6

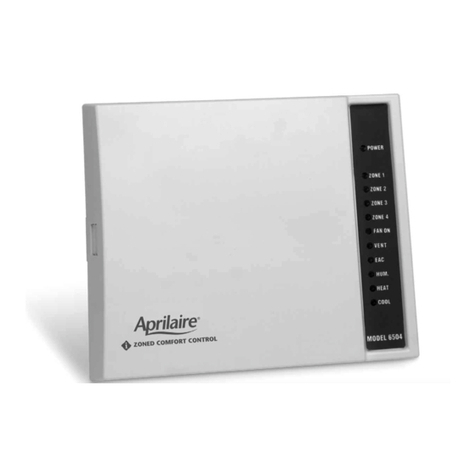

MOUNT THE CONTROL PANEL

NOTE: Mount in location where the temperature will not exceed 158°F and will not drop below freezing (32°F). Do not

mount on foundation walls, or on the HVAC equipment or ductwork. These locations can cause the enclosure to become

cooler than the surrounding air, which can cause moisture to condense on the enclosure.

1. Press in the latch on the left side of the enclosure and pull open the cover.

2. Use #8 screws (field supplied) to mount the base.

SET CONTROL PANEL FOR APPLICATION

There are six setup switches that must be set to meet your particular zoning application.

➤ZONE 1/ANY ZONE determines how the control panel will

control the mode of operation. In the ZONE 1 configuration,

Zone 1 sets the mode of operation through the use of the O

and B thermostat inputs. When the Zone 1 O terminal is

energized, the system is in the cool mode and only cool and

fan calls will be satisfied. When the Zone 1 B terminal is

energized, the system is in heat mode and only heat and

fan calls will be satisfied. If neither the Zone 1 O nor B

terminal is energized, the system will not respond to cool or

heat calls, but fan operation is unaffected. This

configuration offers restricted control and is likely to be

used in commercial applications where control from Zone 1

is desired (i.e. restaurants, churches, etc.). In the ANY

ZONE configuration, the control panel responds to each

individual thermostat equally. This allows thermostats to

call for heating or cooling as required. If opposite calls

(heating and cooling) occur at the same time, the zone

panel will alternate between the heating and cooling call in

20 minute intervals. This offers control flexibility and is

likely to be used in most residential applications and office

or retail type commercial applications where the heating

and cooling needs of the zones are completely independent.

TALK WITH THE CUSTOMER TO DETERMINE WHICH

CONTROL CONFIGURATION SHOULD BE USED. Refer to the

sequence of operation sections on the following pages for

additional details.

➤HEAT PUMP or HEAT/COOL refers to the type of heating

and cooling system. If a heat pump is to be used, set the

switch to the ON position. If different equipment is used for

heating and cooling (i.e. furnace and air conditioner, or boiler

and air conditioner), set the switch to the OFF position.

➤ELECTRIC/GAS refers to the heat source. If electric heat is

to be used, set the switch to the ON position. This will turn

on the fan (G output terminal) with a heat call (W1 output

terminal). If the switch is left in the OFF position, it is

assumed that the heating equipment will control the fan.

For Dual Fuel Heat Pump systems, leave this switch in the

GAS position.

➤NO PURGE / PURGE determines whether the zone control

panel or the equipment will control the compressor fan

purge. If the NO PURGE/PURGE switch is set to PURGE, the

G terminal will remain energized for a one minute purge

delay following the completion of a compressor call. If set

for NO PURGE, the G terminal will de-energize immediately

following the completion of a compressor call. The NO

PURGE setting is designed for use with systems where the

equipment has a built in fan purge.

➤CL-45/40: If using a plenum temperature sensor, this switch

controls the temperature at which the cooling equipment

will cut out to prevent freezing the indoor coil. For a low

limit temperature of 45°F, move the switch to the ON

position (45). For a low limit temperature of 40°F, leave the

switch in the OFF position (CL-40).

➤HT-140/170: If using a plenum temperature sensor, this

switch controls the temperature at which the heating

equipment will cut out to prevent overheating. For a high

limit temperature of 140°F, move the switch to the ON

position (140). For a high limit temperature of 170°F, leave

the switch in the OFF position (HT-170).