FINE FIELD Harvy200 User manual

Harvy200 Version 2.1 - 2019 Page 1 of 18

Harvy200

Instruction manual

Version: 2.1 - 2019

Original instruction manual

Harvy200 Version 2.1 - 2019 Page 2 of 18

© opyright Fine Field B.V. Melderslo, the Netherlands.

No part of this publication may be reproduced and/or published in any form or by any means,

without prior written permission from Fine Field B.V.

Fine Field B.V.

Vlasvenstraat 41

5962 A Melderslo

The Netherlands

Tel: +31 (0)6 542 479 80

Fax: +31 (0)77 398 81 85

Harvy200 Version 2.1 - 2019 Page 3 of 18

Index

1 General description ................................................................................................... 4

1.1 Parts Harvy200 ....................................................................................................... 4

1.2 Type plate .............................................................................................................. 5

2 Technical specifications ............................................................................................ 5

3 Safety .......................................................................................................................

3.1 Obligation and liability ............................................................................................. 6

3.2 Use according to the intended purpose ....................................................................... 6

3.3 Warning symbols ..................................................................................................... 6

3.4 Organisational measures .......................................................................................... 6

3.5 Informal safety measures ......................................................................................... 7

3.6 Extremely hazardous places ...................................................................................... 7

3.7 Alterations in the construction ................................................................................... 7

3.8 leaning of the installation ....................................................................................... 7

4 Assembly ................................................................................................................... 8

5 Catch sheet ............................................................................................................... 9

5.1 Adjust the width ................................................................................................... 15

5.2 Adjust the height of the collection tray ..................................................................... 15

5.3 Adjust the angle of the brushes ............................................................................... 15

5.4 Adjust the end position of the collection tray ............................................................. 16

Harvesting .............................................................................................................. 17

7 Maintenance ............................................................................................................ 17

8 Declaration of conformity ........................................................................................ 18

Harvy200 Version 2.1 - 2019 Page 4 of 18

1General description

The Harvy200 has been developed as a tool for harvesting (blue) berries. The Harvy200 is adjustable

in width and is driven between the rows of berry bushes, in such a manner that one row of berry

bushes is situated between the collection trays of the Harvy200. The collection trays are equipped

with a brush at the front in between which the berry bushes are able to move. By means of shaking

the berry bushes, all berries of the bush will fall into the collection trays and into the crates that are

situated at the bottom of the collection trays. Once all berries have been shaken from the bush, the

Harvy200 can proceed to the next bushes. As soon as the crates are full, the collection tray can be

pulled backwards in order to replace the full crates by empty crates. The Harvy200 contains racks at

the back that can be used to stock piles of empty crates.

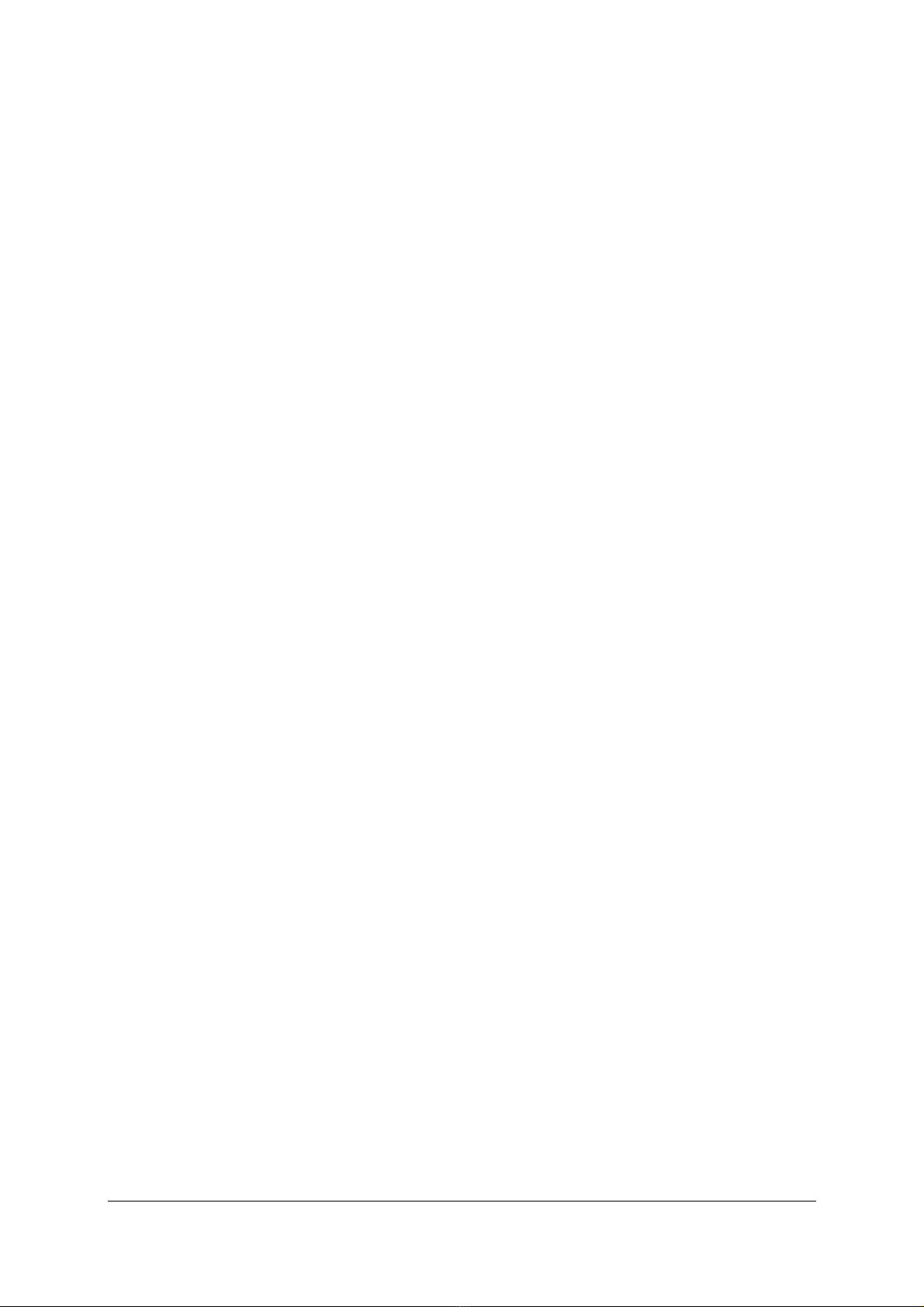

1.1 Parts Harvy200

Figure 1.1 Harvy200

1. Stock of empty crates 3. ollection tray

2. Base frame 4. rates filling position

1.

4.

2.

3.

Harvy200 Version 2.1 - 2019 Page 5 of 18

1.2 Type plate

The type plate is located on the rear suspension of the Harvy200. This plate displays a few details of

the Harvy200.

Figure 1.2 Type plate

2Technical specifications

DVP

-

EH

-

01

Length 3300 [mm]

Minimum width 2150 [mm]

Maximum width 3000 [mm]

Height 2160 [mm]

Total mass 180 [kg]

Mass collection tray 22 [kg]

Harvy200 Version 2.1 - 2019 Page 6 of 18

3Safety

Attention: Read this instruction manual carefully. Familiarise yourself with the instruction

manual and the correct use of the Harvy200, prior to operating the Harvy200.

3.1 Obligation and liability

The Harvy200 has been developed and produced according to the latest state of technology. This

means the Harvy200 complies with the applicable European Directives regarding safety and health

and is therefore provided with the E-marking. Nevertheless, hazards to the life and the goods of the

user or third parties or damages to the Harvy200 and/or other matters may arise during the

operation.

The Harvy200 should only be used:

•for use according to the regulations,

•in a perfect condition of safety.

Defects that could impair the safety have to be repaired immediately.

3.2 Use according to the intended purpose

The Harvy200 is intended as a tool for harvesting (blue) berries, during which harvest all berries

from the bush end up through the collection trays into the empty crates by shaking the berry bushes.

Usage according to the intended purpose also includes observing this instruction manual.

Any usage beyond the description given above, does not comply with the intended purpose. Usage

not complying with the intended purpose mainly includes overload and the incorrect rectification of

defects.

The manufacturer is not responsible for damage arisen from usage that does not correspond with the

intended purpose – this is at the risk of the user.

3.3 Warning symbols

Some warning symbols have been applied to this instruction manual and to the Harvy200. The

meaning of the warning symbols is as follows:

When this symbol is displayed, information is provided in order to prevent damage and

incorrect use of the Harvy200.

When this symbol is displayed, information is provided in order to prevent injury or

damage.

Parts displaying this pictogram may cause a danger of crushing. Do not place body

parts below and/or between these parts in order to prevent injuries.

3.4 Organisational measures

The required, personal protective equipment has to be provided by the operator. The ARBO-

legislation (Health & Safety), Occupational Safety and Health Administration (OSHA) and nationwide

safety and health regulations must be observed.

Harvy200 Version 2.1 - 2019 Page 7 of 18

3.5 Informal safety measures

In addition to the instruction manual, the generally applicable and local regulations for the

prevention of accidents and for the protection of the environment also have to be provided and

observed. All safety instructions and instructions with regard to hazards relating to the Harvy200

have to be kept in a readable condition and replaced if necessary.

3.6 Extremely hazardous places

The collection trays are suspended to the frame in a hinged manner using some sheet metal strips. If

the user grabs the sheet metal strip and uses it to try pulling the collection tray closer, there is a

risk of entrapment of the hand between the sheet metal strip and the collection tray. In order to

prevent this, a warning symbol has been applied to the back of the collection tray, near the sheet

metal strip.

3.7 Alterations in the construction

Alterations to the product by third parties require permission from the manufacturer. This also

includes the application of replacement parts other than the ones prescribed.

3.8 leaning of the installation

The proper functioning of the Harvy200 can only be guaranteed during a longer period of time if the

Harvy200 is cleaned regularly.

Harvy200 Version 2.1 - 2019 Page 8 of 18

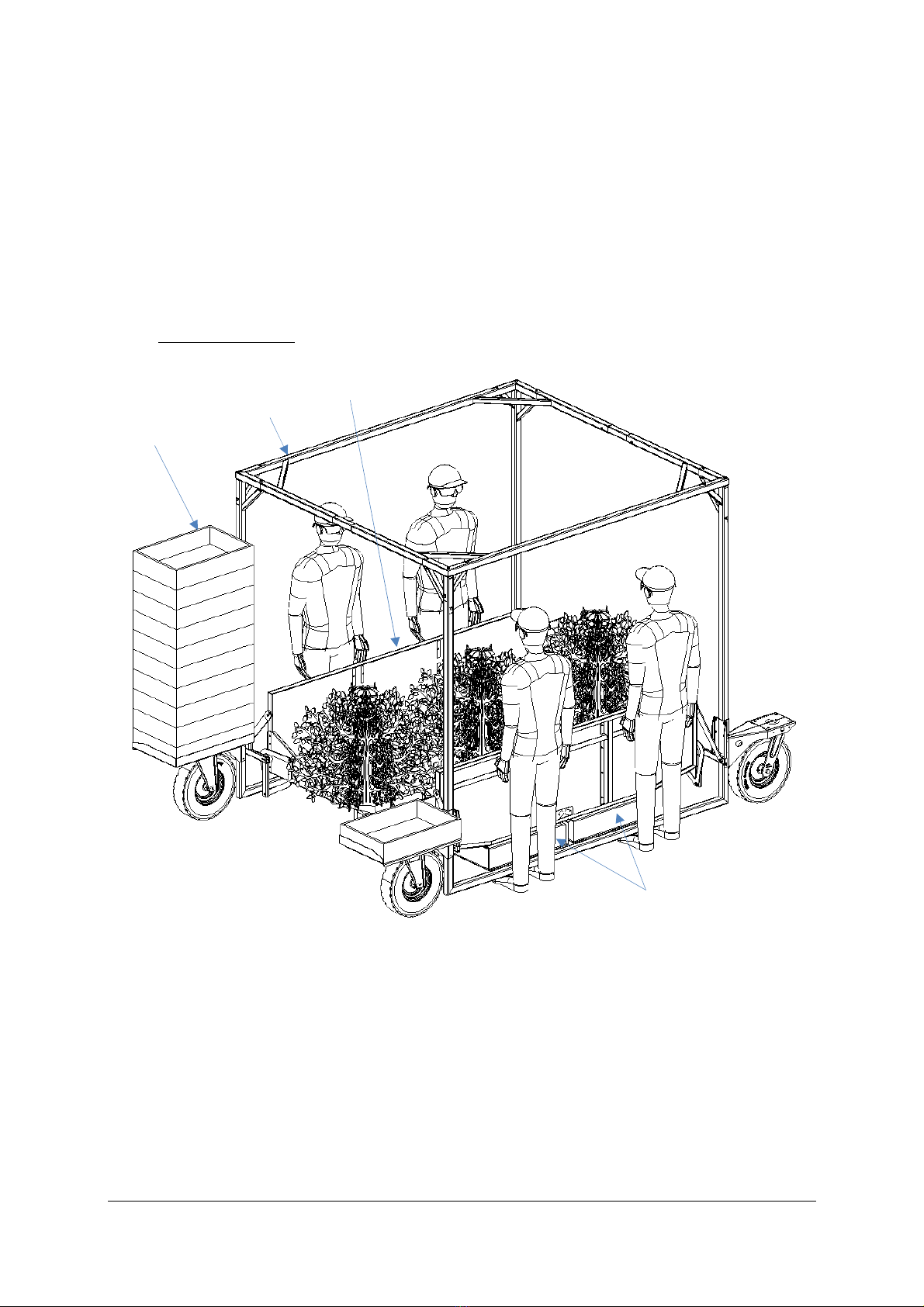

4Assembly

1. The base frame consists of two sub-frames. Assemble both sub-frames using the supplied fixing

materials, as displayed in the images below.

Figure 4.1 Assemble sub-frames

2. onnect both frames by means of two connecting tubes. Both tubes are fastened using 4 bolts.

3. Mount the crate racks onto the rear suspension.

Figure 4.2 onnect sub-frames together

Fixing materials:

A Hex bolt M8x16 + washer Hex bolt M8x60 + washer

B Hex bolt M8x20 + washer D Hex bolt M8x60 + locknut + 2 washers

Swivel castors

onnecting tube

onnecting tube

B

B

D

A

A (4x)

Harvy200 Version 2.1 - 2019 Page 9 of 18

4. Place the collection trays between the frames and fasten them using the clamping brackets (2 for

each collection tray) to the base frame.

Figure 4.3 Place collection trays

5atch sheet

If You ordered a atch sheet you will find the mounting instructions down here.

Step 1: check the content of your delivery you should have 2 sets of hooks and the 2 sheets.

lamping brackets

Harvy200 Version 2.1 - 2019 Page 10 of 18

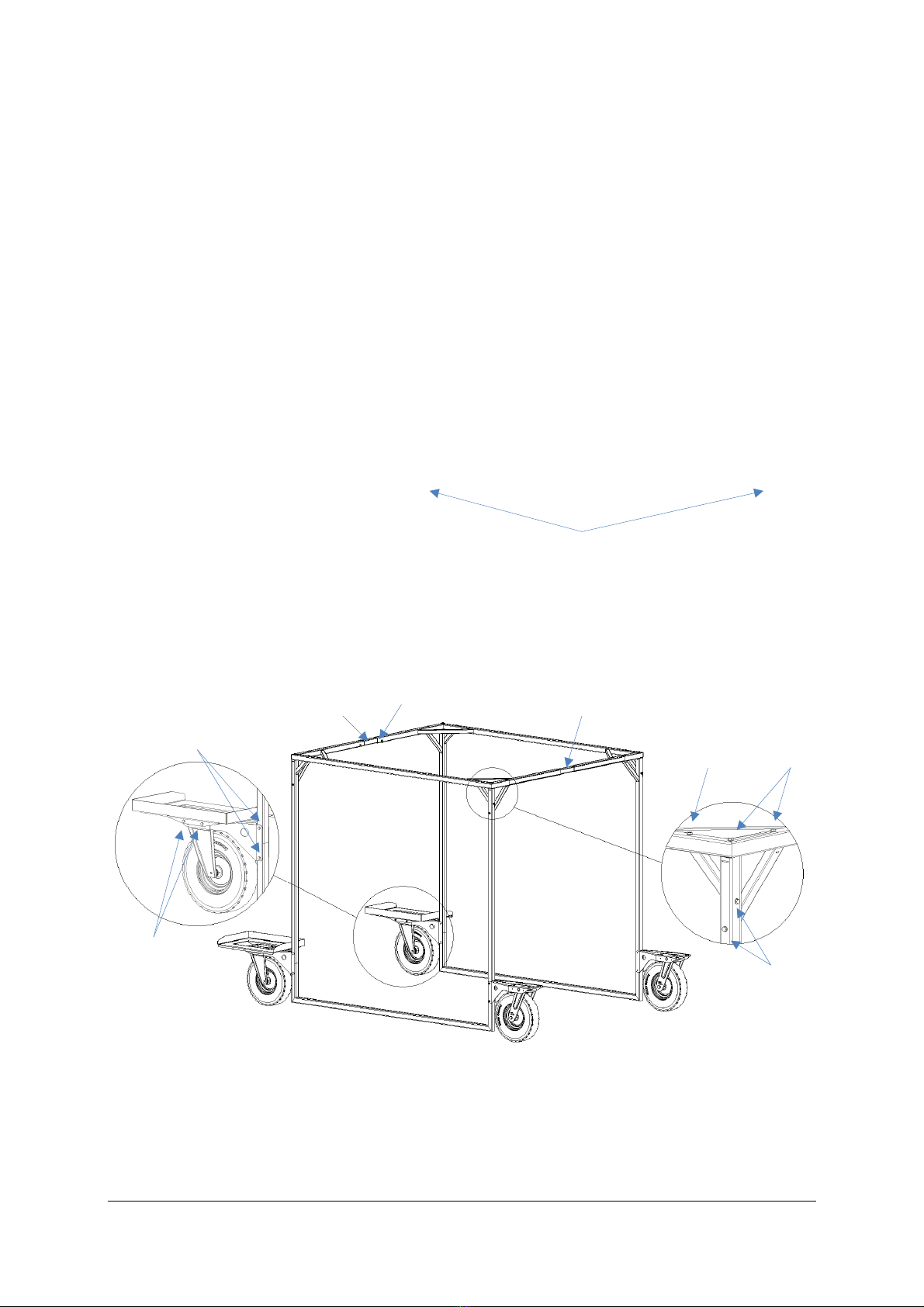

Step 2: mount the hooks on all four of the lower corners at the adjustment knob for the brush angle.

Step 3: hold the catch sheet over the collect tray.

Step 4: pull the side sleeves over the tray upper corners.

Harvy200 Version 2.1 - 2019 Page 11 of 18

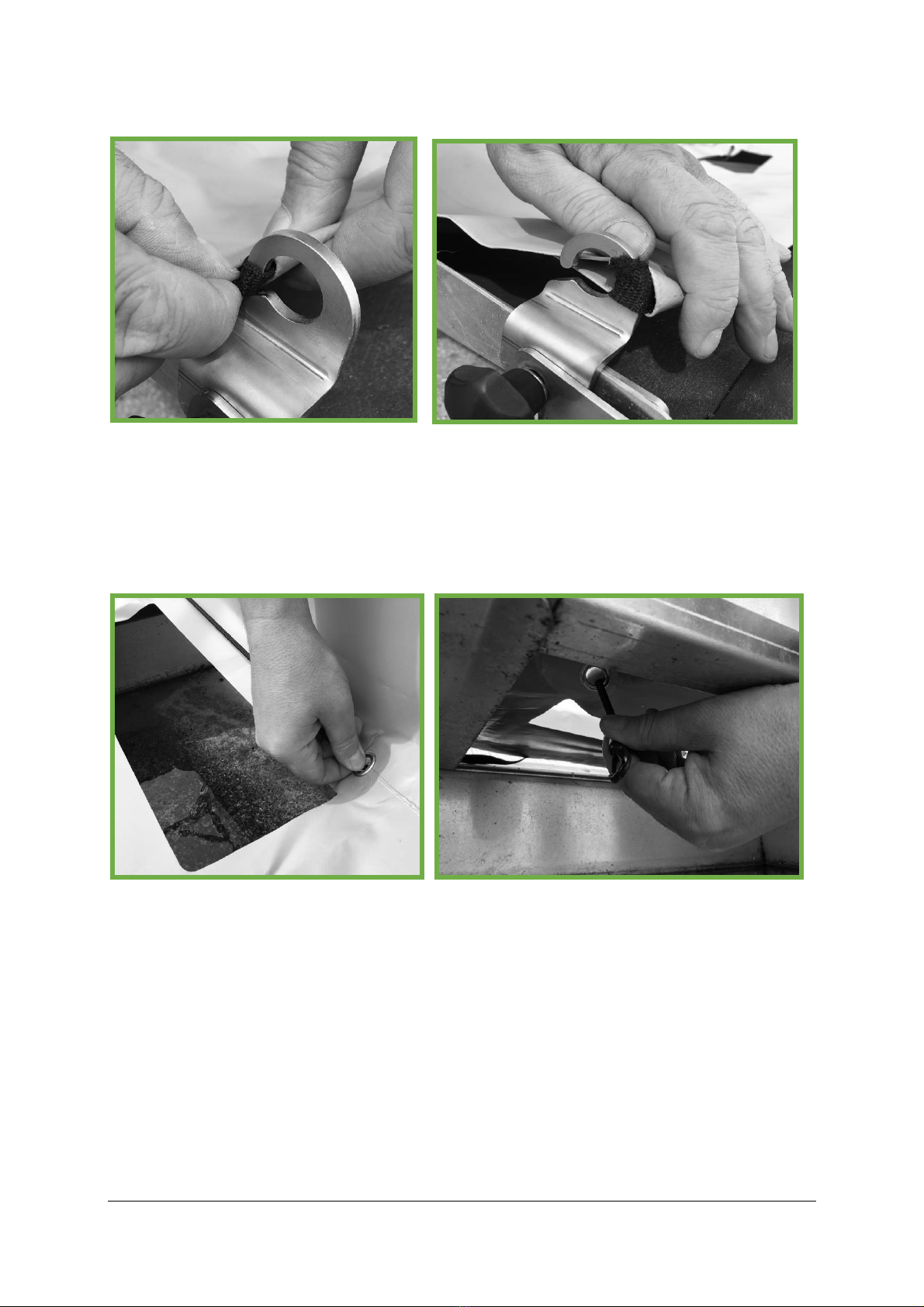

Step 5: slide the loop of the tightening belt over the hooks.

Step 6: push the plastic hook down with one hand and grab it trough the crate holder with the other

hand.

Harvy200 Version 2.1 - 2019 Page 12 of 18

Step 7: hook the plastic hook to the upper side walls of the crate holder.

Step 8: tightening the strap.

Harvy200 Version 2.1 - 2019 Page 13 of 18

Step 9: push the remaining strap back in the sleeve.

Harvy200 Version 2.1 - 2019 Page 14 of 18

Ready!

Harvy200 Version 2.1 - 2019 Page 15 of 18

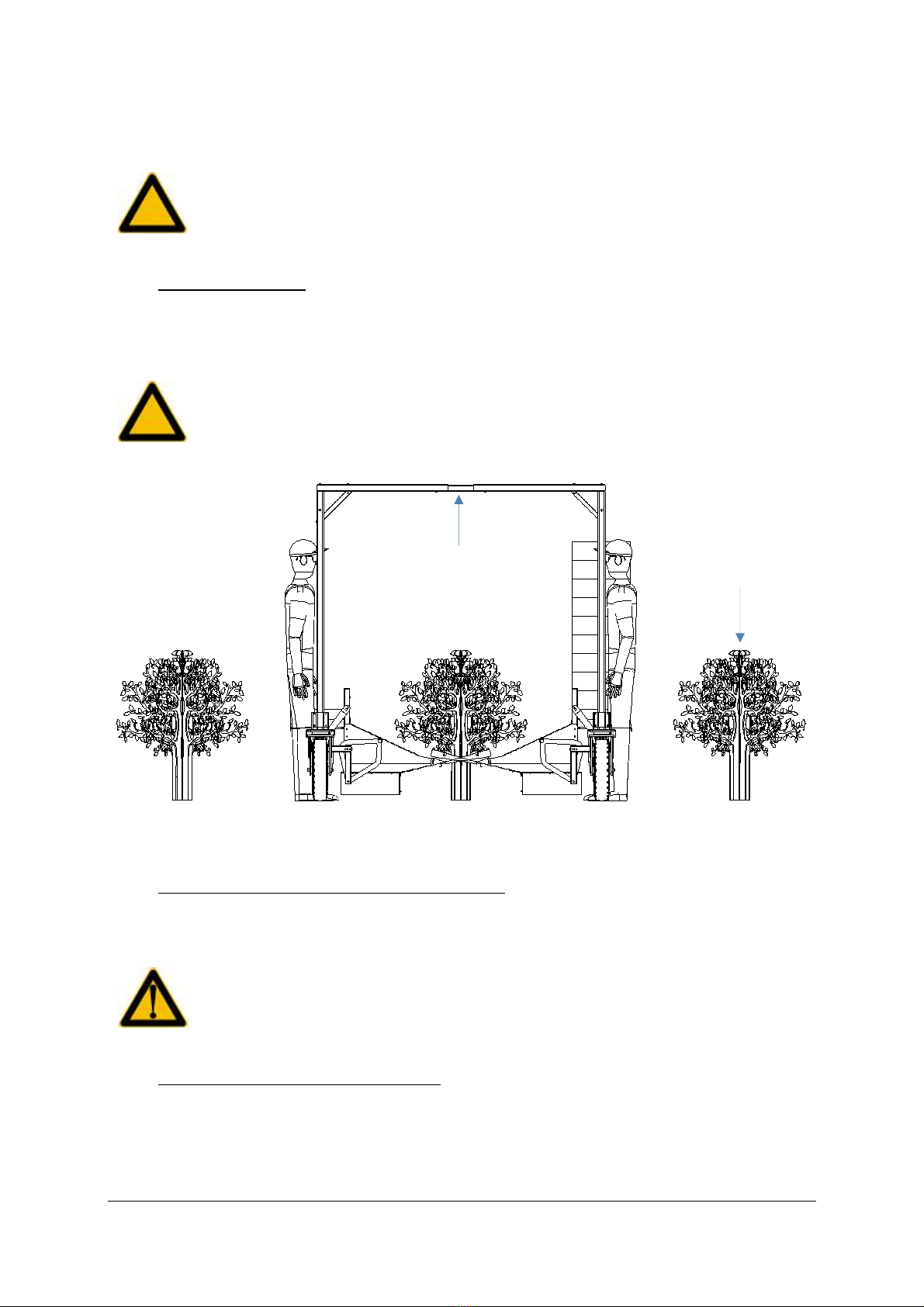

Adjustment

In order to ensure that no berries are lost during the harvest, the brushes mounted onto the

collection trays have to enclose the brushes below the lower braches, such as displayed in Figure

5.2. The Harvy200 is adjustable at several points.

After a setting has been altered, always check whether all fastening screws have been

tightened securely.

5.1 Adjust the width

The left part and the right part of the base frame are connected with each other by means of a

connecting tube. As a result, the width of the Harvy200 can be easily adjusted to the distance

between the rows of berry bushes on the field. By loosening the bolts for the width adjustment (see

Figure 5.1) and moving one side of the Harvy200, the width can be adjusted.

Never make the base frame wider than 3 metres. The connecting tube contains a

marking indicating the middle of the connecting tube.

Figure 5.1 Setup Harvy200

5.2 Adjust the height of the collection tray

The position of the collection tray is adjustable in height. Both collection trays are attached on both

sides to the base frame by means of a clamping bracket (see Figure 5.2). By loosening the bolts of

both clamps, the collection tray can be adjusted in height.

Make sure the collection tray is supported and cannot fall down, prior to loosening the

bolts of the clamps!

5.3 Adjust the angle of the brushes

The angle of the brushes is adjustable. By loosening the star-knob (see Figure 5.2) on both sides of

the collection tray, the angle of the brushes can be adjusted manually.

Width adjustment

Be

rry bushes

Harvy200 Version 2.1 - 2019 Page 16 of 18

5.4 Adjust the end position of the collection tray

The collection tray can be moved forwards and backwards. A positioning block is located on both

sides of the collection tray which determines the end positions of the collection tray. If desired, the

positioning block can be placed further forwards or backwards by unscrewing the star-knob from the

positioning block.

Make sure the collection tray is supported and the hinge bracket does not touch the

positioning block, prior to unscrewing the star-knob from the positioning block!

Figure 5.2 Adjustment collection tray

lamp

Positi

oning block

Angle adjustment brushes

Harvy200 Version 2.1 - 2019 Page 17 of 18

6Harvesting

Place the Harvy200 between the rows of berry bushes, in such a manner that one row of berry

bushes is situated between the collection trays of the Harvy200 (Figure 5.1).

Place a stock of empty crates on the crate racks and place two empty crates at the bottom of every

collection tray.

Make sure the empty crates on the crate racks are stacked neatly in order to prevent

the pile from tipping over.

Push the collection trays towards the berry bushes so the brushes enclose the bushes.

Shake the berry bushes so that all berries of the bush fall into the collection trays and end up in the

empty crates that are located at the bottom of the collection trays.

It is not allowed to stand on or to sit down on the collection trays.

Move the Harvy200 to the next bushes once all berries have been removed from the bush.

As soon as the crates at the bottom of the collection tray are full, the collection tray can be pulled

backwards in order to easily replace the full crates by empty crates.

Move the collection trays forwards or backwards by grabbing the upper edge of the collection tray.

Never pull the collection trays backwards by grabbing the sheet metal strips used to

fasten the collection trays in a hinged manner.

7Maintenance

Regularly check whether the fastening screws of the base frame and the collection trays are

tightened securely.

lean the Harvy200 regularly.

Harvy200 Version 2.1 - 2019 Page 18 of 18

8Declaration of conformity

EC-declaration of conformity

according to annex II A of Machinery Directive 2006/42/E

Fine Field B.V.

Vlasvenstraat 41

5962 A Melderslo

The Netherlands

herewith declares, entirely under its sole responsibility, that product:

Name: Harvy200

Type: DVP-EH-01

Function: Harvest cart for harvesting (blue) berries

complies with the provisions of Machinery Directive 2006/42/E

The Netherlands, Melderslo

29 May 2013

L. Driessen

Director

Table of contents

Popular Farm Equipment manuals by other brands

MK Martin

MK Martin MK Series Operator's manual

MASCHIO GASPARDO

MASCHIO GASPARDO ADMIRAL Use and maintenance

Lifetime

Lifetime 60058 Assembly instructions

AgTerra

AgTerra SprayLogger E3 Installation & quick start guide

Pottinger

Pottinger NOVACAT V 9200 Original operating instructions

Raven

Raven RS1 installation manual

Degelman

Degelman PRO-TILL 41 quick start guide

Agriweld

Agriweld Prevent 4-Leg Operator's manual

Raven

Raven SmarTrax installation manual

Anderson

Anderson GB series Operation guide

Redexim

Redexim OVERSEEDER 3D Series User manual and parts book

Kongskilde

Kongskilde 300FL Assembly Instructions & Operating Guide