Filtertechnik FS9V4 User manual

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

1 of 26

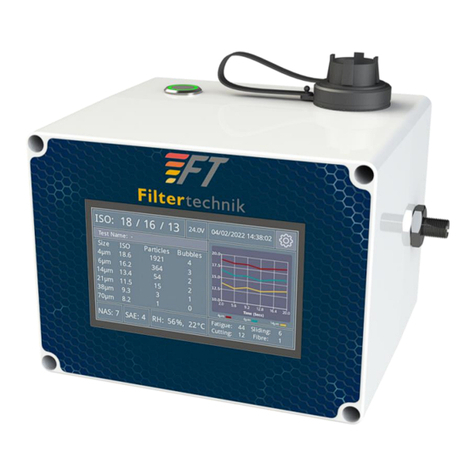

FS9V4

Fuel & Oil Cleanliness Analyser

User Manual

August 2022

V1.01

© Copyright 2022 Filtertechnik

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

2 of 26

Table of Contents

Specifications........................................................................................................................................... 4

Component Identification ....................................................................................................................... 5

Suction & Return Hose Connections ....................................................................................................... 6

Suction Strainer....................................................................................................................................... 7

Operating the Unit .................................................................................................................................. 8

On/Off Switches .................................................................................................................................. 8

Touch Screen Layout ........................................................................................................................... 8

Priming and Flushing the Pump ...................................................................................................... 9

ISO Alarm Limits ............................................................................................................................ 10

Datalogging.................................................................................................................................... 10

Time Zone Adjustment.................................................................................................................. 11

Entering a Test Name .................................................................................................................... 12

Battery Charging.................................................................................................................................... 13

Battery Charging Unit........................................................................................................................ 13

Charging Instructions ........................................................................................................................ 13

Fluid Viscosity........................................................................................................................................ 14

Internal Gear Pump............................................................................................................................... 14

Water Sensor –% Saturation (RH) ........................................................................................................ 15

Sensor Specifications......................................................................................................................... 16

Sensor Working Range ...................................................................................................................... 16

Water Sensor –Parts Per Million (PPM) ............................................................................................... 17

Specifications..................................................................................................................................... 17

Density and Viscosity Sensor................................................................................................................. 18

Specifications..................................................................................................................................... 18

Density........................................................................................................................................... 18

Viscosity......................................................................................................................................... 18

High-Pressure Device (HP)..................................................................................................................... 19

Troubleshooting .................................................................................................................................... 20

General Operational Errors ............................................................................................................... 20

Particle Counting ............................................................................................................................... 20

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

3 of 26

RH & Water Content.......................................................................................................................... 20

Water Sensor - % Saturation (RH) ..................................................................................................... 21

Water Sensor –Parts Per Million (PPM) ........................................................................................... 21

Density & Viscosity Sensor ................................................................................................................ 21

Errors & Corrective Actions........................................................................................................... 21

Particle Count ISO Codes....................................................................................................................... 22

ISO Codes (ISO4406).......................................................................................................................... 22

ISO Decimal Codes............................................................................................................................. 23

Warranty Statement.............................................................................................................................. 25

EC Declaration of Conformity................................................................................................................ 26

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

4 of 26

Specifications

Specification

Detail

Dimensions

Small –(w)314mm x (d)257mm x (h)152mm (12.4” x 10.1” x 6.0”)

Large –(w)398 mm x (d)310 mm x (h)172 mm (15.7” x 12.2” x 6.8”)

Weight

Small –4.46 kg (9.8 lbs)

Large –7.10kg (15.7 lbs)

Finish

Black impact resistant case

Nominal Battery Voltage

22.5 VDC

Charge Voltage

25.2 VDC

Capacity

4000 mAh

Charge time

2 hours (80%) 5 hours (100%)

Run time

Up to 10 hours (depending on fluid viscosity)

Modes of operation

Tank sampling

Bottle sampling (200ml minimum sample bottle recommended)

Cleanliness standards

ISO 4406, NAS 1638, SAE AS4059

Pump type

Gear pump

Duty cycle

Continuous

Viscosity range

Small Unit –1-460 cSt (1-300 cSt with High Pressure device)

Large Unit –1-2400 cSt (1-300 cSt with High Pressure device)

Fluid compatibility

Diesel & oil (hydraulic, lubrication, mineral, synthetic)

Fluid temperature

0 to 60°C (oils)

0 to 50°C (diesel)

Ambient temperature

0°C to +60°C

Environment

Lid closed –IP67

Lid open –IP54

Connections

1604 minimess test points, with 0.6m long 8mm tubing

Pressure

2.5 bar max (up to 350 bar with optional High Pressure device)

Maximum humidity

97% relative humidity, non-condensing

Certification

Factory calibration certificate

CE declaration

Verification frequency

12 months recommended

PC requirements

Windows/Mac (with USB port), spreadsheet software (e.g. MS Excel)

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

5 of 26

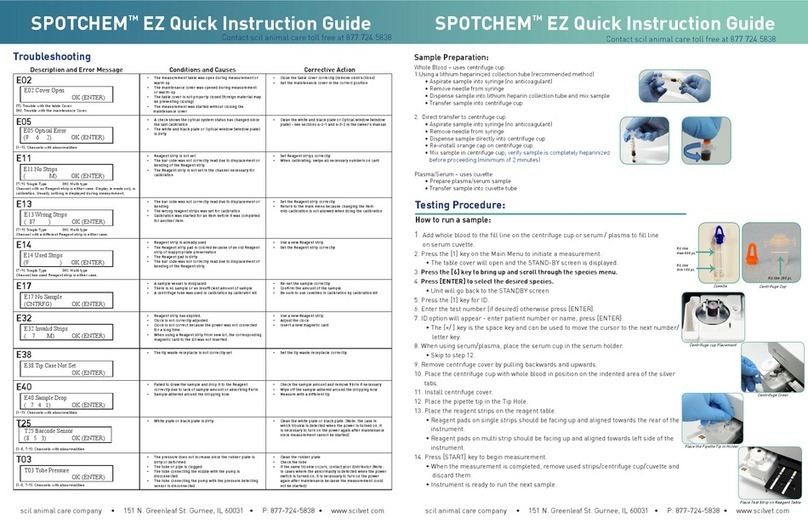

Component Identification

Key:

1.) Touch screen display

5.) Return / Outlet (Minimess Test Point)

2.) Pump on/off switch

6.) Suction / Inlet (Minimess Test Point)

3.) Display/sensors on/off switch

7.) USB port (at rear of case)

4.) Charging port

1

2

3

5

6

7

4

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

6 of 26

Suction & Return Hose Connections

The unit comes equipped with Minimess Test Points. These seal automatically as the coupling is

removed, so the connections won’t leak during transit.

To connect the hoses, screw them onto the Minimess Test Points, hand tight only.

Make sure the hose assembly with the strainer is always used on the suction/inlet port.

To disconnect the hoses, unscrew from the Minimess Test Point. The hose assemblies do not contain

a self-seal mechanism and may drip; keep an oil absorbent spill mat ready and store hoses in a clean

plastic bag when not in use. Placing a finger over the end of the hose can prevent oil dripping out of

the test point onto the fascia of the unit.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

7 of 26

Suction Strainer

Units are supplied with a strainer fitted to the suction tube assembly. The inline strainer has a 270

micron mesh and is used for keeping accidental debris from damaging the pump gears or clogging

other components.

The strainer must always be used, otherwise the units warranty may become void.

The strainer can be disassembled for cleaning as shown below and should be checked periodically to

ensure the flow is unrestricted.

When taking apart the strainer, note the orientation of the mesh for correct reassembly.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

8 of 26

Operating the Unit

On/Off Switches

Units have two push button switches,

one for the pump and one for the touch

screen.

Note that because the screen regulates

the pump speed, the pump will only

work when the screen is switched on

Touch Screen Layout

The main window of the touch screen displays all information provided by the particle counter and

any other sensor that may be installed. Time and remaining battery capacity is also displayed. The

ISO code can change from white to green or red depending on the alarm limits set.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

9 of 26

In the top right corner of the screen is a settings icon, clicking this will open the settings page.

At the bottom left of the settings page the software version is displayed.

Priming and Flushing the Pump

In some situations, the pump speed may need to be increased for priming or flushing the unit.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

10 of 26

Speed can be adjusted using the “-“and “+” buttons. When moving away from this page the pump

will return to its normal speed.

ISO Alarm Limits

Alarm limits for low (clean) or high (dirty) can be set. Low refers to oil achieving required cleanliness

codes in all size categories. High refers to oil exceeding any one of the codes for particulate

contamination. When the oil is clean the ISO code on the main screen will turn green, when dirty it

will become red, between the two values the text is white.

Datalogging

The unit contains two internal dataloggers, one for the graph and one for the tests. Whenever the

unit is switched off the graph will be reset, but this can also be done from the screen without having

to switch off the unit. The main data log tied to the sensors will hold 100,000 lines of data (100,000

polls of the sensors) which equates to 138 days of testing.

To create a new log file the button needs to be held down for a couple of seconds, until a

confirmation message is displayed. This creates a new log file but does not delete the previous.

Clearing log files from the device must be done through the software, either the Particle Pal CSV

Reporting Tool or the Particle Pal Device Utility.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

11 of 26

Time Zone Adjustment

The display screen is pre-set with the date and date to GMT +0 (UK time) this can be adjusted

according to your time zone if required. Specific time adjustments can be done via the Particle Pal

Device Utility software.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

12 of 26

Entering a Test Name

The main screen shows a “Test Name” field, which can be clicked to bring up a new window. Here a

test name can be entered and when the back button is clicked this will be stored in memory. Even if

the unit is switched off this test name will remain in memory until it’s been cleared or changed.

The test name will show as a repeating field in the data log file, for easily finding the relevant test.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

13 of 26

Battery Charging

Units are fitted with a 6S lithium battery

pack and require use of the supplied

25.5V battery charger.

A charge port on the side of the case

allows for charging of the battery, which

from a complete discharge takes

approximately 5 hours (2 hours to reach

80% charge).

To maintain the overall life of the

battery, avoid complete discharges.

If the unit is to be stored for prolonged

periods of time the battery is best left at 60% charge to maintain an optimum lifespan.

Battery Charging Unit

The battery charge unit is designed for indoor use only and should not come into contact with water,

dust, oils or grease. To prevent overheating, the product should not be covered whilst in use.

The mains socket should be easily accessible. In the event of operational error, the plug should be

immediately removed from the socket.

A fuse protects the product against short circuit and overload. If the fuse needs to be replaced, the

same type and size of fuse should always be used.

Charging Instructions

The charger has a small LED which when connected to a discharged unit will illuminate red. Once

charging is complete the LED will turn green.

Note the LED will not turn green if the unit is switched on and in use.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

14 of 26

Fluid Viscosity

The portable analysers are designed to handle a fluid viscosity of up to 460 cSt for the small unit or

2400 cSt for the larger units. It’s possible to pass high viscosity oils through the unit if they are

preheated as per the below table.

Note that as a pre-heated oil passes though the unit it will cool, therefore increasing its viscosity and

strain on the pump.

Temperature

°C

Viscosity (cSt)

ISO 32

ISO 46

ISO 68

ISO 100

ISO 150

ISO 220

ISO 320

ISO 460

ISO 680

10.0

161

262

442

711

1185

1921

2911

4827

8042

12.0

141

227

379

605

1001

1611

2435

3991

6588

14.0

124

198

327

518

850

1358

2048

3318

5427

16.0

109

173

283

446

726

1150

1730

2774

4496

18.0

97

152

246

385

622

979

1469

2331

3745

20.0

86

134

215

334

536

838

1254

1968

3135

22.0

77

118

188

291

464

720

1074

1670

2638

24.0

69

105

166

255

403

621

925

1423

2230

26.0

62

94

147

224

352

538

799

1219

1894

28.0

56

84

130

198

308

469

694

1048

1616

30.0

51

75

116

175

271

409

604

905

1385

32.0

46

68

103

155

239

359

528

784

1192

34.0

42

61

93

139

212

316

464

683

1030

36.0

38

56

83

124

188

279

408

596

894

38.0

35

50

75

111

168

247

361

523

778

40.0

32

46

68

100

150

220

320

460

680

42.0

29

42

62

90

135

196

285

406

596

44.0

27

38

56

82

121

176

254

360

525

46.0

25

35

51

74

109

158

227

320

463

48.0

23

33

47

67

99

142

204

285

411

50.0

21

30

43

62

90

128

183

255

365

Internal Gear Pump

The internal gear pump provides a steady flow for accuracy of results. Fluids above the rated

viscosity can cause excess motor strain and cause it to overheat or slip. It’s important to pay

attention to the grade of oil being analysed and its temperature.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

15 of 26

Water Sensor –% Saturation (RH)

The RH option incorporates a sensor into the fluid circuit which measures water saturation as a

percentage.

The RH sensor measures water content relative to the saturation point of the liquid and outputs the

degree of saturation in the range 0-100%. A reading of 0% would indicate a fluid free of water, while

a reading of 100% would indicate a fluid that is saturated with water (see diagram below). The

capacitance sensor absorbs water molecules from the fluid which change its capacitance value, that

capacitance value is directly proportional to the saturation level of the fluid.

Since the effects of free water are more harmful than those of dissolved water, water levels should

be maintained well below the saturation point. However, even dissolved water can cause damage,

therefore every reasonable effort should be made to keep the saturation levels as low as possible.

As a guideline we recommend maintaining saturation levels below 45% in all equipment.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

16 of 26

Sensor Specifications

Specification

Details

Fluid type

Oil

Measurement range

0-100%

Measurement temperature range

0-100°C

Measurement accuracy

±3%

Operating pressure

-0.5 to 50 bar

Voltage supply

1-32 VDC

Power consumption

30-60 mA

Output

4-20 mA

Protection type

IP67

Recalibration

Intervals depend on use, recommended annually

Sensor Working Range

The graph shows the permitted working range for RH sensor. If the sensor is operated permanently

outside the range indicated in blue, lasting damage can occur to the sensor element.

If the fluid sample contains free water, it should not be passed through the portable analyser.

0

10

20

30

40

50

60

70

80

90

100

110

-40 -30 -20 -10 010 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190

Saturation Level (%)

Temperature (°C)

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

17 of 26

Water Sensor –Parts Per Million (PPM)

The PPM option incorporates a water moisture sensor into the fluid circuit of the portable analyser.

The sensor offers real time measurement of absolute water content in ppm (parts per million) and

outputs a value up to the fluids saturation point.

As per BS EN 590 diesel fuel should contain no more than 200ppm (0.02%) of water.

The sensor is calibrated specifically for use with diesel fuel, use with other fluid types will provide

inaccurate readings.

Note: If the fluid sample contains free water or has a water content of above 300ppm (cloudy/hazy

appearance) it should not be passed through the portable analyser. Samples above 300ppm will

cause the sensor to lock out. If this occurs, clean dry diesel (<100ppm) will need to be flushed

through the unit for 15 minutes to 2 hours (depending on level of exposure), where the readings will

gradually fall back within its normal operating range.

Specifications

Specification

Details

Fluid type

Diesel

Measurement range - water content

0-300 ppm

Measurement temperature range

0-50°C

Measurement accuracy

Less than 10% of limit of measurement range accessible

Operating pressure

Vacuum to 300 bar

Voltage supply

18-28 VDC

Power consumption

30-70 mA

Output

4-20 mA

Protection type

IP65

Recalibration

Intervals depend on use, recommended annually

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

18 of 26

Density and Viscosity Sensor

The density and viscosity sensor uses a piezo electric device for continuous determination of fluid

density and viscosity.

To ensure accurate density and viscosity readings the fluid should be clean and maintained at a

steady temperature similar to the unit. Contaminant in the form of water or solids may cause higher

than expected readings, while an aerated fluid sample will cause lower than expected readings.

Specifications

Specification

Details

Accuracy

Density –2%

Viscosity –5%

Measurement Range

Density –0.6 g/cm³ - 1.3 g/cm³

Viscosity –25 - 400mPa·s

Resolution

Density –0.001g/cm³

Viscosity –0.1mPa·s

Working Voltage

DC 9V‐32V

Power Consumption

< 30mA @ 24Vdc

Operating temperature

0°C to 70°C (0°C to 50°C for diesel)

Operating pressure

10 bar

Applicable standards

ASTM1657, EN61326-1, EN61326‐2‐3, ICES‐003 B

Density

The unit displays density as kg/m³, which is the same as g/cm³. To convert this to a units such as kg/l

divide the value by 1000.

Viscosity

The unit displays dynamic viscosity as mPa.s (millipascal-second). This is the same as cP (centipoise)

e.g. 100 mPa.S = 100 cP.

To convert from dynamic to kinematic viscosity such as centistokes, the dynamic viscosity value must

be divided by the fluid density.

Example:

If the unit is showing a viscosity of 150 mPa.s and density of 886 kg/m³ then, 150 / 0.886 = 169.3 cSt

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

19 of 26

High-Pressure Device (HP)

The high-pressure device allows the portable analyser to sample directly from a high-pressure line

with a maximum allowable inlet pressure of 350 bar, reducing this down to 2.5 bar at the outlet. It

has a working viscosity range of 1-300 cSt.

The High-Pressure Device can be purchased

separately and used with existing units by

connecting it to the end of the suction tubing.

While the High-Pressure Device feeds the

portable analyser with fluid pressurised to 2.5

bar, the pump must be switched on to maintain a steady flowrate.

Fluid passing out of the discharge/outlet tube should be fed into a suitably sized sample container for

disposal or emptying back into the fluid reservoir.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

20 of 26

Troubleshooting

General Operational Errors

Problem

Possible Cause

Solution

Unit will not

switch on.

Fully discharged battery.

Connect to the mains and fully charge the unit.

If the LED switches still fail to illuminate there

could be an electrical fault or damage to the

battery pack from over discharge.

Unit will not

prime.

Internal tubing/pump gears

are dry.

High viscosity fluids.

Restriction in the

suction/discharge lines.

Go into the settings for priming to increase the

pump speed.

Raise the height of the fluid sample to gravity

assist, or create a vacuum using a hand operated

thief pump to pull fluid through.

Check the hoses and strainer for blockages.

Screen is

behaving

erratically.

Dirt on the screen or hands.

Wipe the screen clean to remove traces of dirt or

oil. In most cases gloves will not work with the

touch screen.

Particle Counting

Problem

Possible Cause

Solution

Contamination

codes dropped

to near zero

A blockage in

the flow path

Check there is adequate flow going through the unit

(approximately 20-100ml/min)

Check/clean the suction strainer for any contamination

Erratic count

levels

Unstable

sample

Check for the presence of air. Bubble counts should be

maintained below 200 bubbles/ml in each channel.

RH & Water Content

Problem

Possible Cause

Solution

Water content

is above 95%

High moisture levels

in the sample.

Damaged moisture

sensor.

Flush the unit immediately with dry oil to avoid damage

to the moisture sensor. If levels still don’t fall the sensor

could be permanently damaged.

Water content

bouncing from

near 0 to 100%

Damaged moisture

sensor.

Permanent damaged due to excessive moisture. Sensor

will require replacing.

Table of contents

Other Filtertechnik Measuring Instrument manuals