CLA-VAL VC12 Programming manual

Hardware

VC12 Assembly X-143MP & CVM-33 Assembly

CPM Assembly

X143MP

CPM pilot

3-Way valve

X43 Strainer

CLA-VAL VC12

Quick Start Instructions

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 1

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 2

Mounting Instructions

Install the VC12 on the wall

a) Fix the wall-mounting plate with the provided screws

b) Mount the VC12 on the wall-mount fixing plate

c) Secure with the wing nuts provided

IMPORTANT!

For communicating devices, if the antenna is plugged directly

on the device (without extension lead), please ensure that the

VC12 is mounted vertically with the USB and antenna connectors

on the top.

The connection to the VC12 controller is made via circular plug

connectors which are pre-wired, therefore no internal wiring is

necessary. Each connector has a pre-defined function which

only allows the relevant component to be connected (dedicated

connectors).

1

3

4Connect the various elements to the VC12

VC12 controller packaging

delivered with accessories

a)

b)

c) Antenna

USB

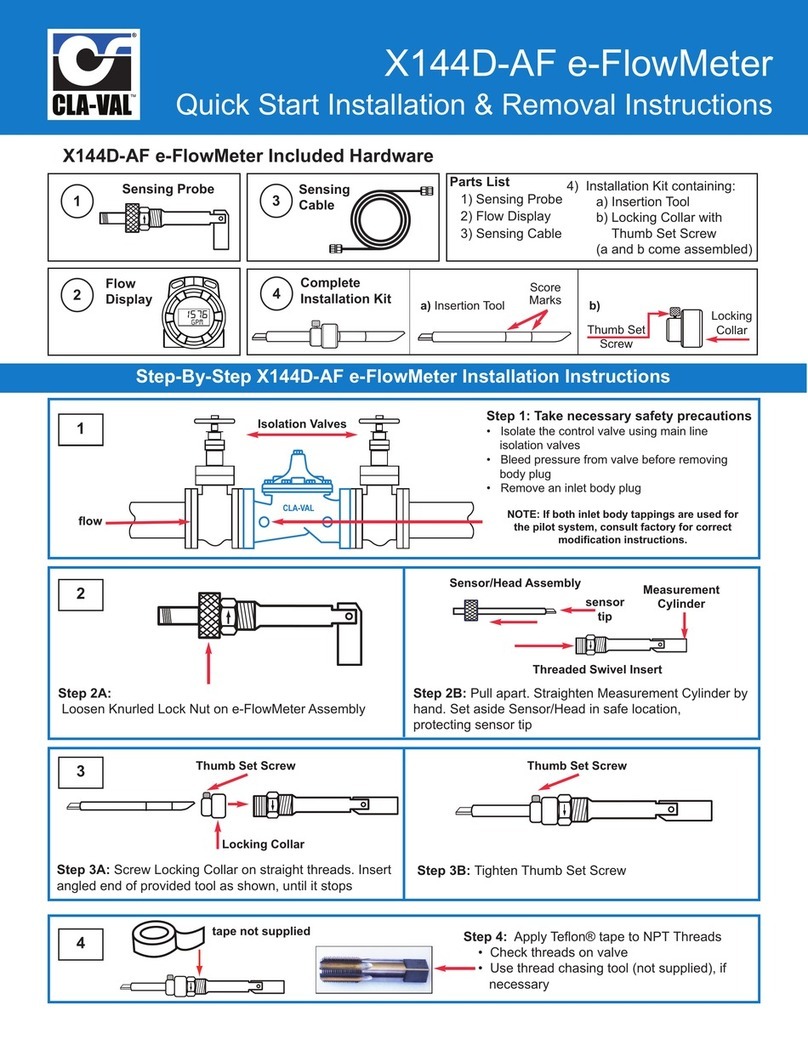

Flow: Flowmeter connection

P1: Inlet pressure sensor connection

P2: Outlet pressure sensor connection

e-Power MP : e-Power X-143MP/2MP turbine connection

3

4

15

6

2

1. Wall-mount fixing bracket

2. VC12 controller

3. Magnetic stick

4. Calibration certificate and

USB stick

5. Antenna (optional)

6. Pressure sensor(s)

ratiometric

a) To run the VC12, connect the e-Power-MP connector

or the start key on socket (a)

b) When the connector above is connected,

the VC12 is powered (internal battery is activated)

c) When the connector is removed from socket (a),

the VC12 is disabled (internal battery is de-activated)

d) IMPORTANT!

To access the internal USB port, perform operation in a dry

and clean environment. If not possible, make sure that no

humidity or dust enters the device.

2

Run the VC12

d)

(a)

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 3

Laptop Wifi pairing and parameters

6-24 VDC IN: External power supply connection

2: Solenoid #2 output connection

1: Solenoid #1 output connection

CVP/CVM: CVP/CVM actuators connection

e-Lift: CLA-VAL valve position sensor connection

I/O:General Input/Output signal connection

a:CLA-VAL Antenna connection

b:USB-A port connection

a) b)

2 Activate the VC12 controller

Hold the magnetic stick over the button of the VC12

(approximately 5 seconds) until a green light flashes.

Check that the Wifiicon is present in the toolbar of your

computer. If not, please refer to the user manual of your

computer to activate the Wifiinterface.

1 Activate the Wifiinterface on the computer

3 Display the list of Wifidiscovered devices on your

computer

a) Click on the Wifi icon and select the VC12 in the devices list for

connection via Wifi.

b) Enter the Wifi security key shown on the VC12 OLED display to

allow Wifi Peering to the VC12 controller.

a)

b)

VC12-Loic

VC12-Loic

5

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 4

Mobile Wifi pairing and parameters

a) Launch a VNC viewer (for instance TightVNC Viewer).

b) Enter the IP address shown on the VC12 OLED screen in the

VNC viewer application.

c) Establish the connection.

d) Enter the password shown on the VC12 OLED screen in the

second screen of VNC viewer application.

Check that the Wifiicon is displayed in the toolbar of your

mobile. If not, please refer to the user manual of your mobile to

activate the Wifiinterface.

4 Connect to the VC12 controller

2 Activate the VC12 controller

1 Activate the Wifiinterface on the mobile device

b) Click on the Wifi icon and select the VC12 in the devices list for

connection via Wifi.

a)

3 Display the Wifidiscovered devices on your mobile

Hold the magnetic stick over the button of the VC12

(approximately 5 seconds) until a green light flashes.

VC12-Loic

VC12-Loic

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 5

You are connected on VC12.

4 Connect to the VC12 controller

b) Enter the Wifi security key shown on OLED display to allow Wifi

peering to the VC12 controller.

b)

b)

c)

a) Launch a VNC viewer (for instance VNC Viewer).

b) Create a new connection & enter the IP address and

password shown on the VC12 OLED screen in the VNC

viewer application.

c) Launch the connection and click OK for unencrypted

connection, then Introduce the password shown on the VC12

OLED screen in second screen of VNC viewer application.

VC12-Loic

VC12-Loic

VC12-Loic

VC12-Loic

Visit www.cla-valpacic.com for more details. Contact the Factory at info@cla-valpacic.com 6

1VC12 commissioning

2VC12 in service

b) 1st battery connection or VC12 in standby mode

(OLED display off): upper LED stays green and

lower LED blinks green during system boot up

(OLED display and Bluetooth activation).

a) Wake up the OLED display and establish

Bluetooth communication, or put the device in

standby mode, by holding the magnet stick on the

symbol for 5 seconds (lower LED (1) remains

Green) until the upper LED (2) blinksGreen once.

c)

After the VC12 commissioning is completed, the

OLED display is off. Lowest LED flashes green

every 10 seconds

.

d) During data transfer, the OLED display and

magnetic contacts are disabled (not possible to

wake-up display).

Lowest LED flashing red (slight flashing red on

upper LED.

2) 1 x blinking

Green LED

1) 5 sec Fixed

Green

Fixed Green

Blinking Green

Off

Blinking green

every 10 seconds

Slight Red

blinking

Blinking red

Once

commissioned

Data transfer

1st Connection

or Standby

Wake-up

LED Diagnostics

IMPORTANT!

Disconnect the CVM actuator from the VC12 controller

before calibrating the CPM pilot. Please refer to the

dedicated CPM document for its adjustment.

1Auto mode: The CPM hydraulic pressure

reducing pilot setting is controlled by the

CVM actuator.

2Manual mode: The CVM actuator is

isolated from the CPM hydraulic pressure

reducing pilot. Outlet pressure returns to

the lower Pressure setting of the CPM

pilot.

Auto Mode or Manual Mode Settings

(

2

F

)

(

2G

)

(

2

F

)

(

2

G

)

Open ball valve (2F)

Close ball valve (2G)

Close ball valve (2F)

Open ball valve (2G)

pressure until the pressure is a minimum

Initial setting

1) Low pressure adjusting screw must be fully

screwed in.

2) 3-Wayvalve handle must point towards the red

tube (connected from the Inlet pressure)

: Remove air from bias chamber of the

modulation pilot using the bleed screw (5).

HIGH PRESSURE limit PH

ADJUSTMENT

3) Adjust the high pressure hydraulic limit PHin

dynamic conditions with the high-pressure

adjusting screw

: The setting should be min. 2mhd higher

than your programmed profile.

LOW PRESSURE limit PLADJUSTMENT

4) Close 3-Way valve asillustrated.

5) Adjust the low pressure hydraulic limit PLunder

flowing conditions with the low-pressure

adjusting screw using the screwdriver provided.

Access is via the hole in the high pressure

adjusting screw. Slowly unscrew (anti-clockwise)

the low pressure adjusting screw to adjust low

PL

2mhd below the minimum programmed profile.

: During this adjustment, ensure that the main

valve is under flow conditions.

: Do not apply any force on the low pressure

adjusting screw as this will affect outlet pressure

during adjustment.

Electronic operation (Auto)

6) Turn the 3 -Way valve handle towards the Green

tube (connected to the CVM Motor)

1)

3)

PH

5)

CPM Pilot Adjustment

PACIFIC

AUTOMATIC CONTROL VALVES

45 KENNAWAY ROAD

WOOLSTON

CHRISTCHURCH 8023

!"#$%#"&

#'()*+(,-&!).(/)0&%+0123&4)/&5).6&7,00,.8

!"#$%#"&'#()*)(

+,&-.//#0#1 23#45&633"783/5&!9:)78(9;:(95&<.0&=.#"#/4

>."?&@A+&BCDE&FA+&+GAC

H$I#)"?J#(7#".7K("#$L#"M(3N

6?&000M("#$L#"J#()*)(M(3N

Cla-Val Pacic

45 Kennaway Road, Woolston, Christchurch

Tel: +64 (0)3 964 4860

Email: aspacsales@cla-val.com

www.cla-valpacic.com

!"#$%#"&

#'()*+(,-&!).(/)0&%+0123&4)/&5).6&7,00,.8

7

Other manuals for VC12

1

This manual suits for next models

2

Table of contents

Other CLA-VAL Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ILX Lightwave

ILX Lightwave LDX-32420 user guide

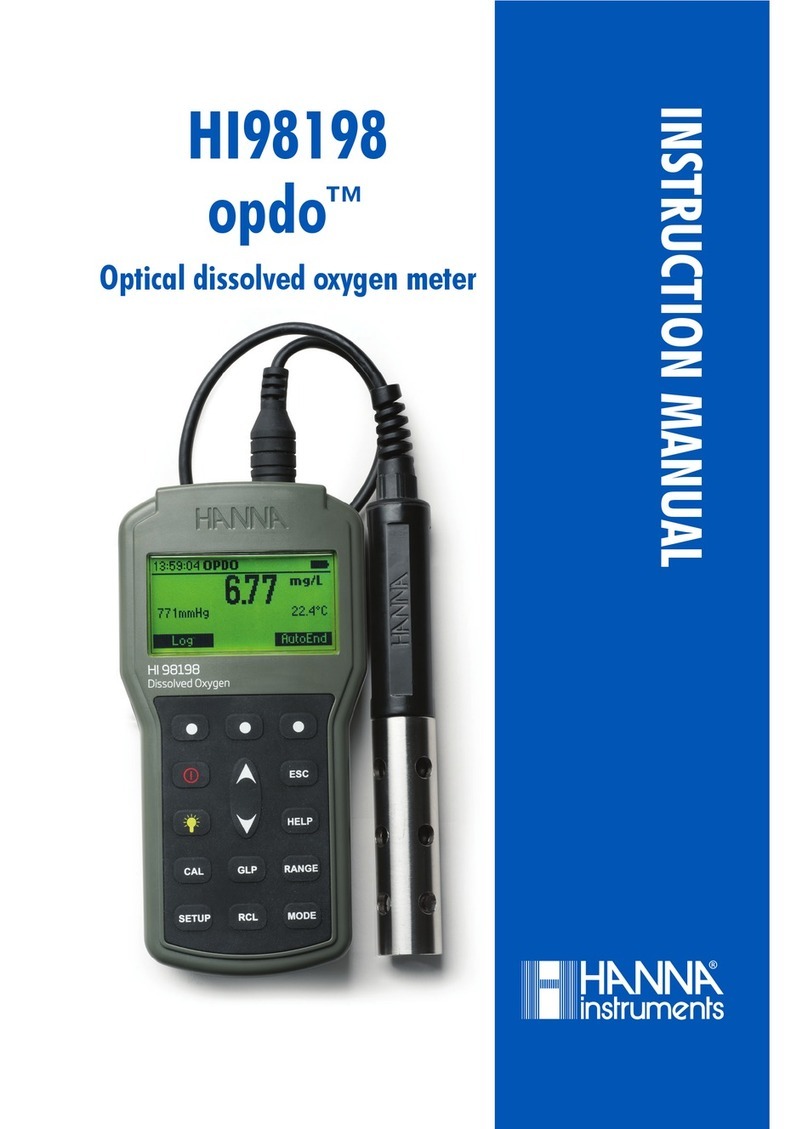

Hanna Instruments

Hanna Instruments HI98198 OPDO instruction manual

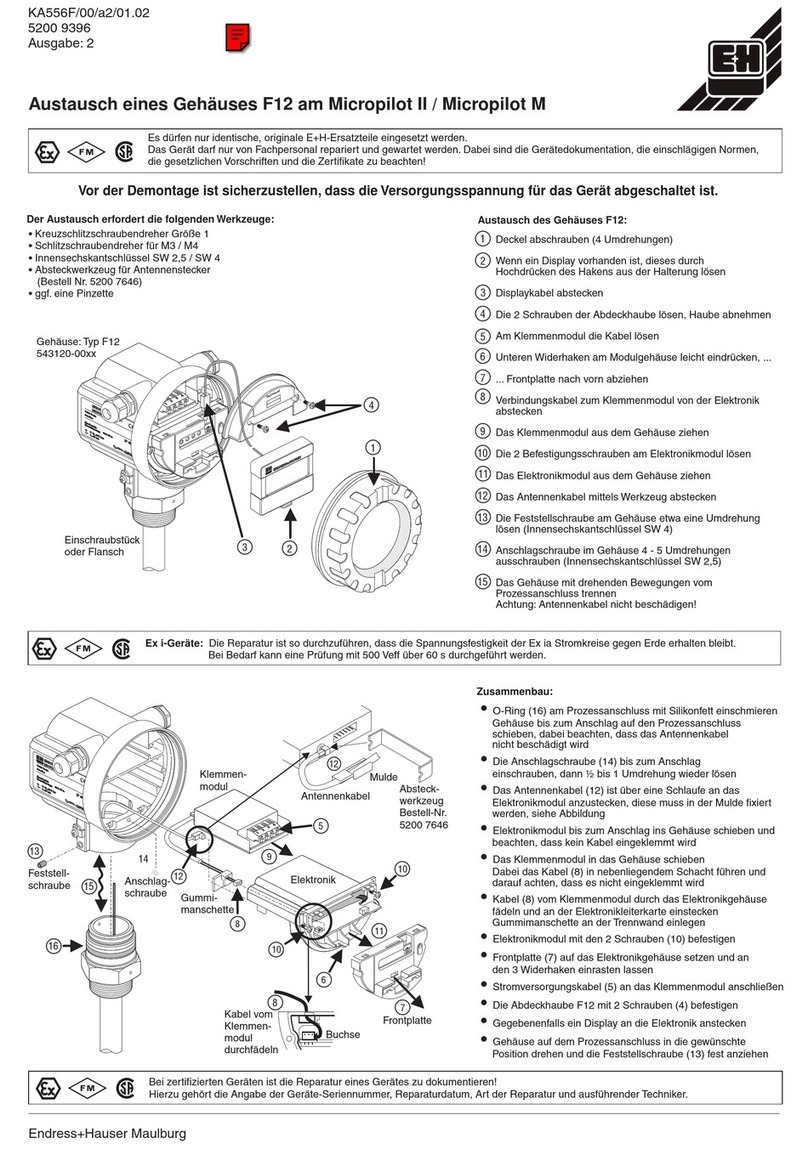

Endress+Hauser

Endress+Hauser Micropilot II manual

Velleman

Velleman DVM8681 user manual

York Survey Supply

York Survey Supply 354420 operating instructions

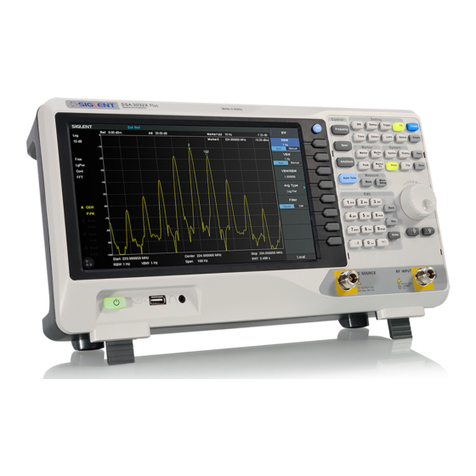

SIGLENT

SIGLENT SSA3000X Plus quick guide