FIBERROAD 7 Series User manual

-

2

-

Overview

Thanks for your purchasing. Please read the Quick Installation Guide for better user

experience. Fiberroad 7 Series Industrial Ethernet Switch is environmentally hardened

at standard operating temperature range -40 to 75°C for stable operation in harsh

Industrial environment. The Industrial Switch is mini size, no fan, low power

consumption, high reliability and stability, and easy to maintain. Housed in rugged DIN

rail or wall mountable IP40 aluminum enclosures, these switches are perfect choices

for harsh environments, such as industrial networking, intelligent transportation

systems (ITS) and are also suitable for many military and utility market applications

where environmental conditions exceed commercial product specifications.

The Industrial PoE Switch can provide up to 30 watts of power per PoE+ port in

Ethernet 802.3at mode for industrial heavy-duty PoE devices, such as IP

surveillance cameras, IP phones and wireless access points. It is designed especially

for outdoor applications with 4KV~8KV surge resistance to keep continuous reliability

of the PoE systems.

The Industrial Managed Fiber Switch is high-performance layer 2 switch, with SFP

fiber ports transmitting data up to 120km from the device to control center with

effective immunity to EMI. The management function, includes STP/RSTP, MSTP,

ERPS, PoE power scheduling, PoE power management, PoE device auto-checking,

VLAN, IGMP, QoS, RMON, port mirroring, and bandwidth management etc.

Package List

The Industrial Switches is shipped with the following items. If any of these items are

missing or damaged, please contact your customer service representative for

assistance.

•

Industrial Fiber Ethernet Switch

•

Protective caps for unused SFP ports

•

DIN-Rail mounting kit

(attached to Industrial Switch’s rear panel by default)

•

Quick Installation Guide & User Manual (attached in CD)

•

Warranty card (Printed)

-

3

-

Panel Views of Industrial Switch

Front Panel View

1 2 1 3 3

5

1. PWR: Power on LED

2. Fiber: Fiber LED

3. LK/ACT: Fiber link active

4. SYS: Switch working

5. Green LED: Gigabit port speed LED

6. Yellow LED: Current port link up

7. LINK: Fiber link active

1 4

1 5

6

7

-

4

-

Top Panel View

99 10

8

8

11 10

11

12

8. PWR1: Terminal block power input 1

9. PWR2: Terminal block power input 2

10. Grounding M3 screw

11. 5V DC: Input voltage DC5V

12. RS-232 serial console port

13. Reset

910

8

13

11

12 13

-

5

-

Rear Panel View

15 17 19

15

16

18

15. Wall mounting plate

16. DIN-Rail mounting kit

17. Wall mounting hole M3 screw

18. Metal spring

19. Aluminum case for heat dissipation

-

6

-

Mounting Dimensions (unit = mm)

Small-size Industrial Switch - Unmanaged 2~5Ports

Medium-size Industrial Switch - Managed 5~10Ports

Big-size Industrial Switch - Managed 16~24Ports

-

7

-

LED Indicators

The front panel of the Industrial Switch contains several LED indicators.

The function of each LED is described in the following table:

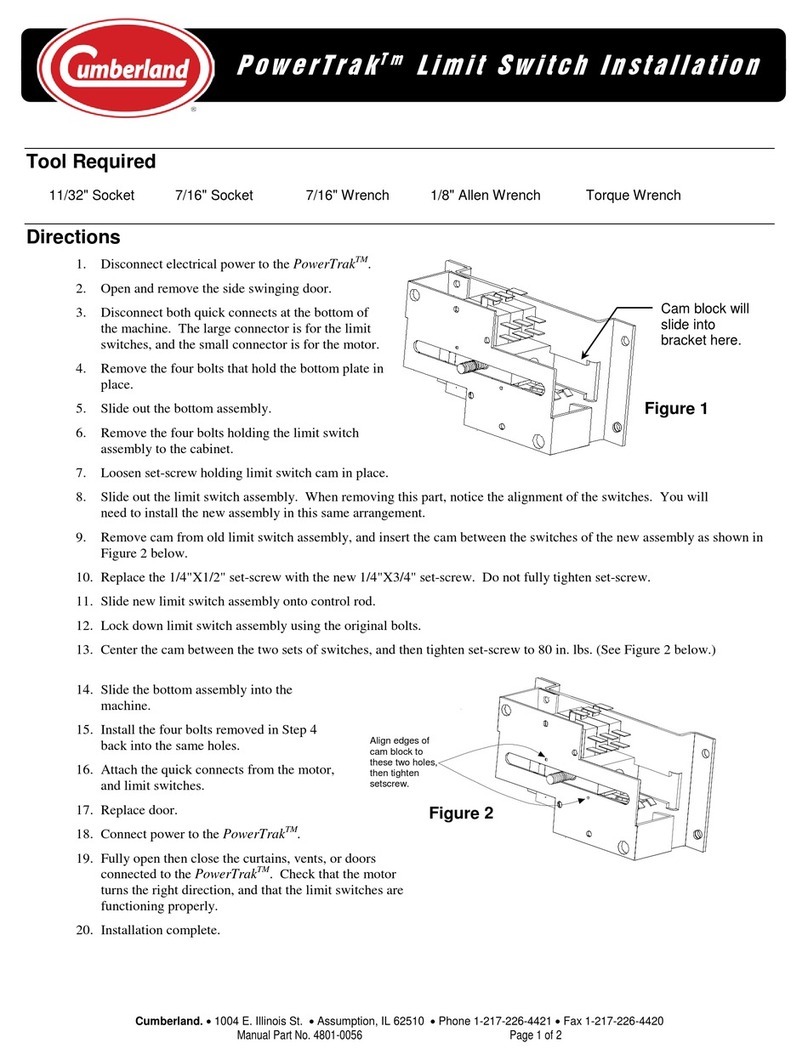

DIN-Rail Mounting

When you take the Industrial Ethernet Switchout of the package., the aluminum DIN-Rail

attachment plate should be fixed to the back panel already. If you need to re-attach

the DIN-Rail attachment plate to the industrial switch, please make sure the stiff

metal spring is situated towards the top, as shown by the following pictures.

STEP 1 ☞

Insert the top of the DIN-Rail into the

slot just below the stiff metal spring.

STEP 2 ☞

The DIN-Rail unit will snap into place as

shown in the following illustration.

* To remove the Industrial Ethernet Switch from the DIN-Rail, simply reverse STEP 1

and STEP2 above.

LED

Color

State

Description

PWR

Green

On

Power is being supplied to power input.

Off

Power is not being supplied to power input

Fiber

LK/ACT

LINK

Yellow

On

Fiber link active

Off

Fiber link not working

SYS

Green

On

Switch working

Off

Switch non-working

-

8

-

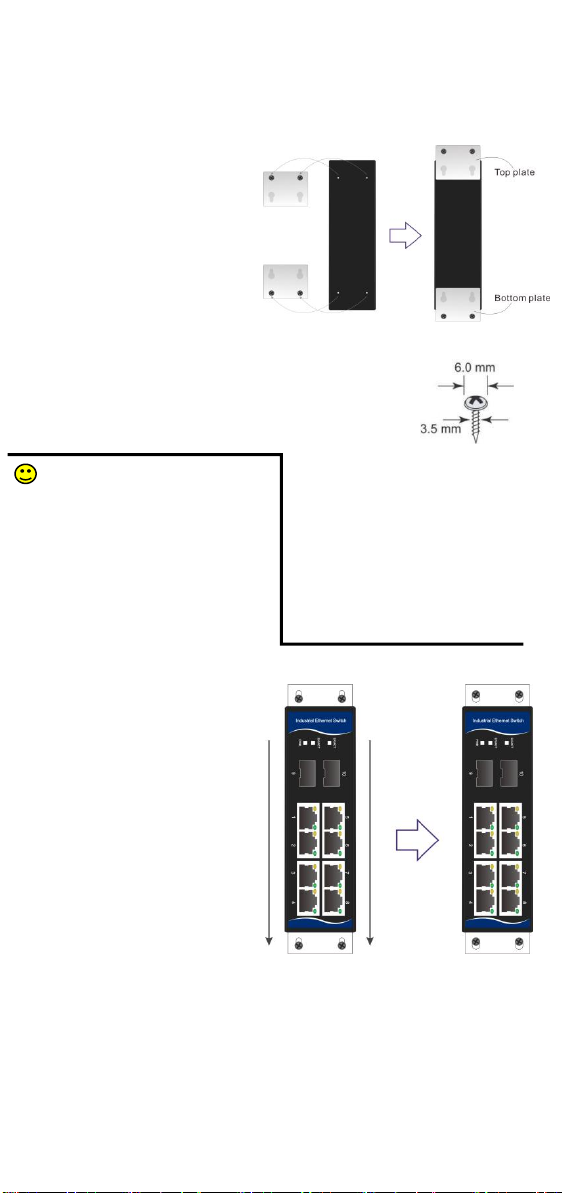

Wall Mounting

You will find it convenient to mount Fiberroad Industrial Switch on the wall for some

applications, as shown in the following figure:

STEP 1 ☞

Remove the aluminum DIN-Rail plate

from the rear panel of Industrial Switch,

and then attach the wall mount plates

with M3 screws as shown in the figure.

STEP 2 ☞

Mounting the Industrial Switch on the

wall requires 4 screws. Use the Industrial Switch, with

wall mount plates attached, as a guide to mark the correct

locations of the 4 screws. The heads of the screws should be less

than 6.0 mm in diameter, and the shafts should be less than

3.5mm in diameter as shown in the figure.

Before tightening the screws into the

wall, make sure the screw head and shank

size are suitable by inserting the screw

through one of the keyhole-shaped

apertures of the Wall Mounting Plates.

Do not screw the screws in all the way,

leave 2mm+/- to allow room for sliding

the wall mount panel between the wall

and the screws.

STEP 3 ☞

Once the screws are fixed to the wall,

insert the four screw heads through the

wide parts of the keyhole-shaped

apertures, and then slide the Industrial

Switch downwards, as indicated in the

figure. Tighten the four screws for more

stability.

-

9

-

Wiring Requirements

WARNING

Do not disconnect modules or wires unless power has been switched off or the area

is known to be non-hazardous. The devices may only be connected to the supply

voltage shown on the type plate. The devices are designed for operation with a

Safety Extra-Low Voltage. Thus, they may only be connected to the supply voltage

connections and to the signal contact with the Safety Extra-Low Voltages (SELV) in

compliance with IEC60950-1/EN60950-1.

ATTENTION

This unit is a built-in type. When the unit is installed in another piece of equipment,

the equipment enclosing the unit must comply with fire enclosure regulation

IEC60950-1/EN60950-1 (or similar regulation).

Safety First

Be sure to disconnect the power cord before installing and/or wiring your the

Industrial Switch.

Calculate the maximum possible current in each power wire and common wire.

Observe all electrical codes dictating the maximum current allowable for each wire

size. If the current goes above the maximum ratings, the wiring could overheat,

causing serious damage to your equipment.

Please read and follow these guidelines:

▶Use separate paths to route wiring for power and devices. If power wiring and

device wiring paths must cross, make sure the wires are perpendicular at the

intersection point.

NOTE: Do not run signal or communications wiring and power wiring through the same

wire conduit. To avoid interference, wires with different signal characteristics should be

routed separately.

▶You can use the type of signal transmitted through a wire to determine which wires

should be kept separate. The rule of thumb is that wiring that shares similar electrical

characteristics can be bundled together.

▶Please separate input wiring from output wiring.

▶Please label the wiring to all devices in the system.

-

10

-

Grounding the Industrial Switch

Grounding and wire routing help limit the effects of noise due to electromagnetic

interference. Run the ground connection from the ground screw to the grounding

surface prior to connecting devices.

ATTENTION

This product is intended to be mounted to a well-grounded mounting surface such as

a metal panel.

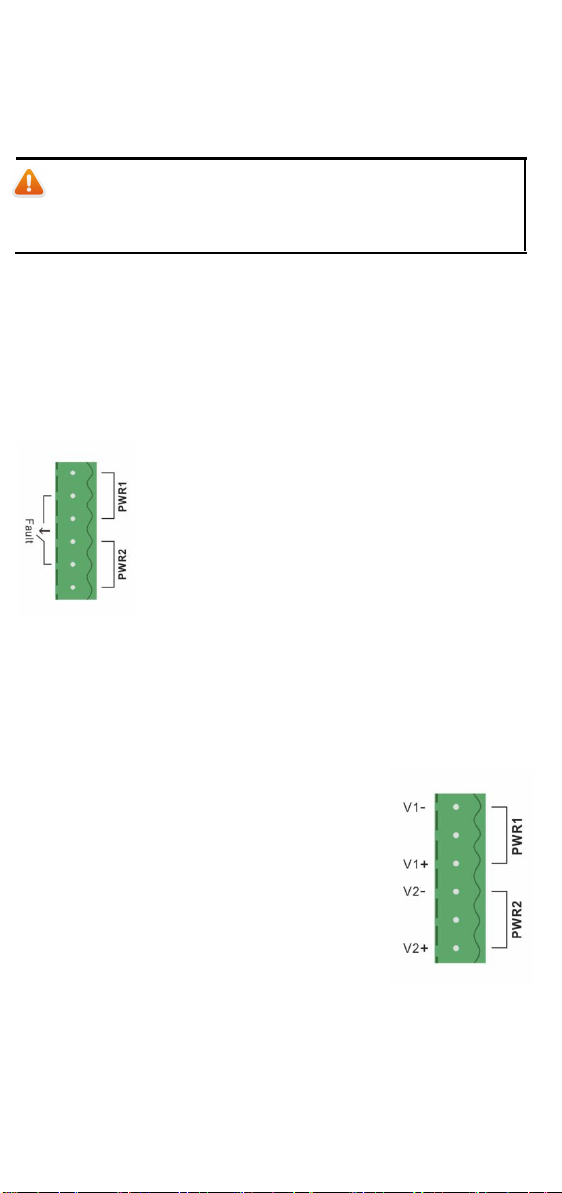

Wiring the Relay Contact (Optional)

The Industrial Switch has one relay output. The relay contact uses two contacts of the

terminal block on the Industrial Switch’s top panel. Refer to the next section for detailed

instructions on how to connect the wires to the terminal block connector, and how to

attach the terminal block connector to the terminal block receptor.

In this section, we illustrate the meaning of the two contacts used to connect the relay

contact.

FAULT✘

The relay contacts of the 2-pin terminal block connector are

used to detect user-configured events. The two wires

attached to the fault contacts form an open circuit when a

user-configured event is triggered. If a user-configured event

does not occur, the fault circuit remains closed.

Wiring the Redundant Power Inputs

The Industrial Switch has two sets of power inputs—power input 1 and power input 2.

The two terminal block connectors on the top-left of the Industrial Switch's top panel are

used for the two power inputs. The top and front views of one of the terminal block

connectors are shown here.

STEP 1 ☞Insert the negative/positive DC

wires into the V-/V+ terminals, respectively.

STEP 2 ☞To keep DC wires from pulling loose, use

a small flat-blade screwdriver to tighten the wire-clamp

screws on the front of the terminal block connector.

STEP 3 ☞Insert the plastic terminal block connector

prongs into the terminal block receptor, which is located

on the Industrial Switch’s top pane

Table of contents

Other FIBERROAD Switch manuals

Popular Switch manuals by other brands

Honeywell

Honeywell V15W2 Series installation instructions

NIVOFLOAT

NIVOFLOAT NL-100 Series user manual

Eminent

Eminent EM8038 manual

Extreme Networks

Extreme Networks EAS 200-24p Switch Hardware installation manual

NETGEAR

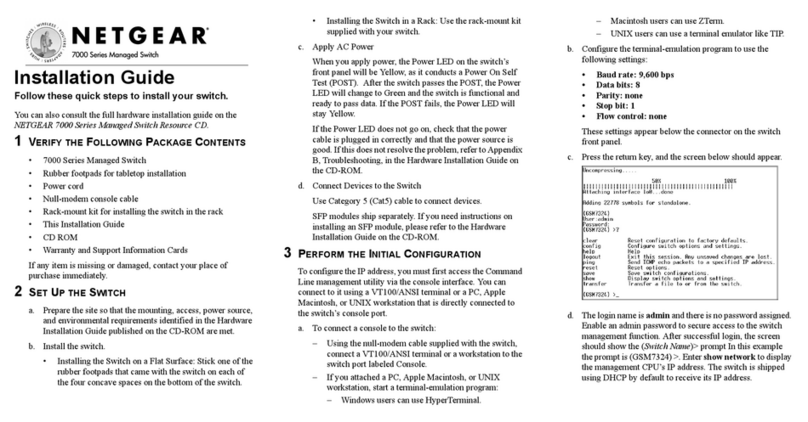

NETGEAR GSM7212 - ProSafe Switch installation guide

DIVERSITECH

DIVERSITECH CS1200 installation instructions