32333029EEN | E | 09/20

© 2020 Honeywell International Inc. All rights reserved.

SCHEDULE OF LIMITATIONS

The voltage, current, mechanical mounting, connections,

creepage, and clearance distance specifications must be as per

the instruction manual.

The switch body shall be installed using a protective cover

providing resistance to impact according EN/IEC 600790

clause 26.4.2 table 13 (after thermal endurance tests according

to clause 26.7 for relevant non-metallic cover) for equipment

grouping II and classification high risk for mechanical danger

for protective covers.

The electrical termination of the device installed in the

application shall have a suitable enclosure providing a degree

of protection of at least IP54 according to EN/IEC 6007915

clause 6.3. Creepage distances and clearance specifications

at the terminals must be taken into account when making

electrical connections. Reference table 2 of EN/IEC 6007915.

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free

of defective materials and faulty workmanship during the

applicable warranty period. Honeywell’s standard product

warranty applies unless agreed to otherwise by Honeywell

in writing; please refer to your order acknowledgement or

consult your local sales office for specific warranty details.

If warranted goods are returned to Honeywell during the

period of coverage, Honeywell will repair or replace, at its

option, without charge those items that Honeywell, in its sole

discretion, finds defective. The foregoing is buyer’s sole

remedy and is in lieu of all other warranties, expressed or

implied, including those of merchantability and fitness

for a particular purpose. In no event shall Honeywell be

liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance

personally, through our literature and the Honeywell web site,

it is buyer’s sole responsibility to determine the suitability of

the product in the application.

Specifications may change without notice. The information

we supply is believed to be accurate and reliable as of this

writing. However, Honeywell assumes no responsibility for its

use.

FOR MORE INFORMATION

Honeywell Sensing and Internet of Things services its

customers through a worldwide network of sales offices

and distributors. For application assistance, current

specifications, pricing, or the nearest Authorized Distributor,

visit sensing.honeywell.com or call:

USA/Canada +302 613 4491

Latin America +1 305 805 8188

Europe +44 1344 238258

Japan +81 (0) 367307152

Singapore +65 6355 2828

Greater China +86 4006396841

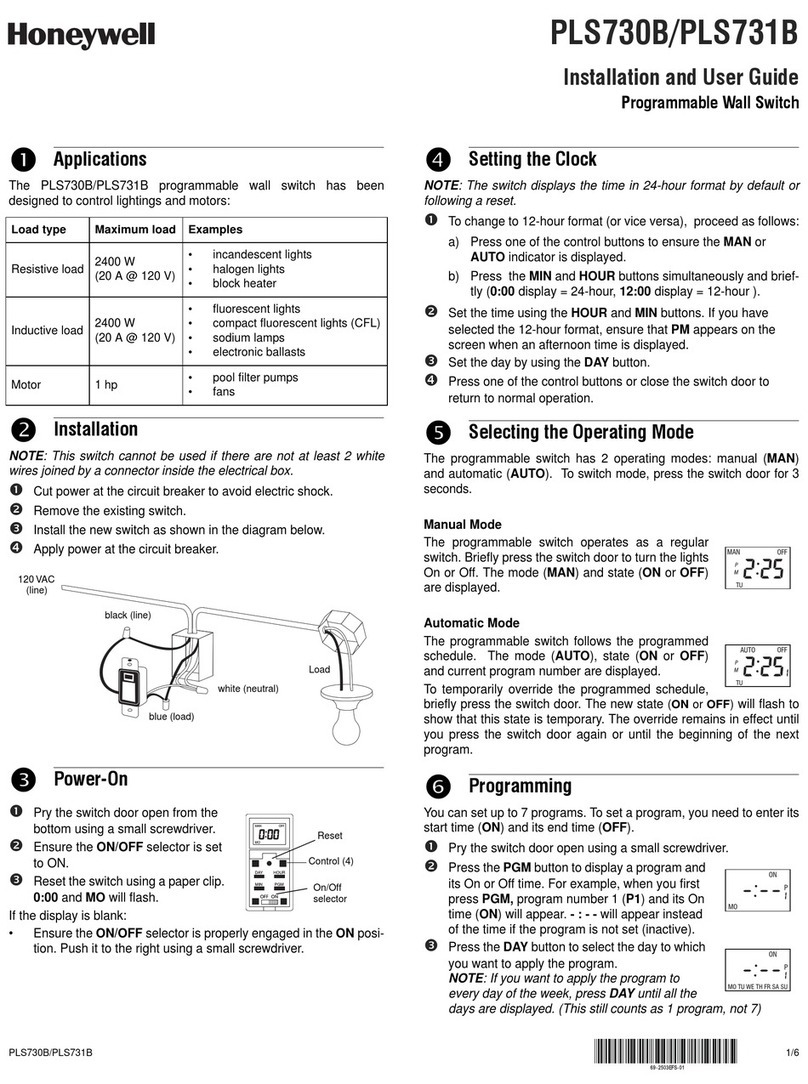

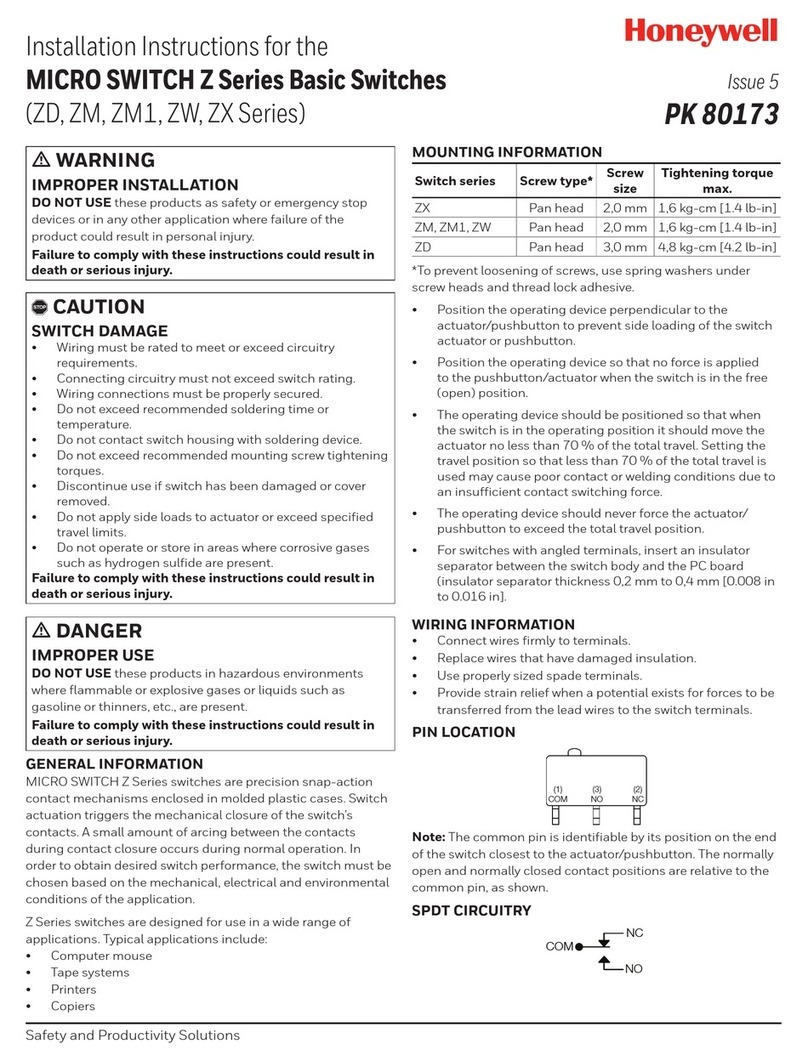

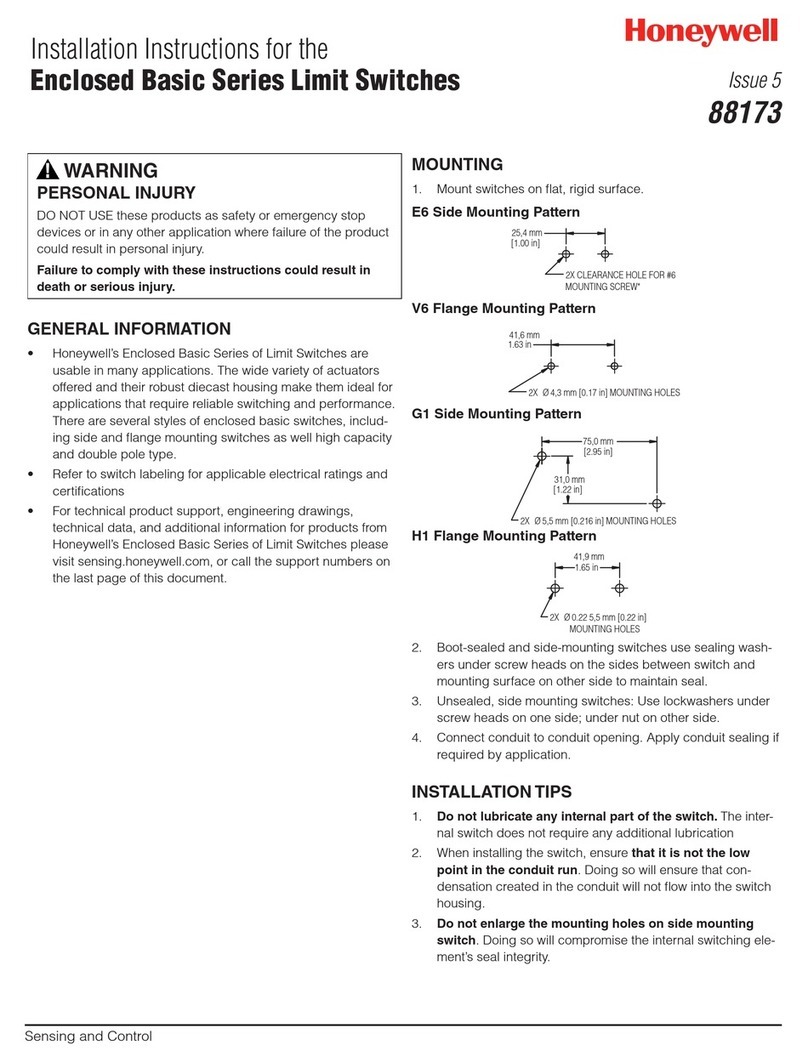

MOUNTING AND CIRCUIT INFORMATION

Mounting dimensions shown below.

A circuit diagram is included on the switch case labeling each

of the terminals. The normal position corresponds to the

switch plunger in its released position.

[0.11]

[0.098]

3X 4,7

[0.19]

3X R 0,6

[0.02]

3X R 1,2

[0.05]

2,5

[0.098]

OP

2,8

[0.11] 0,50 ±0,03

[0.02 ±0.001]

5,2 [0.20]

5,2 [0.20]

Ø 3,1 [Ø 0.12] - Metric mounting hole

Ø 2,9 [Ø 0.11] - USA mounting hole "K

Ø3,2 [Ø0.125]

22,2 [0.87]

33 [1.3] 7,8

[0.31]

15,9

[0.63] 10,3

[0.41]

Ø 3,1 [Ø 0.12]

Metric mounting hole

Ø 2,9 [Ø 0.11]

"

SOLDERING GUIDELINES

When hand soldering the switch’s terminals, do not exceed

five seconds at 350 °C [662 °F]. Contacting the switch

housing with the soldering device may damage the switch

housing. Solder joints must not be moved for at least one

minute after soldering.

Do not try to clean the switch with a solvent or similar

substance after the soldering process.

SPECIFICATIONS

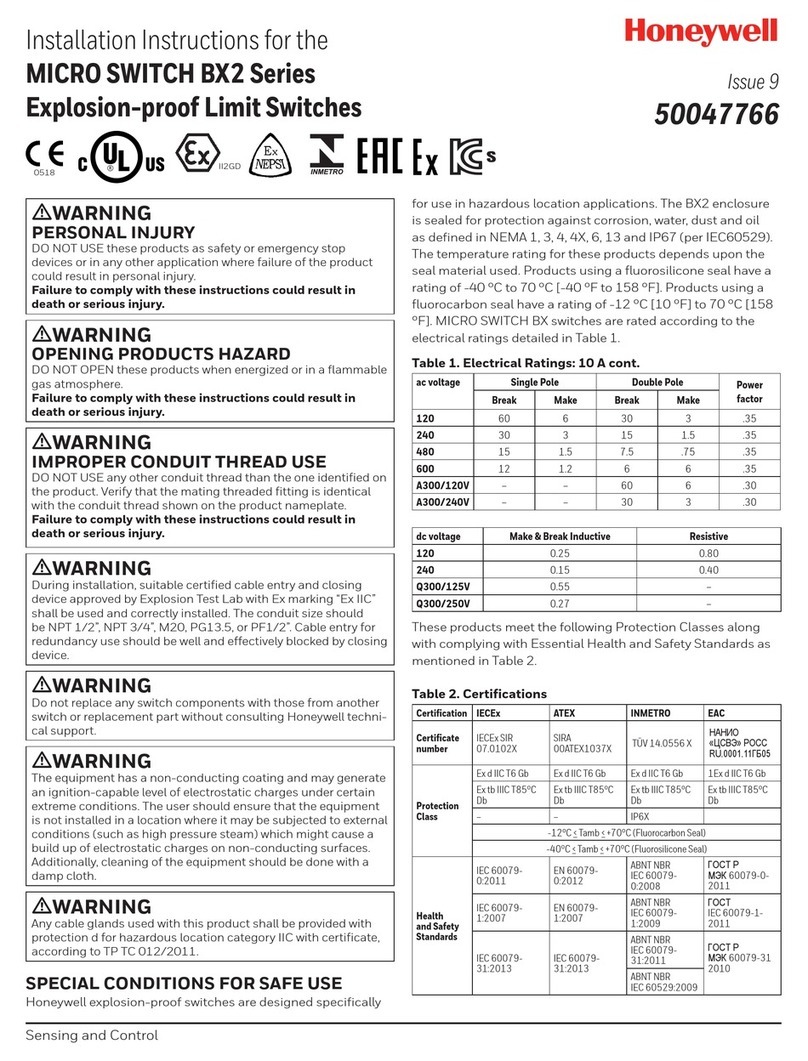

TABLE 2. SPECIFICATIONS

Electrical rating 5 A (resistive), 125 Vac/250 Vac

Operating

temperature range 25 °C to 85 °C [13 °F to 185 °F]

Rate of actuation

(pin plunger) 0,1 mm/s to 1000 mm/s

Operating frequency

(electrical) 25 operations/minute max.

Operating frequency

(mechanical) 60 operations/minute max.

MICRO SWITCH HAZARDOUS AREA BASIC SWITCHES,

V15W2 SERIES

Issue E

32333029

Honeywell Sensing and Internet of Things

830 East Arapaho Road

Richardson, TX 75081

honeywell.com