Getting Started

1--3

Getting Started

DL305 User Manual, Rev. D

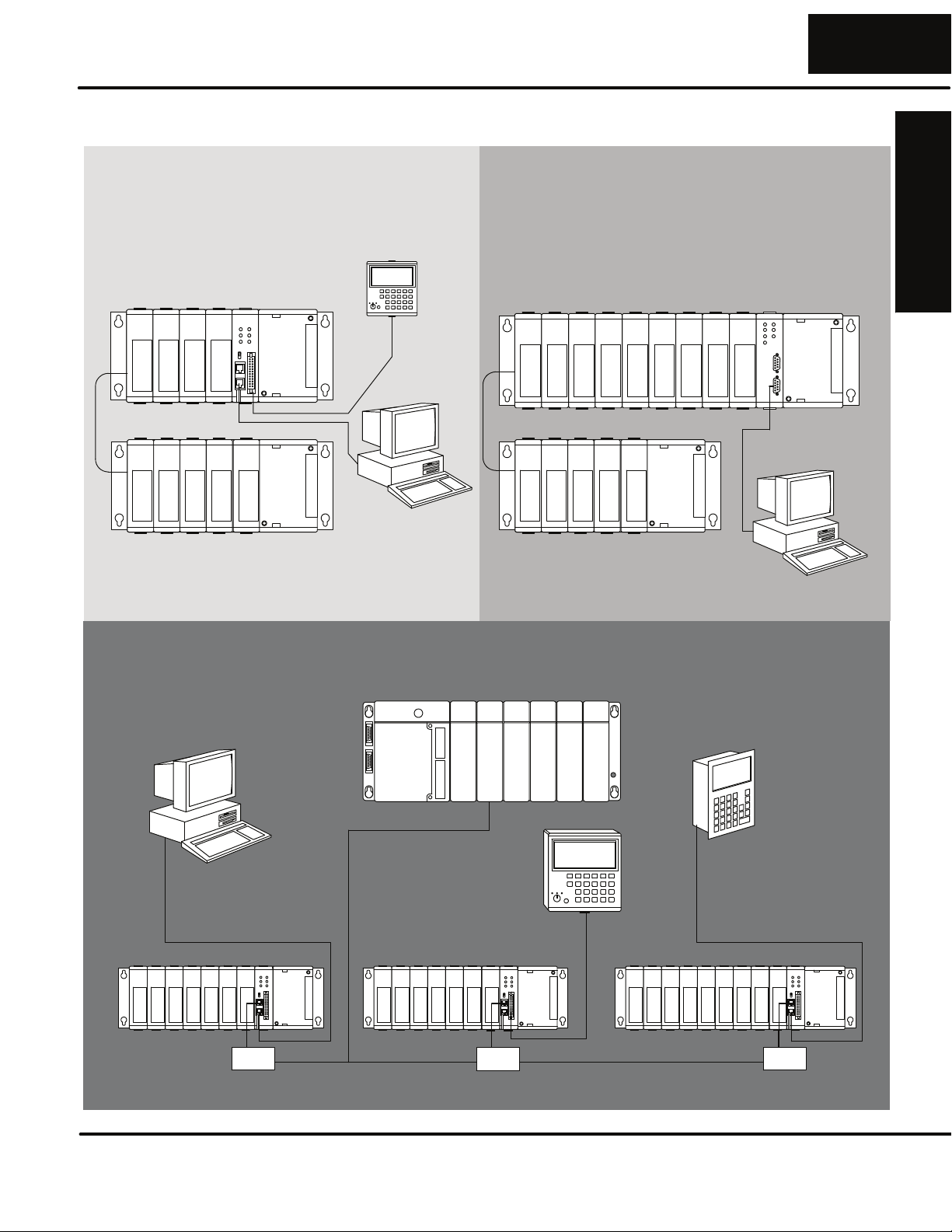

Ch 1: Getting Started -- provides an overview of all the components that can be

used to make up one or many DL305 systems. This chapter shows the basic

concepts of how the pieces fit together. It also explains the DL305 part numbering

system, which will help you quickly identify the various types of modules.

Ch 2: Installation and Safety Guidelines -- shows you how to prepare for system

installation, and gives you guidelines for providing a safe environment for your

personnel and process. Be sure to read this chapter so potential safety problems

can be avoided. In this chapter you will find topics you must consider when installing

a system, the environmental specifications, component dimensions, safety

guidelines, installation guidelines, etc.

Ch 3: DL330/DL330P/DL340 CPU Specifications -- provides details of each of the

DL305 CPUs. This chapter contains the operating specifications for the CPUs,

detailed information on the different types of program storage media available, and

some basic procedures needed to get the CPU ready for programming.

Ch 4: System Configuration, Bases and Expansion Bases -- provides selection

and installation criteria for Local I/O and Local Expansion I/O. This chapter also

discusses the system power budget, which is an important part of the planning and

installation process.

Ch 5: I/O Module Selection Criteria -- contains specific considerations which affect

I/O selection such as sinking, sourcing, and temperature derating characteristics.

Ch 6: Discrete Input Modules -- explains each term you will find on our specification

sheets, provides specifications, wiring diagrams and derating curves (where

applicable) for the DL305 Discrete Input Modules.

Ch 7: Discrete Output Modules -- explains each term you will find on our

specification sheets, provides specifications, wiring diagrams and derating curves

(where applicable) for the DL305 Discrete Output Modules.

Ch 8: System Operation -- explains how the DL305 CPUs control the system

operation. This includes information on I/O updates, application program execution

and memory structure.

Ch 9 : RLL Programming Concepts -- explains the basic concepts used in RLL

programming.

Ch 10: RLLPLUS Programming Concepts -- explains the basic concepts used in

the RLLPLUS programming. This programming method greatly reduces program

design time and simplifies machine startup and troubleshooting.

Ch 11: Instruction Set -- explains how each individual instruction operates.

Ch 12: RLLPLUS Instruction Set -- explains the instructions used with the DL330P

CPU. It also shows some instructions that operate differently with this CPU.

Ch 13: Maintenance and Troubleshooting -- is a guide designed to aid you in

diagnosing, repairing and avoiding system problems.

Appendices A -- D -- there are several appendices referred to throughout the

manual. These include things such as a quick start, error code listing, instruction

execution times, etc.

We realize even though we strive to be the best, we may have arranged our

information in such a way you cannot find what you are looking for. If you need

assistance, please, call us at 1--800--633--0405. Our technical support group is glad

to work with you in answering your questions. They are available weekdays from

8:00 a.m. to 6:00 p.m. eastern standard time. If you find a problem with any of our

products, services or manuals, please fill out and return the Suggestions card

included with this manual.

How this Manual is

Organized

Technical

Assistance