Film-Tech IREM EX-100GM3 Series User manual

Film-Tech

The information contained in this Adobe Acrobat pdf

file is provided at your own risk and good judgment.

These manuals are designed to facilitate the

exchange of information related to cinema

projection and film handling, with no warranties nor

obligations from the authors, for qualified field

service engineers.

If you are not a qualified technician, please make no

adjustments to anything you may read about in these

Adobe manual downloads.

www.film-tech.com

Electronic power supply

INSTALLATION AND OPERATION MANUAL

MAN01554E/1

IREM SpA Via Abegg 75 - 10050 Borgone Torino Italy - tel. ++39 0119648211 - fax ++39 0119648222 - E-mail: [email protected] - www.irem.it

3

MAN01554E/1

Caution !

You should read this manual before attempting any intervention inside the unit.

The noncompliance with the instructions given in this manual can lead to seri-

ous damage to the unit which in this case will invalidate the warranty.

No compensation or indemnity under any kind will be acknowledged for injury

or damage due to use or misuse of the product, for poor operation of the appli-

ances connected to IREM product or for immediate or indirect damage caused

to the powered equipment.

During the warranty period the replacement of defective parts and maintenance

procedures will be exclusively carried out at IREM servicing centre.

Keep this manual along with the unit.

5

MAN01554E/1

Description

Thiselectronicpowersupplyfor threephase208and400Vac50/60Hz input,hasbeen

designed to feed from 1000 to 3000W short arc Xenon lamps, meeting all the

requirements of lamp manufacturers to ensure correct operation, long life to the lamp,

and high reliability.

This compact and lightweight power supply has been designed to meet the require-

ments of a unit to be installed inside a cabinet.

Its particularly compact design, the advanced circuitry and the displacement of input

and output terminal board and the lamp current adjustment make the unit suitable to a

wide variety of applications both in vertical and horizontal position and specifically:

-film projection (traditional and digital applications)

-theatre applications

-architectural applications

-solar simulations.

The main characteristics of this power supply are:

- digital setting of parameters and operation modes,

- internal control of the delivered power

- two hour meters (total and partial)

- RS232 communication interface

MAN01554E/1 6

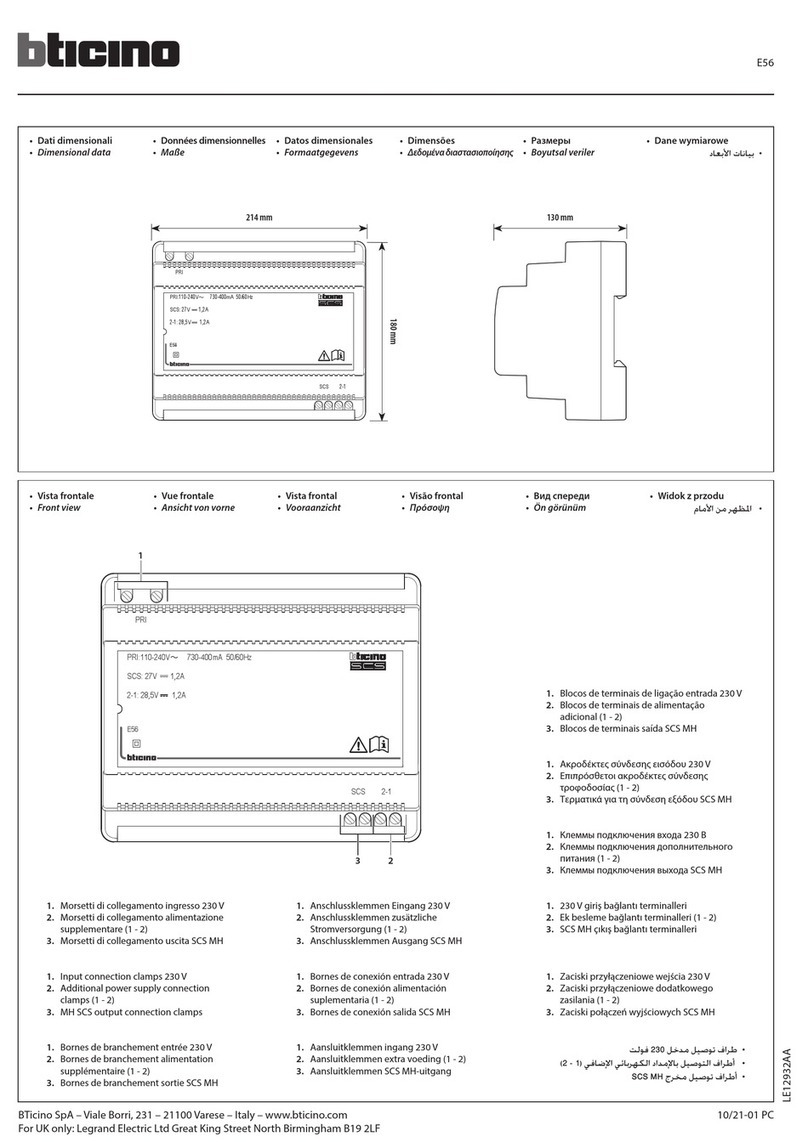

1. Input filter board

Limiting the high frequency interferences (complying with EMI/EEC Standards).

2. Diode bridge rectifier

Converting the alternated voltage from the mains into direct voltage

3. Inverter board

Designed in compliance with IGBT technology, H type full bridge configuration

4. High frequency transformer

Ensuring the galvanic insulation between input and output

5. Output rectifier circuit

Composed by two fast low noise diodes

6. Output filter

Ensuring the lamp ripple current value at ≤1.5% pk- pk.

7. Auxiliary powering board

8. µp board and controls

9. Synoptic board

Block diagram

7

MAN01554E/1

Technical characteristics

EX-100GM3-E EX-100GM3-US

400V version 208V version

Ordering code 00831031 00831036

Lamp capacity [W] 1000 to 3000

Input voltage range [V] 360-460 3ph 187-230 3ph

Input frequency [Hz] 50/60

Max. input current [A] 11 15

Sinusoidal absorption not provided

DC output current range [A] 30-110

DC voltage range [V] 17-34

DC max. output voltage at 110A [V] 31

Max. output power [W] 3400

No-load voltage range [V] 120-140

No-load voltage rising time [s] 3

Ripple [%] <1.5

Efficiency 0.87

Output overload protection electronic

Lamp striking soft-start ignition current

Input circuit protection fuse

Input extra voltage protection provided

Serial line protection*

optoisolator

Output current stabilisation provided

Synoptic panel LCD displaying: current, rated power, voltage

unit internal temperature,

operation hours (in total)

operation hours (for each lamp)

ON/OFF control keyboard, external switch, serial line

Lamp current adjustment keyboard, 0-10V signal, serial line

Remote control RS232 serial line - baud rate: 19200, parity: none

data bit: 8, communication protocol: IREM

Output signals lamp ON, alarms ON

Input signals 0-10V signal, emergency, ON/OFF remote

stand-by mode

Operating temperature [°C] 0 to +40

Storage temperature [°C] -20 to +60

Degree of protection IP20

Markings CE

Insulation class CL1

Ventilation forced

Dimensions [mm] 225 x 465 x 350h

Weight [kg] 19

* on request for both versions

MAN01554E/1 8

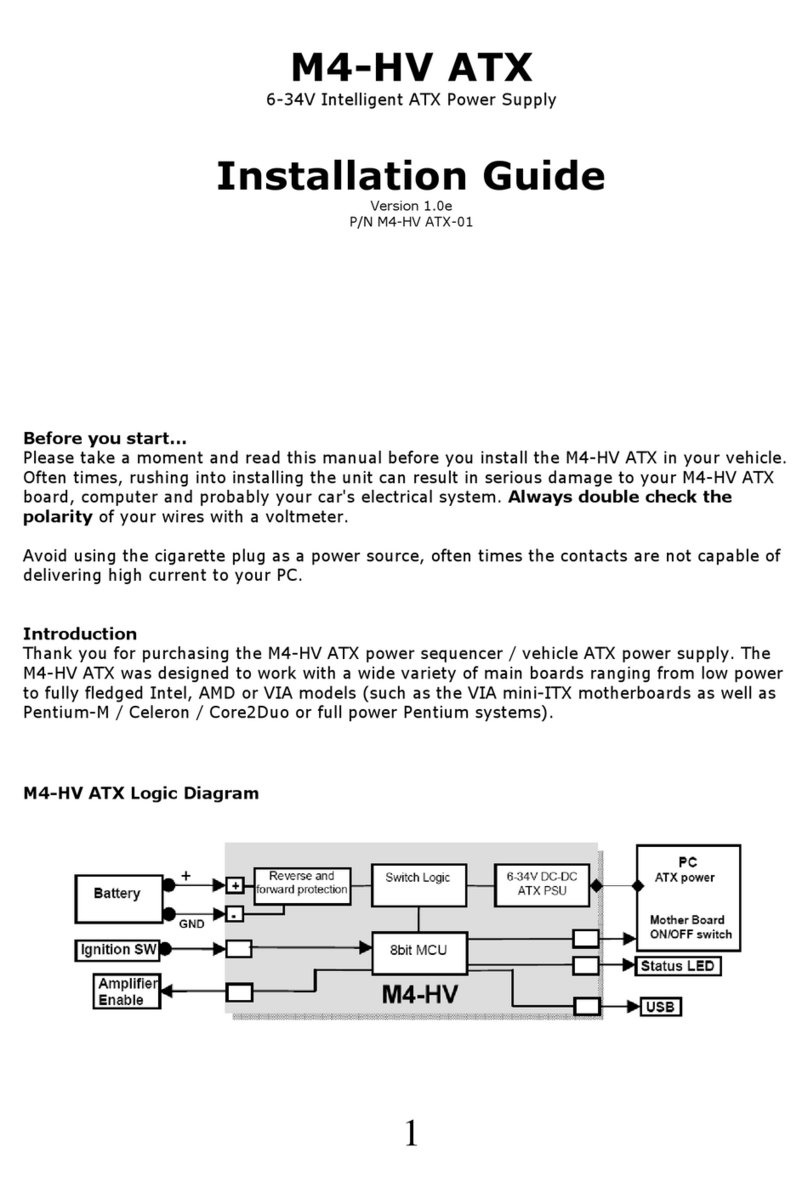

Functions and controls

Control devices

1. Input circuit protection

2. Ground terminal

3. Synoptic panel

4. Auxiliary terminal board

5. RS232 connector

6. Output terminal board

9

MAN01554E/1

Connection and operating information

Receiving the equipment

After receipt, check that the unit is in good condition. When necessary, contact the

forwarding agent.

Delivery arrangement

The supply consists of:

EX-100GM3... electronic power supply

plate for terminal protection

metal brackets

three spare fuses

serial line optocoupler + adapter 9/25 pin (on request)

synoptic panel

auxiliary connector

installation and operation manual

warranty card.

Storage

If the unit is stored before installation, check that it is kept dry and cannot come into

contact with water in any form. Do not expose the unit to the sun rays or other sources

of heat.

Package removing and handling

Remove the packing and keep it in case of future transportation needs.

Carefully lift the unit by means of its handles. Avoid any shock when moving.

Installation - environment

TheperformanceoftheEX-100GM3... electronicpowersup-

ply is guaranteed for a temperature range variable between

0°C and +40°C. Check that the place where the equipment

is to be installed is sufficiently ventilated to prevent the air

around the unit from exceeding this limit. Avoid dusty envi-

ronments.

Ensure that the ventilation slots are unobstructed.

To prevent blockages caused by excessive temperatures,

do not expose the unit to the sun rays or other sources of heat.

40°C max.

MAN01554E/1 10

Warnings

Caution: dangerous voltage inside the power supply. Disconnect the unit from

the mains before checking the internal components.

Prevent water, liquids in general and/or foreign objects from getting inside the

appliance (do not open the unit, contact IREM servicing centre !).

Installation must be carried out by trained personnel only.

This power supply must be installed inside a grounded cabinet provided with a

circuit breaker duly rated.

Important note: the fuse holder powering cables are located in the lower part of

the unit (see label on the front panel).

If the plant is provided with a residual current breaker having a tripping value of

30mA, this breaker could trip when switching on the power supply. This does

not normally mean a failure, but is due to the capacitors of the EMI filter. Switch

on the breaker again to alleviate the problem.

Feet mounting

EX-100GM3... electronic power supply is equipped with two fixing brackets that may

be used as an anchoring for the unit (B) or as normal feet when the unit is normally

displaced without any fixing (A).

Connection and operating information

11

MAN01554E/1

Connection and operating information

Feet mounting

If feet are used as fixing flanges, holes have to be done as per following picture:

MAN01554E/1 12

Connection and operating information

Mounting the synoptic panel

The unit is fitted with a synoptic panel, vertically mounted onto the front panel (pict.

no. 1).

Directions for horizontal mounting:

Please follow the instructions below to place the synoptic panel horizontally (pict. no.

2):

-Take off the synoptic panel on the front panel by releasing the two fixing screws;

-Unscrew the four screws fixing the metal plate that supports the sub-D 15 pin fe-

male connector

-Rotate (90°) the metal plate supporting the sub-D 15 pin female connector

-Screw the four screws again to fix the metal plate

-Place the synoptic panel in its housing and tighten the two screws again.

Pict. no. 1 Pict. no. 2

13

MAN01554E/1

Connection and operating information

Preliminary checks

The connection must be carried out in compliance with the current safety stand-

ards. To ensure a correct operation of the unit, please strictly follow these rec-

ommendations:

-the input powering has to be:

400V version: 360-460V, 50/60Hz plus ground, withstanding a current of 11A per

phase

208V version: 187-230V, 50/60Hz plus ground, withstanding a current of 15A per

phase

-the earth installation must comply with current standards

-the cables to be connected to the output terminals must have a size suitable to the

lamp power.

During connection pay attention to the lamp polarity.

Important note: the ground connection of the power supply must be equipotential

with respect to the ground connection of the lamphouse. To do this, perform a

connection between the ground (PE) of the power supply and the ground of the

lamphouse (cable length: 400 mm max.).

Connecting input/output cables

Connect the input/output cables to the relevant terminal board.

Pay attention to lamp polarity and terminal identification:

Input terminals Output terminals

U-V-W: phases +: positive

PE: ground -:negative

After having performed the cable connection, take in place the protective plate (see

directions on next page).

MAN01554E/1 14

Connection and operating information

Directions for inserting the protective plate

Mount the metal protective plate as per following steps:

- be sure the unit is not powered

- loose the fixing screws (B) located on the front panel (bottom)

- take in place the plate

- tighten the screws (B) of the protective plate

- check the earth connection.

15

MAN01554E/1

Connection and operating information

Auxiliary terminal boards

When using the remote control perform connections through J4 terminal board or J3

connector placed on the front of the unit.

Important note: different connections may cause dangerous failures

to the unit !

J3 connector

RS-232 serial port for remote control

We recommend to protect the input serial line by means of a galvanic

insulator (on request) to avoid damages to the PC during the igniter dis-

charge. This protection has to be connected to the PC directly.

J4 terminal board

1-2 (INPUT) 0-10V analog input for lamp current monitoring (under Ext_10V mode)

3-4 (INPUT) ON/OFF remote

Input for lamp striking under manual mode (from remote control)

and Ext_10V mode (close the contact to strike the lamp)

5-6 (INPUT) Input for switching off the power supply in emergency

(insert a jumper, if not used)

7-8 (OUTPUT) Lamp ON output (normally open dry relay contact - 30V 1A max.)

9-10 (OUTPUT) Alarms ((normally open dry relay contact - 30V 1A max.)

11-12 (INPUT) Stand-by

(close down this contact to have the stand-by lamp current previously entered)

The connection cables to terminals 3-4 (remote), 5-6 (emergency) and 1-2 (0-10V

analogue input) have to be twisted and as short as possible.

MAN01554E/1 16

Thanks to the microprocessor control some safety functions, related to the power sup-

ply and the lamp connected to it, have been improved.

The max. power is one of the parameters that now can be set. During the operation,

the power supply checks that the delivered power does not exceed the preset value.

When exceeding, it reduces the delivered current down to a power (voltage by cur-

rent) equal or lower that the preset limit.

If the preset power value is referred to the lamp in use, an automatic control of the

max. power applied to the lamp will be obtained. The default value (3400W) aims at

protecting the power supply.

The synoptic panel allows to set/change the different operation modes (factory set-

ting: manual mode).

The possibility to set different operating modes permits an optimum use of the power

supply avoiding incorrect use.

The operation modes are exclusive i.e. when a mode has been entered, the others will

be automatically ignored (i.e. if the RS232 mode has been entered, then possible

commands from synoptic panel or from 0-10V analogue input will be automatically

ignored).

The operation modes are: manual from synoptic panel, manual from remote control,

through serial line and through 0-10V analogue input.

Two hour meters (total and partial lamp operating hours) are located on the synoptic

panel. The first one (total operating hours) cannot be reset.

A remote contact (J4, pins 11-12) activates the stand-by mode. Under this mode the

delivered current corresponds to the value set in “input parameters”. This mode is

useful during the projection timeout if the lamp must stay on. This contact can be

activated under any operation mode.

What’s new

Connection and operating information

17

MAN01554E/1

Connection and operating information

Parameter setting

For more detailed information, please refer to EX communication protocol on

sections: “programming the lamp parameters” and “behaviour to wrong lamp

parameters sent to bytes m.s.b. command data (dh) and dato l.s.b. command

data (dl) via RS232”.

Lamp Pmax : max. power of the lamp. When entered, an automatic control will avoid

exceeding this value. Factory setting: 3400W (corresponding to the max. power of the

power supply).

Lamp Imax (operating range: 30 - 110A): lamp max. admitted current. When entered,

an automatic control will avoid exceeding this value. Factory setting: 110A

When entering an Imax value lower than Imin , Imin will be the delivered current value.

Lamp Imin (operating range: 30 - 65A): lamp min. admitted current. When entered, an

automatic control will avoid exceeding this value. Factory setting: 30A

Lamp stand-by (operating range: Imax - Imin): lamp stand-by current when the contacts

11 and 12 of J4 have been closed. When the contacts have been closed, an automatic

control will change the current according to the admitted operating range. Factory

setting: 30A.

The stand-by mode can be also activated through the serial line.

Factory setting of the output current: 30A.

Remarks:

1) when entering an Imax value lower than Imin the message “ERROR, Imax < Imin -

value not accepted” will be displayed. Imin will be set to 30A (default). Enter a new Imin

value.

2) when entering a min. value exceeding 65A, 30A will be set as default value.

MAN01554E/1 18

Directions for use

Start-up

-Be sure the emergency terminals 5,6 on J4 are short circuited through a wire if

there is no emergency switch.

-If the switching on of the unit has to be performed remotely , insert a switch or two

N.O. dry relay contacts between terminals 3 and 4 on J4 (ON-OFF remote)

-Before switching on the unit, be sure that the input voltage corresponds to the one

shown on the data plate.

-The power supply must be ON for at least 10 seconds before activating the remote

operation through the RS232 serial line (PC typically).

Getting started

-Be sure the unit has been correctly connected to the mains supply and to the lamp.

-Power the unit.

-Select the operation mode (through serial line or synoptic panel). Otherwise the

default parameters (manual mode) will be ON.

-Enter the lamp parameters (according to the lamp type) through the serial mode or

thesynopticpanel. Otherwise the default parameters (i.e. the factory setting) will be

ON.

-Strike the lamp according to the preset operation mode.

19

MAN01554E/1

Functions and controls

Synoptic panel

The synoptic panel is formed by:

1) Display

2) LEDs

3) keys for programming/displaying purposes

In details:

1) Display

two 16-characters lines. It is useful for displaying menus, machine parameters and

measurements performed.

2) LEDs, lit to indicate

green LED input mains ON

yellow LED manual mode ON

yellow LED programming mode/remote commands ON

red LED Alarms ON

3) Program/display keys

Dual-function keys, according to the check or setting modes selected through the

synoptic panel.

This manual suits for next models

2

Table of contents