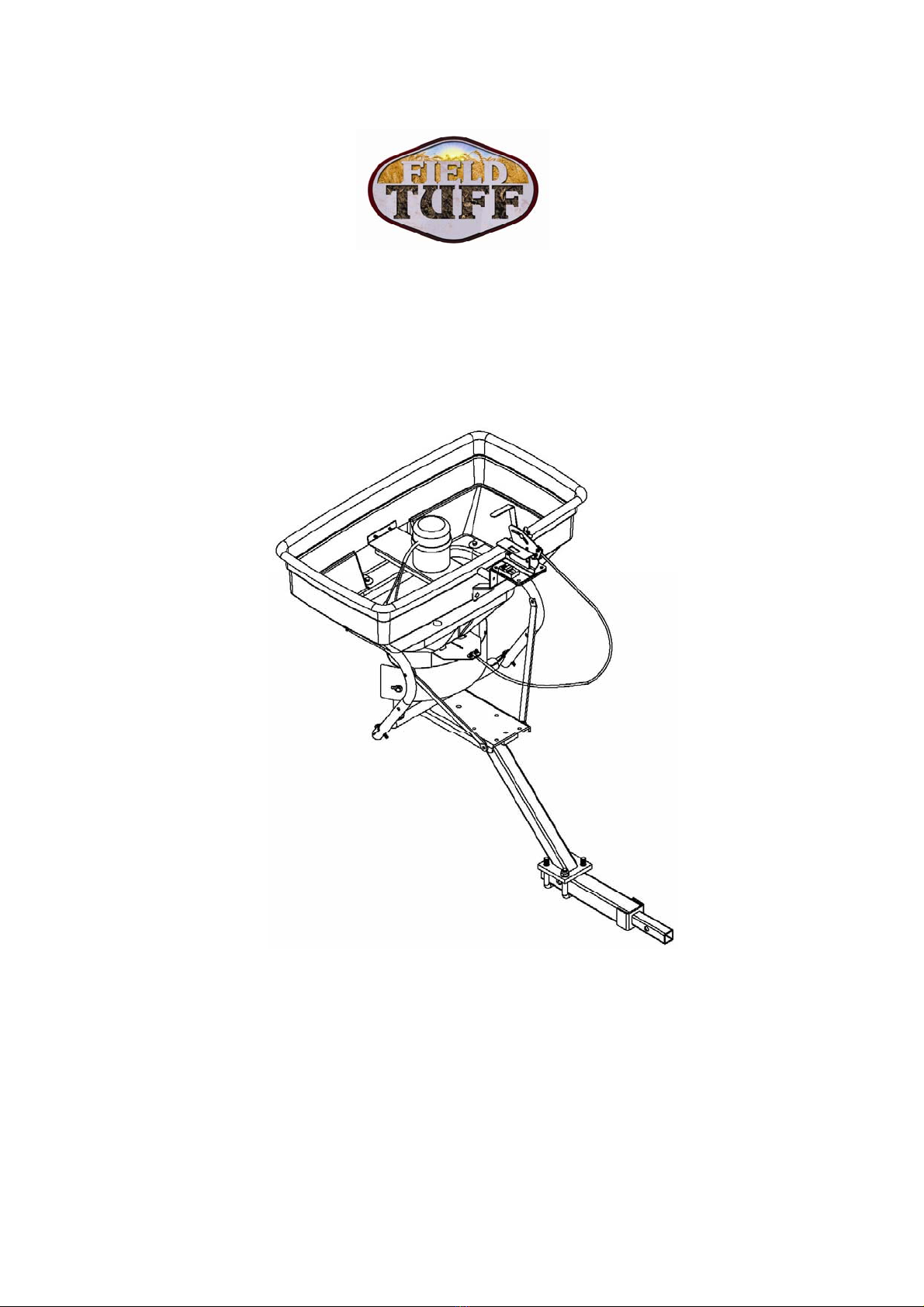

Field Tuff AS-125ATV12 User manual

125LB ATV RECEIVER

MOUNT SPREADER

ModelAS-125ATV12

08022013

1. Be sure to wear safety glasses, a dust mask, and proper clothing to

prevent coming in contact with any chemicals or dangerous materials that

are being applied by this spreader.

SAFETY PRECAUTIONS

2. Make sure to remove any contents that are in the spreader’s hopper

before attaching, detaching, or lifting this unit.

3. Avoid attaching and detaching this unit alone. To avoid damage to this

unit and injury always have someone help attach and detach due to shape

and weight of this unit.

4.

Always refer to the load rating for the vehicle which is located in the

4.

Always

refer

to

the

load

rating

for

the

vehicle

which

is

located

in

the

vehicle’s owners manual. Make sure that the unit weight of 37lbs plus the

weight of the contents in the hopper do not exceed that of the vehicle’s

recommended load rating.

5. To avoid damage to this unit and injury NEVER overload the hopper.

6. Stay clear of all moving and spinning parts or objects of this unit

7

Always follow directions on the package of whatever you are applying with

7

.

Always

follow

directions

on

the

package

of

whatever

you

are

applying

with

this unit.

Operation Instructions

1. After assembly attach to front or rear receiver of vehicle.

2. Read and follow directions on the package of the material being spread

by this unit.

3. Fill hopper with desired material to be spread by this unit not exceeding

maximum load of 125lbs.

4. Adjust the handle on the gauge assembly so that it is at the desired

settin

g

. Then ti

g

hten the win

g

nut on the

g

au

g

e assembl

y

to set the

gg g gg y

desired opening. This allows the driver to set the opening to the same

place every time while driving the vehicle. See page 3 for spread

calculations.

5. Adjust handle on the gauge assembly until desired amount of spreading

material is flowing out of the hopper onto the turning plate.

6. Flip rocker switch on cable assembly to on position and begin

spreading.

7. Turn Rocker switch off when wanting to stop or pause spreading.

8. Empty and clean hopper when finished.

1

Note: Settings for this product need to be determined by

user since factors such as coarseness and density of

“

material used

”

affect the spread rates See page 3

“

rate

material

used

affect

the

spread

rates

.

See

page

3

rate

worksheet” to calculate approximate spread rates.

When Rate settings are not available, follow these guidelines to calculate

spread rates:

On the bag of material to spread o ill find recommended spread rates s all in

On

the

bag

of

material

to

spread

, y

o

u w

ill

find

recommended

spread

rates

, u

s

u

all

y

in

terms to

the effect of: so many pounds will cover so many sq. ft.

Read these steps, then refer to the guide (worksheet page 3)

1.Determine how much material to apply per 1,000 sq. ft.

1.Determine

how

much

material

to

apply

per

1,000

sq.

ft.

2. Measure off a distance of 50ft, preferably on a paved area (ie: parking lot)

3. Weigh out enough material from bag to fill hopper ½ full (recommend at least ½ full

hopper)

Record weight for later.

4. Set the stop at position with opening of hopper at position you feel appropriate.

5. Now with hopper ½ full, bring vehicle to desired speed before start line of your 50 ft test

area.

When you arrive at start line, turn on spreader, then off at finish line

6. Stop the vehicle and note the width of spread path from your test run.

7. Repeat if necessary; Then empty remaining material from hopper back to your weighing

device and record new weight.

8. Be sure to record your results, see below guide on page 3.

2

On the bag of material to spread, you will find recommended spread rates, usually in terms

to the effect of: so many pounds will cover so many sq. ft.

Find your Desired Application (spread) Rate

Example: To find your desired rate, divide the area (sq. ft.) that bag of material covers by

the weight of the bag of material itself. Then multiply by 1,000.

Example: 25lb bag / 2000 sq ft coverage = .0125

.0125 x 1,000 = 12.5 (12.5 is your desired lbs per 1,000 sq. feet)

Record Desired Rate = (lbs per 1,000 sq. ft.) _________

TEST RUN to DETERIME SPREAD RATE:

•Determine lbs (weight) of Material in Hopper for Test Area

_________ Weight of Material put into Hopper

(Example: pour a 25lb bag into spreader)

(-)_______ Subtract Weight of Material in Hopper (After Test Area is spread)

(=)_______ Weight of Material Used (will be used below)

•Test Area Measurements

_________ Length of Test Area (Recommend: 50 ft)

(x)_______ Width of Spread Area

(=)_______ Total Spread Area

Determine Rate of Spread

Divide the Weight of Material Used in #2, by your Total Spread Area in #3.

Weight of Material Used/Total Spread Area = lbs per sq. ft.

Example: 2 lbs / 500 ft = 004

Example:

2

lbs

/

500

ft

=

.

004

Multiply lbs per sq ft (x)1000 = _____ lbs per 1000 sq ft

Example: .004 x 1000 = 4

Compare these results to your desired application rate in #1.

Adjust the rate setting stop on the spreader accordingly and run test area again.

Example: Adjust 2 times more open to achieve double the rate of test.

Now you should approx. match your desired application in #1.

Repeat the process if necessary until you achieve your desired application rate.

Settings and guidelines furnished on this Rate Worksheet are intended as a guide only.

Variations in materials applied, ground roughness, speed of operator, may affect rate.

There is no warranty as to the rate of coverage derived from above guidelines.

3

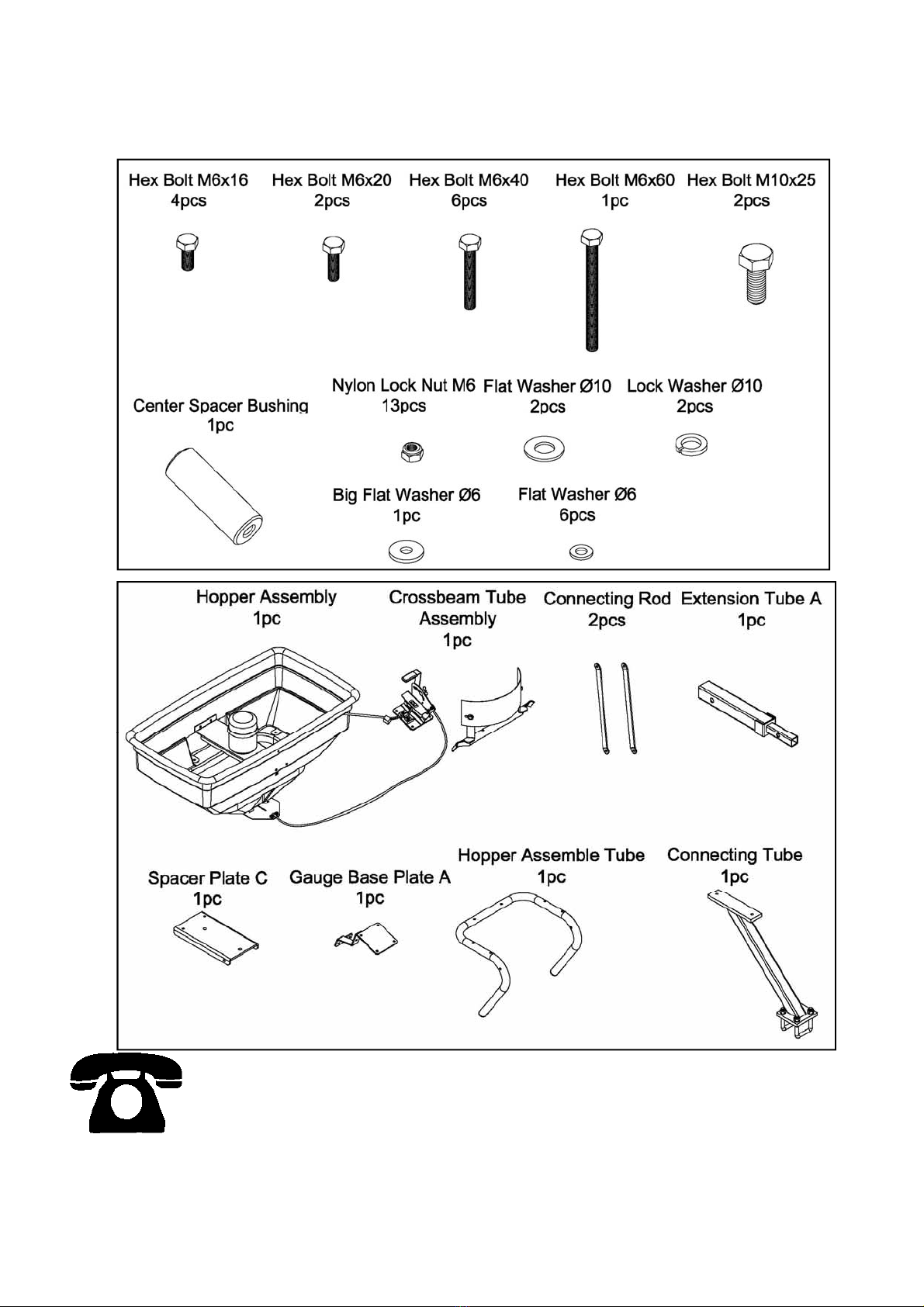

Carton Contents

NOTE: If you have questions, problems, or missing parts please call our customer

service before returning to your retailer. Contact us at 218-943-6296 ,8 a.m.-5 p.m.,

Monday-Friday CST.

4

Assembly Instructions

Step 1:

1. Connect the deflector plate (#16) to the crossbeam tube (#17) using hex bolt

M6x16 (#5), hex lock nut M6 (#15) and big flat washer Ø6 (#4). And then tighten them.

2. Connect the crossbeam tube (#17) , connecting rod (#18) and hopper assemble

tube (#14) using hex bolt M6x40 (#3), hex lock nut M6 (#15) and flat washer Ø6

(#50). Don't tighten them.

5

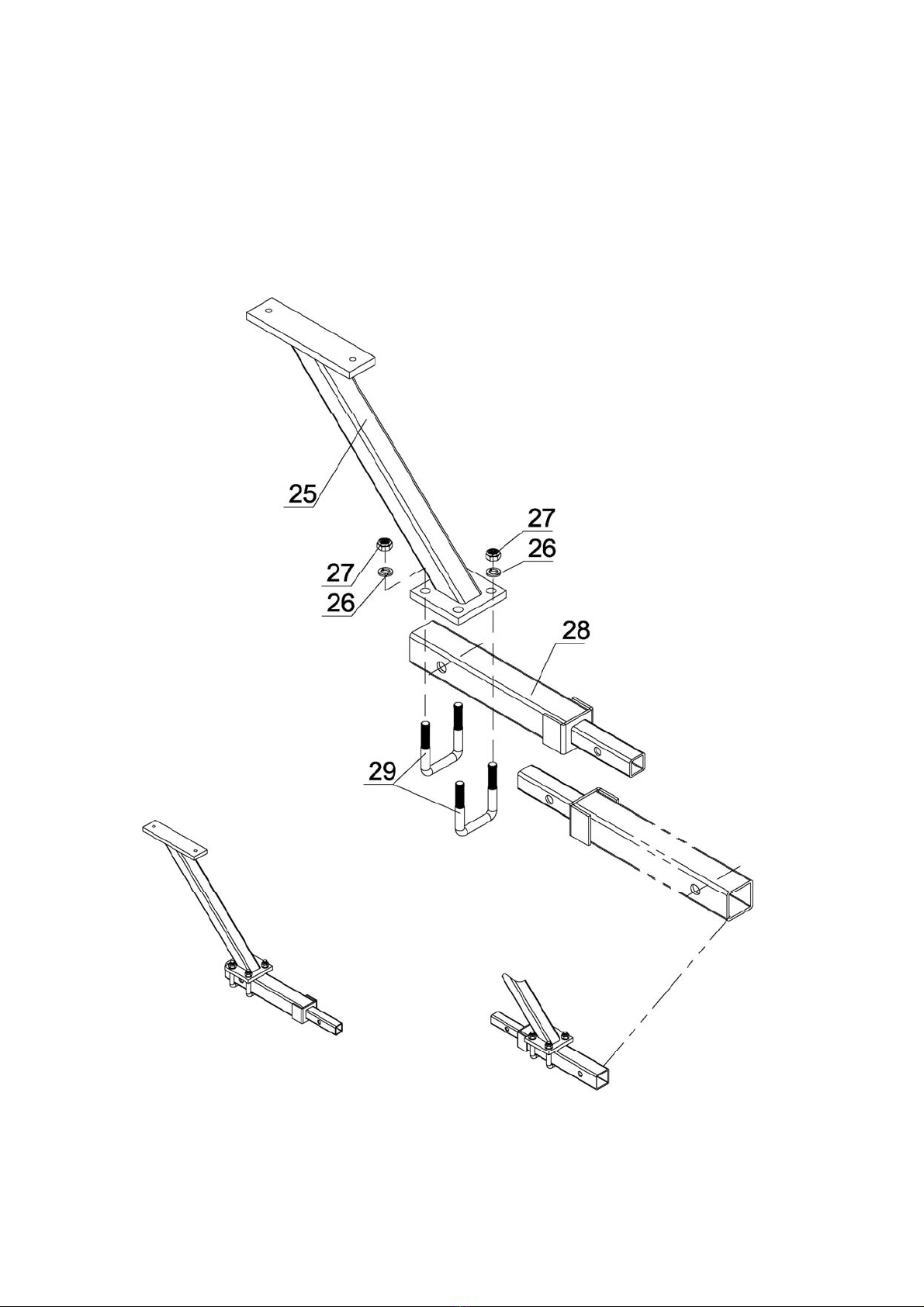

Step 2:

Assemble the connecting tube assembly (#25) and extension tube (#28)

using “U” bolt (#29), lock washer Ø12 (#26) and hex lock nut M12 (#27),

then tighten it. NOTE: extension tube (#28) can be reversed to fit 1.25” or

2” receiver (see step 7 for more detail.)

6

Step 3:

Connect the hopper assemble tube (#14) and spacer plate(#21) using hex

bolt M6x40 (#3), hex bolt M6x20 (#20) ,hex lock nut M6 (#15) and flat washer

Ø6 (#50). Fully tighten.

7

Step 4:

Assemble the connecting tube assembly (#25) and hopper tube assembly

(#14) using hex bolt M10x25 (#22), lock washer Ø10 (#23) and flat

washer Ø10 (#

24

) Fully tighten

washer

Ø10

(#

24

)

.

Fully

tighten

.

8

Step 5:

1. Pull out the switch box on the cable assembly , insert switch into the hole on the

gauge base plate , then plug-in the cable, and connect the other end of the cable

with the cable on the motor.

2. Secure the gauge base plate(#34) and cable assembly (#57) using screw M5x12

(#11), Spring washer Ø5 (#63) mounting the clamp press plate (#64).

9

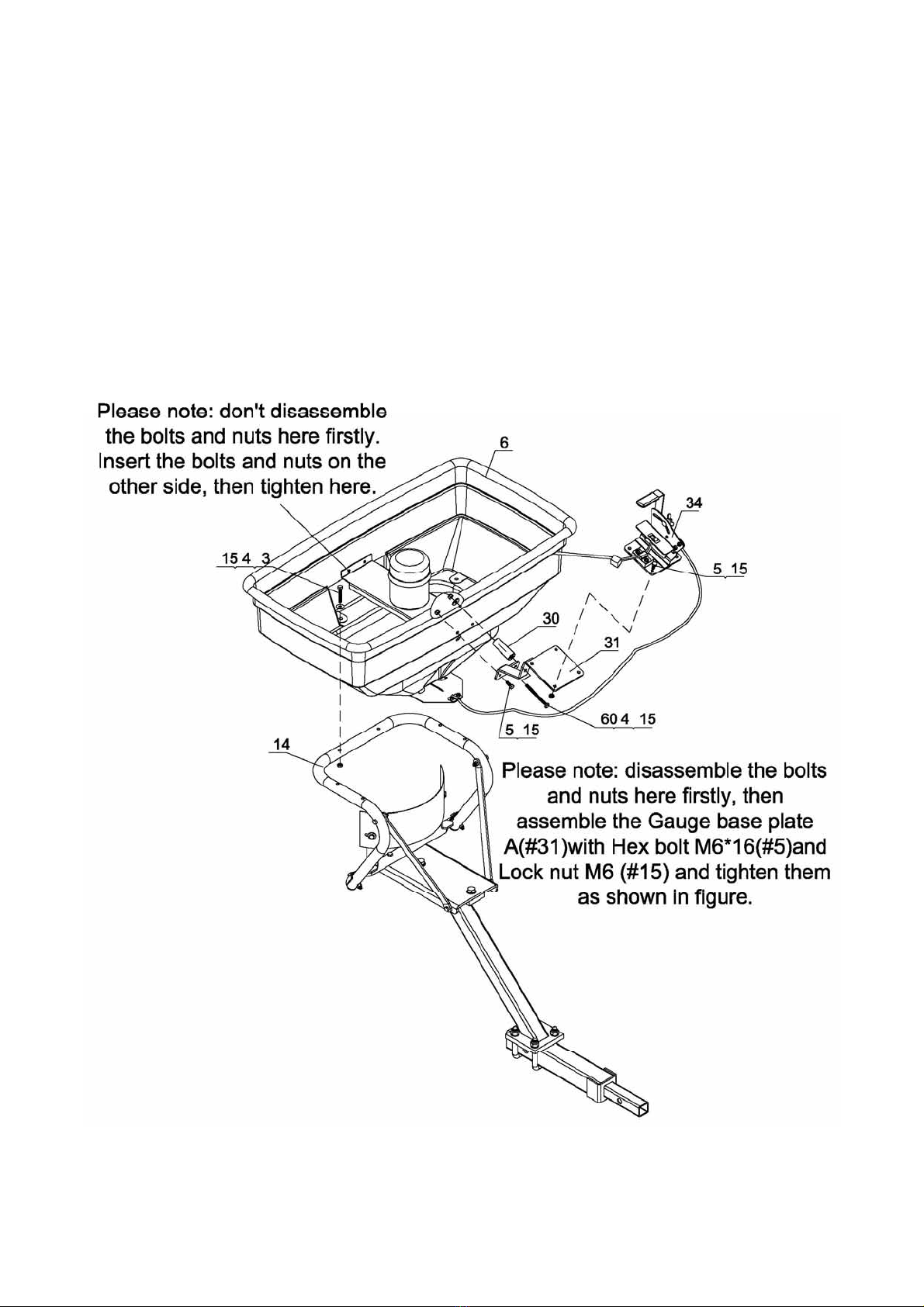

Step 6:

1. Connect the hopper assembly (#6) and hopper assemble tube (#14) using hex bolt

M6x40 (#3),big flat washerØ6(#4) and hex lock nut M6 (#15), then tighten.

2. Connect the gauge base plate(#31) center spacer busing(#30) and hopper

assembly (#6) using hex bolt M6x60(#60), big flat washer Ø6 (#4) and hex lock nut

M6 (#15), then Connect the lower hole of gauge base plate (#31) and hopper

assembly (#6) using hex bolt M6x16(#5) and hex lock nut M6 (#15). Then tighten

all the bolts.

3. Attach the gauge base plate assembly (#34) onto gauge base plate (#31) using

hex bolt M6x16(#5) and hex lock nut M6 (#15). Then tighten.

10

Step 7:

Tighten all the nuts and bolts.

11

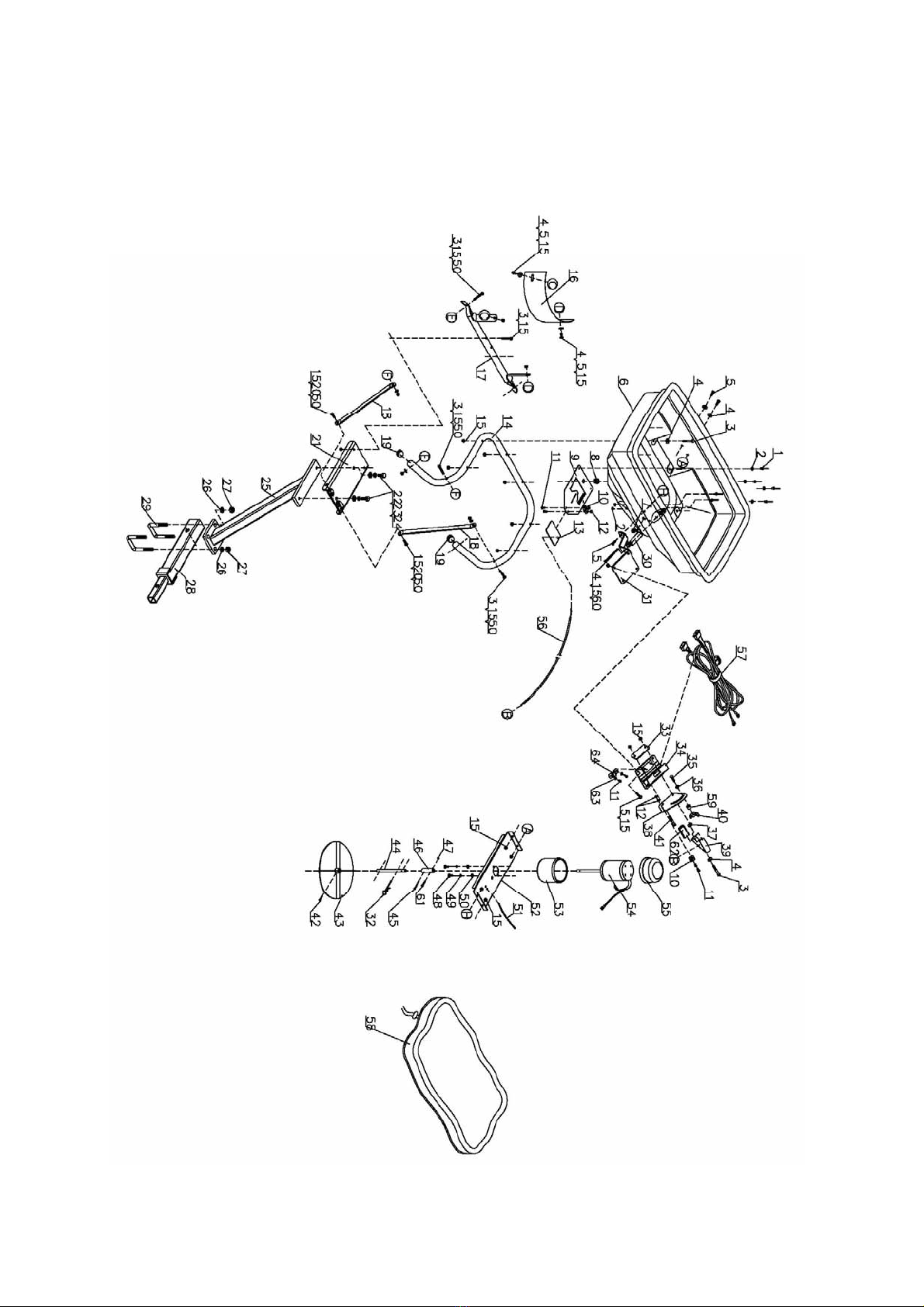

Exploded Diagram

12

Part List

REF# DESCRIPTION QTY REF# DESCRIPTION QTY

1 RivetΦ5x13 6

2 Big Flat WasherΦ56

3HexBoltM6x40 13

4 Big Flat WasherΦ612

5HexBoltM6x16 10

6 Hopper Assembly 1

7

Wire

Clamp

1

33 Fixed Plate 1

34 Gauge Base Plate 1

35 Step Bolt M6X25 1

36 External Teeth Lock Washer Φ81

37 Nylon Washer 1

38 Gauge & Level Assembly 1

39

Adjustable

Handle

1

7

Wire

Clamp

1

8 Shaft Bushing 1

9 Fixed Adjustable Plate 1

10 Link Clamp Press Plate 2

11 Screw M5x12 6

12 Nylon Lock Nut M5 4

13 Active Adjustable Plate 1

14

H

Abl

Tb

1

39

Adjustable

Handle

1

40 Wing Nut 1

41 Hex Bolt M6x35 1

42 Screw M4X20 1

43 Impeller 1

44 Shaft Φ10x135 1

45 Cotter Pin Φ4x30 1

46

Sh ft

Cti

Tb

1

14

H

oppe

r

A

ssem

bl

e

T

u

b

e

1

15 Nylon Lock Nut M6 27

16 Deflector A 1

17 Crossbeam Tube Assembly 1

18 Connecting Rod 2

19 Tube End CapΦ25X13 2

20 Hex Bolt M6X20 2

46

Sh

a

ft

C

onnec

ti

ng

T

u

b

e

1

47 Nylon Lock Nut M4 1

48 Screw M6x16 2

49 Lock Washer Φ62

50 Flat Washer Φ68

51 Ribbon 1

52 Motor Assemble Plate 1

21 Spacer Plate C 1

22 Hex Bolt M10x25 2

23 Lock Washer Φ10 2

24 Flat Washer Φ10 2

25 Connecting Tube Assembly 1

26 Lock Washer Φ12 4

27 Hex Lock Nut M12 4

53 Motor Cover 1

54 Motor 1

55 Motor Cap 1

56 Adjustable Rod Assembly 1

57 Cable Assembly 1

58 Rain Cover 1

59 S

p

ace

r

Bushin

g

1

28 Extension Tube A 1

29 "U"Bolt 2

30 Center Bushing 1

31 Gauge Base Plate A 1

32 R Pin 1

p

g

60 Hex Bolt M6x60 1

61 Screw M4x25 1

62 Handle Grip 1

63 Spring Washer Φ52

64 Link Clamp Press Plate A 1

13

For replacement parts and technical questions, please call 1-218-943-6296.

WARRANTY

One-year limited warranty

TG

PO Box 203

Miltona

,

MN 56354

,

Made in CHINA

14

Table of contents

Popular Spreader manuals by other brands

Baumann

Baumann 440E Operator's manual

Precision Products

Precision Products SB550 Use and maintenance manual

Agri-Fab

Agri-Fab 45-02102-101 owner's manual

Western

Western Drop 250 Owner's manual and installation instructions

Craftsman

Craftsman 486.243234 owner's manual

Millcreek

Millcreek 25 Operator's manual

Metal-Fach

Metal-Fach N 272/1 operating manual

Fisher

Fisher QUICK-CASTER 300W Owner's manual and installation instructions

Agri-Fab

Agri-Fab 45-04631 operating instructions

Meyer

Meyer PV Series INSTALLATION AND INSTRUCTIONAL MANUAL

Kramer

Kramer VM-4DVI-R user manual

PRONAR

PRONAR PRONAR N262 Operator's manual