Fike Quadnet PSU V3 User manual

26-0853 Issue 5

Fire Detection & Alarm System Power Supply Unit V3

Power Supply Unit Installation Manual

(TO BE RETAINED BY THE COMMISSIONING ENGINEER)

Quadnet Power Supply Unit Installation Manual

2

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every care

has been taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability whatsoever in

respect of such contents.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential, and commissioning should

only be carried out by competent persons.

Fike cannot guarantee the operation of any equipment unless all documented instructions are complied with, without variation.

E&OE.

Fike equipment is protected by one or more of the following patent numbers: GB2426367, GB2370670, EP1158472, PT1035528T,

GB2346758, EP0917121, GB2329056, EP0980056, GB2325018, GB2305284, EP1174835, EP0856828, GB2327752, GB2313690

Quadnet Power Supply Unit Installation Manual

3

Contents

Introduction..........................................................................................................................4

System Design..........................................................................................................4

Equipment Guarantee ..............................................................................................4

Anti Static Handling Guidelines ................................................................................4

Warning.....................................................................................................................4

EMC ..........................................................................................................................4

The Quadnet System...........................................................................................................5

Advantages of Addressable Systems .......................................................................5

Power Supply Unit...............................................................................................................6

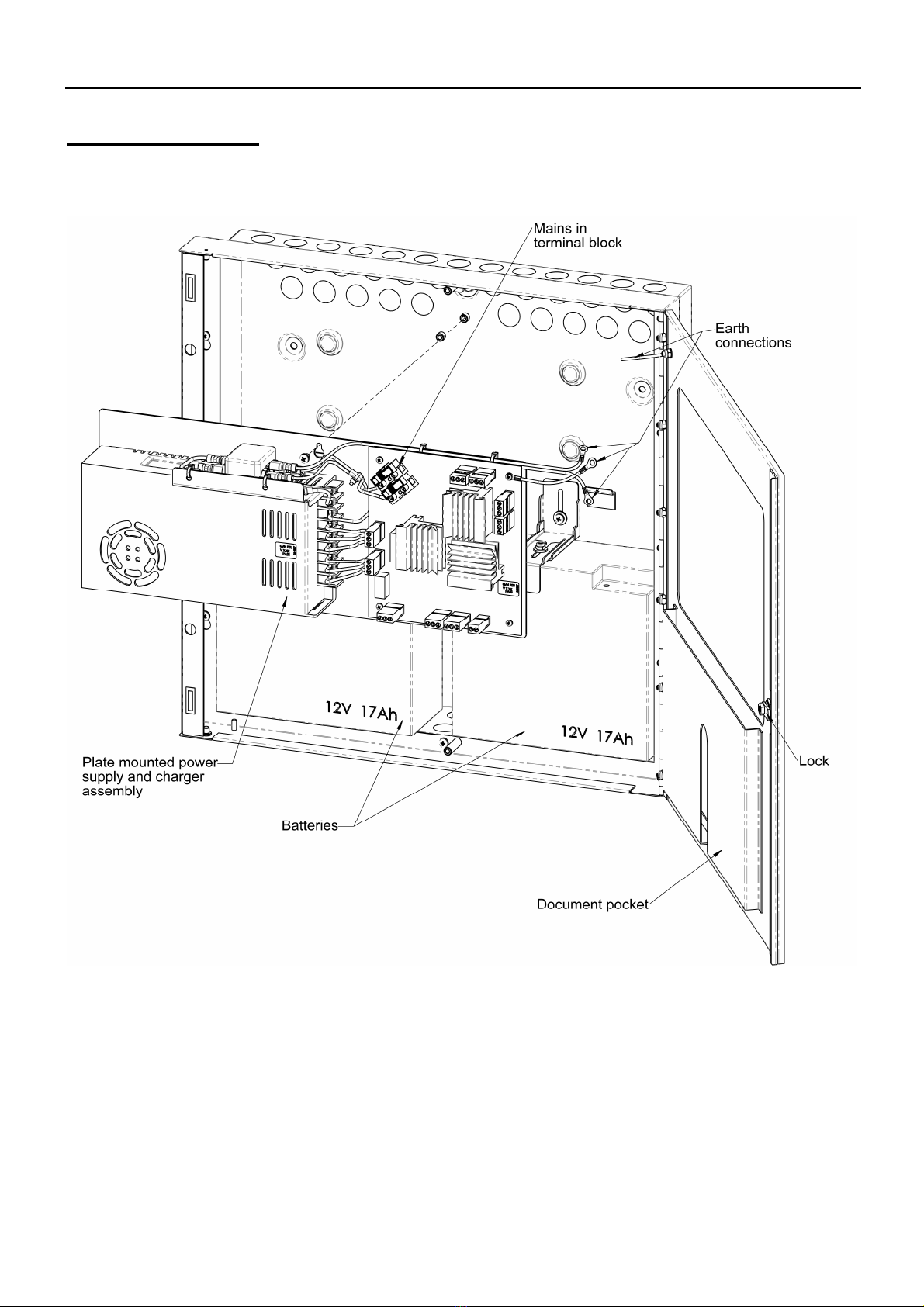

The General Assembly .............................................................................................6

Power Supply Disassembly.......................................................................................7

Cabinet Installation....................................................................................................7

Physical Dimensions .................................................................................................8

Power Supply Assembly............................................................................................8

Topology and Cabling ...............................................................................................9

Cable Specification ...................................................................................................9

Mains Supply & Batteries ..........................................................................................10

PSU Termination Schematic.....................................................................................11

PSU Terminals..........................................................................................................12

Address Select Links ................................................................................................15

Example Connection Diagram ..................................................................................15

Fuses ........................................................................................................................16

Commissioning....................................................................................................................17

Installation 1st Stage ................................................................................................17

Power Up ..................................................................................................................17

Good Practice ......................................................................................................................18

Battery Data .............................................................................................................18

Cable Readings.........................................................................................................18

Technical Data .....................................................................................................................19

Power Supply Unit.....................................................................................................19

Further Information .............................................................................................................20

PSU Cable Continuity & Insulation Test Results.......................................................20

Your Notes............................................................................................................................21

Important Points ..................................................................................................................24 – Back Page

Quadnet Power Supply Unit Installation Manual

4

Introduction

This Manual is intended as a guide to the engineering and commissioning principles of the Quadnet

Addressable Intelligent Fire Alarm and Detection system, and covers the Power Supply Unit only.

Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on this

equipment is essential, and commissioning should only be carried out by competent and approved persons.

For further details of the availability of commissioning services contact your supplier.

System Design

This document does not cover Fire Alarm system design, and a basic understanding is

assumed.

A knowledge of BS5839: Pt 1: 2002 +A2: 2008 : Fire Detection and Alarm Systems for

Buildings is essential.

It is strongly recommended that a suitably qualified and competent person is consulted in

connection with the Fire Alarm System design and that the entire system is commissioned in

accordance with the current national standards and specifications.

Equipment Guarantee

The equipment carries no warranty unless the system is installed, commissioned and serviced

in accordance with this manual and the relevant standards by a suitably qualified and

competent person or organisation

Anti Static Handling Guidelines

Immediately prior to handling any PCBs or other static sensitive devices, it is essential to

ensure that a personal connection to earth is made with an anti-static wrist-strap or similar

apparatus.

Always handle PCBs by their sides and avoid touching any components. PCBs should also be

stored in a clean dry place, which is free from vibration, dust and excessive heat, and protected

from mechanical damage.

Warning

Do not attempt to install this equipment until you have fully read and understood this

manual.

Failure to do so may result in damage to the equipment and could invalidate the warranty.

Technical support will not be available if the instruction manual has not been read and

understood. Please have this instruction manual available whenever you call for technical

support.

For further technical support please contact your distributor. Do not call the Fike Safety

Technology support department unless your distributor has first given their advice and

attempted to rectify the issue.

EMC

This equipment when installed is subject to the EMC directive 2004/108/EC. It is also subject

to UK Statutory Instrument 2006 No. 3418.

To maintain EMC compliance this system must be installed as defined within this manual. Any

deviation from this renders the installer liable for any EMC problems that may occur either to

the equipment or to any other equipment affected by the installation.

!

!

!

!

!

Quadnet Power Supply Unit Installation Manual

5

The Quadnet System

The Quadnet system is an addressable intelligent detector system, with many advantages over traditional

addressable analogue detector systems. In order to understand the benefits let us look more closely at the

terms Fire Detector and Fire Sensor. These terms are often used interchangeably but actually have quite

different meanings. A fire detector is the device (component as defined in EN54) which automatically

detects a fire. In the majority of addressable fire detection systems, the fire devices are in fact fire sensors

which only transfer data relating to smoke and heat levels to the control panel, and the fire decision is made

by the panel.

Nearly all current addressable systems are Addressable Analogue Detector Systems where the control

panel continually scans the fire sensors, processes the returned data, and makes decisions about fires and

faults.

The Quadnet system is defined as an Addressable Intelligent Detector System, or an Addressable Fire

Detection and Alarm System with Independent Distributed Intelligence. Distributed intelligence

signifies that the signal processing is spread throughout the system, in order that the decisions about fires

and faults are taken within the detector itself. The detector is capable of being remotely programmed for

different modes of detection.

Thus the Quadnet system is indeed an analogue addressable system, but with the processing power

distributed across the entire system. This dramatically reduces the complexity of the control panel and the

data traffic, and improves the efficiency of the system.

The system addressing is carried automatically upon initialisation from the control panel, and does not need

to be programmed manually at each device.

Advantages of Addressable Systems

The nature of a microprocessor control system with individually identified devices means that the precise

location of fires and faults may be indicated, more complex actions may be implemented, system flexibility

is improved and installation and cabling costs are reduced.

In the Quadnet system, very efficient communications mean that very low quiescent power consumption

maximises the standby capacity, high power transfer capabilities allow more sounders to be connected to

the loop, and a very fast response to events is achieved as the control panel does not have to poll every

device for status data.

Quadnet Power Supply Unit Installation Manual

6

Power Supply Unit

The General Assembly

NOTE: The diagram above shows a V3 PSU. Earlier models differ slightly.

The power supply is normally supplied disassembled to make first fix easier. If the panel is already

assembled it must be disassembled in order to fix the backbox to the wall.

If the power supply needs to be disassembled in order to fix the box to the wall see “Power Supply

Disassembly”.

Quadnet Power Supply Unit Installation Manual

7

Power Supply Disassembly

Remove the collar / flange assembly complete with door as follows. Loosen the 4 screws in the keyhole

slots (2 per side). Remove the retaining screws (2) one at the top and one at the bottom. Lift off the collar /

flange assembly complete with door and set aside.

The PSU Assembly is mounted on a chassis which is fixed into the box by 1 screw through a keyhole slot at

the top of the chassis. There are two metal retainers at the bottom.

The screw must be loosened then the chassis plate can be lifted up and out of the box.

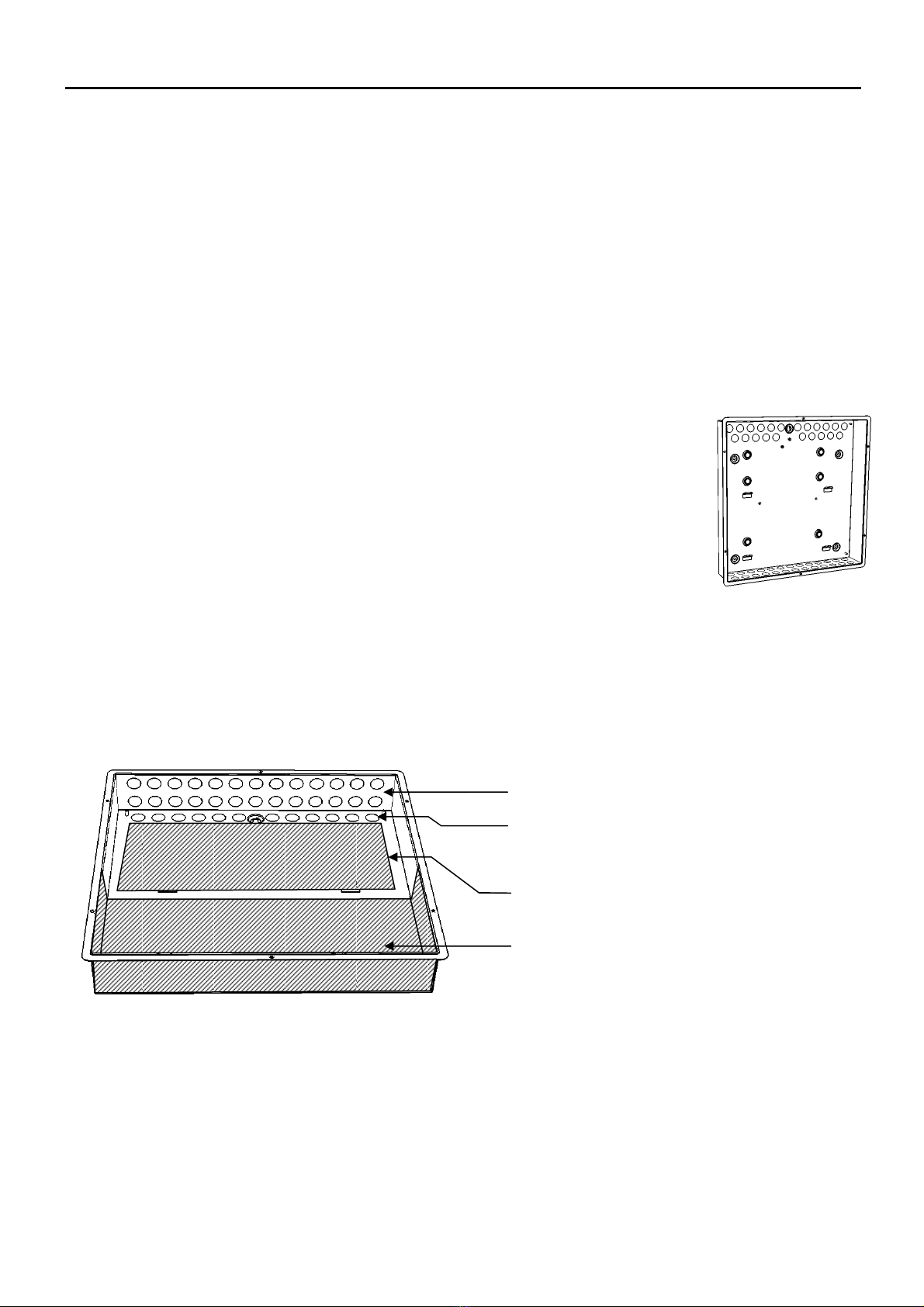

Cabinet Installation

This back box is compatible with the Quadnet range of Fire Alarm Control

Equipment and is common to the range of control panels, repeater panels and

power supply units.

Surface Mounting

At least four of the five mounting holes should be used to secure the cabinet to a

solid wall using suitable screws of at least 50mm in length. A gap of at least 50mm

should be left between this enclosure and the control panel enclosure (if mounted

adjacent).

.

Cable Entry

The cable entry locations available will depend on the type of unit that is intended, and it is important to note

which cable entry areas are suitable for each derivative.

Quadnet Power Supply Unit

The two rows of knockouts at the top are suitable.

The single row of knockouts in the rear at the top

is suitable (not the second row).

The main rear face in the top half must be kept

clear for mounting the electronics.

The main rear face and the two sides in the

bottom half, and the bottom edge, must be kept

clear for mounting the batteries.

Technical Data

Dimensions: Width x Height (excluding flange) 415mm x 415mm

Width x Height (including flange) 445mm x 445mm

Depth 75mm

Flush Mount Hole Size Backbox only 420mm x 420mm

Quadnet Power Supply Unit Installation Manual

8

Physical Dimensions

Power Supply Assembly

This is the reverse of the disassembly process above.

50mm

50mm

420mm

420mm

FLUSH MOUNT HOLE IN WALL

Quadnet Power Supply Unit Installation Manual

9

Topology & Cabling

All system wiring should be installed to comply with BS 5839: Pt 1: 2002: Amendment 2: 2008 and BS 7671

(wiring regulations) and any other standards relevant to the area or type of installation. A cable complying

with the BS 5839: Pt 1: 2002 Category 1 (cables required to operate for prolonged periods during fire

conditions) is required. This must be a 2-core 1.5mm2screened fire resistant cable (ie. MICC, FP200,

Firetuff, Firecell, Lifeline or equivalent). Ventcroft No-Burn multicore cable was utilised during the LPCB

approval testing.

If connected to the Quadnet control panel, the Power Supply Unit requires both a data connection and dual

power connections. Thus, one x 2 core 1.5 mm2screened fire resistant cable must be installed between the

PSU and the control panel for data connection, and 2 x 1.5 mm2screened fire resistant cable must be

installed between the PSU and the control panel for 24V DC power connections if each cable is no longer

than 6.3m (use 2.5 mm2for 24V DC power cables up to a maximum of 9.5m).

In order to protect against possible data corruption it is important to ensure the following points are adhered

to:

1. The data and power cables must have the screen/earth connected at the control panel and

at the Power Supply Unit using the terminals provided.

2. Do not use a 4-core cable to save the installation of two 2-core cables. It is essential that

individual 2-core cables are used.

When fitting the mains, power and signal cables to the Power Supply Unit equipment and before attaching

the connectors, slide the ferrite sleeve over the cable so that it butts up against the Power Supply Unit case.

Fit the tywrap around the cable under the ferrite sleeve to lock the ferrite into position on the cable.

Cable Specification

For DC Power and Communications between PSU and Control Panel:

Max Capacitance Core to Screen................................................... 180pF / m

Max Capacitance Core to Core....................................................... 100pF / m

Max Inductance............................................................................... 1.0mH / km

Max Resistance Two Core Screened 1.5mm²................................ 12.1Ω/ km

Fire Proof ........................................................................................ BS5839: Pt1: 2002 Category 1

Example .......................................................................................... Datwyler 8700

Quadnet Power Supply Unit Installation Manual

10

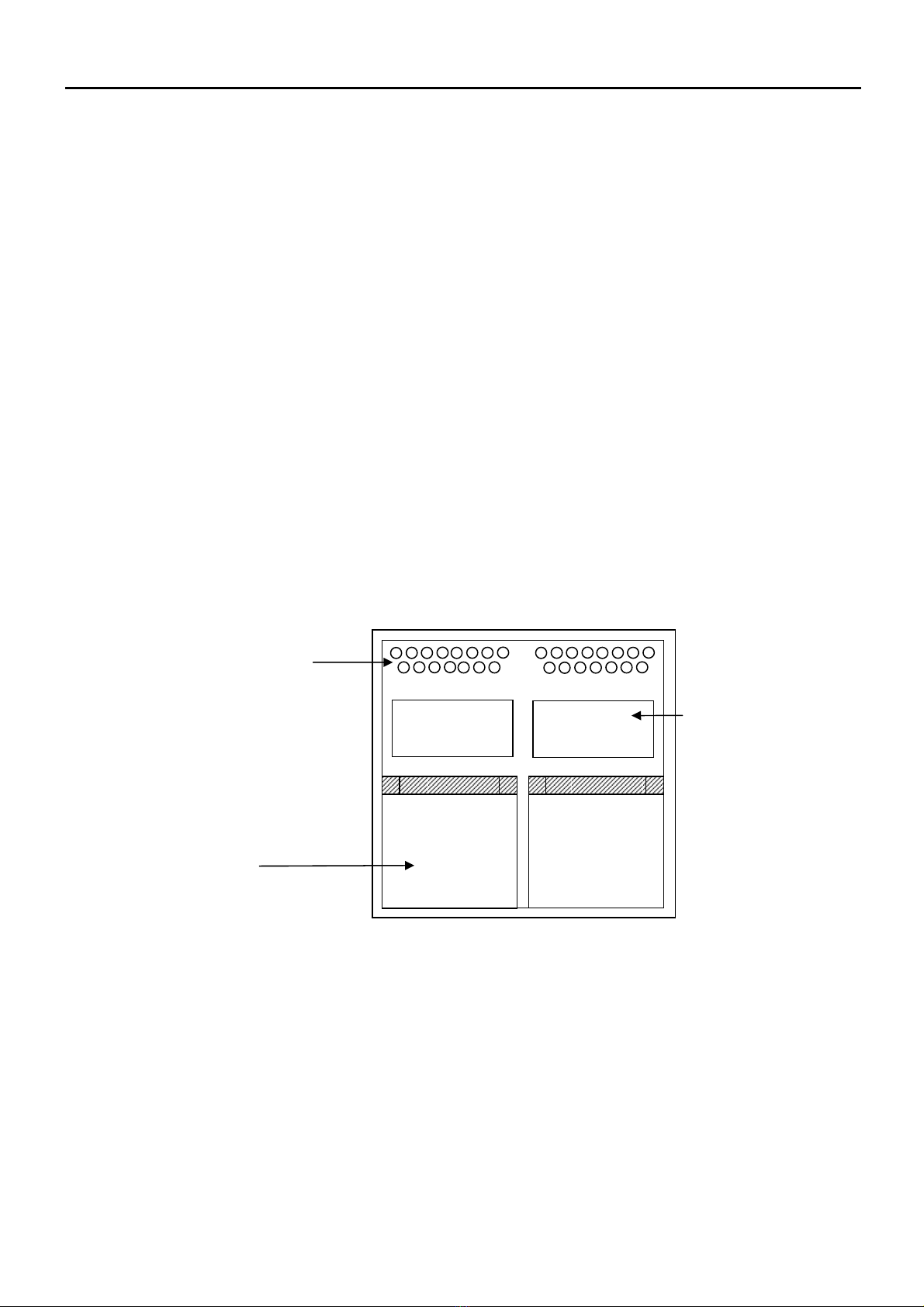

Mains Supply & Batteries

The Fire Alarm Panel 230V AC supply requires fixed wiring between 0.75 mm2and 2.5 mm2, a 3 amp fused

un-switched spur with local isolation, to be terminated into the fused terminals provided in the power supply

back box. The mains supply should be dedicated to the Fire Alarm Panel and should be clearly labelled

‘FIRE ALARM: DO NOT SWITCH OFF’ at all isolation points.

The standby will vary depending on the system loading. The PSU requires 2 x 12V 17Ah sealed lead acid

batteries. These are to be sited in the power supply back box in the provided enclosure along the bottom

edge. The batteries should be connected in series using the connection leads supplied. We recommend

the use of type Yuasa NP17-12I (FR) or other equivalent approved type.

Do not use larger or smaller capacity batteries on this system, larger batteries will not fully charge in the

time allowed and smaller ones will be overcharged and the service life will be reduced.

Using different capacity or type of batteries could also invalidate any warranty.

Note that batteries are electrically live at all times and great care should be taken to ensure that the

terminals are never presented with a short circuit. Care should be taken at all times, especially during

transit, installation and normal use.

Use caution as there is a risk of explosion if the batteries are replaced by an incorrect type.

Batteries no longer required should be disposed of in a safe and environmentally friendly manner by the

battery manufacturer or a suitable recycling service. They should never be incinerated or placed in normal

rubbish collection facilities. Dispose of used batteries according to the instructions.

Knockouts at top and rear

Field Wiring Connections

2 x 12V 17Ah sealed

lead acid batteries

12V 17AH

BATTERY

12V 17AH

BATTERY

CHARGE

CONTROLLER

SWITCHED

MODE PSU

Quadnet Power Supply Unit Installation Manual

11

PSU Termination Schematic

NOTE: The diagram above shows a V3 PSU. Earlier models differ slightly.

Quadnet Power Supply Unit Installation Manual

12

PSU Terminals

Mains Input: L, N, E

The 230V AC input is to be connected into the terminals provided on the Charge Controller Unit. This input

is protected by the 4AT live and neutral fuses adjacent to the terminals. Please use caution as double pole

live and neutral fusing is used.

Battery Connections: +24V, 0V

The battery terminals require 24V from 2 x 12V 17Ah sealed lead acid batteries, connected in series, in

order to provide secondary backup power when the primary power fails. This input is protected by the 10AT

fuse adjacent to the terminals.

Fault Relay: NO, NC, COM

The Fault relay is a single-pole change-over ‘volt-free’ relay contact. The relay contacts are rated at 30V

DC / 1A max. All inductive loads should be diode protected to prevent back EMF. However, if this is not

done, the load should be limited to 200mA to reduce the likelihood of back EMF causing damage to the

relay contacts.

The relay is de-energised in the fault condition.

Terminal Description

COM Common contact

NC Normally closed contact

NO Normally open contact

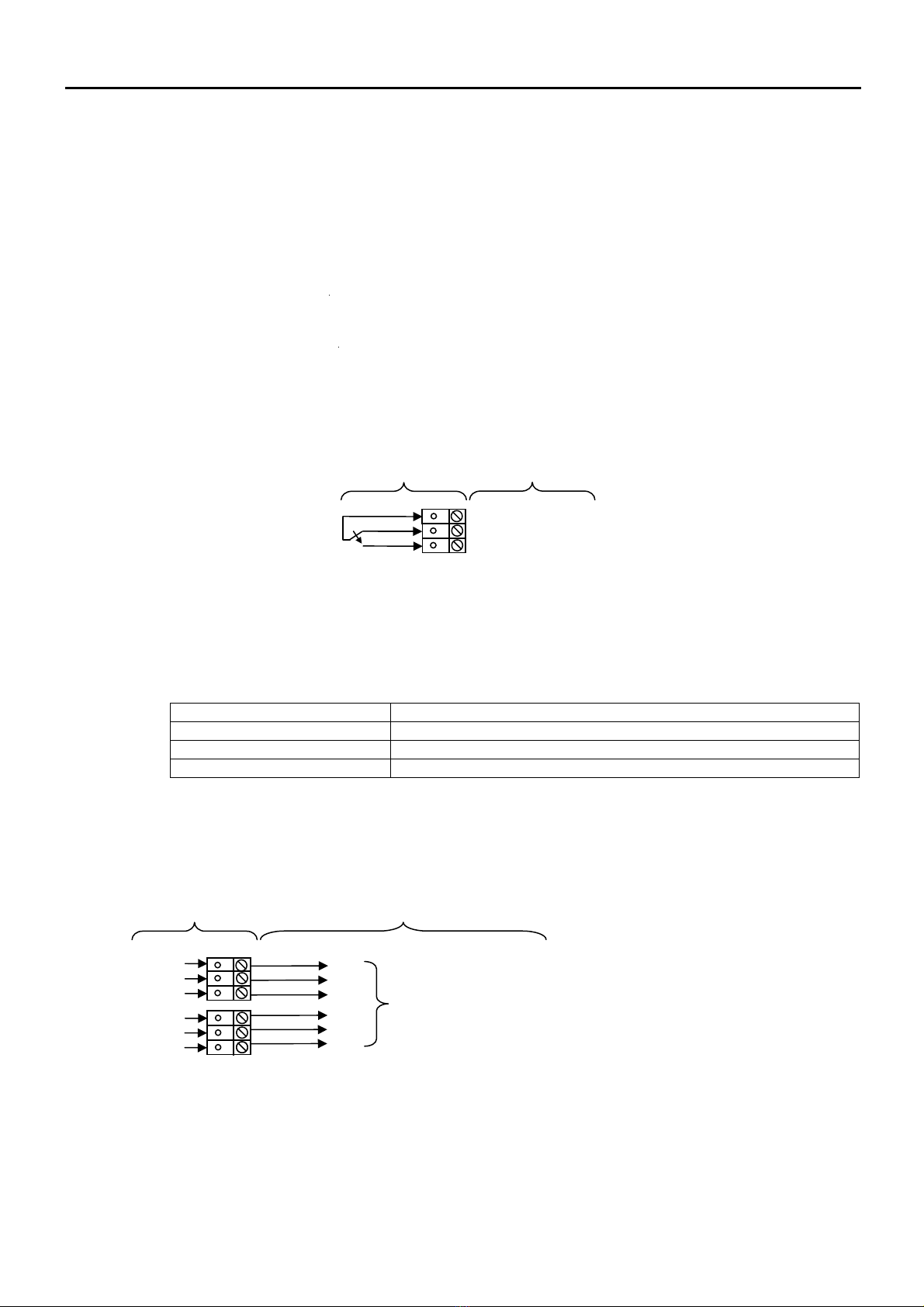

PSU OUTPUT TO CIE: SCRN, 0V, +24V, SCRN, 0V, +24V

The PSU OUTPUT connections connect the DC power from the PSU to the main control panel.

COM

NO

NC

ON BOARD PCB EXTERNAL CONNECTIONS

ON BOARD PCB EXTERNAL CONNECTIONS

TWO CABLES TO PSU INPUT

TERMINALS ON CONTROL PANEL

BACKPLANE

SCRN

OV

+24V

SCRN

SCRN

OV

+24V

SCRN

OV

OV

+24V

+ 24V

CN1

CN2

Quadnet Power Supply Unit Installation Manual

13

The PSU connections connect the Power Supply Unit to the control panel.

To comply with EN54-4, two 2-core 1.5mm2screened cables must be used for the +24V and 0V power

connections, up to a maximum of 6.3m in length. These cables should be connected at each end using the

SCRN terminals provided

If a greater distance is required between the main PSU and the main control panel, then two 2-core 2.5mm2

screened cables should be used for the +24V and 0V power connections, up to a maximum of 9.5m in

length. These cables should be connected at each end using the SCRN terminals provided.

NOTE: that if using multiple external PSUs, the quoted maximum cable lengths are the total length

from the CIE to the last PSU, not the length of each individual cable run.

Duonet control panels prior to V3 (backplane PCB Issue 3) do not have twin power connections for an

external PSU or the facility for monitoring comms with an external PSU so it is recommended that no

external PSU is used with those panels. For V3 Duonet control panels, wire as per Quadnet control panels

above.

Terminal Description

SCRN Cable screen connection

+24V Power Supply +24V connection

OV Power Supply 0V connection

PSE INPUT: SCRN, 0V, +24V, SCRN, 0V, +24V

The PSE INPUT connections connect a Secondary PSU to the main Power Supply Unit.

The Secondary PSU must be installed adjacent to the main Power Supply unit. Two 2-core 1.5mm2or 2.5

mm2 screened cables should be used for the +24V and 0V power connections. These cables should be

connected to earth at each end at the SCRN terminals provided

Terminal Description

SCRN Cable screen connection

+24V Power Supply +24V connection

OV Power Supply 0V connection

ON BOARD PCB EXTERNAL CONNECTIONS

FROM PSU OUTPUT TERMINALS (CN1

an CN2) ON SECONDARY PSU

SCRN

OV

+24V

SCRN

SCRN

OV

+24V

SCRN

OV

OV

+24V

+ 24V

CN3

CN4

Quadnet Power Supply Unit Installation Manual

14

CIE COMMS: A, B, SCRN,

The CIE COMMS connections transmit the PSU status to the main CIE panel. These cables are fault

monitored and are required for full fault monitoring of the PSU.

A 2-core 1.5mm2screened cable should be used for the Data connections (A and B), up to a maximum of

9.5m in length.

NOTE: If using multiple external PSUs, the quoted maximum cable length is the total length from

the CIE to the last PSU, not the length of each individual cable run.

Terminal Description

A Serial Data connection A

B Serial Data connection B

SCRN Cable Screen connection

PSE COMMS: A, B, SCRN,

The Secondary PSU must be installed adjacent to the main Power Supply unit. The PSE COMMS

connections transmit the status of any secondary PSUs to the main PSU. These cables are fault monitored

and are required for full fault monitoring of any secondary PSU fitted.

A 2-core 1.5mm2screened cable should be used for the Data connections (A and B).

Terminal Description

A Serial Data connection

B Serial Clock connection

SCRN Cable Screen connection

B

ON BOARD PCB EXTERNAL CONNECTIONS

TO QUADNET CIE PANEL

A

SCRN

B

A

SCRN

ON BOARD PCB FIELD CONNECTIONS

TO CIE COMMS OF SECONDARY PSU

SCRN

B

A

SCRN

B

A

Quadnet Power Supply Unit Installation Manual

15

Address Select Links

Each PSU connected to the same control panel must be given a unique address.

Addresses are set using the address select links on the Quadnet PSU Charge Controller Unit, fitting link

jumpers in the appropriate positions as follows:

ADDRESS 0 1 2 3 4

LINK JUMPERS

For normal Quadnet systems where only one PSU is used with the panel, the PSU’s address must

be set to 0 or 1.

If connecting secondary PSUs to the Quadnet system the main PSU should be address 1 and up to 3

more PSUs may be connected (addressed in sequence).

Note that if the Quadnet PSU is used as an additional external PSU for a Duonet control panel, the

internal PSU within Duonet already has address 1. Therefore the external PSU addresses should

start at 2 and continue in sequence up to address 4.

Example Connection Diagram

Quadnet Power Supply Unit Installation Manual

16

Fuses

The following fuses are located on the Charge Controller Unit.

Fuse No Label Fuse Type Breaking

Capacity

Max Rated

Voltage

FUSE1 Input from SMPS 10A T Glass 100A 250VAC

FUSE2 Battery 10A T Glass 100A 250VAC

FUSE3 Mains Input: Live 4A T Ceramic 1500A 250VAC

FUSE4 Mains Input: Neutral 4A T Ceramic 1500A 250VAC

Quadnet Power Supply Unit Installation Manual

17

Commissioning

Installation 1st Stage

The Power Supply Unit back box should be mounted, with the mains supply tested, connected and isolated

at the un-switched fused spur, ready for the commissioning engineer.

The installer needs to provide a set of As-Wired drawings and proof of cable continuity and insulation

test readings etc., to enable commissioning to proceed. This information is essential for commissioning

and programming to proceed, and may be entered onto the forms provided at the rear of the manual.

Power Up

It is generally advisable that this Power Supply Unit should be powered up by making the 230V AC mains

connection before the batteries are connected.

Quadnet Power Supply Unit Installation Manual

18

Good Practice

The following suggestions are good practice if carried out during commissioning, and may help avoid

common problems at a later date. The Fike Technical Support department may be unable to assist if the

information is unavailable, and the guidelines not followed.

Battery Data

Make a clear note by labelling of the batteries of the installation date and the battery voltage. The battery

voltage should be taken for each battery with the 230V AC mains supply removed, and the system in the

quiescent state. The voltage should also be noted on the label of each battery as a part of the system

servicing.

Cable Readings

Make a clear note in the Power Supply Unit of the cable continuity and insulation resistance readings,

including those for the screen and mains earth.

Quadnet Power Supply Unit Installation Manual

19

Technical Data

Power Supply Unit

Quadnet Power Supply Equipment

Dimensions W x H x D 445mm x 445mm x 110mm

Power Supply Standby batteries

Mains supply

Vmax

Vmin

Ri max

I min

I max a

Battery Charging

Voltage/Current Details

Ripple and noise

2 x 17Ah 12V sealed lead acid batteries

230V AC nominal

31V

19V

0.5R (max internal resistance)

350mA (min output current)

5.5A (max output current)

27.3V @ 21oC, temperature compensated

-5o/+40oC, max charge current 1.7A

<= 5% of Vmax

Outputs Relay Outputs x 1

Volt free contact SPCO Fault Output

30V DC @ 1.0A max

Note: Refer to the relevant sections in the manual for full details of output ratings

Quadnet Power Supply Unit Installation Manual

20

Further Information

PSU Cable Continuity & Insulation Test Results

After installation of the cable, and termination into all the relevant back-boxes, take cable continuity and

insulation readings. Make sure that all the cables are dressed smoothly and neatly into their back-boxes in

order that they will not be disturbed after the readings are taken.

The commissioning engineer will require these readings, along with correctly marked ‘as-wired’ drawings

and completed configuration sheets, before attending site to commission the system.

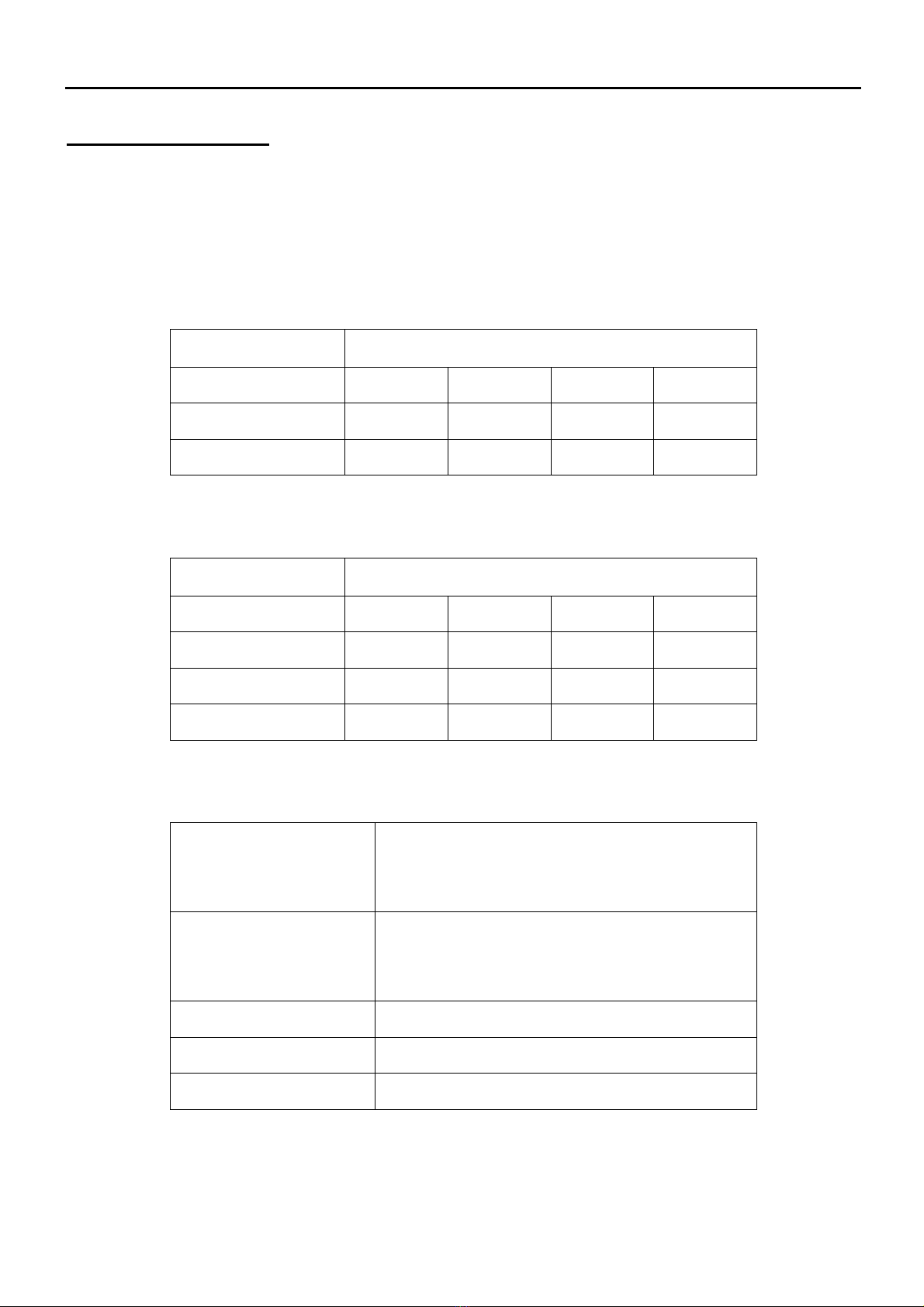

CORE CONTINUITY READING (OHMS)

PSU Data Power 1 Power 2

+ve to -ve with temp

short circuit applied

-ve to Earth with temp

short circuit applied

+ve to Earth with temp

short circuit applied

A reading of approximately 1 ohm per 100 metres of 1.5 mm2cable is expected and any significant

variation from this should be investigated. If the above readings are satisfactorily showing circuit continuity

then you may also take the reading below.

CORE INSULATION READING (OHMS)

PSU Data Power 1 Power 2

+ve to -ve

+ve to Screen

-ve to Screen

Screen to Mains Earth

A reading in excess of 1 M ohm is expected and any significant variation from this should be investigated. If

the readings are satisfactory then the loop wiring is largely proven other than for faults such as complete

polarity reversal.

Site Name & Address:

Installation Company:

Testing Engineer:

Signature:

Date:

Table of contents

Other Fike Power Supply manuals