Fike DuraQuench JPC User manual

INSTRUCTION MANUAL

DuraQuench™

MODEL JPC JOCKEY PUMP CONTROLLER

P/N 06-791-6 (Rev. 0 / July, 2015)

COPYRIGHT INFORMATION

This document may not be reproduced, in whole or in part, by any means without the prior express written permission of the

copyright owner. All Fike documentation and hardware are copyrighted with all rights reserved.

Fikeis a registered trademark of Fike.

DuraQuench™ is a registered trademark of Fike.

DISCLAIMERS

The information contained in this manual is as accurate as possible. Fike does not guarantee that this manual is technically correct,

complete, or free from writing problems or that this product is free from minor flaws.

In accordance with our policy of continuing product and system improvement, Fike reserves the right to change designs or

specifications without obligation and without further notice.

Any questions concerning the information presented in this manual should be addressed to:

704 South 10th Street

P.O. Box 610

Blue Springs, Missouri 64013 (U.S.A.)

Phone: (816) 229-3405

Fax: (816) 229-5082

Webpage: www.fike.com

READER RESPONSES

Fike encourages input from our distributors and end users on how we can improve this manual and even the product itself. Please

direct all calls of this nature to Fike’s Systems Sales Department at (800)-979-FIKE (3453), option 22.

Any communication received becomes the property of Fike.

WARRANTIES

Fike provides a one-year limited manufacturer's warranty on this product. The standard warranty is printed in each Marketing Price

List. All warranty returns must be returned from an authorized Fike Distributor. Contact Fike's Marketing Department for further

warranty information. Fike maintains a repair department that is available to repair and return existing electronic components or

exchange/purchase previously repaired inventory component (advance replacement). All returns must be approved prior to return.

A Material Return Authorization (MRA) number should be indicated on the box of the item being returned. Contact the appropriate

Regional Sales Manager for further information regarding Return Material Procedures.

LIMITATION OF LIABILITY

Fike cannot be held liable for any damages resulting from the use or misuse of this product.

QUALITY NOTICE

Fike has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all respects.

REVISION HISTORY

ORIGINAL RELEASE DATE: ........................................................................................................................................... July, 2015

REVISION /DESCRIPTION OF CHANGE REVISION DATE

P/N 06-791-6 (Rev. 0 / July, 2015)

Page 1

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

TABLE OF CONTENTS

Section Page No.

1. General ........................................................................................................................................................................ 2

2. Installation Instructions............................................................................................................................................... 2

2.1. Mounting.............................................................................................................................................................. 2

2.2. Safety Precaution ................................................................................................................................................. 2

2.3. Power Supply........................................................................................................................................................ 2

2.4. Wiring ................................................................................................................................................................... 2

2.5. Plumbing............................................................................................................................................................... 2

2.6. Protection............................................................................................................................................................. 2

2.7. Service Factor ....................................................................................................................................................... 2

3. Start Up........................................................................................................................................................................ 3

4. Sequence of Operation................................................................................................................................................ 3

4.1. General ................................................................................................................................................................. 3

4.2. Power Wiring........................................................................................................................................................ 3

4.3. Overload Relay ..................................................................................................................................................... 3

4.4. Manual Control .................................................................................................................................................... 3

4.5. Automatic (Pressure) Control............................................................................................................................... 4

5. Replacement Parts List ................................................................................................................................................ 4

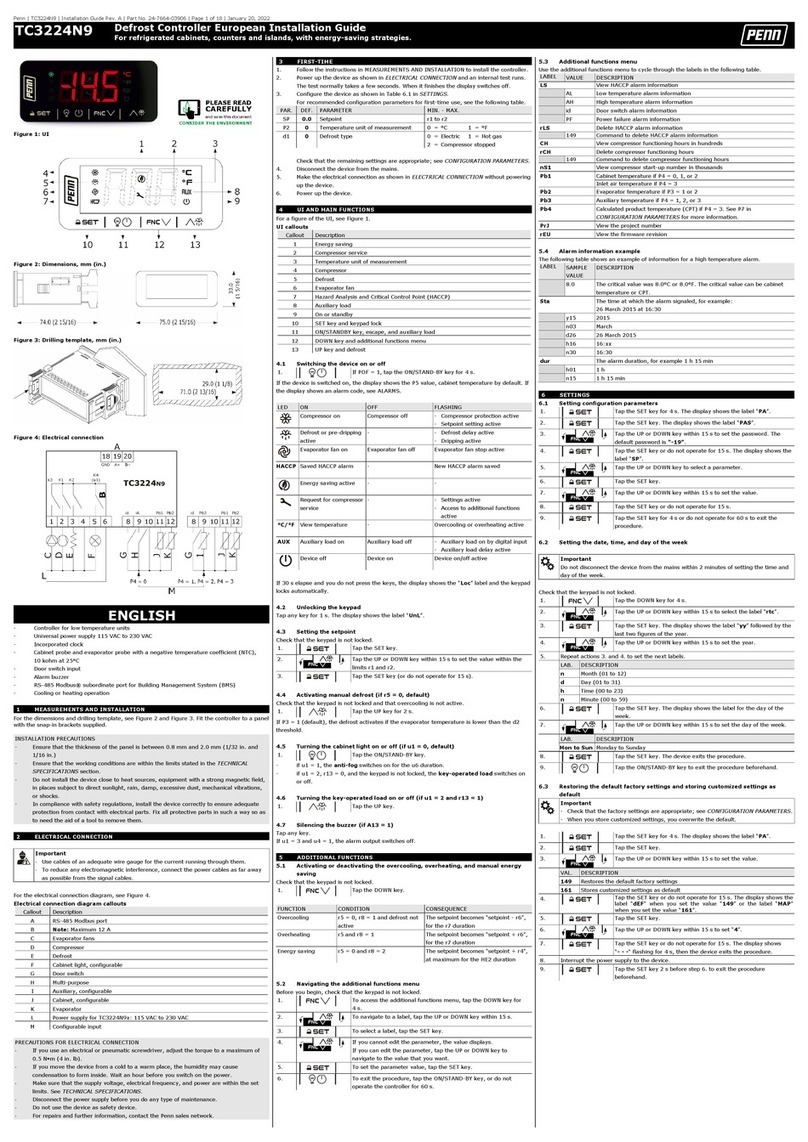

Controller Schematic Diagram ........................................................................................................................................... 5

Page 2

P/N 06-791-6 (Rev. 0 / July, 2015)

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

1. GENERAL

The Model JPC is a fusible combination motor starter with a built in pressure switch for use with pump motors such as

make-up pumps, booster pump, or `jockey' pumps which are used with automatic sprinkler systems. Some units are

supplied with a circuit breaker in lieu of the fusible disconnect (switch and fuse block).

2. INSTALLATION INSTRUCTIONS

2.1. Mounting

The JPC enclosure must be mounted in the vertical position, and in an area free from dripping and spraying water.

2.2. Safety Precaution

Before any electrical work is done on the JPC make sure the disconnect switch and the control switch are in the off

position.

2.3. Power Supply

Use branch circuit protection on the incoming line (mains). Check the motor and JPC nameplates to verify they match

the incoming line voltage, frequency and current requirements.

2.4. Wiring

All motor circuit conductors should be sized according to the National Electric Code article 430, part B. Insulation for

these conductors should be chosen so it will not be affected by the surrounding environment. The input power wiring

is connected to the fusible disconnect, and the output motor wiring is connected to the motor starter. Protect internal

components from drilling chips and debris.

2.5. Plumbing

The brass pressure sense line should be connected to the 1/4"-18 NPT female pressure connection provided on the

bottom of the cabinet.

NOTE For fire pump systems, the sense line runs from between the system side of the make-up pump check valve

and the pump side of the control valve to the pressure connection on the JPC. See NFPA standard for Fire

Pumps (NFPA-20 fig. A-7-5.2.1 for details).

2.6. Protection

Fuses are furnished according to the National Electric Code (NFPA-70) table 430-148 (Single Phase) and 430-152

(Three Phase) which is based on the full load motor current. If not specified, the full load current is taken from a

standard motor current table for Design "B", 1.15 service factor, 40% rise, 60 Hz (50 HZ for 380 Vac or 220 Vac

Controllers), A.C. Squirrel Cage Induction 2 Pole or 4 Pole motors. The table is applied to the voltage and horsepower

applicable.

The Overload Relay is furnished and set according to the motor Service Factor Amps which is based on the full load

motor current times its maximum

2.7. Service Factor

Both fuse sizes and overload (Trip) settings are shown on M.C.S. drawing SK-0844, included in standard units, or

separate label for others.

P/N 06-791-6 (Rev. 0 / July, 2015)

Page 3

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

3. Start-up

After the mounting, wiring, and plumbing are completed, and the system is ready to be pressurized, initiate the

following:

1. Adjust the pressure switch to the desired turn-on and turn-off settings.

2. Close and latch the door (Operation of the disconnect switch is interlocked with the door).

3. Set the disconnect switch to the "on" position.

4. Momentarily turn the selector switch to manual position while watching the direction of the motor rotation.

If correction is necessary, open (turn off) the disconnect switch and interchange two of the motor leads.

Repeat the last two steps.

5. Turn the selector switch to the "auto" position to put the pump in service.

4. SEQUENCE OF OPERATION

4.1. General

The JPC controls a make-up pump-motor combination to maintain the pressure in a system within a selected range.

This is accomplished with an adjustable pressure switch which has independently adjustable turn-on and turn-off

setting. Refer to the wiring or schematic diagram for details.

4.2. Power Wiring

The input lines (mains) connect to the top of the Disconnect Switch DS. Power flows through the short circuit

protection motor Line (Mains) Fuses LF, and then to the Motor Starter, which is horsepower rated. The Motor Starter

consists of Motor Contactor MC and Overload Relay OLR. When the Motor Contactor Coil M is energized, Motor

Contactor contacts close to feed power through the Overload Relay to its output terminals where the motor is

connected.

4.3. Overload Relay

The Overload Relay furnished in the motor starter provide protection from excessive currents. The overload relay has

been sized and set to trip open when the motor exceeds 125% of the Full Load Current (FLA) multiplied by the rated

Service Factor (SF). Trip times vary depending on the magnitude of the current overload, the number of previous

starts, the ambient temperature of the controller, and the size of the overload element. Briefly, the Overload Relay is

sized to allow initial starting currents while protecting the motor from excessive long starting currents or excessive

running currents. (See Installation Instructions - Protection for proper sizing).

4.4. Manual Control

Control power wiring is tapped off the incoming power on the load (down-stream) side of the Line Fuses or Circuit

Breaker. It is routed to the three position (Auto-Off-Manual) selector switch.

In the OFF position, the Motor Contactor coil is de-energized to prevent the motor from running.

In the manual position, the Pressure Switch contacts are bypassed so the contactor coil is continuously energized by

the selector switch. The Overload

Relay contacts also override the manual position to again protect the motor.

Page 4

P/N 06-791-6 (Rev. 0 / July, 2015)

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

CAUTION Use care when using the MANUAL (MAN) position of the control switch to avoid causing system Over

Pressure. Use extra caution with positive displacement, regenerative or other pumps capable of

generating high output pressures until or unless the presents and status of a pressure relief valve is

determined.

4.5. Automatic (Pressure) Control

In the AUTO position, control power is routed to the Pressure Switch PS. The Pressure Switch is normally closed (closes

on falling pressure). When the pressure is below the Turn-On setting of the Pressure Switch, its contacts close to

energize the Motor Contactor coil to start the motor.

In the event of excessive motor current or sustained locked rotor contacts, the thermal element of the Overload Relay

will open pilot Contacts OLC to de-energize the Motor Contactor Coil to open the Motor Contactor contacts and de-

energize the motor. After the motor and Overload Relay cool down, the Overload Relay is manually reset to re-enable

the controller and motor.

Option "1" - Control Transformer: When Option "1" is supplied, control power is supplied by a Control Power

Transformer (CPT). Its primary is supplied by two control line fuses F2 and F3. The secondary output of the

transformer is protected by secondary fuse F1. When used, control power is 115 Vac (110 - 120 Vac) rather than line

voltage. The motor contactor coil and any other relay coils are rated at 110 Vac to 120 Vac in this case.

Option "2" - Minimum Run Timer: This option is used to prevent excessively frequent pump starting. The option

consists of the Minimum Run Time Delay Relay TM. It is equipped with a Timer head TMD as well as instantaneous

contacts TMA. The timer head is equipped with an adjustment dial. The standard range of adjustment is zero to 180

seconds. The Minimum Run Timer does not operate with the selector switch in the MANUAL position.

Option "3" - Line (Mains) Fuses: Three extra line fuses are furnished to provide protection from short circuit or high

current faults. (See Installation Instructions - Protection, for proper sizing).

5. REPLACEMENT PARTS LIST

Symbol

Part No.

Description

Notes

DS

304472

Disconnect Switch, 600 Vac, 30/40 Amp (Internal Switch only)

401864

Disconnect Switch Handle Operator only, (30 thru 100 Amp)

401990

Auto-Off-Manual Selector Switch

401992

Auto-Off-Manual Selector Switch Contact

PS

305410

Pressure Switch (Mercoid No. DA-31-1-R.9) 10-300 P.S.I.

TM

613056

Minimum Run Time Delay Relay/Timer Head Ass'y, 120 Vac (Opt. 2)

TM

613050

Minimum Run Time Delay Relay/Timer Head Ass'y, 208 Vac " (1)

TM

613051

Minimum Run Time Delay Relay/Timer Head Ass'y, 230 Vac " (1)

TM

613052

Minimum Run Time Delay Relay/Timer Head Ass'y, 380 Vac " (1)

TM

613053

Minimum Run Time Delay Relay/Timer Head Ass'y, 460 Vac " (1)

305040

Control Power Transformer, 50 VA, 208/240/460 Vac (Opt. 1)

305041

Control Power Transformer, 50 VA, 380/575 Vac (Opt. 1)

LF

303475

Fuse Holder, 3 Pole, 600 Volt, 30 Amp

F1

900611

Fuse Holder, 1 pole, 250 Vac, 30 Amp (Opt.1)

F2,F3

303471

Fuse Holder, 2 pole, 250 Vac, 30 Amp (Opt.1)

Notes:

1) Line voltage Motor Contactor coils are used only when Option "1" is Not provided.

2) One or more renewal parts such as fuses, heaters, contacts, and etc. may be obtained from local electrical

distributor(s).

P/N 06-791-6 (Rev. 0 / July, 2015)

Page 5

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

Page 6

P/N 06-791-6 (Rev. 0 / July, 2015)

704 SW 10th Street, P.O. Box 610, Blue Springs, Missouri 64013-0610 U.S.A. ●Phone: (816) 229-3405 ●www.fike.com

This page intentionally left blank.

Table of contents

Other Fike Controllers manuals