FHP AHP 641-224 User manual

1

I/O ZONE 560/583

641-224

641-242

641-237

USERS GUIDE

Hot Gas Re-Heat Valve On/Off:.................................15

THE ZONE CONTROLLER......................4 Modulating Re-Heat Valve:..........................................16

Filter:..............................................................................16

SPECIFICATIONS ................................5

Heating and Cooling – (1 and 2 Compressor Stages): 16

The heating will be enabled whenever:.......................17

CONTROLLER COMPONENTS...............6 The cooling will be enabled whenever: ......................17

LED Indicators..............................................................6

DIP and Rotary Switches...............................................7 Reversing valve:.............................................................17

Jumpers and settings......................................................8

Supplemental Electric Heating Stage: ......................... 17

LONWORKS® CARD OPTION...............9 Discharge Air Temperature: ........................................18

High Discharge Air Temp:..........................................18

WATER TO AIR OPERATION..............10 Low Discharge Air Temp:..........................................18

Discharge Air Sensor Failure:..................................... 18

General Description.......................................................10 Discharge Air Control...................................................18

Key Features and Benefits.............................................10 Single Outside Air Temperature (OAT) Reset: ..........19

Multiple Outside Air Temperature (OAT) Reset:.......19

Inputs ..............................................................................11 Leaving Water Temperature:.......................................20

Outputs............................................................................11 High Leaving Water Temp:........................................20

Low Leaving Water Temp:......................................... 20

Leaving Water Sensor Failure: ...................................20

Control & Status Parameters and Alarms...................11

Control.........................................................................11

Status...........................................................................12 WATER TO WATER OPERATION........25

Alarms.........................................................................12

GENERAL DESCRIPTION...................27

SEQUENCE OF OPERATION ...............13 Inputs .......................................................................... 27

Outputs........................................................................27

Run Conditions: .............................................................13

Occupied Mode ...........................................................13

Unoccupied Mode (night setback):..............................13 CONTROL & STATUS PARAMETERS

AND ALARMS.....................................28

Zone Temperature .........................................................14 Status and Control....................................................... 28

High Zone Temp: ........................................................14 Alarms ........................................................................28

Low Zone Temp:.........................................................14

Zone Sensor Failure: ...................................................14

SEQUENCE OF OPERATION...............29

Zone Setpoint Adjust:....................................................14

Run Conditions:.............................................................29

Zone Unoccupied Override:..........................................14 Occupied Mode........................................................... 29

Unoccupied Mode (night setback):............................. 29

Freeze Protection: ..........................................................15 Auto Changeover Mode..............................................29

Digital Input Mode......................................................30

Fan:..................................................................................15 BAS Mode..................................................................30

Constant Volume.........................................................15

VAV............................................................................15 Lead - Lag Compressor operation ...............................31

Compressor 1 Runtime:..............................................31

Zone Humidity:..............................................................15 Compressor 2 Runtime:..............................................31

Table of Contents

2

Pump Control (optional)................................................31

Pump Runtime Alarm:.................................................31

Load Water (Entering) Temperature: .........................32

Load High Temp: ........................................................32

Load Low Temp:.........................................................32

Load Sensor Failure: ...................................................32

Source Water (Leaving) Temperature:........................32

Leaving High Temp: ...................................................32

Leaving Low Temp:....................................................32

Leaving Sensor Failure:...............................................32

BACview Termination Detail........................................35

RS-Sensor Termination Detail......................................37

NOTES................................ Error! Bookmark not defined.

NOTES ...........................................................................41

3

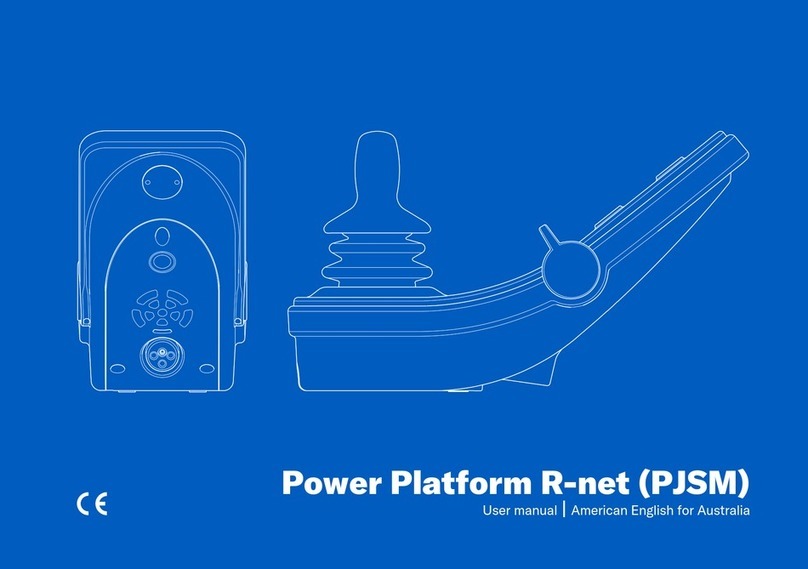

The Zone Controller

The Zone control board also known as DDC

and shown in figure 1 is used in most

configure to order applications.

It is BACnet® native which makes it flexible

and easy to integrate into existing Building

Automation Systems (BAS). The main

difference between the 560 and the I/O 583

is the Analog Output (AO) plug enclosed in

figure 1.

The controller is programmed in the factory

with software versions that suit the different

applications FHP offers. User settings such

as the time and test and balance set points

shall be set up during the installation and

commissioning process at the job site.

Figure 1 - Zone Controller

Analog plug enclosed in red box on figure above is only available on Zone I/O 583.

4

Specifications

Power: 24VAC ± 10%, 50-60Hz, 20VA power consumption

(Single Class II 70VA or 100VA option available)

Physical: Rugged plastic housing protects circuitry.

Environmental

Operating Range: 40° to 130°F (-17.8° to 54.4°C); 10 to 90% relative humidity, non-condensing

Digital Outputs: Five digital outputs relay contacts rated at 1A resistive @ 24VAC; configured as dry contact,

normally open.

Universal Inputs: 8 inputs. Inputs 1 and 2 are configurable for 0-5VDC, 10K ohm thermistor,

or dry contact; inputs 3 and 4 support thermistor or dry contact only; inputs 5 and 6 support

thermistor, dry contact, or LogiStat. Inputs 7 and 8 are used for 1-10K adjustment pots or dry

contacts.

Standard Comm Port: 3-pin port configurable for ARC156 (BACnet-over- ARC156) or

Communication EIA-485communications (BACnet MS/TP, Modbus RTU, orN2).

Ports: Rnet Port: 4-pin port for interface with remote mounted BACview6 or RS sensors

Local Access Port: For local communication with a laptop computer running WebCTRL or

for communication with a BACview6.

Status Indication: Visual (LED) status of network communication, running, errors, power, and

all digital outputs

Battery: Lithium 3V coin cell battery, CR2032, provides a minimum of 10,000 hours of

Data retention during power outages

Protection: Surge and transient protection circuitry for power and communications.

Listed by: FCC Part 15 - Subpart B - Class A. Pending listings at the time of publishing

this document: UL 916 (PAZX), cUL C22.2 No. 205-M1983 (PAZX7), CE (1997).

Weight: 0.6 lbs. (0.27 Kg).

Overall

Dimensions: 5-1/16” (width) by 5-11/16” (height) by 1-1/2” (recommended panel depth).

129mm (width) by 144mm (height) by 38mm (recommended panel depth).

Mounting Hole

Dimensions: Two mounting holes center line as at left with 5-9/16” (141mm)

Spacing (height)

5

6

Controller ComponentsController Components

LED IndicatorsLED Indicators

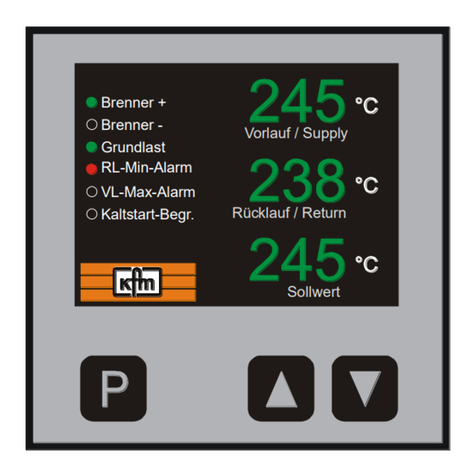

The DDC controller is equipped with three

bank sets of LED that help the user

diagnose problems and or identify normal

operation.

The DDC controller is equipped with three

bank sets of LED that help the user

diagnose problems and or identify normal

operation.

Figure 2 - Network LEDsFigure 2 - Network LEDs

The first bank is located in the upper left

hand corner as shown in the figure 2. They

flash repeatedly when the controller is

communicating with the network and usually

service support refers to them as Rx and Tx.

The first bank is located in the upper left

hand corner as shown in the figure 2. They

flash repeatedly when the controller is

communicating with the network and usually

service support refers to them as Rx and Tx.

The second bank is located on the upper

right hand corner of the controller as shown

in figure 3. The first one from top to bottom

is normally lit (on) while the controller is

powered the second is the heart beat and

will flash during normal operation, the third

LED will remain off and will lit red in case

there is an error in the controller.

The second bank is located on the upper

right hand corner of the controller as shown

in figure 3. The first one from top to bottom

is normally lit (on) while the controller is

powered the second is the heart beat and

will flash during normal operation, the third

LED will remain off and will lit red in case

there is an error in the controller.

Figure 3 - Power LEDs

In addition, when downloading new or

modified versions of software these LEDs

will flash on and off indicating new files are

being written to its non-volatile memory.

In addition, when downloading new or

modified versions of software these LEDs

will flash on and off indicating new files are

being written to its non-volatile memory.

Figure 4 – Digital Output LEDs

The Third Bank of LEDs are located on the

bottom right corner of the controller as

shown on figure 4 (right) and their purpose

is to show the status of individual Digital

Outputs (DO) as they are energized

DIP and Rotary Switches

Two sets of switches can be found on the

controllers, they must be set properly to

allow correct operation of the unit.

The first set are rotary switches, as shown in

figure 5, is located on the left hand corner

near the top and their function is to provide

the controller address it always convenient

to identify the rotary for the tens and the

rotary for the ones as shown in figure 6.

The second set is located on the top left

hand corner of the controller and it is used

for two purposes:

(1) SW1 and SW2 set the baud rate of the

communications port on the controller:

BAUD RATE SW1 SW2

9600 Off Off

19.2K Off On

38.4K On Off

76.8K On On

Figure 5 – Controller Address Rotary DIP switch

Figure 6 – Rotary switches

Figure 7 – DIP Switches

(2) SW3 and SW4 enable different

supported protocols on the controller

additional hardware is needed for LonTalk®.

IMPORTANT:

Controllers must be

addressed correctly

for multiple units to

work on a network.

7

8

PROTOCOLS SW3 SW4

BACnet®MS/TP Off Off

N2 On Off

Modbus Off On

Option Card On On

Typical DIP switch for LonTalk® (Option

Card) is shown in figure 8.

Jumpers and settings

Controllers come equipped with a series of

jumpers which allow different types of inputs

to be terminated in a particular point.

Most inputs allow thermistor or dry contact

input devices to be terminated in them,

however IN1 and IN2 can be used as analog

or digital input points and their available

options are as follows:

0-5 VDC Analog Input

Thermistor

Dry Contact

FHP sets most switches in the factory,

however there are certain cases where a

particular sensor is required by the

customer, therefore it is important for the

installer to understand jumper settings and

their relationship with unit configuration and

operation. Figure 9 shows the location of the

jumpers on the controller.

Figure 8 - LonTalk® DIP Settings

EIA-485

BACnet

over ARC156

Figure 9 - Jumper setting for LonTalk® only.

Figure 10 - Jumper Settings

1234

IMPORTANT:

The LonTalk® card

must be installed.

Jumpers set up will be

cover under the jumper

section.

ON

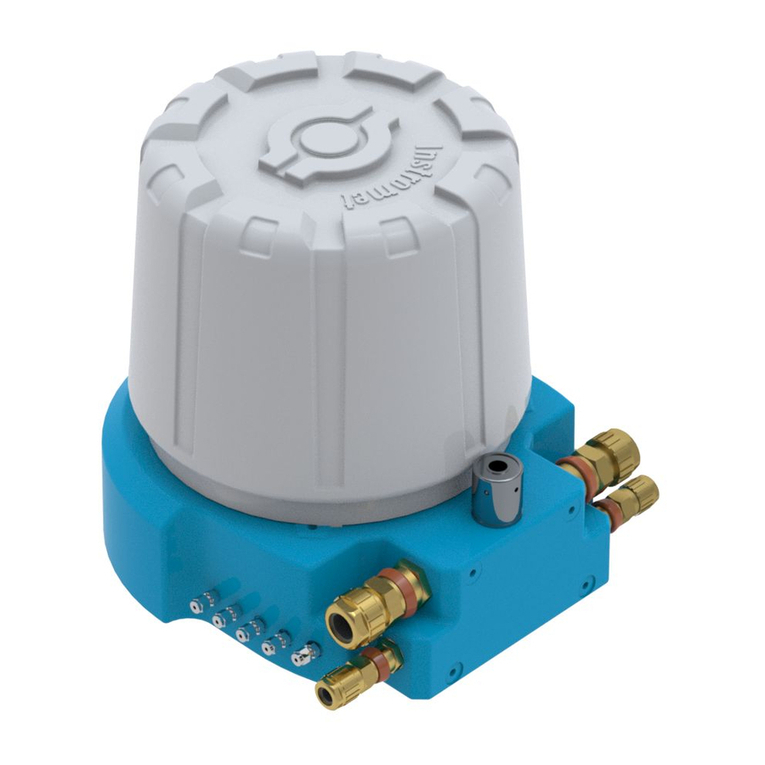

LonWorks® card option

LonWorks® is a network platform that allows any facility or to integrate sub-systems using a

common system architecture and infrastructure.

This platform provides fully open operability of the components within a system or sub-system,

this enables the facility owner to utilize different vendors and still have the capability of

integrating their system into one single server or front end.

The LON card option is available for both controllers 641-224 and 641-242.

The Lon card connects to the option card port as shown in figure 11.

Figure 11 - LonTalk® Card – 641-237

9

Water to Air Operation

General Description

The Heat Pump Factory mounted I/O Zone 560 or 583 DDC Controllers are factory configured

with the Water to Air application program and factory installed in the unit to be job site

configureable to run.

The unit will operate in a 100% stand-alone control mode or connect to a Building Automation

System (BAS) using open protocols BACnet® (ARCNET and MS/TP), Modbus RTU, N2 or

LonWorks® (additional network interface board required for LonWorks® option).

The point mapping to all of these protocols is available in www.fhp-mfg.com and can be pre-set,

so that the protocol and baud rates desired can be easily field-selected and commissioned

without the need for any additional downloads or technical assistance.

The DDC Controller also supports communications to intelligent RS Room sensors and

BACview keypad/display panels.

Key Features and Benefits

I/O point count: 5 Digital outputs and 6 Universal inputs

Powerful high speed microprocessor with 1MB Flash memory and 1MB of battery-backed

RAM

Built-in protocol support: BACnet® (ARCNET and MS/TP), Modbus, N2 and LonWorks®

(additional network interface board required for LonWorks® option)

Built-in local access support: BACview6 keyboard/display and Intelligent RS Room

sensors

On-board lithium battery holds Controller time clock settings

Program archived in non-volatile memory allows unit to be ready after long periods of

power outages.

10

Inputs

RS Room temperature sensor (Rnet)

RS Room temperature sensor Set point adjust (Rnet)

RS Room temperature sensor Occupancy override (Rnet)

Discharge air temperature sensor

Leaving water temperature sensor

Unit Protection module (UPM) Alarm codes (7 safety shutdown alarms)

Unit Filter status (optional)

Unit Enable manual control (optional DI Enable)

Outputs

Unit blower control

Reversing Valve

Cooling Stage 1

Cooling Stage 2 (Comp 2 Circuit or Comp1 Stage 2)

Humidity control output (optional Hot gas re-heat)

Auxiliary/Emergency Heating Stage (optional Electric Heat)

Control & Status Parameters and Alarms

Control

BACview occupancy schedule

System control: Schedule, Manual ON, BAS command or DI Enable

Room temperature occupied cooling/heating set point

Room temperature unoccupied cooling/heating set point

Unit blower control

Reversing valve control

Compressor 1 control

Compressor 2 control (Comp 2 Circuit)

Unit Enable manual control (optional)

Humidity Control ( hot gas re-heat optional)

Auxiliary/Emergency Electric heat output control (optional)

11

Status

Cooling/Heating control status

Cooling/Heating percentage (0-100%)

Room temperature

Discharge air temperature

Leaving water temperature

Changeover temperature

Unit filter status (optional)

Fan-Hours runtime counter (filter replacement indicator)

Fan starts counter

Comp 1 starts counter

Comp 2 starts counter (Comp 2 Circuit)

Alarms

Room temperature high/low differential

Leaving water temperature high/low trip

Discharge air temperature high/low trip

Sensor failure alarm

Unit filter Runtime trip (optional)

Comp 1 Runtime trip

Comp 2 Runtime trip (Comp 2 Circuit)

Freeze Stat sensor UPM alarm (optional)

Low pressure sensor UPM alarm

High pressure sensor UPM alarm

Low pressure sensor UPM alarm (Comp 2 Circuit)

High pressure sensor UPM alarm (Comp 2 Circuit)

Condensate overflow UPM alarm

High/low voltage UPM alarm

12

13

Sequence of Operation

Run Conditions:

The unit will run according to a user definable time schedule, dry contact (physical digital input

number 1), manual ON command from BACview control interface, timed local override from

Zone temperature sensor or via third party front end start command (software point). When

commanded to run the unit will operate in the following modes:

Occupied Mode: The unit will maintain

A 74°F (adj.) Cooling setpoint

A 70°F (adj.) Heating setpoint

Unoccupied Mode (night setback): The unit will maintain

A 90°F (adj.) Cooling setpoint.

A 55°F (adj.) Heating setpoint.

The unit will operate and adjust the setpoints according to the heating and cooling limits which

can be changed by the technical agent during the commissioning process if needed. The factory

default limits are the following:

Occupied Limits:

75 °F Heating High

60 °F heating Low

85 °F Cooling High

65 °F Cooling Low

Unoccupied Limits:

70 °F Heating High

50 °F Heating Low

95 °F Cooling High

80 °F Cooling Low

IMPORTANT: It is important not to overlap these limits on their respective modes (occupied and

unoccupied), overlapping may result in unit cycling between heating and cooling.

Zone Temperature

The occupant will be able to see the zone temperature on the sensor LCD display in addition the

user will be able to see other parameters that have been configured in the controller such as

alarm status, alarm codes, Inputs and outputs status among others.

NOTE: These codes and values vary from version to version for additional information on what

is available on the RS-Pro sensor please check its commissioning BACview manual in our web

site www.fhp-mfg.com.

Alarms will be provided as follows:

High Zone Temp: If the zone temperature is greater than the cooling setpoint plus a user

definable amount (adj.), the factory default for this amount is 10.

Low Zone Temp: If the zone temperature is less than the heating setpoint minus a user

definable amount (adj.) the factory default for this amount is 10.

Zone Sensor Failure: If Zone sensor outside of normal operating limits, typically produced by a

wire failure between the sensor and the controller.

Zone Setpoint Adjust:

The occupant will be able to adjust the zone temperature heating and cooling setpoints at the

zone sensor (when RS Plus or RS Pro sensors are used). Zone sensor adjustment will allow for

+/-5°F of adjustment. If RS Standard sensor is used, then setpoint adjustments must be done at

the BACview keyboard/display or through BAS third party control.

Zone Unoccupied Override:

A timed local override control will allow an occupant to override the schedule and place the unit

into an occupied mode for an adjustable period of time (presets at 1-2-4 or 6 hours). At the

expiration of this time, control of the unit will automatically return to the software schedule or

third party control.

14

Freeze Protection:

The unit shall shut down and generate an alarm upon receiving a freezestat status.

Fan:

Constant Volume

In the occupied mode, the fan shall run continuously or cycle with the compressor(s) depending

on fan mode settings. In the unoccupied mode, fan cycles as required for unoccupied heating

and cooling setpoints while in night setback.

Variable Frequency Drive

On units equipped with a factory or field installed Variable Frequency Drive (VFD) the controller

will command the VFD signal to maintain a particular ( User Definable) value of Static pressure,

this is typical on VAV applications with discharge air control requirements.

Zone Humidity:

If specified the controller has the capability to monitor and control the zone humidity via the hot

gas re-heat option.

There are two hardware options for humidity control:

Hot Gas Re-Heat Valve On/Off: This valve is controlled based on a 60% relative humidity

setpoint (User Definable) and will only be energized once the temperature set points are

satisfied, this valve is a two position valve and therefore is an on/off operation.

Alarms will be provided as follows:

High Zone Humidity: If the zone humidity is greater than 75% (adj.).

Low Zone Humidity: If the zone humidity is less than 35% (adj.).

The controller prioritizes the sensible load and therefore if temperature rises or decreases

during the re-heat operation the controller will switch to heating or cooling operation.

15

Modulating Re-Heat Valve:

This valve is an analog device and has the capability to modulate the amount of hot gas that is

allowed through the re-heat coil, thus allowing control of the discharge air temperature to a user

defined setpoint.

The operation is similar to the on/off control except once the space temperature is satisfied the

controller will monitor the space humidity if the value is greater than the setpoint the controller

will modulate the valve to meet a particular a desired discharge air temperature on zone

applications only.

A typical application of modulating re heat valves can be seen on Discharge Air Control systems

where the unit is required to maintain a particular value of supply air temperature (neutral air).

For this particular type of units the unit will only discharge air to meet the specific setpoint, this

operation is done via a reverse acting PID closed loop, and its sequence of operation is

described in detail under the Discharge air section of this document.

Filter:

Based on fan runtime, a filter alarm message is generated after a user definable amount (adj.

factory default 2000 hours) or can be enabled by an optional differential pressure switch.

Heating and Cooling – (1 and 2 Compressor Stages):

The controller will measure the zone temperature and stage the compressor(s) to maintain its

setpoint. To prevent short cycling, there will be a 5 minute delay between compressor stages (if

equipped with 2 compressors). Additionally, there will be a 1 minute delay when transitioning

between heat and cool modes. The compressor will run subject to internal safeties and controls

provided by UPM board.

16

The heating will be enabled whenever:

The fan output is on.

AND the reversing valve is in heat mode (de-energized).

The cooling will be enabled whenever:

The fan output is on.

AND the reversing valve is in cool mode (energized).

Reversing valve:

The reversing valve is energized on a call for cooling and will remain energized until a call for

heating. Upon a call for heating, the reversing valve is de-energized and remains de-energized

until a call for cooling or a call for re-heat on units with humidity (on/off) control option. The

compressor will be disabled and remain off for 10sec after the reversing valve has changed

position.

Alarms will be provided as follows:

Compressor 1 Runtime Exceeded: Compressor 1 runtime exceeds a user definable limit (adj.).

Compressor 2 Runtime Exceeded: Compressor 2 runtime exceeds a user definable limit (adj.).

Supplemental Electric Heating Stage:

The controller will measure the zone temperature and stage the heating to maintain its heating

setpoint should the compressors not meet the heating demand. To prevent short cycling, the

stage will have a 5 minute delay allowing compressor stages to meet the needs of the space.

The heating will be enabled whenever:

The heat pump is in heating mode.

AND the zone temperature is below heating setpoint.

AND the fan is on.

17

The controller will only allow supplemental heating if the unit is configured to allow this

operation, units equipped with hot gas re heat valves or damper control enable will not have

supplemental electric heat functionality.

Discharge Air Temperature:

The controller will monitor the discharge air temperature to be located at discharge side of coil. If

the supplemental heating is installed then sensor will be in the discharge side of heating coil.

Alarms will be provided as follows:

High Discharge Air Temp: If unit running in cool mode and the discharge air temperature is

greater than 70°F (adj.).

Low Discharge Air Temp: If unit running in heat mode and the discharge air temperature is

less than 75°F (adj.).

Discharge Air Sensor Failure: If discharge air sensor outside of normal operating limits.

Discharge Air Control

On units with factory mounted modulating re-heat valves the controller will operate the unit to

maintain a particular discharge temperature setpoint. The discharge air temperature sensor

(DATS) will be located at discharge side of coil preferable 3/4 downstream of the total length of

the duct work.

The controller can operate on single or Multiple Outside Air Temperature Reset, the controller

will monitor the value of the Outside Air temperature via a BACnet point or via a physical point

terminated in one of the controllers available inputs. The controller will stage the unit’s

compressors and modulate the re-heat valve mode to maintain the Discharge Air Setpoint (User

adjustable).

Two modes are selectable for Discharge Air Control (DAC) Applications are as follows:

Single Outside Air Temperature Reset point

Multiple Outside Air Temperature Reset points

18

Single Outside Air Temperature (OAT) Reset:

OAT> OAT Reset °F (adj.):

Controller will initiate cooling call to run compressors and modulate Re-heat Valve only when

the outside air temperature is greater than 55°F (Factory Default)

OAT< OAT Reset °F (adj.):

Controller will initiate a call for heating. Straight cool units will run their fan continuously or if the

unit is equipped with a Variable Frequency Drive (VFD) it will command the drive to maintain its

static pressure setpoint.

Multiple Outside Air Temperature (OAT) Reset:

OAT Reset °F < OAT< OAT Reset 2 °F (adj.):

Controller will command the unit to run free-cooling operation the fan will run continuously or if

the unit is equipped with a Variable Frequency Drive (VFD) it will command the drive to maintain

its static pressure setpoint.

OAT Reset 2 °F < OAT< OAT Reset 3 °F (adj.):

Controller will command the unit to run single stage of cooling operation, the valve will be set for

cooling operation and the first compressor will be commanded on, the fan will run continuously

or if the unit is equipped with a Variable Frequency Drive (VFD) it will command the drive to

maintain its static pressure setpoint and the re-heat valve will be modulated to maintain a 65°F

(Factory Default (adj.)) discharge air temperature setpoint .

OAT > OAT Reset 3 °F (adj.):

19

20

Controller will command the unit to run full mechanical cooling operation (on units with more

than two compressors please check with factory), the valve will be set for cooling operation and

both first and second compressors will be commanded on, the fan will run continuously or if the

unit is equipped with a Variable Frequency Drive (VFD) it will command the drive to maintain its

static pressure setpoint and the re-heat valve will be modulated to maintain a 65°F (Factory

Default (adj.)) discharge air temperature setpoint .

Leaving Water Temperature:

The controller will monitor the leaving water temperature.

Alarms will be provided as follows:

High Leaving Water Temp: If compressor(s) is running and the leaving water temperature is

greater than 135°F (adj.).

Low Leaving Water Temp: If compressor(s) is running and the leaving water temperature is

less than 35°F (adj.).

Leaving Water Sensor Failure: If leaving water sensor outside of normal operating limits.

Should a High or Low Leaving Water Temperature Alarm occur, the call for heat or cool will be

removed.

UPM Fault Monitor:

The controller will monitor the Unit protection Module (UPM) fault input.

Upon hard lock out alarm, compressors are disabled by FHP UPM board.

Alarms will be provided as follows:

HP1: High Pressure Alarm (circuit 1)

HP2: High Pressure Alarm (circuit 2)

LP1: Low Pressure Alarm (circuit 1)

LP2: Low Pressure Alarm (circuit 2)

FRE: Freeze Alarm

CON: Condensate Alarm

BRN: Brownout Alarm

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

HEIDENHAIN

HEIDENHAIN ND 287 - GUIDE Quick reference guide

Redarc

Redarc Tow-Pro Elite instruction manual

National Instruments

National Instruments PXIe-8861 Getting started guide

Endress+Hauser

Endress+Hauser Liquiline CM442R operating instructions

Flexitron

Flexitron Webdyn SunPM user manual

Advantech

Advantech ADAM-5630 Series user manual