Fimer MVCS User manual

Medium Voltage

Compact Skid

FIMER solar

Hardware manual

Medium Voltage Compact Skid

Hardware manual

1

2

3

4

5

6

7

8

9

10

11

Table of contents

Safety instructions

Introduction to this manual

Hardware description

Storing, lifting and transporting

Mechanical installation

Electrical installation

Finalizing the installation

Start-up and operation

Maintenance

Technical data

Documents

Contents

06

06

06

07

07

07

07

08

09

10

10

10

11

11

11

11

12

12

13

15

16

17

18

19

19

20

20

21

22

22

23

23

24

25

26

26

Safety instructions

• Allowed usage

• Safe installation, start-up and maintenance

• General safety instructions

• MVCS working area safety

–Personal Protective Equipment (PPE)

–Safety instructions for MV switchgear and MV transformer area

–Safety instructions for the auxiliary services board

• Safe operation

Introduction to this manual

• Related documents

• Terms and Abbreviations

Hardware description

• Product overview

–Mechanical characteristics

• Layout drawing

–Working areas and main components

• Main Components Overview

–MV Switchgear

–MV Transformer

–AC Cabinet

–Inverter inputs (A)

–Auxiliary service board (B)

• List of signals

• Main circuit diagram

• Type designation label

• MVCS Configuration

–MVCS optional codes

Storing, lifting and transporting

• Storing

• Lifting

–Lifting instructions

• Transporting

• Unloading

–Unloading Instructions (truck shipping)

–Unloading Instructions (container shipping)

Mechanical installation

• Foundation guidelines

–Placing the MVCS on the foundation

–Fastening the MVCS

• Constructing earthing electrode and earthing

• Filling the pit and finalizing the surroundings

Electrical installation

• Routing the cables

• LV busbar interconnection

• Earthing

–Protective earthing (grounding) inside the MVCS

–Measuring the insulation resistance of the cabling

• Connecting the inverter inputs

• Auxiliary and Communication Interconnection

• MV Side (Grid) Interconnection

Finalizing the installation

• Finalizing the installation

• Checking the installation of MVCS

–Commissioning Pre-Conditions

–Pre-Commissioning Checklist

Start-up and operation

• Start-up procedure

Maintenance

• Maintenance intervals

–Annual maintenance

–Maintenance intervals

• Cleaning procedure

• Maintenance of painted surfaces

–Repainting the scratched areas

–Painting the damaged surface (no visible rust)

–Painting the damaged surface (visible rust)

–Maintenance of Zinc coated surfaces

• Maintenance of grounding bars and points

Technical data

• Technical data and types: MVCS

Documents

• List of documents

27

27

27

28

29

29

30

31

31

32

32

32

32

33

33

34

34

34

34

35

38

38

40

42

42

42

42

44

44

44

44

44

45

46

46

48

48

6

1

Safety instruction

1 - Introduction to this manual

Contents of this chapter

This chapter presents the use of warnings in the manual and gives instructions for safe installation, start-up, use and

maintenance of the Medium Voltage Compact Skid “MVCS”.

Use of warnings

Warnings caution you about conditions which can result in serious injury or death and/or damage to the equipment

and advise on how to avoid the danger. The following warning symbols are used in this manual:

WARNING!

Electricity warning warns of hazards from electricity which can cause physical injury and/or damage to the

equipment.

WARNING!

General warning warns about conditions, other than those caused by electricity, which can result in physical injury

and/or damage to the equipment.

WARNING!

General warning warns about weather conditions, prohibited maintenance operations during a typhoon, thunder-

storm, snow, rain, and electrical storm. Maintenance in such conditions can result in physical injury and/or damage

to the equipment.

WARNING!

General warning warns about maintenance work on the roof which should always be done from the outer perimeter,

considering the local safety regulations.

Allowed usage

• The Medium Voltage Compact Skid “MVCS”, is designed to group the energy generated by a group of string

inverters and adapt it to the power grid. Use the MVCS only at its permissible input/output ratings and ambient

conditions. Make sure this compliance is satisfied before commissioning.

• The operation and maintenance of the MVCS must be carried out by certified technicians that fulfill all local skill

set and safety requirements. Any unqualified personnel must maintain a safe distance from the MVCS. All activi-

ties must be in accordance with the criteria described in the FIMER technical documents and local regulations.

• Make modifications to the MVCS only with authorization of FIMER. Any alterations done outside FIMER approval

will invalid the warranty for the product. FIMER is not liable for any damages caused by these changes.

• The MVCS is a non-walk-in type station, designed to be operated from the outside. Make sure the side doors are

closed at all times during operation and that no personnel is inside or in the near vicinity of the MVCS.

Safe installation, start-up and maintenance

This section contains the safety instructions which you must follow when installing, commissioning, and maintaining

the MVCS. If ignored, physical injury or death may follow, or damage may occur to the equipment.

• Only authorized electricians/personnel are allowed to install, start-up and doing maintenance on the MVCS.

Working methods, tools, components etc. must follow the IEC regulations.

• Obey all local safety regulations concerning electrical sub-stations.

• The MVCS should be energized and de-energized only by an authorized person who has the task-specific instruc-

tions for the operation of an MV substation and permission from the on-site foreperson in charge of electrical

work.

• If other people must be in the vicinity while the door is open, warn them, and if required, provide supervision and

guidance.

7

General safety instructions

WARNING!

Before you perform any work in the MVCS, obey the following safety precautions.

1. Obtain a work permit.

2. Clearly identify the work location.

3. Read the safety instructions of the working area and the component you are working on.

4. Make sure that there is no voltage presence in the working area you are going to work on, see Safety instructions

for MV switchgear and MV transformer area and Safety instructions for the auxiliary services board.

5. Secure against reconnection.

6. Use a voltage tester to ensure that there is no voltage in working area.

7. Make sure that the MVCS is properly grounded.

8. Secure against reconnection.

9. Use protection against any live parts.

10. Take special precautions when you work close to exposed conductors.

MVCS working area safety

The MVCS has three main working areas:

• AC Cabinet Area

• MV Transformer Area

• MV Switchgear Area

Each working area has separate safety instructions.

Personal Protective Equipment (PPE)

• Perform any operation on the equipment with suitable work clothes and instruments.

• When choosing a personnel protective equipment, consider environmental conditions such as humidity, noise, etc.

and local regulations.

• The minimum required safety equipment is as follows:

–Safety shoes

–Safety gloves

–Safety glasses

–Head protection

–Hearing protection

–Work clothes

Safety instructions for MV switchgear and MV transformer area

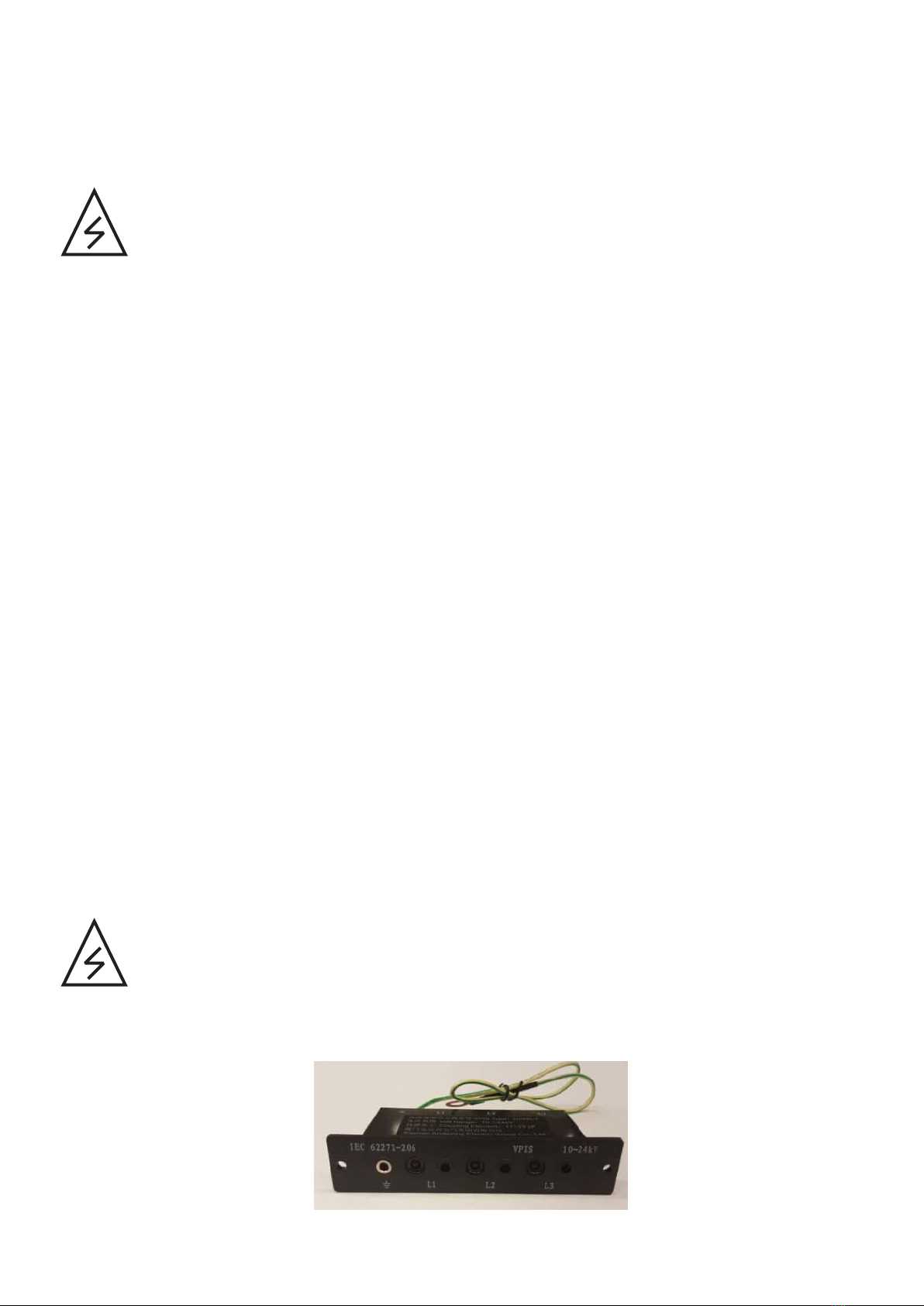

WARNING!

Perform the below instructions before you start working inside the MV switchgear and/or MV transformer area. Ignoring

the instructions can cause physical injury or death, or damage to the equipment.

1. Obtain a work permit.

2. Identify the MV switchgear and read its safety instructions.

3. Check the operation of the capacitive voltage indicators in all MV switchgear bays (all phase LEDs are switched on

when a voltage is connected). Capacitive voltage indicators:

1 - Introduction to this manual

8

4. Disconnect the MV switchgear from the grid and all possible power supplies (external, auxiliary, and inverters as well as any parallel

connection stations), secure by locking and tagging.

a. Stop the string inverters outside the MVCS. Open the DC disconnecting switches in each inverter unit and add warning notices. If appli-

cable, open the AC disconnecting switches in each inverter unit, lock and add warning notices.

b. Open all auxiliary breakers, switches and fuses in the auxiliary service board, lock and add warning notices.

c. Open main low voltage circuit breaker (if present), and all fuse base switches of the inverter inputs (AC Cabinet), lock and add warning

notices.

d. Turn the vacuum circuit breaker of the MV switchgear (V/L module) to open position. Lock and add warning notice.

e. Turn the disconnecting switch of the MV switchgear (V/P module) to open position. Lock and add warning notice.

f. Turn the earthing switch of the MV switchgear (V/P module) to earthed position. Lock and add a warning notice.

g. Turn the disconnecting switch of the MV switchgear (C/L modules) to open position. Lock and add a warning notice.

h. Turn the earthing switch of the MV switchgear (C/L modules) to earthed position. Lock and add a warning notice.

i. With above operation the MV Switchgear, and so the MVCS, should be disconnected. See “Switchgear”, “MVCS Interconnection Cables

and Electrical Layout” and the general scheme of the PV plant to assure that no external supply is connected to the MV Switchgear.

5. Check that all shrouds/screens are in place.

6. Check that you are not near to any live parts while working. All live circuits must be protected with shrouds/screens.

7. Make sure that the MV switchgear is dead.

–Check the status of voltage indicators in all MV switchgear bays. Also note that all phase LEDs which were switched on AC cabinet

before step 3 are now switched off).

8. Check that the MV transformer is dead (high voltage terminals, low voltage terminals, any auxiliary power, and instrumentation). Use an

appropriate high voltage tester only for the high voltage side, and a voltage detector with suitable testing heads for the low voltage side.

Safety instructions for the auxiliary services board

1. If there is no main low voltage circuit breaker installed in the power section, then follow Safety instructions for MV switchgear and MV

transformer area

a. Check that there is no voltage presence, with a voltage tester, neither in the power section nor in the auxiliary services board.

2. If main low voltage circuit breaker is installed, then follow:

a. Obtain a work permit.

b. Open the main circuit breaker or main switch upstream auxiliary service transformer, secure by locking and tagging.

c. Open the circuit breaker downstream auxiliary service transformer, secure by locking and tagging.

d. Open all switches, breakers, and connectors of the auxiliary service board, and secure by locking and tagging.

e. Make sure you are not near to any live parts while working. Disconnect the live circuits or protect them with shrouds/creens.

f. Check the status of the voltage indicators in the auxiliary service board.

g. Check that the auxiliary service board is dead.

1 - Introduction to this manual

9

Safe operation

This section contains the safety instructions which you must follow when operating the MVCS. If ignored, physical

injury or death, or damage may occur.

WARNING!

Obey these instructions to prevent injury, death, or damage to the equipment.

WARNING!

Keep all doors locked while the MVCS is operating. Allow access to only authorized personnel.

1. Keep all doors of the MVCS closed during operation. Give the keys only to authorized personnel.

2. Before you start a group of inverters, check the connections of each inverter input, and the recommendations in

the specific inverter manual.

3. Do not open the AC base fuse switches when the MVCS is operating.

4. Before you adjust the group of inverters and set them into service, make sure that all of them are suitable for

operation.

5. Do not use the inverters in a manner not specified in the manual.

Notes:

Spend as little time as possible near the inverters or the MVCS.

1 - Introduction to this manual

Contents of this chapter

This chapter provides information about the manual such as applicability, target audience and contents. It also lists the related documents.

Applicability

This manual is applicable to Medium Voltage Compact Skid “MVCS”.

Target audience

This manual is intended for personnel who transport, store, plan the installation, install, commission, and maintain the MVCS.

Read this manual before working on the MVCS. You are expected to know the fundamentals of electricity, wiring, electrical components,

and electrical schematic symbols.

Related documents

Terms and abbreviations

IEEE device no. references

2

Introduction to this manual

2 - Introduction to this manual

Inverter manuals and guides

PVS-175-TL Product Manual FIMER_PVS-175-TL A.1 Version_Product manual_EN_RevC.pdf

PVS-175-TL Quick installation guide PVS-175-TL-Quick Installation Guide EN-REVA CC.pdf

PVS-175- TL data sheet FIMER_PVS-175-TL_EN_RevB.pdf

PVS-100/120-TL Product Manual FIMER-PVS-100_120-TL-B version-Product manual EN-Rev A

PVS-100/120-TL Quick installation guide PVS-100_120-TL - Quick Installation Guide EN - RevB

PVS-100/120-TL data sheet FIMER_PVS-100-120-TL-6MPPT-2MPPT_EN_RevA

Term/ Abbreviation Description

AC Alternating current

CV/CCV Construction of MV switchgear (L+P/ 2L+P)

DC Direct current

HC High cube container

LV Low voltage (50...1000 V AC)

MV Medium voltage

MVCS Medium voltage compact skid

LVMCB Low Voltage Main Circuit Breaker

PPE Personal protective equipment

SF6 Sulfur hexafluoride (this gas type is used in MV switchgear).

SWG Switchgear

THD Total harmonic distortion

IEEE Protection function

27 Undervoltage

50 Instantaneous Overcurrent

50N Neutral Instantaneous Overcurrent

51 AC time overcurrent

51N Neutral Time Overcurrent

59 Overvoltage

68 Transformer inrush detector

81 Medium voltage

List of documents

See List of documents.

Note: The drawings are delivered with the unit only on request -

11

Contents of this chapter

This chapter provides an overview of the Medium Voltage Compact Skid “MVCS”. It also includes layout, general data sheet of the main

components, type designation label and ordering information.

Product overview

The medium voltage compact skid connects a group of inverters to a medium voltage power grid. This solution is constructed around a

skid house that contains:

• MV switchgear—connects to the power grid. It is also the main protecting, switching, breaking and disconnecting equipment of the

medium-voltage side of the solar power plant.

• MV transformer—transforms low voltage from inverters to medium voltage for the power grid.

• AC cabinet—contains all parallel connections to the inverter inputs and the auxiliary service boards (required for the autonomous func-

tion of the MVCS). Note that the AC cabinet also includes an additional space for customer use (e.g. communication board, etc).

.

Mechanical characteristics

The MVCS is constructed over a skid, with the appropriate dimensions to be suitable to transport inside 20 ft or 40 ft HC container.

• External dimension (length, width, height) = 5700 x 2150 x 2580 mm.

• Total weight = 9-18 ton (may vary depending on MVCS final configuration).

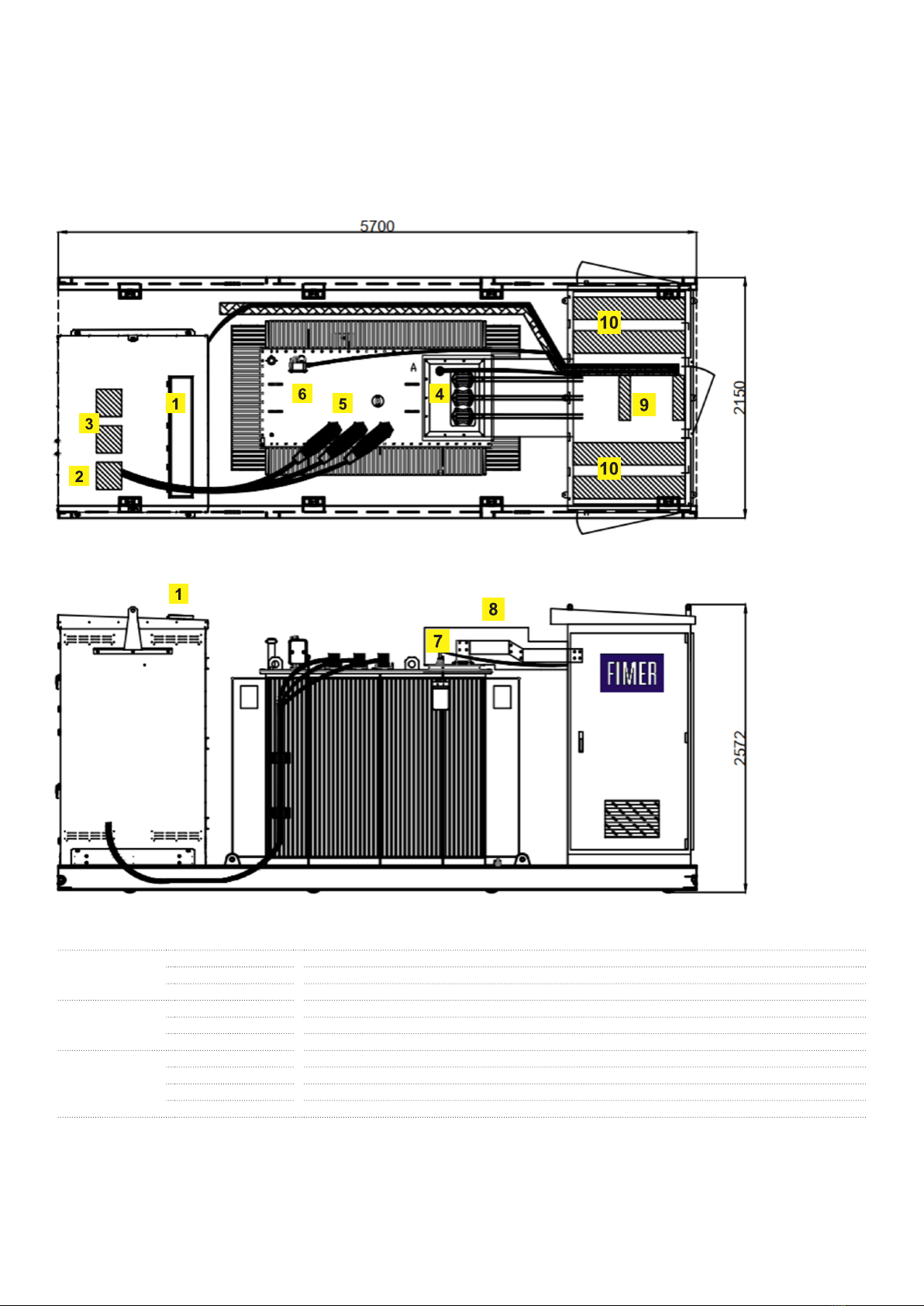

Layout drawing

This section describes the working areas and main components of the MVCS. For additional information, request to your local FIMER sales

contact:

• “MVCS Structural Layout”.

• “MVCS Footprint”.

3

Hardware description

3 - Hardware desription

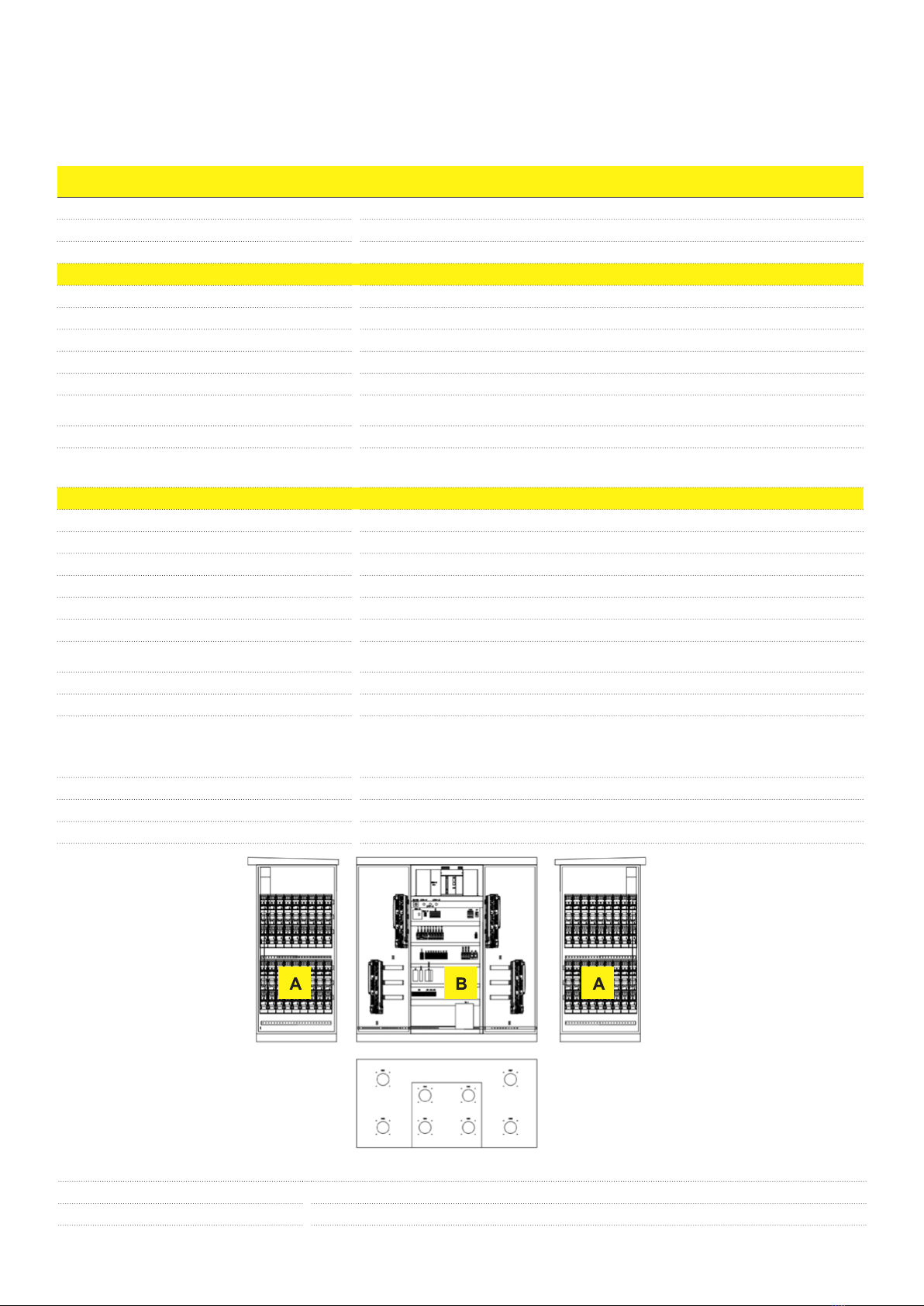

A MV switchgear area. For more information, see section MV Switchgear

B MV transformer area. For more information, see section MV Transformer

C AC cabinet area. For more information, see section AC Cabinet

A B C

12

Working areas and main components

Main Components Overview

A

1SF6 Outlet

2MV Input from transformer (V module)

3 MV Output (C module)

B

4 LV Connection Box

5 MV Bushings

6 Transformer Protection Device

C

7 Neutral Bushing

8 Busduct/Busbars

9 Auxiliary Section input

10 String Inverter cables access

3 - Hardware desription

13

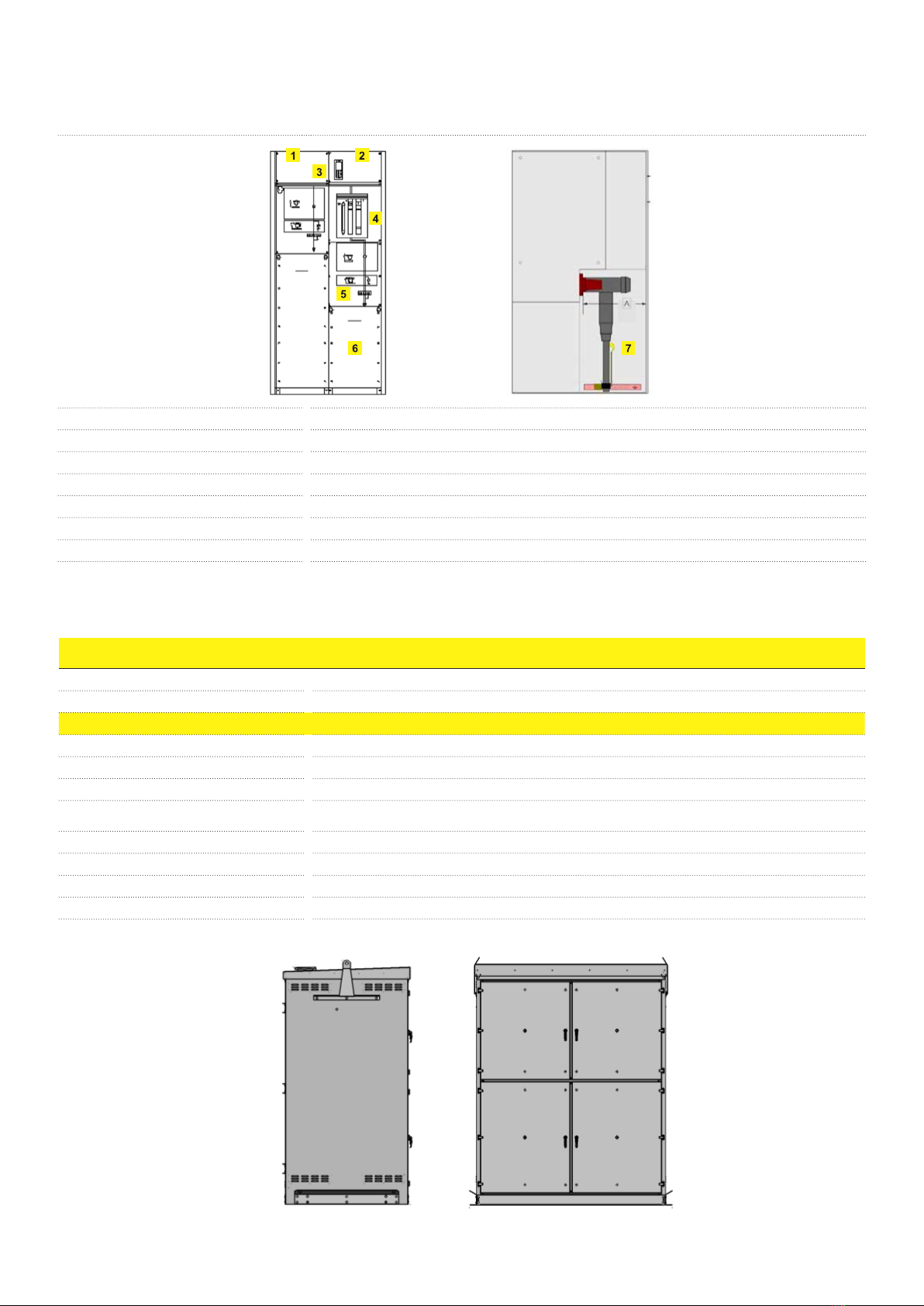

MV Switchgear

Medium voltage switchgears protect MV transformers and the MVCS in general, its also allow the MVCS to be connected to the Grid and

to other MVCS in parallel.

Technical Datasheet Environmental

Minimum Ambient Temperature -25 °C

Maximum Ambient Temperature

(No derating) 60ºC (40 ºC)

Max Altitude <1500 m asl

Relative humidity max. 24 hour mean 95%

Classification (IEC62271-200) LSC2A IAC AFL 16/20/25 kA x 1s → Indoor solution

LSC2A IAC AFLR 16/20/25 kA x 1s → Outdoor solution

SF6 Ventilation Backwards (exhaust channel) → Indoor solution

Downwards (cable trench) → Outdoor solution

Degree of Protection (IEC60529): IP3X (cable compartment) – IP2X (front cover)

IP54 for MV enslosure

Corrosivity protection Standard: C4

Upgrade: C5M

Rated Voltages 24 / 50 / 125 kV

36 / 70 / 170 kV

Frequency 50/60 Hz

Operating Voltage Up to 36 kV

Rated Current 630 A (@40ºC) 500 A (@60ºC)

Rated Short Circuit Current 20 kA – 1s

Internal Arc Fault withstand Standard (24kV/36kV): 16 kA - 1s/ 20kA – 1s

Upgrade (24kV/36kV): 20 kA - 1s/ 25kA – 1s

Configuration Standard: 1 Line Switches + 1 Trafo Feeders

Upgrade: 2 Line Switches + 1 Trafo Feeders

Electrical and mechanical class M1

MV Unit Composition

Line Switch 630A (C module), equipped as follow:

- Nr. 3 capacitive voltage indicators

- Manual line switch with earth position for the incoming

MV cables

- Key lock with key free for earth switch closed

- Simple incoming MV cable (one cable per phase)

Trafo Feeder 630A (V module), equipped as follow:

- Nr. 3 voltage indicators

- Manual line switch with earth position for the MV cables

- Key lock with key free for earth switch closed

- Circuit Breaker (motorized as optional)

- Standard: Nr. 1 electronic protection relay

(50/51-50N/51N)

Optional:Relay with additional protections (59-27-81..) and

measurement + comm functions as optional

- Nr. 3 CT

3 - Hardware desription

14

1 C module (L)

2 V module (P)

3 Protection Relay

4 Circuit Breaker

5 Interlocking

6 Cable compartment protection panel

7 Cable compartment

MV Outdoor Enclosure

This enclosure is included when indoor switchgear is installed.

Technical Datasheet

Minimum Ambient Temperature -25 °C

Maximum Ambient Temperature 60 °C

Classification AFLR

Degree of Protection (IEC60529): IP54

Degree of Protection (IEC62262) IK9/10

Corrosion class Standard: C4

Upgrade: C5M

Paint colour RAL7035

Cooling Natural

SF6 Ventilation Upper exhaust

Dimensions (WxLxH) 1676 x 1300 x 2238 mm

3 - Hardware desription

15

1 LV Bushings + Neutral terminal

2Off-Load Tap changer

3 MV Connectors

4 Earthing terminal and Oil Drain Valve

5 RIS2/DGPT2 (protection device)

6 Oil filling plug

MV Transformer

Technical Datasheet

Minimum Ambient Temperature -25 °C

Maximum Ambient Temperature (No derating) 60ºC

Max Altitude <1000 m asl

Reference Standard IEC60076-1

Cooling type ONAN

Power @30ºC Up to 6,66 MVA

Primary voltage Up to 36 kV

Secondary Voltage 0,8/0,48/0,4 kV

Voltage regulation range +/- 2x2,5%

Vectorial group Dyn11

Primary insulation class 24 / 50 / 125 kV

36 / 70 / 170 kV

Secondary insulation class (ph) 3,6/10/40

Secondary insulation class (N) 1,1/10/20

Losses Standard: EU 548/2014

Optional: EU 2019/17831

Short Circuit Impedance 5…8%

Frequency 50/60 Hz

Max Dimensions (LxWxH) 2650x1700x2200

Corrosion class Standard: C4

Upgrade: C5M

Painting RAL 7035

Load Power derating According nº of inverters and environmental conditions

Safety protection device RIS2/DGPT2 or similar

*This layout may vary depending on final MVCS configuration

1) Included as standard if destination country is in EU

3 - Hardware desription

16

Technical Datasheet

Minimum Ambient Temperature -25 °C

Maximum Ambient Temperature 50 °C

Max Altitude <2000 masl

Reference standard 61439-1 & 2

Max Dimensions (WxLxH) 2080x1200x2295 mm

Max Weight < 3000 kg

Ventilation Forced + Natural (> 3000 m3/h)

IP 54 (20 with doors open)

Corrosion class Standard: C4

Upgrade: C5M

Paint colour RAL 7035

Doors → Cubicles (nº)

-Front → Aux services + MCB (2)

-Lat. Left → Power Section 1 (1)

-Lat. Right → Power Section 2 (1)

Nº of Inputs (Power) Up to 36 (Up to 6,7 MVA)

Input protection Fuse gS NH1

Rated Voltage 800/480/400 V

Frequency 50/60 Hz

Conductor Copper Busbars

Surge Arrester Protection Type I+II

Aux Trafo Power Standard: 10 kVA

Upgrade: 20/30 kVA

Secondary Voltage 400-230 V

Spare Lines 2x16/10 A (1 ph)

Communication

MVCS signal concentration:

-2x Remote I/O module, Digital signals, Input, 8-channel, 2-conductor connection

-1x Remote I/O fieldbus coupler, Modbus/TCP

-1x Network switch, unmanaged, Fast Ethernet, Number of ports

Main Circuit Breaker Optional

UPS Optional

Energy Measurement Optional

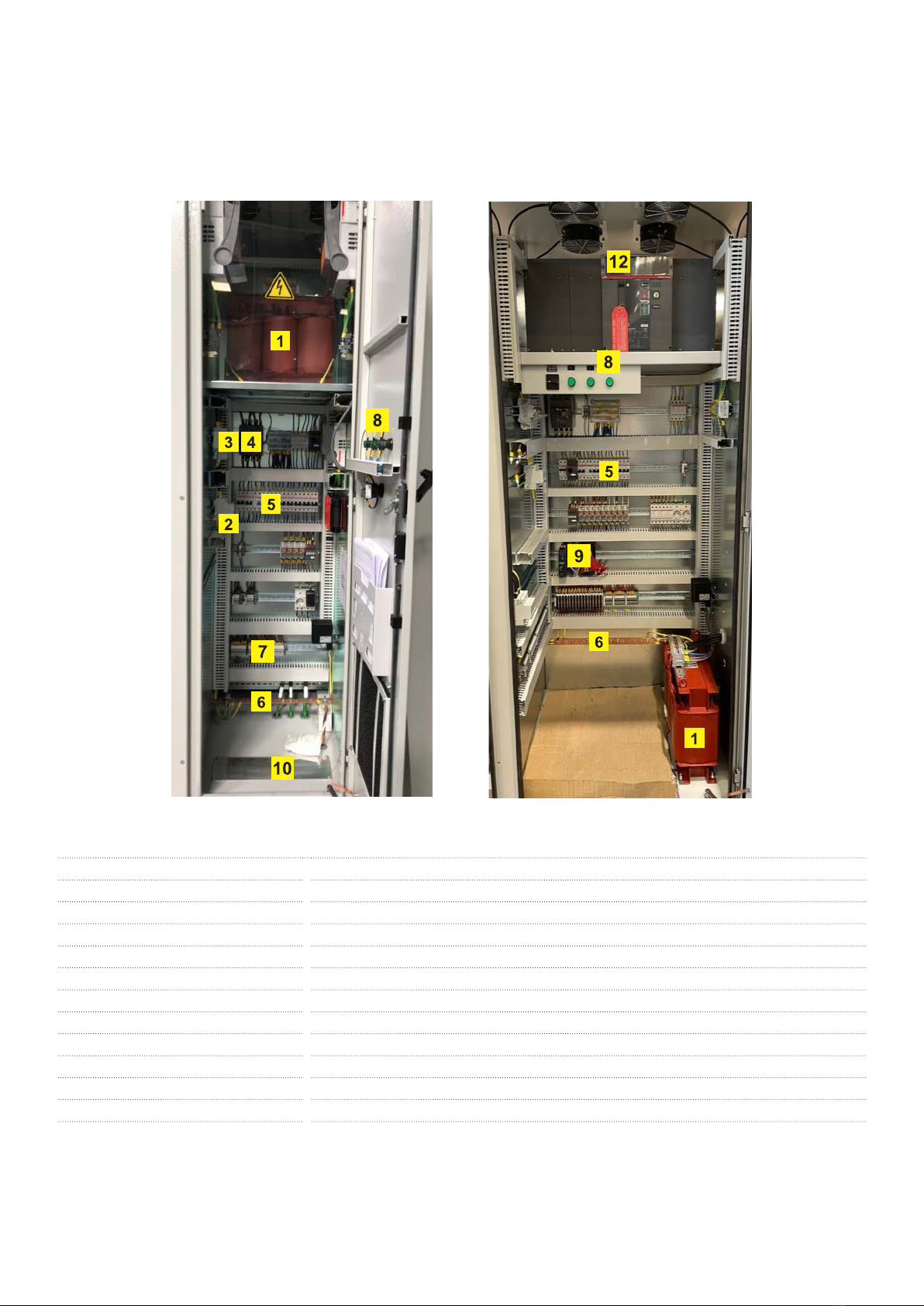

AC Cabinet

AInverter inputs. For more information, see section Inverter inputs (A)

BAuxiliary service board. For more information, see section Auxiliary service board (B)

*This layout may vary depending on final MVCS configuration

3 - Hardware desription

17

1Cover for incoming cables

2Surge arrester protection

3Grounding Busbar

4Fuse holders + fuses for inputs protection

5PVC protection cover

6Ventilation system

*This layout may vary depending on final MVCS configuration

Inverter inputs (A)

3 - Hardware desription

18

1Auxiliary service transformer

2Surge arrester protection for the auxiliary service board

3Upstream on-load fuse switch for auxiliary service transformer protection

4Downstream circuit breaker for auxiliary service transformer protection

5Auxiliary service board circuit breakers and differential protections

6Grounding busbar

7Terminals block

8Voltage presence indication LEDs

9Communication board (if present)

10 Cover for incoming cables

11 Main Circuit Breaker (if present)

12 Ventilation system

*This layout may vary depending on final MVCS configuration

Auxiliary service board (B)

The figure below shows the disposition of the main components of a standard auxiliary service board.

3 - Hardware desription

19

List of signals

Signals from the different devices described above are concentrated in the auxiliary service board (7 & 9). These digital signals are

connected to a Modbus TCP fieldbus coupler + industrial ethernet switch, so it can be integrated with an external SCADA. The list of most

common signals:

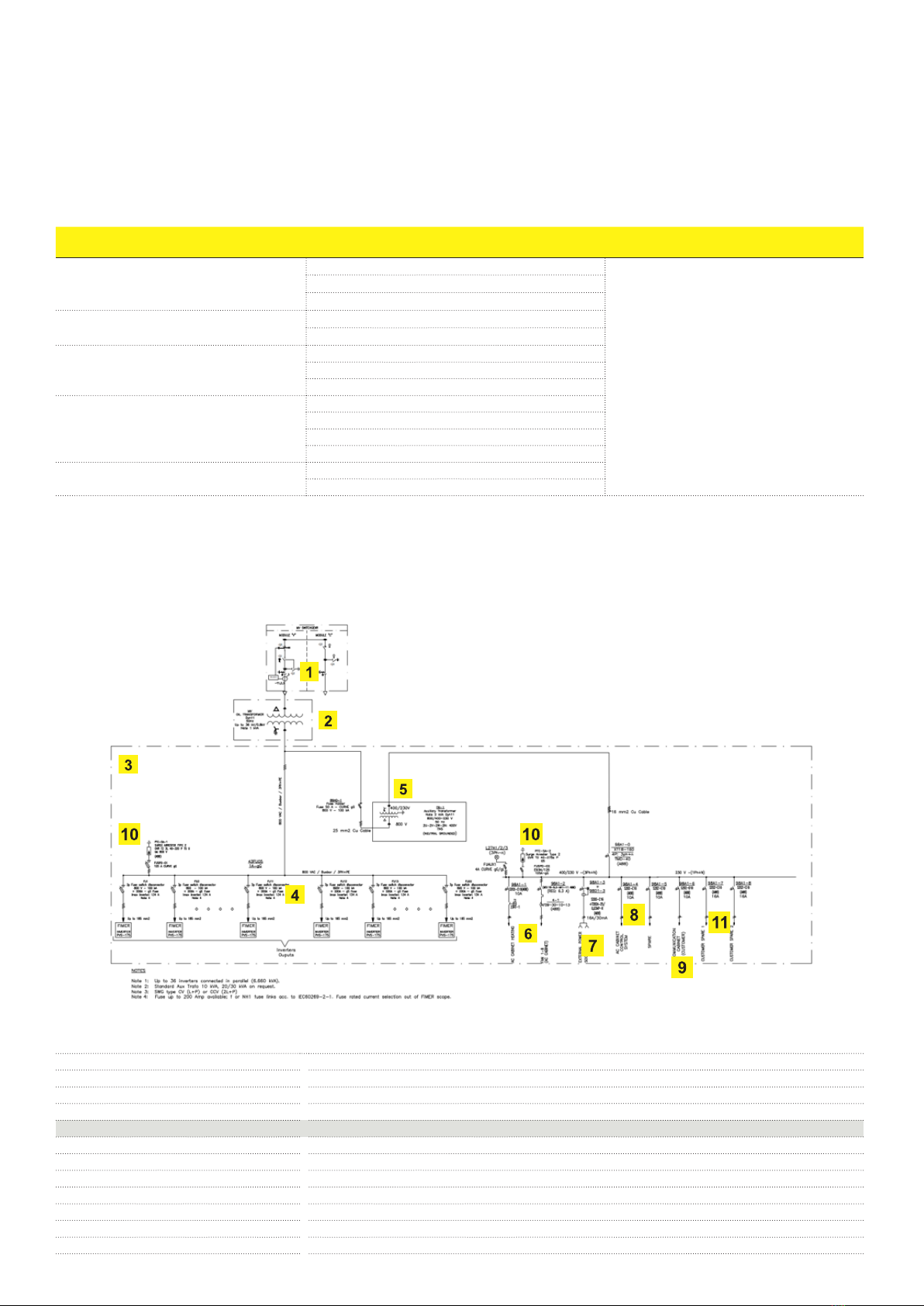

Main circuit diagram

The general single-line diagram depends on the configuration and options of the unit as well as the configuration of the inverter group. The

table below describes the baseline configuration.

Component Signal Signal type

A01 MV Cabinet type "C"

Disconnector Status

DI

Earth Switch Status

Gas Pressure Level

A02 MV Cabinet type "C" Disconnector Status

Earth Switch Status

A03 MV Cabinet type "V"

Disconnector open indication

Earth Switch open indication

Circuit Breaker Status

Oil Transformer (DGPT2/RIS2)

Temperature stop T2

Temperature stop T1

Internal Pressure alarm

Gas

Auxiliary Services Cabinet Aux Transformer secondary breaker status

Ventilation Status

*A02 MV Cabinet type “C” only for MVSWG CCV (2L+P) type

*Optionals, such as main circuit breaker, UPS, LV energy measurement; are not shown in this SLD

1MV Switchgear

2MV Transformer

3AC Cabinet

4Inverter Inputs

Auxiliary Service Board

5Auxiliary Service Transformer

6AC cabinet own loads (fans & heating)

7Sockets (1PH)

8Control

9Communication

10 SPD

11 Spares

3 - Hardware desription

20

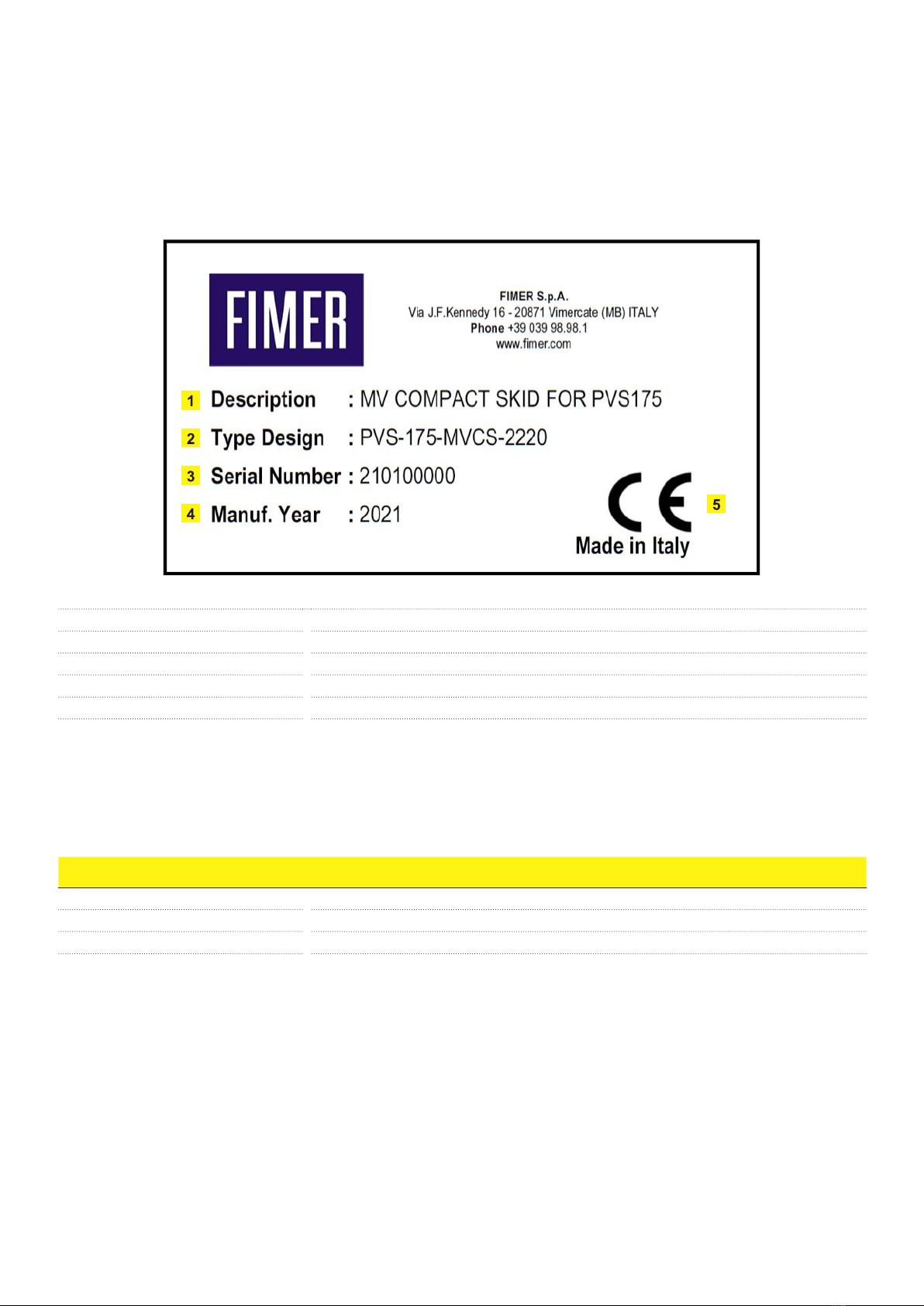

Type designation label

The figure below shows an example of the type designation label. The label contains the basic data of the unit. It is located inside the AC

cabinet, specifically in auxiliary service board section.

MVCS Configuration

To define a MVCS the following inputs are needed:

Eg:

• String Inverter: PVS-175

• Number of inverters connected to the MVCS: 20

• Medium Voltage Level: 15 kV

With the definition of the inputs above, then a standard MVCS will be configured:

• Skid: C4;

• SWG: 24kV;16kA;CV; 50/51-50N/51N-68 Relay;

• MV Transformer: 15/0,8 Dyn11; 3.700 kVA @30ºC; Losses acording EU 548/2014 Regulation

• AC Cabinet: 20 inputs;10kVA Auxtrafo (0,8/0,4-0,23 kV)

If additional features are needed, then the appropriate optional codes from the following section must be selected:

1Product description: MVCS + string inverter name

2General designation: string inverter name + MVCS rated power

3S/N

4Manufacturing Year

5CE marking

Input Value

String Inverter

Number of inverters connected

Medium Voltage level

3 - Hardware desription

Table of contents

Other Fimer Industrial Equipment manuals