READ THIS CAREFULLY BEFORE INSTALLATION!

LEGGERE ATTENTAMENTE PRIMA

DELL’INSTALLAZIONE!

A LIRE ATTENTIVEMENT AVANT L’INSTALLATION!

Before operating, read this document thoroughly and retain

it for future reference.

Non-respect of these instructions may reduce

performances and safety of the devices and cause danger

for people and property.

The products must be installed, operated, serviced and

maintained by qualified personnel in compliance with

applicable standards and regulations.

Don’t open the device, it does not contain replaceable

components, the tripping of the internal fuse (if included) is

caused by an internal failure.

Don’t repair or modify the device, if malfunction or failure

should occur during operation, send unit to the factory for

inspection. No responsibility is assumed by Nextys SAfor

any consequences deriving from the use of this material.

Prima dell’installazione, leggere attentamente questo

documento istruzioni e conservarle per future consultazioni.

L’inosservanza delle presenti istruzioni può compromettere le

caratteristiche e la sicurezza dell’apparecchio e causare

pericolo per le persone e le cose.

Il prodotto deve essere installato, utilizzato eriparato da

personale qualificato e nel rispetto delle normative vigenti.

Non aprire ilprodotto, esso non contiene componentisostituibili,

il guasto del fusibile interno (se previsto) è causato da un

guasto interno. Non tentare di riparare o modificare ilprodotto,

se durante ilfunzionamento siverificano guasti o anomalie,

inviarlo al produttore per il controllo.

Nextys SA non siassume nessuna responsabilità per

qualunque conseguenza derivante dall’uso di questo materiale.

Lisez ces instructions avant l'installation, conservez ce

manuel pour référence future.

Défaut de se conformer à ces instructions peut affecter les

caractéristiques et la sécurité du dispositif de danger et de

causer aux personnes ou aux biens.

Les produits doivent être installés, exploité et entretenus par

personnel qualifié et en conformité avec les règlements.

N'ouvrez pas le produit, il ne contient aucune pièce réparable,

le déclenchement du fusible interne (le caséchéant) est

causé par un défaut interne. Ne pas essayerde réparer ou

modifier le produit ; si des défaillances se produisent pendant

le fonctionnement ou les dysfonctionnements, le retourner au

fabricant pour inspection. Nextys SA n'assume aucune

responsabilité des conséquences éventuelles découlant de

l'utilisation des produits.

RISK OF BURNS, EXPLOSION, FIRE, ELECTRICAL

SHOCK, PERSONAL INJURY.

Never carry out work on live parts! Danger of fatal injury!

The product’s enclosure may be hot, allow time for cooling

product before touching it. Do not allow liquids or foreign

objects to enterinto the products.

To avoid sparks, do not connect or disconnect the device

before having previously turned-off input power and wait for

internal capacitors discharge (minimum 1 minute).

RISCHIO USTIONI, ESPLOSIONE, INCENDIO, SCOSSA,

LESIONI GRAVI.

Non effettuare mai operazioni sulle parti sotto tensione! Pericolo

di lesioni letali! Il contenitore può scottare, lasciar quindi

raffreddare il dispositivo primadi toccarlo.Non far entrare liquidi

o oggetti estranei nel dispositivo.

Per evitare scintille, non collegare o scollegare

l'apparecchiatura prima di avere tolto tensione di ingresso e

prima che sia avvenuta la scarica dei condensatori interni (min.

1 minuto).

RISQUE DE BRULURES, EXPLOSION, INCENDIE,

ELECTROCUTION, DOMMAGE AUX PERSONNES.

Ne jamais effectuerdes opérations sur les parties sous

tension! Danger de mort! Le récipient peut produire des

brulures, le laisser refroidir avant de toucher l'appareil. Ne

faites pas pénétrerdes liquides ou des corps étrangers dans

l'appareil. Pour éviter des étincelles, ne pas connecter ou

déconnecter l'équipement jusqu'à ce que vous avez supprimé

la tension d'entrée et avant qu'elle n'ait lieu de décharge des

condensateurs internes (minimum 1 minute).

DECLARATION OF CONFORMITY

NEXTYS SA.

Via Luserte Sud 6, 6572 Quartino - Switzerland

Phone: +41-(0)91 840 14 46 / 840 14 48; Fax: +41-(0)91 840 14 47

This Declaration ofConformity is suitable to the European Standard EN45014 "General criteria for supplier’sdeclaration of conformity".

We declare underour sole responsibility that the device included in this box,has passed all processing inspections and the final test and it is in conformity with theproduct

requirements, including all reference codesand supply specifications.

ROHS compliance: the product respects the EC requirements related to ROHS substances, according to “Restriction of Hazardous Substances” as per document 2011/65/UE

REACH compliance: theproduct respectsthe EC requirements related to REACH SVHC directive (2015)

Note: all the reported information comes from our suppliers, NEXTYS SA.has not runany test to evaluate if the specific elements arepresent.

All indicated devices are designed according to the latestReference standards,if not expressly indicated through the official documents or files, they havebeen tested through

our internal pre-compliance testing. Consult directlyon www.nextys.com the reference standardsapplied to eachmodel.

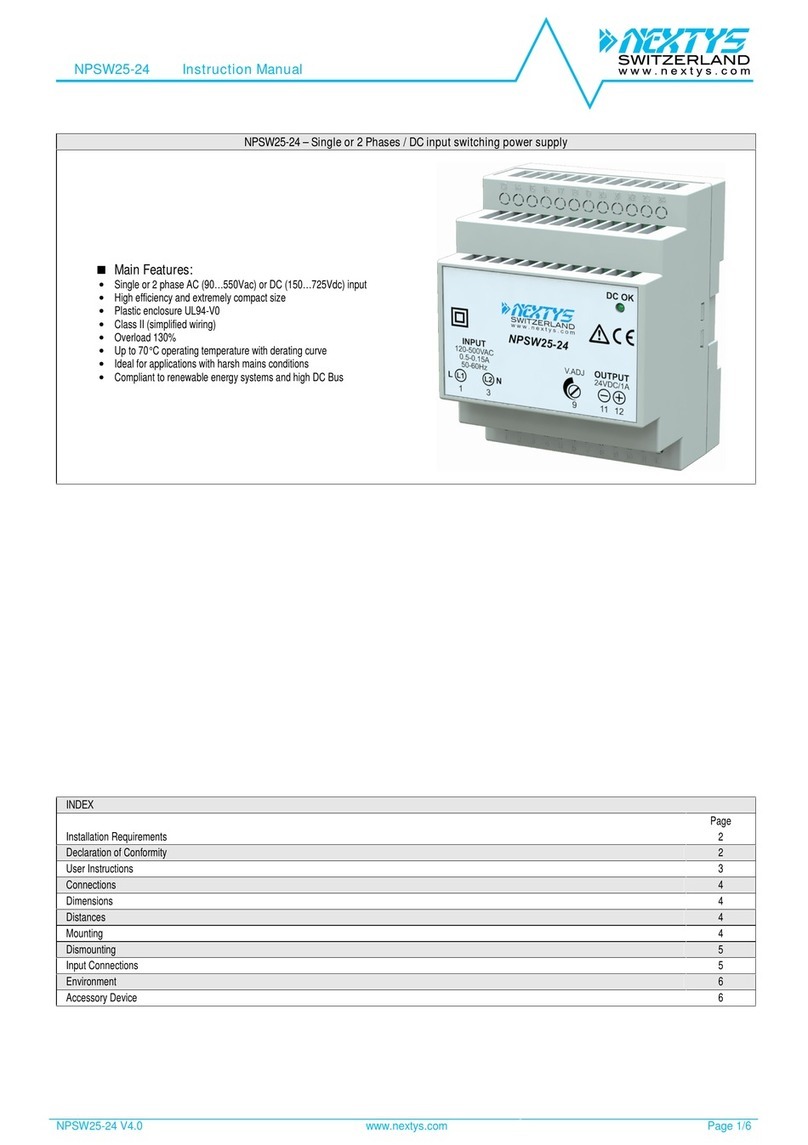

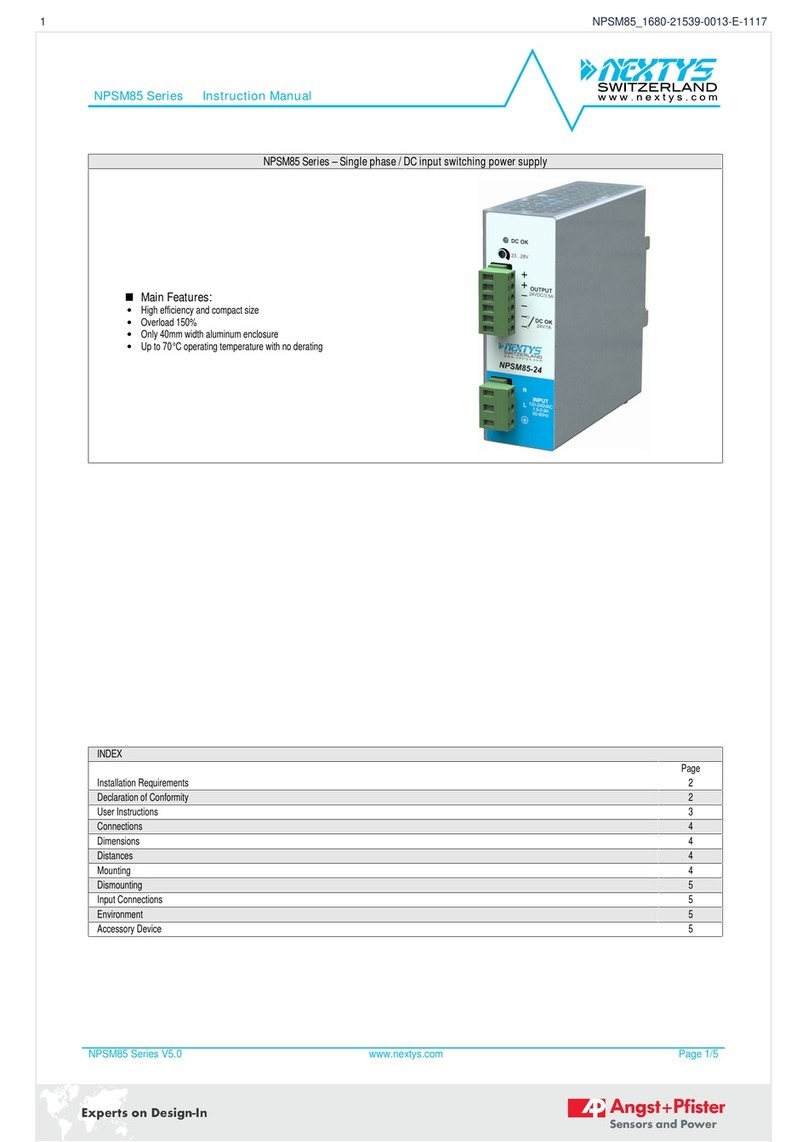

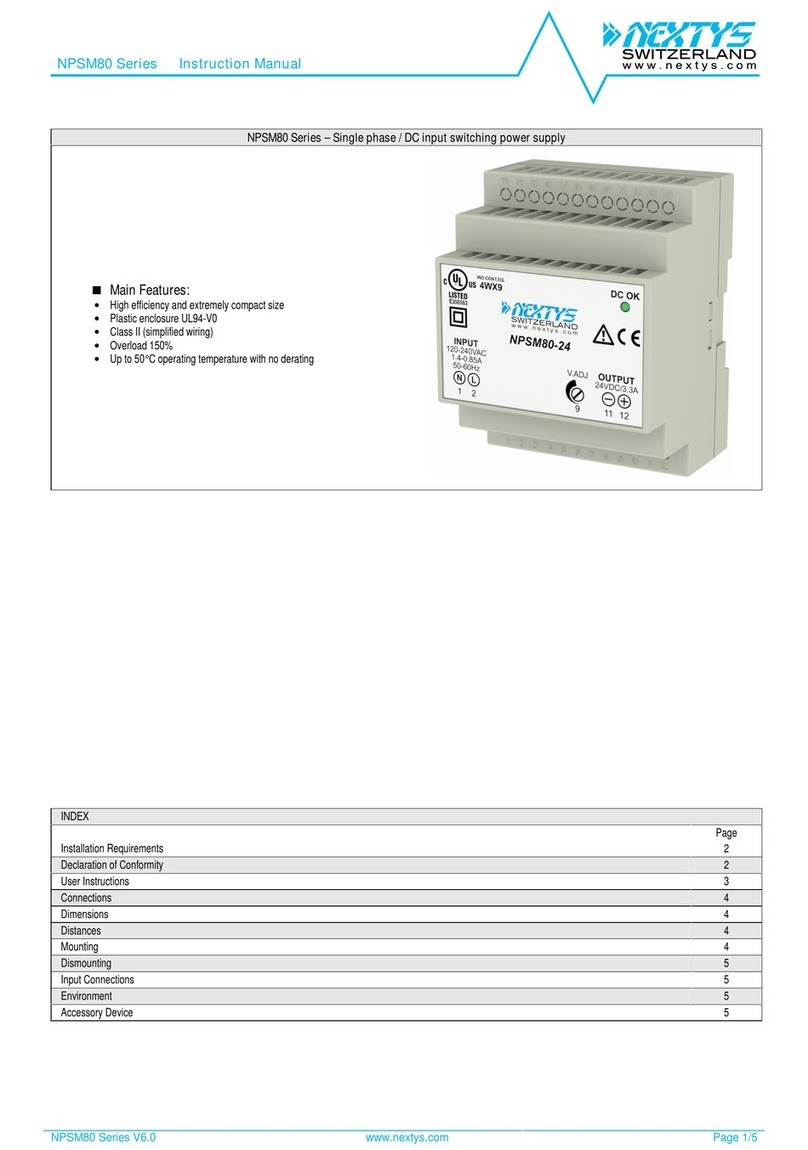

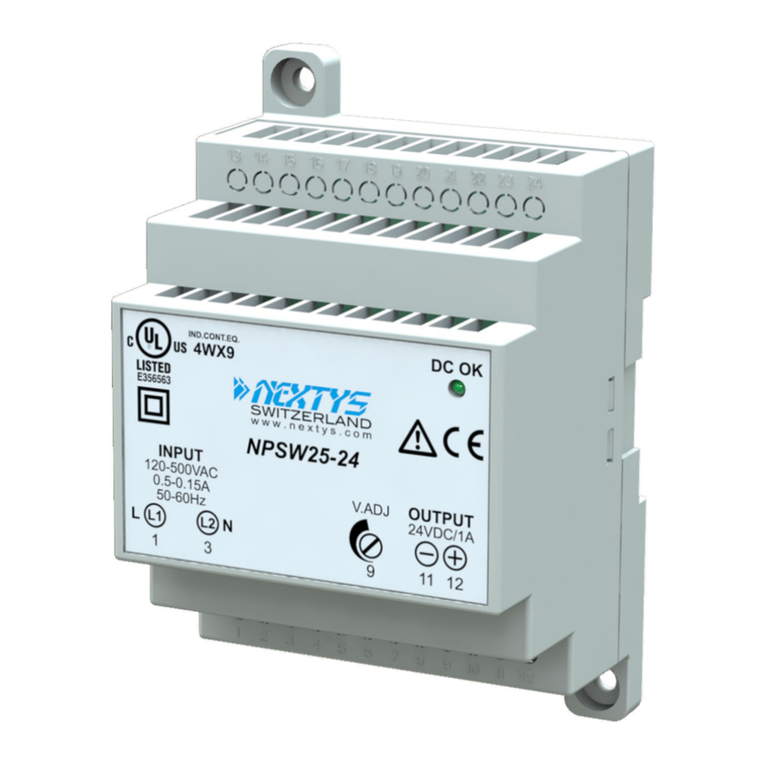

Code Description

NPSM121-24 Single phase with integrated PFCswitching powersupply IN 120 - 240Vac (110 - 345Vdc)/ OUT 24Vdc - 5A

NPSM121-24P Single phase with integrated PFCswitching powersupply IN 120 - 240Vac (110 - 345Vdc)/ OUT 24Vdc - 5A +ORing circuit

NPSM121-48 Single phase with integrated PFCswitching powersupply IN 120 - 240Vac (110 - 345Vdc)/ OUT 48Vdc - 2.5A

NPSM121-48P Single phase with integrated PFCswitching powersupply IN 120 - 240Vac (110 - 345Vdc)/ OUT 48Vdc - 2.5A + ORing circuit

Certifications and approvals

2014/35/EU (2014) (Low Voltage Directive)

2014/30/EU (2014) (EMC directive)

EN60950-1:2006 /A2:2013 (Safety Standards)

UL508 (Certified - IND. CONT. EQ. 4WX9 file no. E356563)

EN61000-6-2:2005 (Generic immunity standard for industrial environments)

- EN61000-4-2:2008 (Electrostatic discharge immunity test)

- EN61000-4-3:2006 /A2:2010 (Radiated, radio-frequency, electromagnetic field immunity test)

- EN61000-4-4:2012 (Electrical fast transient/burst immunity test)

- EN61000-4-5:2014 (Surge immunity test)

- EN61000-4-11:2004 /A1:2010 (Voltage dips, shortinterruptions and voltage immunity test)

EN61000-6-3:2007 /A1:2011 (Generic emission standard for residential environments)

- EN55022:2010 (CISPR22 - EMC)

- EN55011:2009 /A1:2010 (CISPR11 - EMC)

- EN61000-3-2:2014 (Limits for harmonics current emissions)

Date: 25.02.2016

Place: Quartino, Switzerland

The product manager

Marius Ciorica