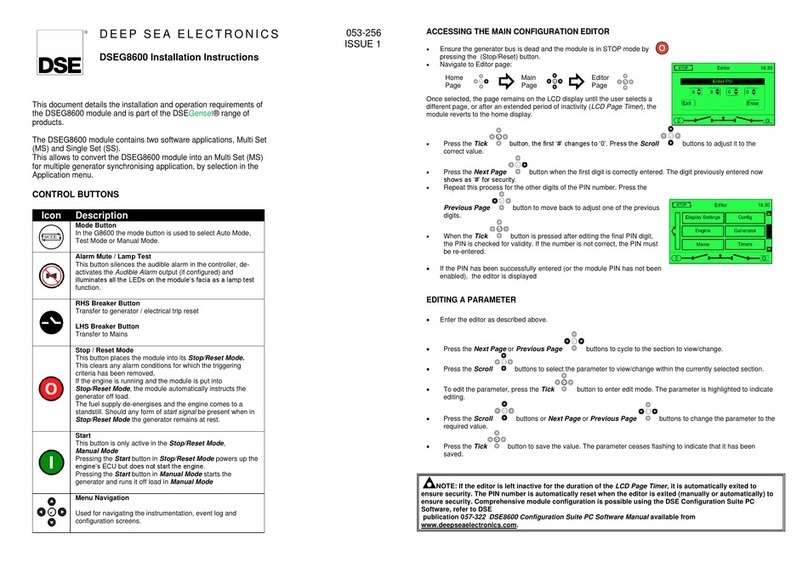

5.1.1

DESCRIPTION OF CONTROLS ..........................................................................28

6

CONTROL PUSH-BUTTONS...................................................................... 29

6.1

MANUAL OPERATION..............................................................................................31

6.2

AUTOMATIC OPERATION........................................................................................33