Fike SITA200plus User manual

26-0540 Issue 5

Sita200plus Repeater Panel V4.14

Repeater Panel

Installation Instructions

(TO BE RETAINED BY THE COMMISSIONING ENGINEER)

Sita200plus Repeater Panel Installation Instructions

2

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every care has been

taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability whatsoever in respect of such

contents.

Due to the complexity and inherent importance of a life risk type system then training on this equipment is essential, and commissioning should only be

carried out by competent persons.

Fike cannot guarantee the operation of any equipment unless all documented instructions are complied with, without variation.

E&OE.

Fike equipment is protected by one or more of the following patent no’s: GB2426367, GB2370670, EP1158472, PT1035528T, GB2346758,

EP0917121, GB2329056, EP0980056, GB2325018, GB2305284, EP1174835, EP0856828, GB2327752, GB2313690

Sita200plus Repeater Panel Installation Instructions

3

Contents

Introduction . . . . . . . . 4

System Design . . . . . . . 4

Equipment Guarantee . . . . . . 4

Anti Static Handling Guidelines . . . . . . 4

Warning . . . . . . 4

EMC . . . . . . 4

Repeater Panel . .

. . . . . .

5

Mounting the Repeater Panel . . . . . . 5

General Assembly . . . . . . . 5

Physical Dimensions .. . . . . . . 6

Power Supply Unit . . . . . . . 6

Topology and Cabling . . . . . . . 7

System Wiring Schematic . . . . . . . 7

Repeater Panel Connections . . . . . . 8

Terminals and Fuses . . . . . . . 8

General Operation . . . . . . . . 12

Repeater Panel Front . . . . . . . 12

Soft Key Menus . . . . . . . . 12

Access Codes . . . . . . . . 13

Access Levels . . . . . . . . 13

Access Level 1 (Normal) . . . . . . 13

Access Level 2 (User) . . . . . . . 14

Access Level 3 (Engineer) . . . . . . 15

Installation & Commissioning . . . . . . 16

Installation 1

st

Stage . . . . . . . 16

Installation 2

nd

Stage . . . . . . . 16

Commissioning . . . . . . . . 16

Fault Finding . . . . . . . . 17

Technical Data . . . . . . . . 18

Repeater Panel . . . . . . . 18

Technical Support . . . . . . . 18

Further Information . . . . . . . . 19

Battery Calculations . . . . . . . 19

Installation Checklist . . . . . . . 20

Commissioning Checklist . . . . . . 21

Cable Continuity and Insulation Test Results . . . . 22

Important Points . . . . . . . 24 – BACK PAGE

Sita200plus Repeater Panel Installation Instructions

4

Introduction

This Manual is intended as a guide to the engineering and commissioning principles of the Sita200plus

Addressable Intelligent Fire Alarm and Detection system, and covers the system hardware information only.

Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on this

equipment is essential. Installation and commissioning should only be carried out by competent and approved

persons. For further details of the availability of commissioning services contact your supplier.

System Design

This document does not cover Fire Alarm system design, and a basic understanding is assumed.

A knowledge of BS5839: Pt 1: 2002 +A2: 2008 : Fire Detection and Alarm Systems for Buildings

is essential.

It is strongly recommended that a suitably qualified and competent person is consulted in connection

with the Fire Alarm System design and that the entire system is commissioned in accordance with the

current national standards and specifications.

Equipment Guarantee

The equipment carries no warranty unless the system is installed, commissioned and serviced in

accordance with this manual and the relevant standards by a suitably qualified and competent person

or organisation

Anti Static Handling Guidelines

Immediately prior to handling any PCBs or other static sensitive devices, it is essential to ensure that

a personal connection to earth is made with an anti-static wrist-strap or similar apparatus.

Always handle PCBs by their sides and avoid touching any components. PCBs should also be stored

in a clean dry place, which is free from vibration, dust and excessive heat, and protected from

mechanical damage.

Warning

Do not attempt to install this equipment until you have fully read and understood this manual.

Failure to do so may result in damage to the equipment and could invalidate the warranty.

Technical support will not be available if the instruction manual has not been read and understood.

Please have this instruction manual available whenever you call for technical support.

For further technical support please contact your distributor. Do not call the Fike Safety Technology

support department unless your distributor has first given their advice and attempted to rectify the

issue.

EMC

This equipment when installed is subject to the EMC directive 2004/108/EC. It is also subject to UK

Statutory Instrument 2006 No. 3418.

To maintain EMC compliance this system must be installed as defined within this manual. Any

deviation from this renders the installer liable for any EMC problems that may occur either to the

equipment or to any other equipment affected by the installation.

!

!

!

!

!

Sita200plus Repeater Panel Installation Instructions

5

Repeater Panel

Mounting the Repeater Panel

Firstly identify the proposed location for the repeater panel. Ensure that the repeater panel will be easily

accessible, and that account is taken of any subsequent work that may affect access.

The repeater panel should be mounted on a flat, vertical wall at a height where the indicators may be seen without

difficulty.

Like all electronic equipment, the repeater panel may be affected by extreme environmental conditions. The

position selected for its installation should therefore be clean and dry, not subjected to high levels of vibration or

shock and at least 2 metres away from any pager or radio transmitting equipment. Ambient temperatures should

be within the range given within the Technical Data section, i.e., not directly over a radiator or heater.

In common with all microprocessor-controlled panels, the repeater panel may operate erratically or may be

damaged if subjected to lightning induced transients. Proper earth/ground connections will greatly reduce

susceptibility to this problem.

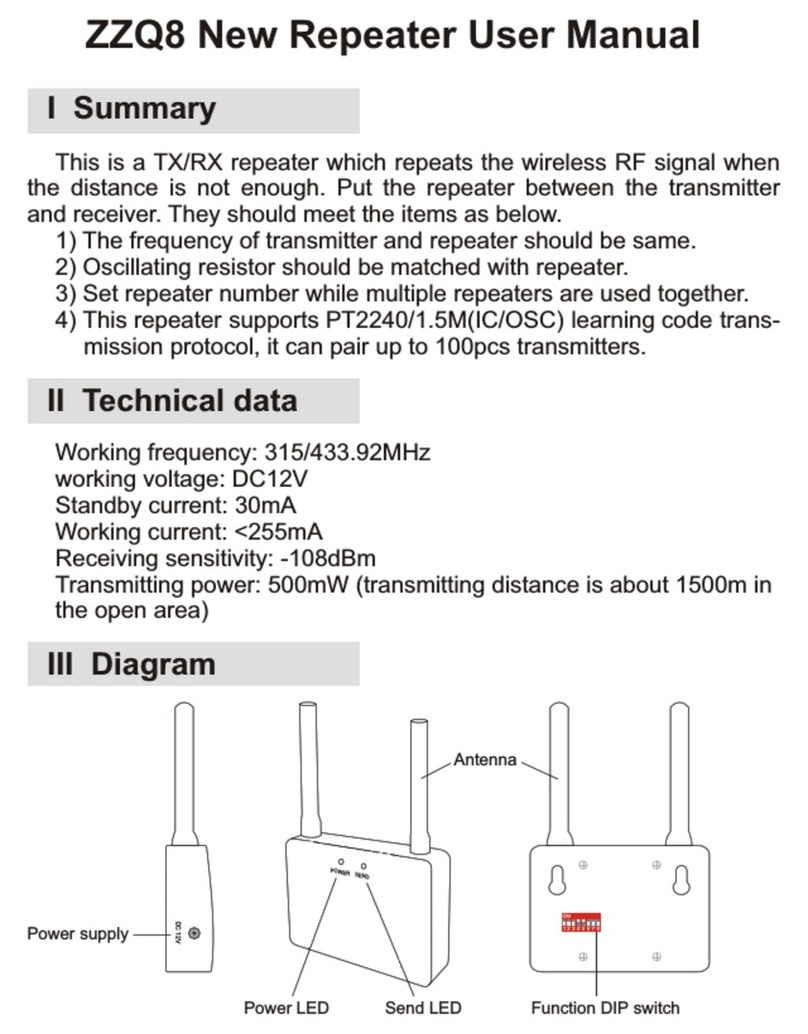

General Assembly

2 x 12V 3.2AH SLA

Yuasa NP3.2-12

Sita200plus Repeater Panel Installation Instructions

6

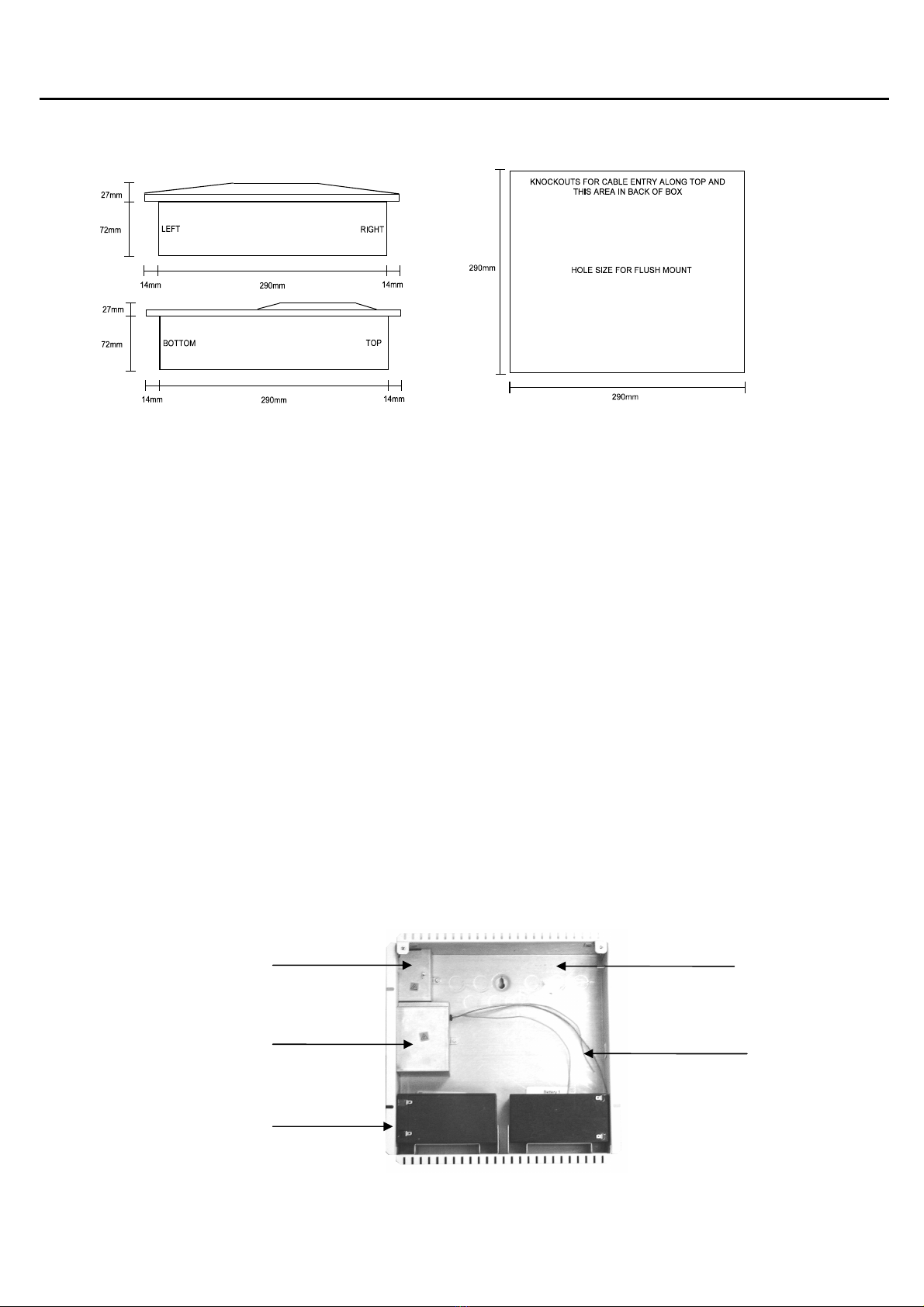

Physical Dimensions

The repeater panel back box is designed as a dual-purpose surface or flush unit. The 14mm flange facilitates

flush mounting. To allow installation of the main front moulding, this flange must be flush with the mounting

surface and not recessed into it.

Power Supply Unit

The repeater panel 230VAC supply requires fixed wiring between 0.75mm

2

and 2.5mm

2

, a 3 Amp fused un-

switched spur with local isolation, to be terminated into the fused terminals provided in the top left hand corner of

the back box and suitably differentiated from the low voltage cables in the repeater panel. The metal cover, held in

place with a locking nut, protects these terminals. The mains supply should be dedicated to the Fire Alarm system

and should be clearly labelled ‘FIRE ALARM: DO NOT SWITCH OFF’ at all isolation points.

The standby requirements are for 2 x 12v 3.2 Ah sealed lead acid batteries to be installed. These are to be sited in

the repeater panel back box in the provided enclosure along the bottom edge, with the terminals facing forward

and outwards (to left/right respectively). This is important to ensure that the battery terminals do not put any

pressure on the main PCB, which could happen if the terminals were bent out at an angle. The batteries should be

connected in series using the connection leads supplied. See the section entitled Repeater Panel Connections for

panel connections.

Note that batteries are electrically live at all times and great care should be taken to ensure that the terminals are

never presented with a short circuit. Care should be taken at all times, especially during transit, installation and

normal use.

Batteries no longer required should be disposed of in a safe and environmentally friendly manner by the battery

manufacturer or a suitable recycling service. They should never be incinerated or placed in normal rubbish

collection facilities.

Incoming mains supply

fuse housing

Transformer housing

2 x 12V 3.2 Ah Sealed

Lead Acid batteries

Knockouts at top

and rear

AC connection

cables

Sita200plus Repeater Panel Installation Instructions

7

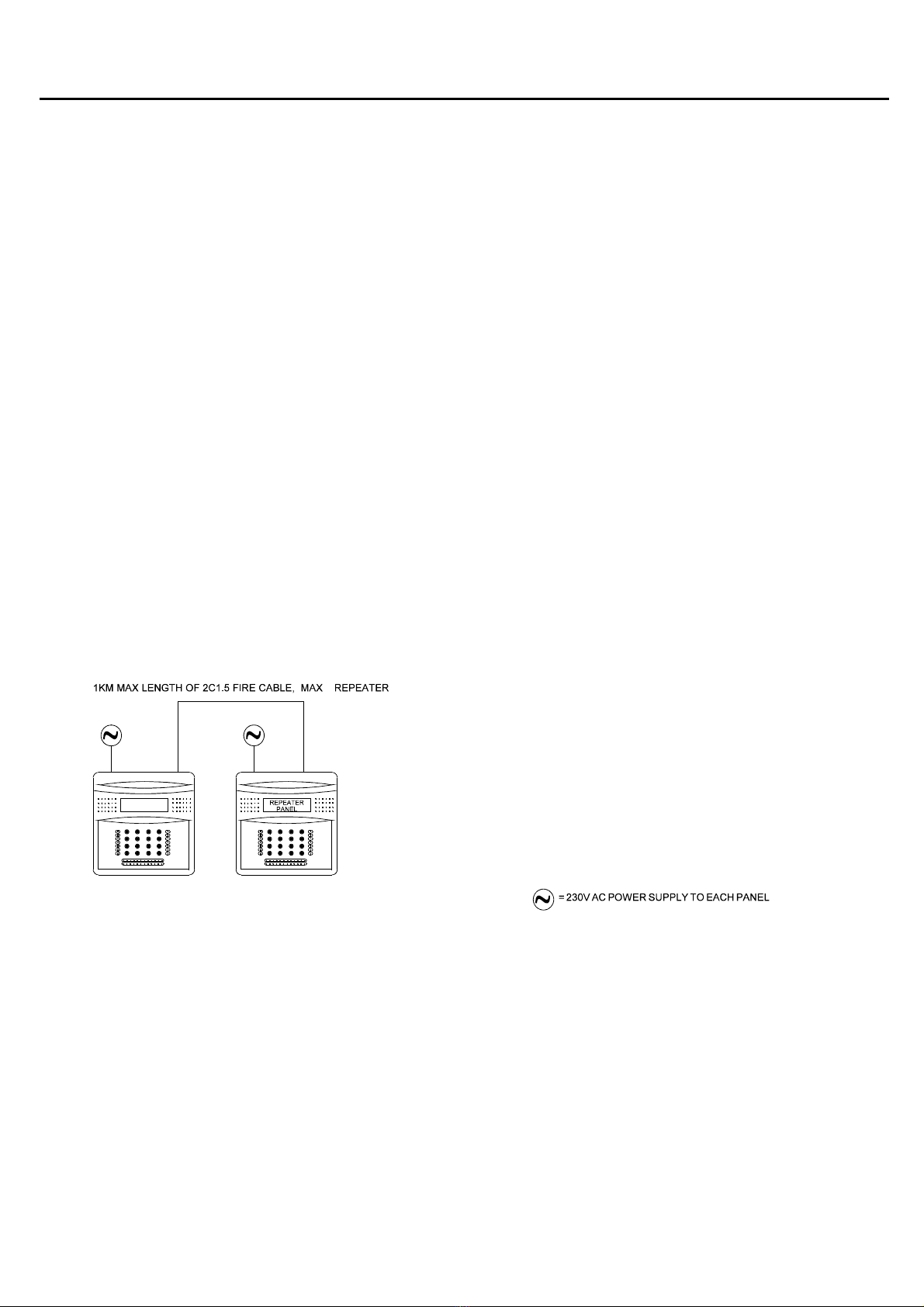

Topology & Cabling

All system wiring should be installed to comply with BS 5839: Pt1: 2002 and BS 7671 (wiring regulations) and any

other standards relevant to the area or type of installation. A cable complying with the BS 5839: Pt1: 2002 (cables

required to operate for prolonged periods during fire conditions) is required. This must be a 2-core 1.5mm

2

screened fire resistant cable (ie. MICC, FP200, Firetuff, Firecell, Lifeline or equivalent).

The Repeater Panel R-Bus connection must be installed as a radial circuit (daisy chain format) with a maximum

length of up to 1 km. A maximum of 1 repeater panel may be connected.

In order to protect against possible data corruption it is important ensure the following points are adhered to:

1. The cable screen between the panel and repeater must be connected to earth/ground at one

end only using the terminals provided. Ensure the end that is not connected is safely terminated in a

connector block to avoid unwanted shorting to any other point.

2. The cable screen must not be connected to earth/ground at any point other than the relevant

control/repeater panel, ie, do not connect the screen to a back box.

3. Do not use a 4-core cable as a data feed & return due to the possibility of data corruption. It is

essential that two 2-core cables are used if this is required.

Refer to the following System Wiring Schematic for further details.

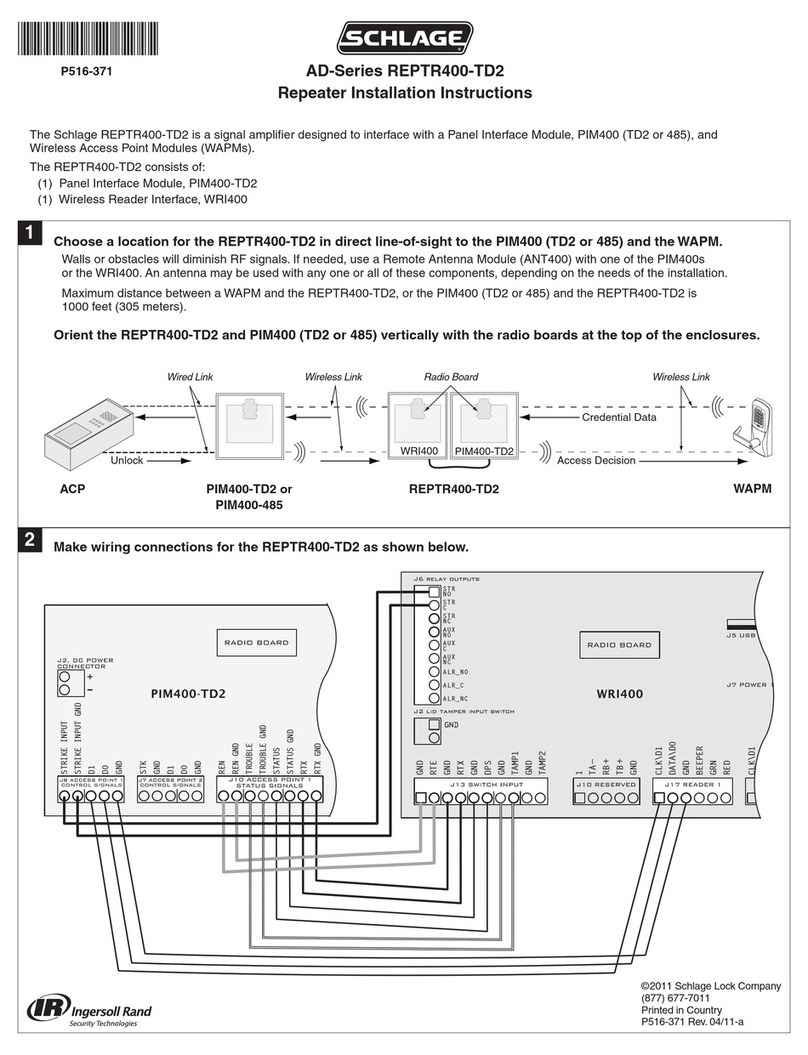

System Wiring Schematic

1

CONTROL

PANEL

CONTROL PANEL MUST BE V4.14 OR LATER

Sita200plus Repeater Panel Installation Instructions

8

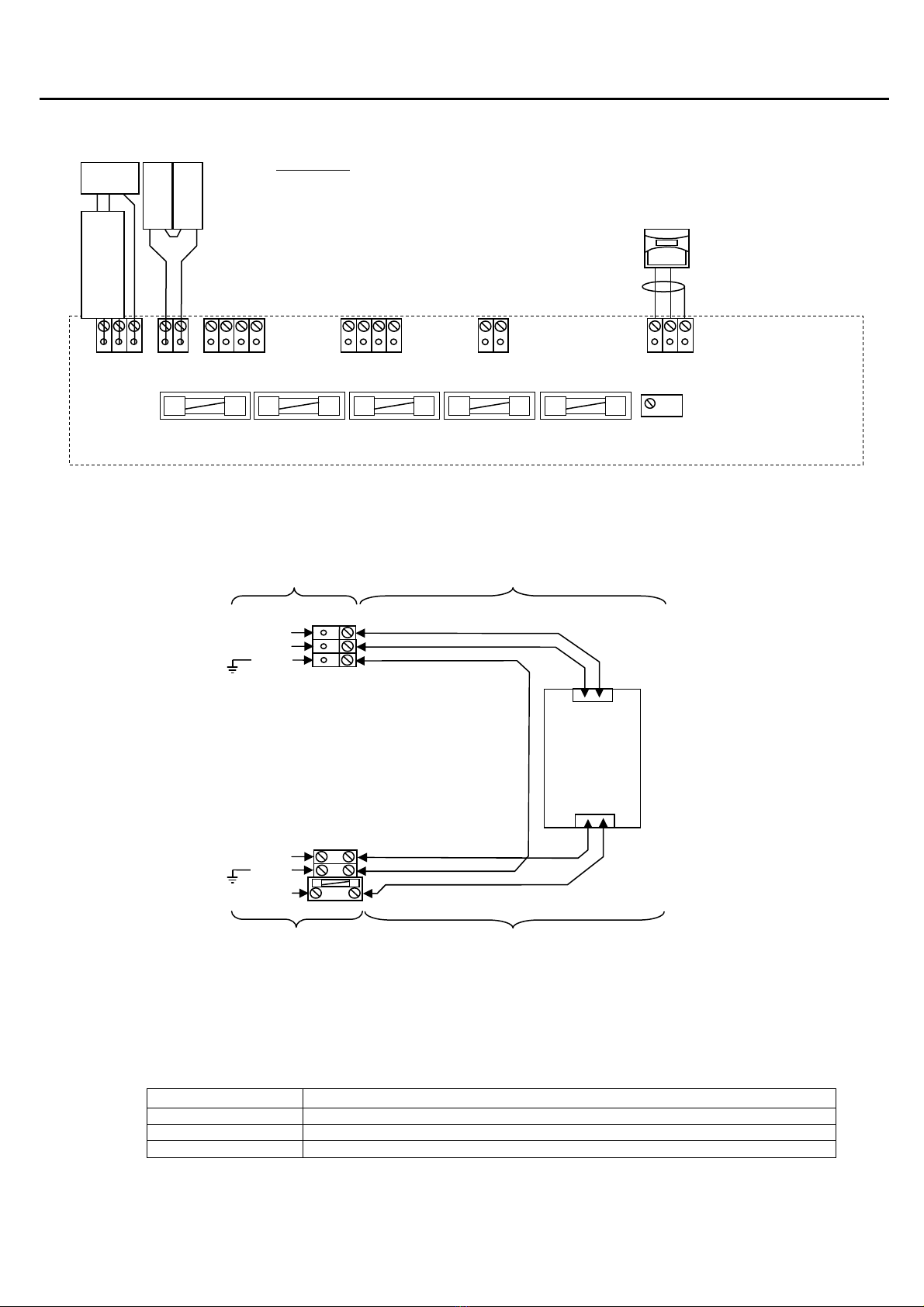

Repeater Panel Connections

Repeater Panel Terminals and Fuses

Power In – PSU+, PSU--, EARTH

The DC input to the main PCB is connected to the red and black leads coming from the switch mode power

supply mounted within the back box, and is the primary power supply for the system. This input is protected by the

3AT fuse labelled ‘F4 3AT POWER’.

Note: Control panels up to V4.11 do not use a switch mode power supply, but instead utilise a 230V AC to 40V

AC transformer, with yellow wires connecting to terminals marked TA and TB.

Terminal Description

PSU+ Power Supply Low Voltage DC +ve: 32V DC In

PSU- Power Supply Low Voltage DC –ve: 0V DC In

EARTH Mains Supply Earth

+ -- E

POWER IN

+ --

BATTERY 24V

C NC NO SPR

RELAY 1

C NC NO SPR

RELAY 2

+24V 0V

AUX PWR

+ -- SCRN

PC / RPT LINK

REPEATER PANEL

PCB

LCD CONTRAST

VR1

F4 3AT POWER F3 3AT BATTERY F5 200mAF AUX PWR F2 200mAF OUTPUT4 F1 200mAF OUTPUT5

230V AC

L N E

SWITC MODE PSU

MOUNTED IN BACK

BAT 1

+

-

BAT 2

+

-

REPEATER LINK:

MAX 1KM OF 2-CORE 1.5MM2 SCREENED CABLE

BETWEEN CONTROL PANEL AND REPEATER..

CONNECT EAC SCREEN TO EART AT ONE END

ONLY.

MAX 1 REPEATER PANEL.

CONTROL PANEL MUST BE VERSION 4.14 OR

LATER.

PSU --

PSU +

MAIN PCB SWITC MODE POWER SUPPLY

EART

RED

SCREEN

EART

BLACK

SWITC MODE

POWER SUPPLY

MOUNTED IN

BACK BOX

-- +

32V DC

230V AC

N L

EART

BLUE

BROWN

EART

LIVE

NEUTRAL

230V AC SUPPLY SWITC MODE POWER SUPPLY

….....

….....

….....

….....

Sita200plus Repeater Panel Installation Instructions

9

Mains Input: L, N, E

The 230V AC input is to be connected into the mains supply connection terminals provided in the back box. This

input is protected by a 3.15AT fuse.

Terminal Description

L Main Supply Live 230V AC Live

E Mains Supply Earth

N Mains Supply Neutral 230V AC Neutral

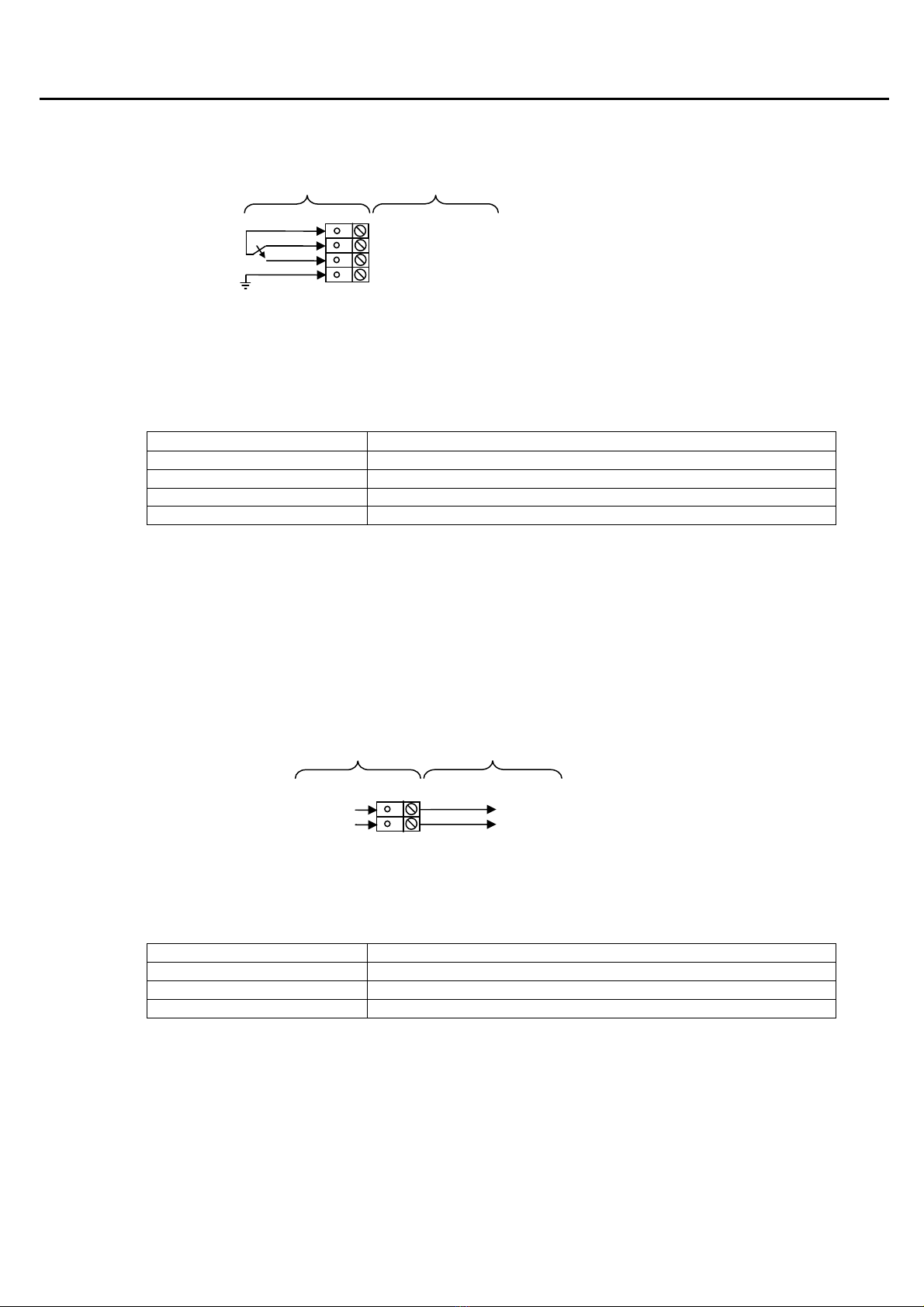

Battery Connections – BAT+, BAT-

The battery terminals require 24v from 2 x 12V 3.2Ah sealed lead acid batteries, connected in series, in order to

provide secondary backup power when the primary power fails. This input is protected by the 3A fuse labelled ‘F3

3AT BATTERY’.

Note that the charging circuit will be in its high impedance state (approximately 3V DC) if no batteries, faulty

batteries or only one battery is connected. The full 27V DC charging voltage should be present if the correct

batteries are connected.

If the system shows a charger or battery fault on first power up, leave the system to charge its batteries for 5-6

hours.

In order to test for correct operation of the batteries, remove the mains 230V AC fuse and allow the batteries to

settle from their charging voltage for approximately 5 minutes. The battery voltage should then be measured using

an electronic test meter and a voltage in the region of 27V DC should be seen.

Note that batteries are electrically live at all times and great care should be taken to ensure that the terminals are

never presented with a short circuit. Care should be taken at all times, especially during transit, installation and

normal use.

Batteries no longer required should be disposed of in a safe and environmentally friendly manner by the battery

manufacturer or a suitable recycling service. They should never be incinerated or placed in normal rubbish

collection facilities.

Terminal Description

BAT + Battery positive: 24V DC +ve

BAT - Battery negative: 0V

BAT --

BAT +

MAIN PCB BATTERIES

RED

BLACK

-- +

12V BATTERY

-- +

12V BATTERY

BACK BOX TO SWITC MODE POWER SUPPLY

EART

BLUE

BROWN

EART

LIVE

NEUTRAL

Sita200plus Repeater Panel Installation Instructions

10

Relay 1 – COM1, NC1, NO1, SPR1

Relay 1 consists of a ‘volt-free’ ‘change-over’ relay contact which is not fault monitored. The relay contacts are

rated at 30vDC / 2A max. The following options may be selected using Sita OSP:

1. Not configured (relay will not operate).

2. Common fire output (relay energised in fire).

3. Fire alarm signal output, monitored by input 1 (MI1+, MI1-) (relay energised in fire).

Terminal Description

COM1 Common contact

NC1 Normally closed contact

NO1 Normally open contact

SPR1 Spare terminal for general use. Not connected internally.

Relay 2 – COM2, NC2, NO2, SPR2

Relay 2 is not used in the Repeater Panel.

Auxiliary Power: +24V, 0V

An auxiliary 24V DC constant power supply is available if required. In order to protect battery standby and alarm

times, this output is limited to 200mA with the fuse labelled ‘F5 200mAF AUX PWR’. Additional remote Power

Supply Units should be installed to provide power for any additional load.

Terminal Description

+24V Aux power positive connection

0V Aux Power 0V connection

SCRN Field cable screen connection

COMMON

NORMALLY OPEN

NORMALLY CLOSED

SPARE

MAIN PCB FIELD CONNECTIONS

OV

+24V

MAIN PCB FIELD CONNECTIONS

24V DC LOAD

Sita200plus Repeater Panel Installation Instructions

11

Fuses

The fuses are located below the control panel terminals.

Label Description Fuse

F1 Output 5 F200mA

F2 Output 4 F200mA

F3 Battery T3A

F4 DC Input Power T3A

F5 Auxiliary 24V Power F200mA

LCD Contrast

The LCD contrast may be adjusted by rotating the screw on the variable resistor located adjacent to the fuses.

This may require many (10 to 20) rotations if the contrast is particularly out of adjustment.

LCD CONTRAST

VR1

Rotate anticlockwise

to reduce the

contrast (lighten text)

Rotate clockwise to

increase the contrast

(darken text)

Sita200plus Repeater Panel Installation Instructions

12

General Operation of Repeater Panel

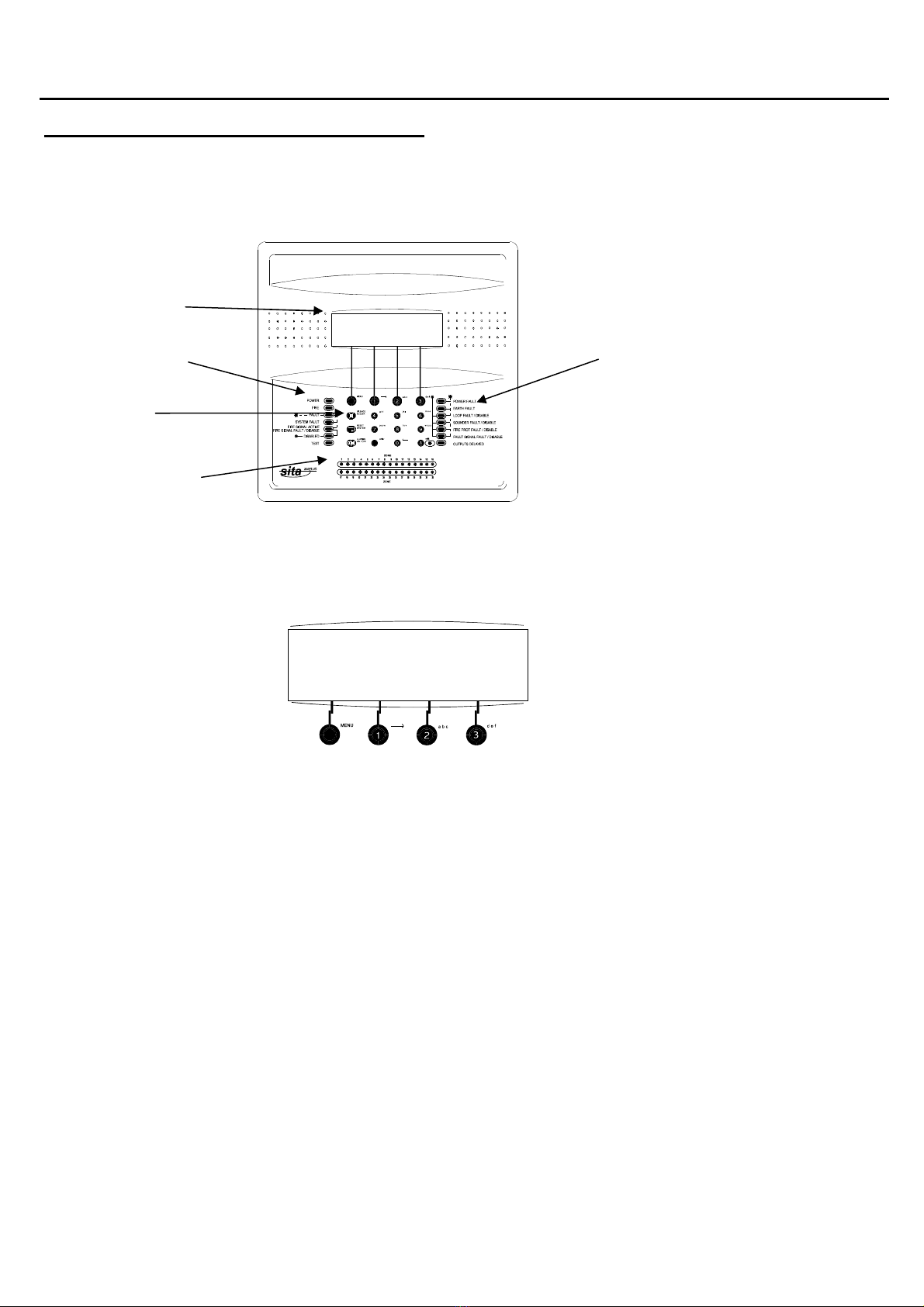

Repeater Panel Front

LCD display

System status Fault & delay status

Keypad

Detection-Zone

Fire Indication

Soft Key Menus

For ease of use, a context driven menu system is used to control access to the system. Soft keys (software

allocation of button function) are used to pilot around the menu system, automatically prompting you with the

relevant options for your Access Level and system status.

The lower line of the display is arranged in the following format:

[DISPLAYon] [testDISP] [AL2 CODE] [->nextMENU]

Each section (eg., ‘[AL2 CODE]’) represents the function of the button immediately below on the keypad.

The high voltages and frequencies that are required to give a low current consumption for the LCD backlight may

cause the display to emit a slight humming tone whilst it is on. This is merely a feature of the technology required

in the system and will cease when the backlight switches off.

ADDRESSABLE FIRE ALARM 4V14

PROGRESSIVE FIRE SYSTEMS LTD

FOR SERVICE CALL 01234 567890

[DISPLAYon][testDISPLAY][AL2 CODE][nextMENU]

ADDRESSABLE FIRE ALARM 4V14

PROGRESSIVE FIRE SYSTEMS LTD

FOR SERVICE CALL 01234 567890

[DISPLAYon] [testDISPLAY] [AL2 CODE] [nextMENU]

Sita200plus Repeater Panel Installation Instructions

13

Access Codes

Access to the system menus requires the correct entry of the access level 2 (User) or access level 3 (engineer)

code in order to protect against unauthorised access to the system. These codes default to the settings below but

may be altered from the Sita OSP software.

Access Level 2 Code - 222

Access Level 3 Code – 333

As the upload and download of system information to the Sita OSP software must take place within access level 3

(engineer) then programming may only be carried out by authorised personnel with the correct access level 3

(engineer) code. If the access level 3 (engineer) code is not known then upload and download will not be possible.

Contact your supplier in this event.

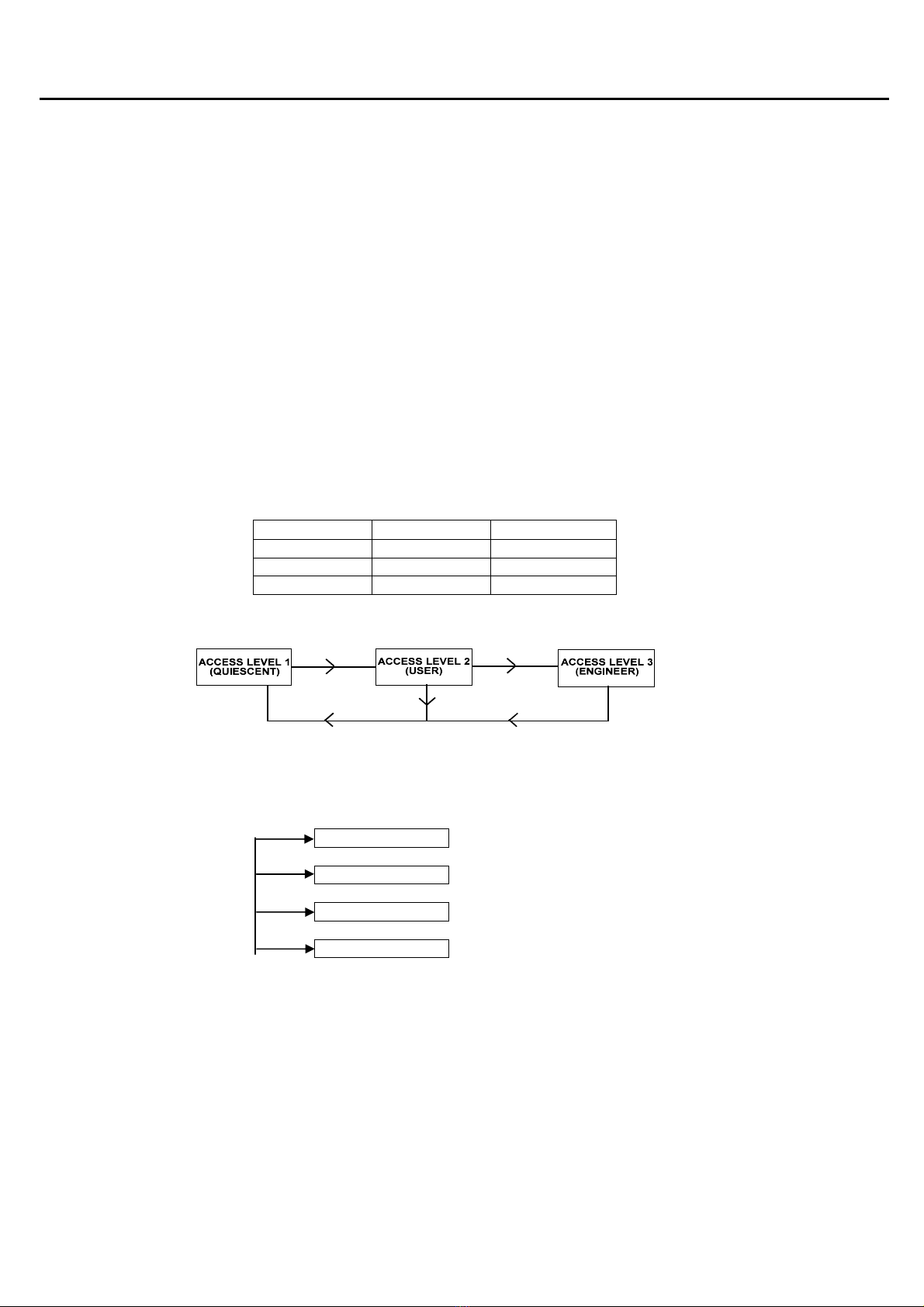

Access Levels

The system menus are set into three access levels as follows. For simple indication the status of the ‘shift LED’

will show the level selected as follows;

Access Level Description Shift LED

1 Normal OFF

2 User ON

3 Engineer FLASHING

Access Level 1 (Normal)

Fault Status

The ‘>faults’ function causes the control panel to display any items which are in fault. One point shows at

a time and the continued pressing of the ‘>faults’ prompt allows the messages to be scrolled through, one

at a time.

Display On

The backlight for the system LCD display switches off after a period of time if the controls are not used.

Whilst the backlight is switched off, the prompt ‘DISPLAYon’ is displayed. The backlight will switch on if

this function is selected or if any other button is pressed.

>FAULTs

DISPLAYon

TestDISP

AL2 CODE

Sita200plus Repeater Panel Installation Instructions

14

Test Display

The ‘testDISP’ function causes the panel LEDs to pulse and the LCD to blacken in order that their correct

operation may be verified.

AL2 Code

The ‘AL2 CODE’ function enables access to Access Level 2 (user level). This is followed by a code entry

prompt, so you will need to enter the code (default 222).

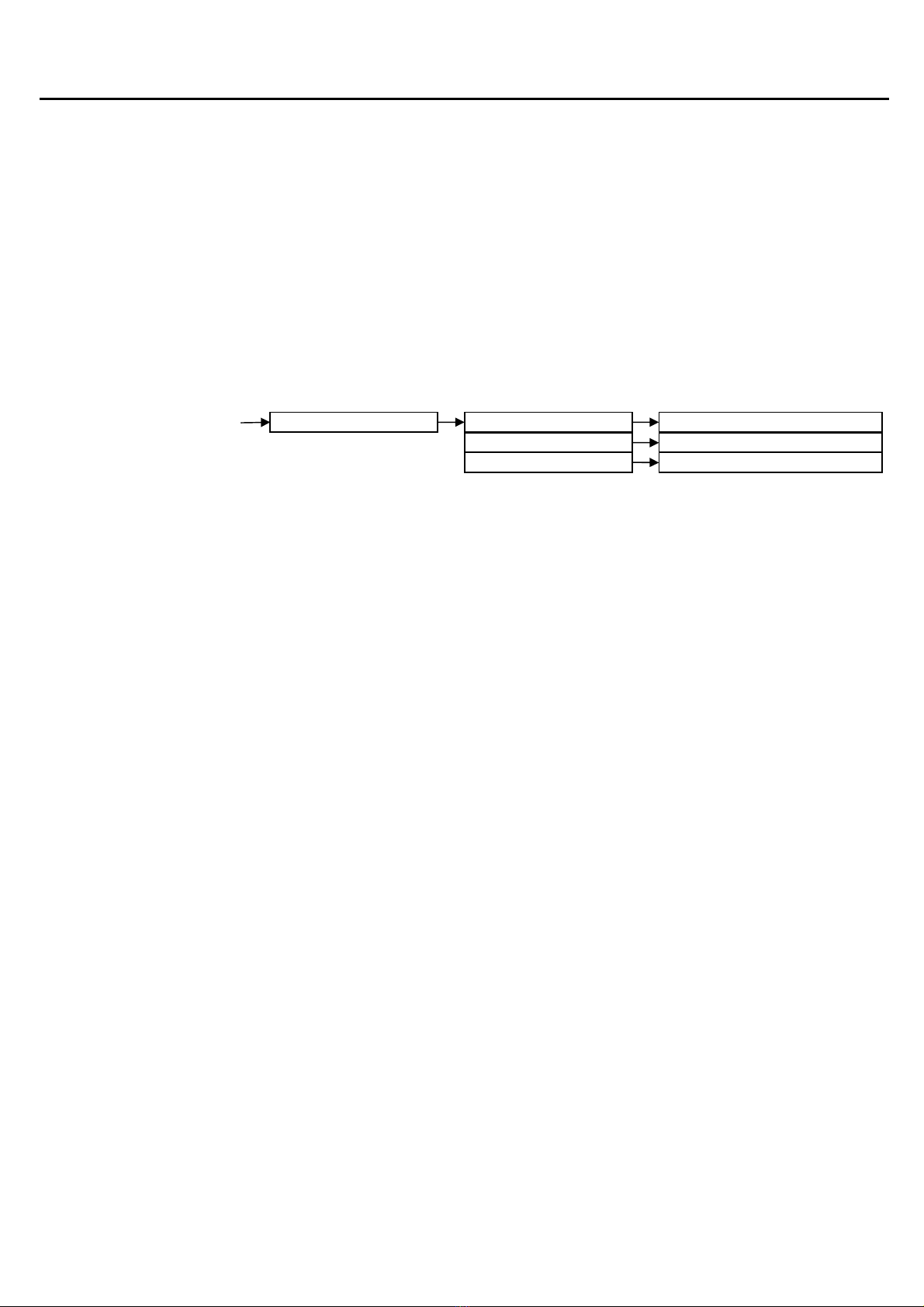

Access Level 2 (User)

Clock Set

The time and date may be set using the ‘CLOCK SET’ function. If these are not set then the panel will not

show the time & date, and the event log will not have a time & date stamp. These settings do not remain

after the complete removal of power, and will need to be re-programmed if the mains and battery power is

allowed to fail.

Minus / Plus One Hour

The time does not automatically adjust for British Summer Time so this feature allows a one hour jump

without having to completely reprogram the time & date.

Exit AL2

The ‘Exit AL2’ prompt returns the control panel to Access Level 1 (Quiescent).

Test Display

The ‘testDISP’ function causes the panel LEDs to pulse and the LCD to blacken in order that their correct

operation may be verified.

AL3 Code

The ‘AL3 CODE’ function enables access to Access Level 3 (engineer level). This is followed by a code

entry prompt, so you will need to enter the code (default 333).

AL2 CODE

Time and date setting

>CONTROL

CLOCK SET

>FAULTs

>EVENT log

Disp

lay current faults

Display event log

>INDICATE

+ 1 HR

-

1 HR

EXIT AL2

Test DISP

AL3 CODE

Advance time by 1 hr

Retard time by 1 hr

Go to Access Level 1 (Normal)

Test LEDs and LCD

Go to Access Level 3 (Engr)

Sita200plus Repeater Panel Installation Instructions

15

From Access Level 2 (user)

Allocate

an add

ress (1

-

4)

AL3 CODE

SetRptr

ID

exitAL3

OSPmode

Go to Access Level 1 (Engr)

Select OSP mode for upload

Fault Status

The ‘>faults’ function causes the control panel to display any items which are in fault. One point shows at

a time and the continued pressing of the ‘>faults’ prompt allows the messages to be scrolled through, one

at a time.

Event Log

The event log stores 255 fire and fault events. These are displayed in text format and may be scrolled

through by pressing the ‘<Events’ / ‘Events> prompt.

Access Level 3 (Engineer)

Set Repeater ID

Only 1 repeater panel can be connected to the Sita200plus control panel. This menu should not be used,

if this option is entered the repeater ID should be set to 1.

Exit AL3

The ‘Exit AL3’ prompt returns the control panel to Access Level 1 (Quiescent).

OSP Mode

The system will only allow an upload or a download to the OSP software programming package when the

‘OSPmode’ is selected.

Sita200plus Repeater Panel Installation Instructions

16

Installation and Commissioning

Installation 1

st

Stage

The installer needs to install the system wiring in the form of a 2-core radial circuit (daisy chain format). The

cabling should be 2 core 1.5mm

2

, screened and fire resistant, of an MICC or FP200 equivalent type.

The cable should remain disconnected from any panels, and must be tested for continuity and integrity with a high

voltage tester, as required for general electrical installations.

The repeater panel back boxes should be mounted, with the mains supply tested, connected and isolated at the

un-switched fused spur, ready for the commissioning.

The installer needs to provide a set of ‘As-Wired’ drawings and proof of cable continuity and insulation test

readings etc., before commissioning may proceed. This information is essential, and may be entered onto the

forms provided at the rear of the manual.

Installation 2

nd

Stage

Once the commissioning engineer is satisfied with the continuity / integrity of the repeater R-Bus cable, the system

may be powered up as follows.

1. Power up and program the main control panel according to the control panel

instructions, leaving the repeater R-Bus disconnected at this stage (see the

Sita200plus Engineering & Commissioning Instructions for further details).

2. Power up the Repeater Panel by applying the 230V AC mains supply, before

connecting the batteries.

3. Select ‘OSPmode’ at Access Level 3 (engineer) and download the control panel

configuration data into the repeater panel.

4. Reset the repeater panel, and exit Access Level 3 (engineer).

5. Connect the Repeater R-Bus at the repeater panel.

.

6. Connect the Repeater Panel R-Bus at the main Control Panel.

7 Select the [RPTmode] button at Access Level 3 (Engineer) at the main control panel.

For control panels Version 4.00 or earlier, the control panel must be powered down

and re-powered at this stage.

8 Check the display to ensure that it successfully locates the repeater panel.

Commissioning

Once the above set up has been completed, the repeater panel should be operative. This must be tested carefully

for correct operation, by activating devices on the main panel and by ensuring that the repeater controls will

silence and reset the alarms.

Sita200plus Repeater Panel Installation Instructions

17

Fault Finding

Summary of Faults

Common Problems

1. R-Bus Integrity Disconnect the R-Bus connector at the panel to enable

testing of the cable. Install a wire link between the R+

and R– connections at the last point in order to be able

to take cable continuity readings, removing it to take

insulation readings.

A reading of approximately 1.2 ohms per 100m of 2c1.5

cable is expected for continuity, and in excess of 1Mohm

is expected for insulation resistance between cores.

Connect the R-Bus at the Control Panel only, and using

an electronic test meter, you should read between 12

and 15v DC on the R-Bus (R+, R-) terminals, at the

repeater panel.

2. No Repeater Panels found Remove power from the Control Panel, and wait 2

minutes.

Ensure that he Repeater Panel is not in OSP mode (Exit

Access Level 3 (engineer) to end).

Power up the Control Panel by applying the 230V AC

mains supply, before connecting the batteries.

Check the display to ensure that it successfully locates

the repeater panel.

Sita200plus Repeater Panel Installation Instructions

18

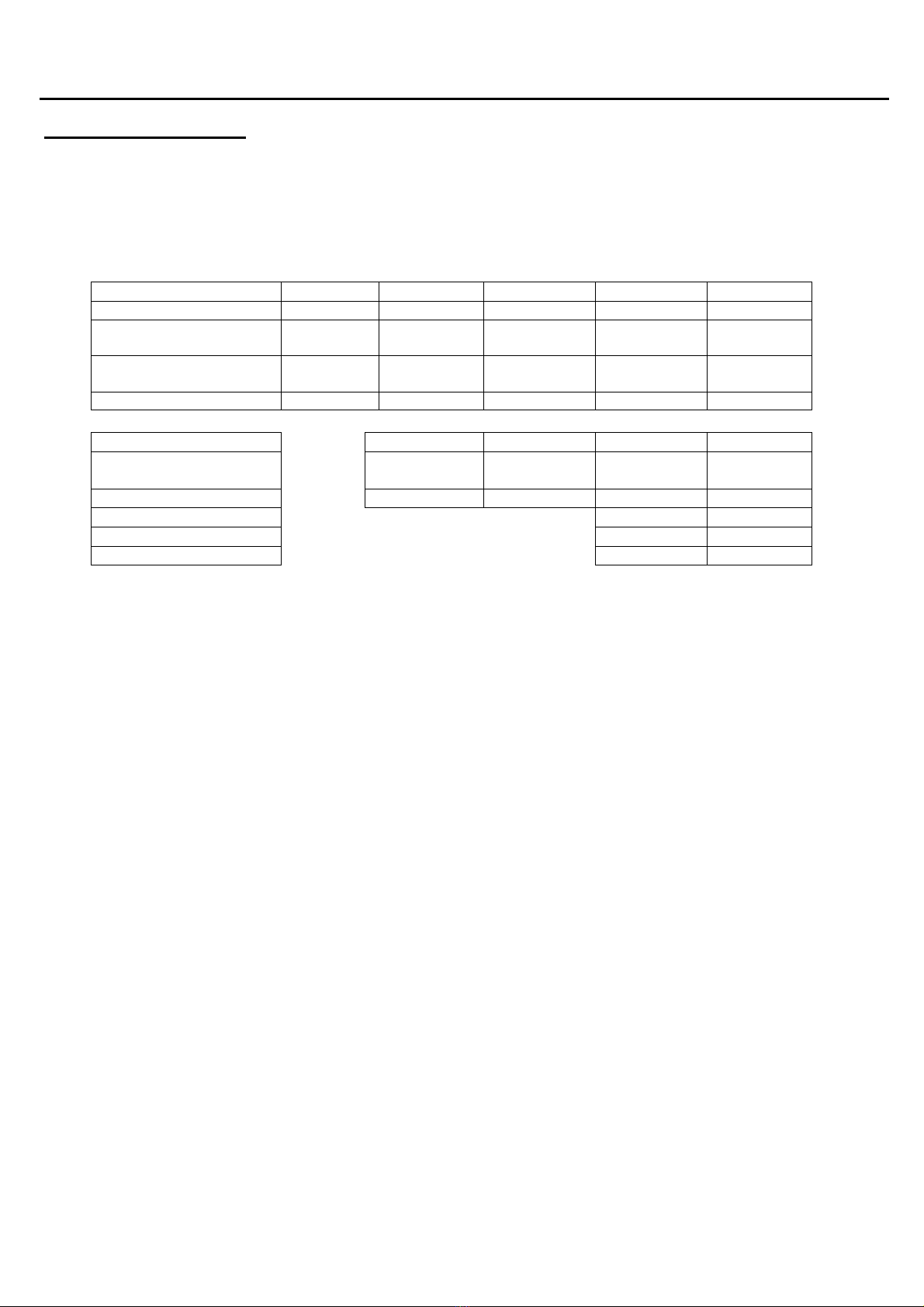

Technical Data

Repeater Panel

Technical Support

For further technical support please contact your distributor.

Do not call the Fike Safety Technology technical support department unless your distributor has first given their

advice and attempted to rectify the issue.

Technical support will not be available if the instruction manual has not been read and understood. Please have

this instruction manual available whenever you call for technical support.

Due to the complexity and inherent importance of a life risk type system then training on this equipment is

essential. Installation and commissioning should only be carried out by competent persons.

Sita200plus Repeater Panel

Dimensions W x H x D 320mm x 320mm x 90mm

Weight < 5kg

No. of zones 32 zones

Device labels 24 characters

LCD display 6 lines of 42 characters

lines 1-3

lines 4-5

line 6

Fire alarms

fault, disablement & test indication

menu functions & prompts

LED Indication Fire

Fault

Disablement

Test

red

steady in general fire

pulsed (0.3s on, 0.5s off) from an MCP

yellow

intermittent (0.3s 0n, 2.1s off)

pulsed (0.3s 0n, 0.5s off)

yellow

continuous

yellow

pulsed (0.3s on, 0.5s off)

Audible Indication 2.5kHzBuzzer continuous in fire

intermittent (0.3s on, 2.1s off) in fault

Keypad 16 way alphanumeric with 4 ‘soft’ keys for menu operation

Number of Repeater panels maximum of 1 2 core 1.5mm

2

(earth/screen) data link

Inputs and Outputs Fire

volt free contacts

30VDC @ 2A max

Power Supply Inbuilt PSU

Standby batteries

Mains supply

Vmax

Vmin

(deep discharge protection)

Max cont output current

Ripple and noise

Switch Mode power supply and charging circuitry

2 x 3.2 Ah 12V sealed lead acid batteries

230VAC, +10%, -15%

31.5V ±1%

21V

1.0A

<=5% of Vmax

IP Rating 21C

Sita200plus Repeater Panel Installation Instructions

19

Further Information

Battery Calculations

Where: IS = Standby Current

IA = Alarm Current

MP = Multi Point Detector

Item Quantity IS (mA) Tot IS (mA) IA (mA) Tot IA (mA)

Repeater Panel 38.000 52.000

Panel O/P 4 (200mA

max)

- 200.000

Panel O/P 5 (200mA

max)

- 200.000

Aux 24V (45mA max) - 45.000

Totals IStot (mA) A

IAtot (mA) B

Times (hrs) Standby (hrs)

C

Alarm (hrs) D

Current required (mAh) IS (mAh) E

IS (mAh) F

Total Current (mAh)

E + F = G

Total Current (Ah)

G / 1000 = H

Battery requirement (Ah)

H x 1.25 = J

Sita200plus Repeater Panel Installation Instructions

20

Installation Checklist

Use the following checklist to ensure that your work is correct and that the commissioning engineer has the

necessary information to complete the commissioning of the system

The commissioning engineer will require this sheet, along with ‘Cable Continuity and Insulation Test Results’,

correctly marked ‘as-wired’ drawings and completed ‘Configuration sheets’, before attending site to commission

the system.

Stage 1

Description

Installation

Engineer Checked

Commissioning

Engineer Checked

R-bus cable installed correctly, clipped or in

containment.

R-bus cable stripped to aprox 500mm, teminated into

temporary connector blocks.

DO NOT CONNECT TO PANEL YET.

Repeater Panel back box installed with 230v AC

supply live, tested and isolated locally

Control Panel back box installed with 230v AC

supply live, tested and isolated locally

Cable insulation and continuity testing complete, and

form filled out.

As-wired drawing marked up showing cable runs and

devices.

Configuration sheets completed with devices

descriptions etc.

Site Name & Address:

Installation Company:

Testing Engineer:

Signature:

Date:

Other manuals for SITA200plus

1

Table of contents

Other Fike Repeater manuals

Popular Repeater manuals by other brands

Westell

Westell Modular 255 Series user guide

Exibel

Exibel WRE6505 v2 quick start guide

Futurecom

Futurecom PDR8000 Programming guide

Andover Controls

Andover Controls InfiLink 200 installation guide

Motorola solutions

Motorola solutions Futurecom PDR8000 Programming guide

TAPKO

TAPKO MECtp operating instructions