Fike Twinflex pro2 User manual

T w i n f l e x P r o ²

R e p e a t e r P a n e l

Q u i c k S t a r t G u i d e

A knowledge of BS5839: Pt 1: 2017: Fire Detection and Alarm Systems for Buildings is essential.

It is strongly recommended that a suitably qualified and competent person is consulted in connection with

the Fire Alarm System design and that the entire system is commissioned in accordance with the current

national standards and specifications.

Equipment Warranty

The equipment carries no warranty unless the system is installed, commissioned and serviced in accordance

with the manual and the relevant standards by a suitably qualified and competent person or organisation.

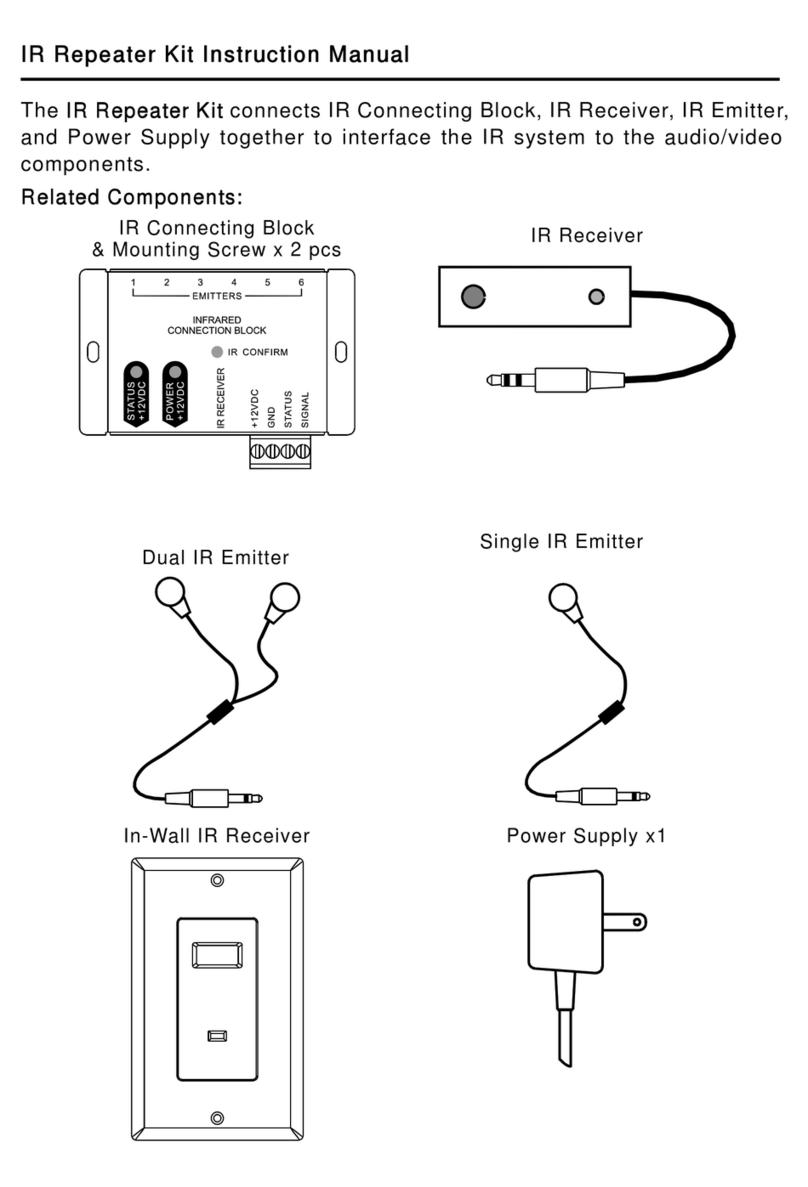

Repeater Panel, Remote Display Unit (RDU)

The TWINFLEX®Pro² repeater panel is smaller than the TWINFLEX®Pro² control panel.

It does not itself connect to or control detection devices. Instead, it connects to a control panel and reports

events which occur on the control panel.

It can also perform system controls over the network (i.e. Silence Alarms, Reset, Sound Alarms & Silence

Buzzer).

A maximum of 8 repeater panels can be connected to a single control panel.

The maximum cable length from the control panel to a repeater is 500 metres. If 8 repeaters are used they

must all be within the maximum 500 metres cable length.

All external connections are made on the back board. The Ext Switches on the back board are not currently

used and are for a future development.

26-1703 Issue 1

Do not attempt to install this equipment until you have fully read and understood the manual

which can be found on our website

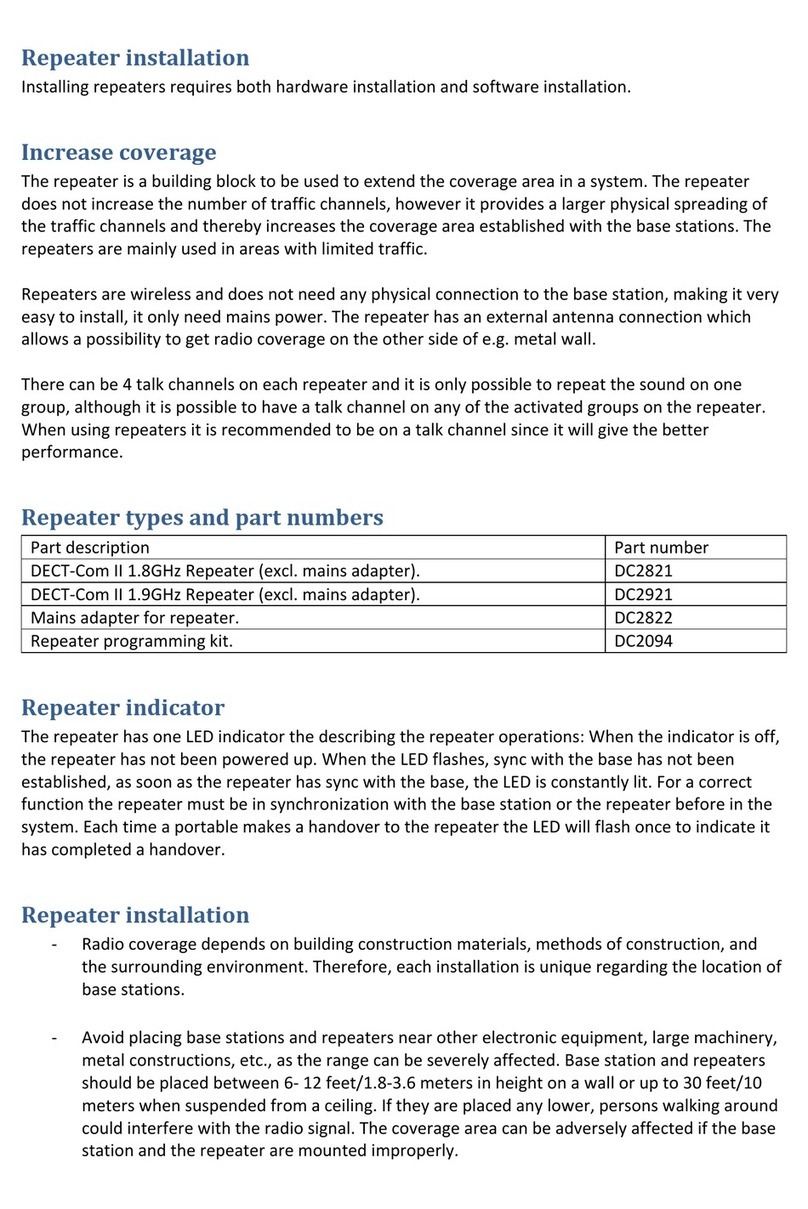

Topology & Cabling

All system wiring should be installed to comply with BS 5839: and BS 7671 (wiring regulations) and any other standards

relevant to the area or type of installation. A cable complying with BS 5839: Pt 1: Category 1 (cables required to operate

for prolonged periods during fire conditions) is required. This must be a 2-core 1.5mm2 screened fire resistant cable (ie.

FP200, Firetuff, Firecell, Lifeline or equivalent).

The maximum total cable length from the control panel to a repeater is 500 metres.

Up to 8 repeaters can be used but they must all be within the maximum 500 metres cable length.

The cable screen must be connected to earth/ground at the control panel only.

The cable screen continuity must be maintained at every point of the circuit, using the terminals provided or a suitable

connection block.

Do not use a 4-core cable as a 24v supply and communications, due to the possibility of data corruption. It is essential

that two 2-core screened cables are used, one for the 24V DC supply and the other for communications.

Power Supply & Connections

24V DC Power is provided from the control panel via Aux+ and Aux-.

2-core 1.5mm2 screened fire resistant cable

When powering a repeater from the panel the extra current will reduce the battery backup run time and has to be

allowed for in the battery calculations.

Current Drawn by Single Repeater @ 24.0V DC

Separate Power Supply Requirements

The repeater can be powered by a separate 24v EN-54 power supply if required.

The repeater working voltage range is between 21V DC to 32V DC with a maximum current of 50.0mA.

Peripheral Bus Connections

Communications between the panel and repeater is via a multi-drop RS-485 Peripheral Bus.

2-core 1.5mm2 screened fire resistant cable ((i.e. FP200, FP200, Firetuff, Firecell, Lifeline or equivalent)

cable should be used for communications to the repeater and connected to the back board.

The peripheral bus must be run from the panel to the first repeater then the second repeater and so on; the peripheral

bus must not be spurred from one point.

26-1703 Issue 1

•MAX CABLE LENGTH 500M

•UP TO 8 REPEATERS PER PANEL

•120Ω

26-1542 Issue 1

Peripheral Bus Connections

There are two sets of peripheral bus connections on the panel. These are linked in the panel so either set can be

used.

A 120Ω Smoothing resistor must also be fitted across NET A & NET B at the panel.

On the repeater a 120Ω Smoothing resistor must also be fitted across A and B but only on the last repeater on the

network.

Connections

A to A, B to B, Screen to Screen and so on up to the maximum of 8 repeaters.

120Ω Smoothing resistor

may also need to be

fitted

26-1703 Issue 1

Technical Data

For specifications of the TwinflexPro², please see the TwinflexPro² Engineering & Commissioning Manual.

Technical Support

Contact your supplier for technical support on this product.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential, and commissioning

should only be carried out by competent persons. Fike cannot guarantee the operation of any equipment unless all documented

instructionsare complied with, without variation. This unit complies with the EMC directive.

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst

every care has been taken to ensure that the contents of this document are correct at time of publication,Fikeshall be under no

liabilitywhatsoever in respect of suchcontents. E&OE.

TWINFLEX, Fike and Fike Corporation are registered trademarks of Fike Corporation and its subsidiaries. All other

trademarks, trade names or company names referenced herein are the property of their respective owners.

Technical Data

Repeater Panel Specification

Fike Safety Technology Ltd

Unit 31, Springvale Ind. Est.

Torfaen, NP44 5BD

Tel: +44 (0) 1633 865 558

13

DoP-505-0010

Other manuals for Twinflex pro2

1

Table of contents

Other Fike Repeater manuals