FineTek JFR-2 Series Technical manual

08-JFR2XX-B1-EK,11/08/2018

JFR-2 Series

FMCW Radar Level Transmitter

Operation Instruction

FineTek Co., Ltd

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 236, Taiwan

TEL: 886-2-22696789 FAX: 886-2-22686682

E-mail: info@fine-tek.com http://www.fine-tek.com

TABLE OF CONTENTS

1. INSTRUCTION .................................................................................................................... 1

2. GUARANTEE ...................................................................................................................... 2

3. INTRODUCTION ................................................................................................................. 3

4. SPECIFICATIONS ............................................................................................................... 4

5. INSTALLATION.................................................................................................................... 8

6. WRING INFORMATION ...................................................................................................... 10

7. CALIBRATION .................................................................................................................... 11

8. MENU SELECTION ............................................................................................................ 13

9. QUICK SETTINGS .............................................................................................................. 25

10 TABLE OF COMMUNICATION PARAMETERS ................................................................ 2 7

1. INSTRUCTION

Forbidden operation

Away from flammable materials or keep environment in electrical safety.

Wrong operation will result in electric shock.

Thank you for your purchasing for FineTek product. This user will introduce the product features, operations,

maintenance and troubleshooting to help user get familiar with product, avoid from the possible dangerous

use. Before operation, please carefully study the details of product. Extra support can find at www.fine-tek.com

or directly contact our representative by telephone and facsimile. On line revision will issue at web site and

not further inform. User can get newest support and download at www.fine-tek.com. In case of any

unexpected problem, don’t disassemble it by yourself or you will lose the product guarantee. Contact us, if

you have any question that hard to be defined.

Danger It indicates for wrong operation that has possible chance to cause disaster or danger to

user.

Attention It indicates for wrong operation that has possible chance to cause damage on

equipment .

Symbol Instruction

!

!

1

8-05, Plaza Azalea, Persiaran

Bandaraya, Seksyen 14, 40000

Shah Alam, Selangor, Malaysia

2. GUARANTEE

Maintenance Guarantee: All the products will get six months guarantee service since repair or replace

components. During six months, any fault caused in same will be serviced in free charge.

•Irresistible environment effects or natural disaster (earthquake, flood disaster, fire, lighting stroke, hurricane)

•Not properly use according to operation manual.

•Human-made damage (scratch, cutting, throwing down, hammering) or abnormal operation (over power

range, over ambient condition, over range operation, corrosion, watering, electric charge), non-proved third-

party device connection or expend, replace non-proved components or module.

All FineTek products will get one year guarantee in regular operation. Product within guarantee period will get

service and no charge for any nominal fee. User finds any defect during delivery process or not be broken by

wrong operation that can ask return or replace. In maintenance, user has the obligation to send all complete

parts back to FineTek in well carefully package. Over range operation, over charge or any abnormal

operation will excess out the guarantee range. Product not in guarantee period and condition will charge

necessary fee for the repair or replace.

•Expiry of the guarantee date.

Things below will not in guarantee coverage and will be charged service fee:

2

Company Address Telephon Fax

Taipei Headquarters

(Taiwan)

No.16, Tzuchiang St., Tucheng

Industrial Park, New Taipei City

23678

+886 2 2269 6789 +886 2 2268 6682

Fine automation

Co., Ltd. (China)

No. 451, Duhui Road,

Zhuanqiao Township, Minhang

District, Shanghai City 201109

+86 021 64907260 +86 021 6490 7276

Aplus FineTek

Sensor Inc.

355 S. Lemon Ave, Suite D,

Walnut, CA 91789 1 909 598 2488 1 909 598 3188

FineTek Pte Ltd.

(Singapore Branch)

37 Kaki Bukit Place,

Level 4 Singapore 416215 +65 6452 6340 +65 6734 1878

FineTek GmbH

(Germany Branch)

Bei den Kämpen 26

21220 Seevetal-Ramelsloh,

Germany

+49 (0) 4185 8083 12 +49 (0) 4185 8083 80

FineTek Co., Ltd.

(Indonesia Branch)

Ruko Golden 8 Blok H No.38

Gading Serpong, Tangerang

Indonesia 15810

+62 (21) 2923 1688 +62 (21) 2923 1988

FineTek Co., Ltd.

(Malaysia Branch) +603 5524 7168 +603 5524 7698

Service Network

3. INTRODUCTION

3

FEATURES

PRINCIPLE

FMCW Radar level transmitter is a non contact

measuring device, which is suitable for high temp.,

high pressure, and corrosive applications. It is

easy to install and free of maintenance, especially

for the high accuracy requirement environment.

Design formula

High voltage : IEC60947-2

Isolated resistance : IEC60092-504

Power supply change : IEC60092-504

Power supply failure : IEC60092-504

Electrical burst testing : IEC61000-4-4

Voltage DIPS : IEC61000-4-11

Humidity : IEC60068-2-30

High/Low temperature test : IEC60068-2-38

IP protection rating : IEC60529

TEST STANDARDS

LINEARITY DIAGRAM

FMCW radar adopts a high frequency signal,

which is emitted via an antenna and swipe

frequency increment by 0.5GHz during the

measurement, reflected by the target surface and

received at a time delay. The frequency difference,

which is calculated from the transmitting frequency

and the received frequency, which is directly

proportional to the measured distance (or material

surface).

The frequency difference then is processed by

Fast Fourier Transformation (FFT) to identify the

signal in Intermedium Frequency (IF). This FMCW

radar is innate with signal / noise enhancement

and filtering of echo-back via Phase-Lock Loop

(PLL) circuit that is the best solution for complex

environment and high accuracy measurement.

Accuracy

Distance to flange

0

-2

-4

-6

-8

-10

-12

12

10

8

6

4

2

cm

0.5m 5m 15m 20m

A0.2%

A0.2%

A3mm

A5mm

A10mm

A20mm

A0.4%

A0.4%

A30mm

A0.4%

-14

-16

ŸNon contact measurement

ŸCorrosive and toxic liquid, hydrocarbons, slurries

ŸNot affected by specific gravity, pressure,

temperature, viscosity, foam, and dust

Ÿ5 digits LCM display

ŸIndicate signal wave inside the silo.

ŸSelection of Different Measurement unit(m, cm,

mm, inch, ft, %, mA)

ŸMeasuring distance and actual level.

ŸLanguage selection of traditional Chinese,

simplified Chinese, English.

Ÿ4-20mA/ 4 wires/2 wires

ŸModbus RS-485 to enhance isolation and easy

for remote control.

ŸCE standards for isolation(EFT 2000V, B class

or better)

Ÿ4mA, 20mA output

Ÿ26GHz JFR2 series could measure all kinds of

material.

4

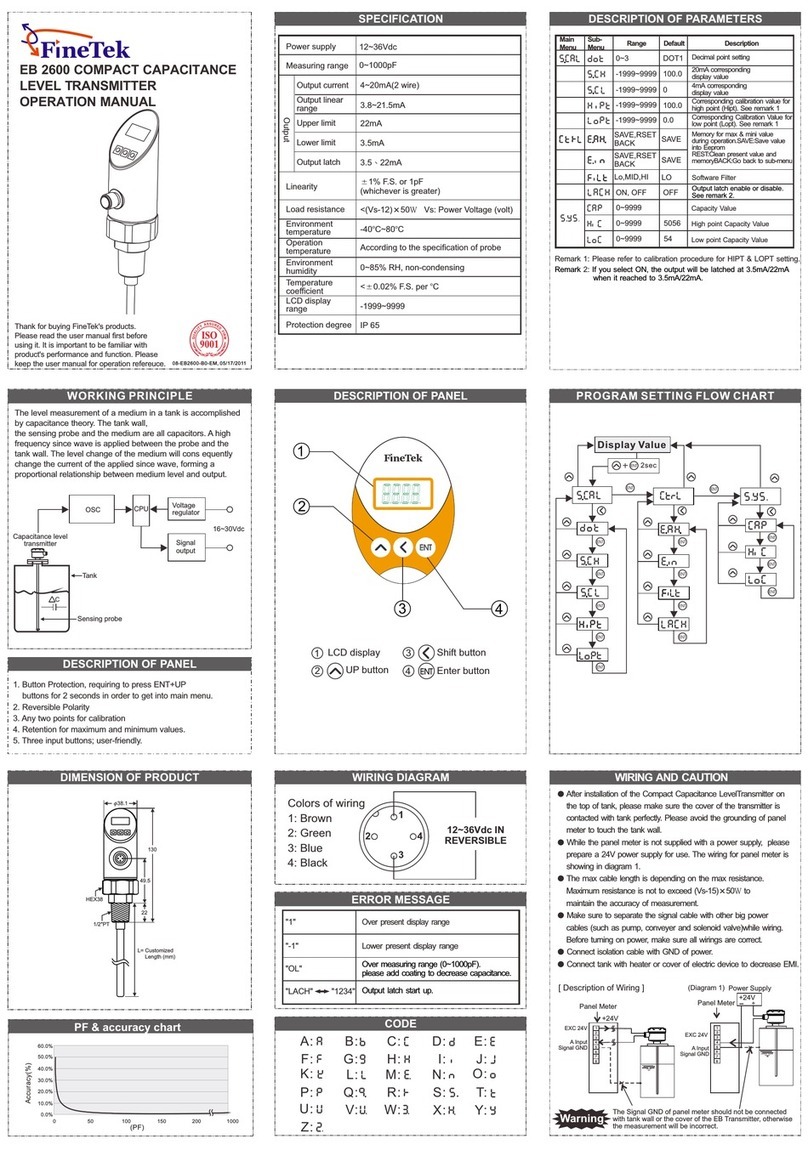

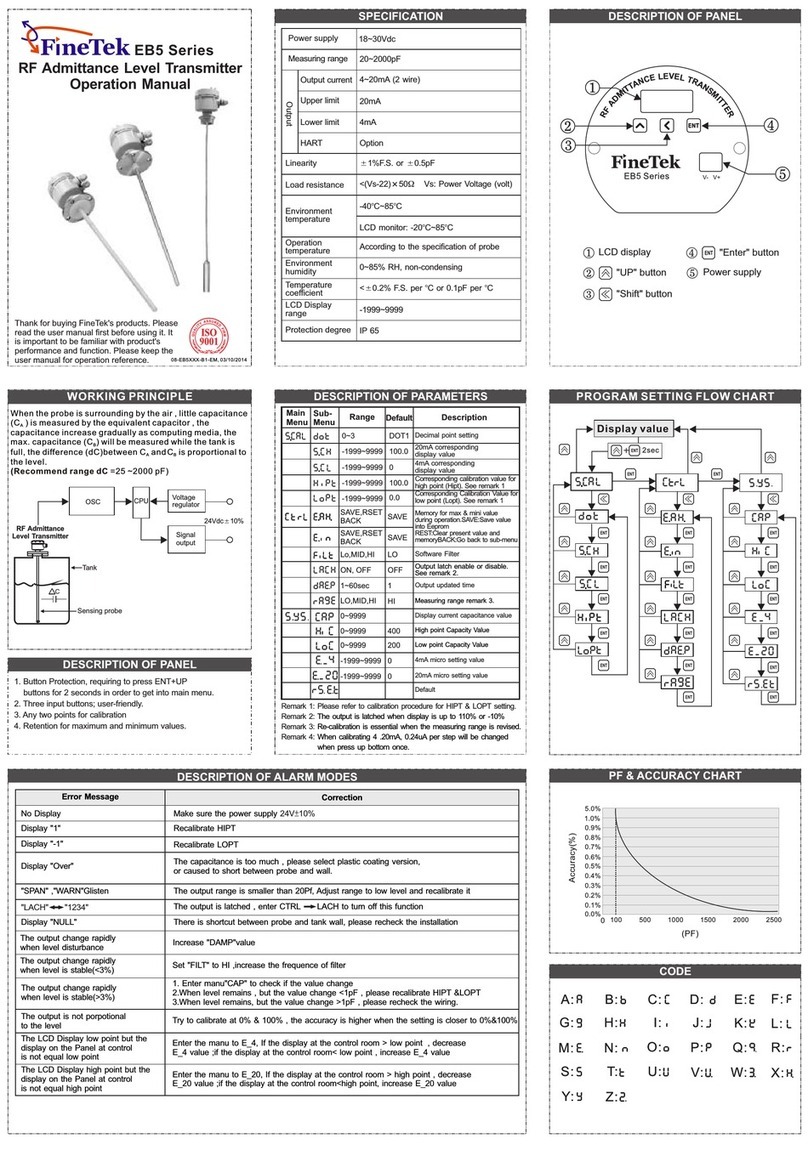

4. SPECIFICATIONS

Medium General liquid and solid

Dimensions

(Unit:mm)

Measuring range

Model

Accuracy

Repeatability

Ambient temperature

Operating temperature

Operating pressure

Frequency

Analog output

Protection rating

Local display

Housing material

Antenna type

Antenna material

Blind distance

Power supply

JFR-204

500mm

5 digits LCM display

Aluminum

Digital communication

Liquid 30m Solid 20m

A3 mm

-40~200 BC

0~40 bar

-40~90 BC(LCM<75BC)

K Band

4~20mA / 4 Wire

IP67

9.5~30Vdc

A1 mm

RS485 (Isolated)

Horn (43D)

SUS316+PTFE

Lens (56D)

PTFE

JFR-214

Min. Dielectric

constant (solid) 1.5

Min. Dielectric

constant (liquid) 1.4

General liquid /suitable for acid and

alkaline in liquid

Half-power beam width ±9°

Liquid 30m

217

f56

2"NPT or 2"PF

f98

1/2"PF

60

PTFE

f98

210

f43

1-1/2"PF

1/2"PF

60

PTFE

JFR-224 JFR-234

-40~200 BC

0~40 bar

-40~90 BC(LCM<75BC)

High gain horn (100)

SUS 316

K Band

4~20mA / 4 Wire

IP67

9.5~30 Vdc

5 digits LCM display

500 mm

A1 mm

RS485 (Isolated)

High gain horn (140)

Dimensions

(Unit:mm)

Measuring range

Model

Accuracy

Repeatability

Ambient temperature

Operating temperature

Operating pressure

Frequency

Analog output

Protection rating

Local display

Housing material

Antenna type

Antenna material

Blind distance

Power supply

Digital communication

P.S. For JFR-224 and JFR-234, customer can connect the compressed air with 1/8"PT thread

connector to avoid dust adhered.

Aluminum

A3mm @distance≤30m, A0.01% F.S.@distance>30m

Medium General liquid and solid

Min. Dielectric

constant (solid) 1.5

Min. Dielectric

constant (liquid) 1.4

Half-power beam width ±5°±3°

JFR-244

Liquid 40m Solid 30m

A3 mm

Liquid 70m Solid 50m Liquid 20m Solid 15m

Lens(43DS)

±10°

PTFE

Suitable For Long dlstance

measurement

Super dlstance

measurement

Corrosion type acid and

alkaline liquid

f98

476

1/2" PF

270

2"PF

compressed

air input

f98

369

f100

1/2" PF

162

2"PF

f98

190

1/2" PF

1-1/2" NPT

f43

43

compressed

air input

f140

5

Aluminum

Dimensions

(Unit:mm)

Model

Protection rating

Local display

Housing material

Antenna type

Antenna material

Blind distance

Power supply

Medium

Half-power beam width

217

f56

2"NPT or 2"PF

f98

1/2"PF

60

PTFE

f98

210

f43

1-1/2"PF

1/2"PF

60

PTFE

JFR-202 JFR-212

General liquid and solid

Liquid 20m Solid 10m

General liquid /suitable for acid and

alkaline in liquid

Liquid 20m

A5mm

-40~200BC

0~40 bar

-40~90BC(LCM<75BC)

K Band

4~20mA

IP67

24VdcA10%

A3mm

HART

5 digits LCM display

Horn (43D)

SUS 316 + PTFE

Lens (56D)

PTFE

±9°

500 mm

Min. Dielectric

constant (solid) 1.5

Min. Dielectric

constant (liquid) 1.4

Measuring range

Accuracy

Repeatability

Ambient temperature

Operating temperature

Operating pressure

Frequency

Analog output

Digital communication

6

Aluminum

Dimensions

(Unit:mm)

Model

Protection rating

Local display

Housing material

Antenna type

Antenna material

Blind distance

Power supply

Medium

Half-power beam width

1.5

1.4

-40~200BC

0~40 bar

-40~90BC(LCM<75BC)

K Band

4~20mA

IP67

24VdcA10%

A3mm

HART

5 digits LCM display

SUS 316 PTFE

500 mm

JFR-222 JFR-232

f98

369

f100

1/2" PF

162

f98

476

1/2" PF

270

f140

JFR-242

f98

190

1/2" PF

1-1/2" NPT

f43

2"PF

2"PF

43

General liquid and solid

Long dlstance

measurement

Super dlstance

measurement

Corrosion type acid and

alkaline liquid

Suitable For

Liquid 30m Solid 20m

A5 mm

Liquid 35m Solid 30m Liquid 15m

High gain horn (100D) High gain horn (140D)

±5°±3°±10°

Lens (43DS)

Min. Dielectric

constant (solid)

Min. Dielectric

constant (liquid)

Measuring range

Accuracy

Repeatability

Ambient temperature

Operating temperature

Operating pressure

Frequency

Analog output

Digital communication

compressed

air input

compressed

air input

A5mm @distance≤20m,

A0.025% F.S.@distance>20m

P.S. For JFR-222 and JFR-232, customer can connect the compressed air with 1/8"PT thread

connector to avoid dust adhered. 7

8

5. Installation

D

L

Diameter D (Inch) Length L (Inch)

Model

JFR-22X

JFR-23X

Diameter D (Inch) Length L (Inch)

D>100 L£150

D>140 L£270

1. JFR-20x can be hidden in the extension tube, the

recommendation of the tube diameter D and length L

are shown in the table.

3. JFR-22X and JFR-23X can be hidden in the extension

tube, the recommendation of the tube diameter D and

length L are shown in the table.

D

L

2. JFR-21x can be hidden in the extension tube, the

recommendation of the tube diameter D and length L

are shown in the table.

Diameter D (Inch) Length L (Inch)

D

L

D

L

2" L£100

4" L£200

5" L£300

6" L£400

4. theJFR-24x can be hidden in the extension tube,

recommendation of the tube diameter D and length L

are shown in the table.

Diameter D (Inch) Length L (Inch)

2" L£160

4" L£300

5" L£400

6" L£500

3" L£200

4" L£300

5" L£400

5. Installation recommendations are as follows :

(1) Antenna installation angle to be perpendicular to the

Horizontal.

(2) JFR installation position with the drum wall suggestions

Are as follows :

Installation location A should be less than 1/6D

Range with A relation is as follows :

a. H<10m, A>300mm

b. 10m<H<20m, A >600mm

c. H>20m, A>900mm

(3)Extended tube is suggested to do the welding process

from outside; welding process from inside, the bulges

might affect the signal transmission. The joint part of

extended tube cannot be less than “D”.

DL

9. Outdoor installation should take shade or rain-proof

measures.

vent hole

X

X

X

10. If drum internal agitator will have a strong vortex and

foam, drum must increase waveguide, the upper

waveguide drill vent holes to ensure the correctness of

the measured value.

11. Installation should be avoided in the feed inlet position,

avoid material interference or obstacles interference.

12. Installation should be avoided in the top center of the

arch or round barrel will cause multiple echo reflections.

X

Reflector

X

6. Radar installation should not be too close to the drum

wall, avoid the drum wall attachment material reflection

interference.

8. When obstructions inside the tank, tank be fitted with

eflectors, steer clear of the error echo reflected to the

receiver, causing radar miscalculation.

7. Radar installation not too close to the drum bracket to

avoid reflection is incorrect

X

9

10

6. WRING INFORMATION

Two ways to calibrate the JFR Series:

4-wire:

1. Display/Adjustment module

2. By pcbased fas soft ware

2-wire:

1. Display/Adjustment module

2. HART

Adjustment module is an adjustment tool with

4 buttons to click on. It also has a transparent

window to allow display reading.

[ ] Button

-Select Edit

-Select parameter

-Parameter

[ ] Button

-Increase

-Select

Power Supply: V+

: V-Power Supply

: I+ (4~20mA)Analog Output

: I- (4~20mA)Analog Output

: TR+ (RS485)Communication

: TR- (RS485)Communication

5

2

1

3

4

6

[ ] Button

-Enter Edit status

-Confirm Edit

-Confirm parameter

modification

[ ] Button

-Return

-Cancel

RS232 / USB Interface Interface

RS232/485

Converter

1

2

5

6

TR- TR+

POWER

DC24V

1

2

3

4

I+

POWER

DC24V

CALIBRATION

WIRING INFORMATION

I-

RS485 wiring

JFR Series and Indicator(External Power)

WIRING DIAGRAM

V+

V-

V+

V-

Panel Meter

JFR-2X4 JFR-2X2

1234 5 6 12

24V DC. 4-20mA Modbus

+

-

+

-

D+ D

-

24V DC

+

-

1

2

POWER

DC24V

V+

V-

5 digits LCM displat

11

7. CALIBRATION

4 wires:With display/adjustment module

2 wires: 1.With display/adjustment module 2. HART

Adjustment module is an adjustment tool with 4 buttons to click on. It also has a transparent window to allow

display reading.

CALIBRATION

[ ] Button

-Select Edit

-Select parameter

-Parameter

[ ] Button

-Increase

-Select

[ ] Button

-Enter Edit status

-Confirm Edit

-Confirm parameter

modification

[ ] Button

-Return

-Cancel

5 digits LCM display

24V DC. 4-20mA Modbus

+

-

+

-

D+ D

-

24V DC

+

-

4 Wires 2 Wires

12

Measurement

Setting 1 Low-level adjustment 1.1

Manual setting 1.2.1

Auto setting 1.2.2

Signal gain 3.1

Filter setting 3.2

Signal selection 3.3

Current 4.1

Display content 2.1

Manual setting 1.1.1

Auto setting 1.1.2

Distance 2.1.1

Distance 2.1.1.1

Percentage 2.1.1.2

Current 2.1.1.3

Material level 2.1.2.1

Percentage 2.1.2.2

Current 2.1.2.3

Material level 2.1.2

Set preserved signal 3.4.1

Reset 3.4.2

Select noise 3.5.1

Reset 3.5.2

Max current output 4.1.1

Min current output 4.1.2

River monitoring 1.6.1

Tank monitoring 1.6.2

Liquid 1.5.1

Powder 1.5.2

Background noise 3.4

Signal elimination 3.5

Signal erasure 3.6 Erase noise 3.6.1

Reset 3.6.2

Eliminate background signal 3.7.1

Reset 3.7.2

Signal threshold setting 3.8.1

Reset 3.8.2

Reset 4.2

Unit 4.3

Language 4.4

Cancel 4.2.1

Confirm 4.2.2

m 4.3.1

cm 4.3.2

mm 4.3.3

in 4.3.4

ft 4.3.5

ENGLISH 4.4.1

Traditional Chinese 4.4.2

Simplified Chinese 4.4.3

Display Setting 2

Echo Pattern 3

Options Setting 4

Connection

Setting 5

Machine Info 6

High-level adjustment 1.2

Range of blind area 1.3

Scale setting 1.4

Material setting 1.5

Environment setting 1.6

Display content 2.1

Background signal 3.7

Signal threshold 3.8

Dynamic range 3.9.1

Signal threshold 3.9

Signal threshold setting

Signal erasure

Background signal

Signal threshold setting

Dynamic range

3.9

Device address 5.1

Connection speed 5.2

4 wires

HART ON/OFF 5.1

Device address 5.2

Connection speed 5.3

2 wires

Press in the measuring screen to enter the echo pattern. You may also press to return to the

measuring screen.

Main Menu

Measurement setting.

Display setting

Echo pattern

Option setting

1

FineTek

16.272

M CM MM INCH FT % MA

FineTek

16.272

M CM MM INCH FT % MA

Measurement Setting

Low point adjustment

High point adjustment

Range of blind area

Measurement setting

1.1

Low point adjustment 1.1.1

Manual setting

Auto setting

Manual setting 1.1.1

04500

MM

13

1.1 Measurement Setting

8. MENU SELECTION

To enter the measuring screen from the main menu, press + for 3 seconds.

It is for setting the major parameters, such as high/low point adjustment, blind area and scale settings.

Press in the main menu, select Measurement Setting, and then press to make settings.

1.1.1 Manual setting

It is to input the low material level value (empty bin) manually. Press in the Low Point Adjustment menu

and select Manual Setting 1.1.1. Then, press to save the settings.

Input the distance required from the flange surface to the low point by using and (in the unit of mm).

After that, press to finish the manual setting for low point.

Measuring screen

Measuring screen

Echo pattern

1.1 Low point adjustment

TManual and auto settings are available for the low material level setting (empty bin). Press in the

Measurement Setting menu and select Low Point Adjustment 1.1. And then press to save the settings.

1.1.2 Auto Setting

Low point adjustment 1.1.2

Manual setting

Auto setting

Manual setting 1.1.2

43317

MM

Measurement setting

Low point adjustment

High point adjustment

Scope of blind area

Scale setting

1.2

Manual setting 1.2.1

00500

MM

Manual setting 1.2.2

43317

MM

High point adjustment 1.2.1

Manual setting

Auto setting

High point adjustment 1.2.2

Manual setting

Auto setting

14

The Auto Setting takes the material level value currently measured on site (based on the basis point of

the flange surface) as the low point value. Then press in the Low Point Adjustment menu and select

Auto Setting 1.1.2. Finally press to save the settings.

1.2 High Point Adjustment

Press to save the modification and finish the auto setting for low point.

Manual and auto settings are available for the high material level setting (full bin). Press in the

Measurement Setting menu and select High Point Adjustment 1.2. And then press to save the settings.

1.2.1 Manual setting

It is to input the high material level value (full bin) manually. Press in the High Point Adjustment menu

and select Manual Setting 1.2.1. Finally, press to save the settings.

Input the distance required from the flange surface to the high point by using and (in the unit of mm).

After that, press to finish the manual setting for high point.

1.2.2 Auto setting

The Auto Setting takes the material level value currently measured on site (based on the basis point of

the flange surface) as the high point value. Press in the High Point Adjustment menu and select Auto

Setting 1.2.2. Finally press to save the settings.

Press to save the modification and finish the auto setting for high point.

Measurement setting

Low point adjustment

High point adjustment

Scope of blind area

Scale setting

1.4

MM

Measurement setting 1.4

04500

15

Press to select Monitoring Mode. Press to save the settings and return to the Measurement

Setting menu, or press to return to the main menu.

Environment Setting

River monitoring

Tank monitoring

1.6.1

Measurement setting

Scope of blind area

Scale setting

Material characteristic

Environment setting

1.6

Material characteristics

Liquid

Powder

1.5.1

1.3 Scope of Blind Area

It refers to the distance beyond the detection scope of the product. This function doesn’t require setting.

Measurement setting

Low point adjustment

High point adjustment

Scope of blind area

Scale setting

1.3

1.4 Scale Setting

It is to input the tank height. Press in the Measurement Setting menu and select Scale Setting 1.4.

Then press to save the settings.

Input the scale range by using and (in the unit of mm). After that,press to save the settings and

return to the Measurement Setting menu. Finally press to return to the main menu.

1.5 Material Characteristics

Select the target material, liquid or powder. Press in the Measurement Setting and select Scale Setting

1.5. Then press to save the settings.

1.6 Environment Setting

Select radar measuring environment, river or tank. Press in the Measurement Setting menu and select

Environment Setting 1.6. And then press to save the settings.

16

Display contrast 2.2

51%

2.2 Display Contrast

Adjust the desired display contrast by using or , and press to save.

Main menu

Measurement setting

Display setting

Echo pattern

Option setting

3

Echo pattern

Signal gain

Filter setting

Signal selection

Background noise

3.1

Echo pattern

Signal gain

Filter setting

Signal selection

Background noise

3.2

回波圖形 3.1

LVL:0001 It is the default value without signal magnification.

LVL:0002 It means the signal is magnified by 2 times.

LVL:0003 It means the signal is magnified by 4 times.

LVL:0004 It means the signal is magnified by 8 times.

LVL:0005 It means the signal is magnified by 16 times.

LVL:0006 It means the signal is magnified by 32 times.

LVL:0007 It means the signal is magnified by 64 times.

Filter setting 3.2

20

Save

3. Echo Pattern

From the echo pattern, the user may observe the echo curve of the current signal and make the settings

obtain the correct echo value by processing various signals (signal gain, filter setting, signal selection,

background noise, signal elimination). Press in the main menu and select the echo pattern 3. Then,

press to save the settings.

3.1 Signal Gains

As shown in the echo pattern, when the echo signal is so weak that the display value is unstable without

interference from other noise, this function can be used to magnify the echo signal. Press in the Echo

Pattern menu and select Signal Gains 3.1. Finally, press to save the settings.

Select the magnification rate by using or . The magnification rate is displayed by LVL on the upper

right of the echo pattern (LVL is 0001 by default). A total of 7 levels are available. Press to save the

settings, as described below.

3.2 Filter Setting

This function is applied to the great fluctuation or bubble generated on the liquid surface, which causes

the echo signal to become unstable. It is used when the display value is unstable. Press in the Echo

Pattern menu and select Filter Setting 3.2. Then press to save the settings.

The default value is 10, which can be adjusted by pressing or . After the setting is finished,

press to save. If the display value is still unstable after the setting, increase the value for test again.

Reset

Cancel

Confirm

3.4.2.1

Echo pattern

Signal gains

Filter setting

Signal selection

Background noise

3.3

Echo pattern

Signal gains

Filter setting

Signal selection

Background noise

3.4

Background noise

Set retained signal

Reset

3.4.1

Background noise

Set retained signal

Reset

3.4.2

Flashing

cursor

Bar cursor

17

3.3 Signal Gains

As shown in the echo pattern, when the interference signal is stronger than the echo signal which may

result in misjudgment, the function can be used to select the echo signal to obtain the correct measurement

value. Press in the Echo Pattern menu and select Signal Selection 3.3. Finally, press to save the settings.

Use or to move the flashing cursor on the echo pattern to the target position of the echo signal.

Press to execute the echo signal to be selected, and then press to save the settings.

3.4 Background Noise

It is to eliminate the interference of the background noise, which is applicable to the empty bin. It can be

used to eliminate all fixed interference noise rather than the echo signal. Press in the Echo Pattern

menu and select Background Noise 3.4. Finally, press to save the settings.

3.4.1 Set Retained Signal

Press in the Background Noise menu and select Set Retained Signal. Finally, press to save the

settings.

Use or to move the bar cursor on the echo pattern to the target position of the echo signal.

Press to execute the echo signal to be selected, and then press to save the settings. Then, the

selected signal will be retained, while other signals will be filtered as background noise.

3.4.2 Set Retained Signal

It is used to reset the function of Set Retained Signal as the default value. Press in the Background

Noise 3.4 menu and select Reset 3.4.2. Finally press to save the settings.

3.4.2.1 Cancel

It is to cancel the reset function. Press in the Reset menu 3.4.2 and select Cancel 3.4.2.1. Finally,

press .

Reset

Cancel

Confirm

3.4.2.2

Reset

Cancel

Confirm

3.5.2.1

Echo pattern

Filter setting

Signal selection

Background noise

Signal elimination

3.5

Signal elimination

Noise selection

Reset

3.5.1

Signal elimination

Noise selection

Reset

3.5.2

Bar cursor

18

Reset

Cancel

Confirm

3.5.2.2

3.4.2.2 Cancel

It is to perform the reset function. Press in the Reset menu 3.4.2 and select Confirm 3.4.2.2. Finally,

press .

3.5 Signal Elimination

It can be used to eliminate all fixed interference noise rather than the echo signal. Press in the Echo

Pattern menu 3 and select Signal Elimination 3.5. Finally, press to save the settings.

3.5.1 Noise Selection

It can be used to eliminate all fixed interference noise rather than the echo signal. Press in the Signal

Elimination menu 3.5 and select Noise Selection 3.5.1. Finally, press to save the settings.

Use or to move the bar cursor on the echo pattern to the target position of the echo signal.

Press to execute the echo signal to be eliminated, and then press to save the settings.

3.5.2.1 Cancel

It is to cancel the reset function. Press in the Reset menu 3.5.2 and select Cancel 3.5.2.1. Finally,

press

3.5.2.2 Confirm

It is to perform the reset function. Press in the Reset menu 3.5.2 and select Confirm 3.5.2.2. Finally,

press

3.5.2 Reset

It is used to reset the function of Signal Elimination as the default value. Press in the Background

Noise menu 3.5 and select Reset 3.5.2. Finally, press to save the settings.

This manual suits for next models

10

Table of contents

Other FineTek Transmitter manuals

Popular Transmitter manuals by other brands

Novus

Novus RHT-XS instruction manual

Denon Professional

Denon Professional DN-500R Serial Command Protocol Guide

Decade

Decade MS-100 series instruction manual

Becker

Becker CentronicPLUS SWC541 PLUS Assembly and operating instructions

Kopp

Kopp 8114.0102.9 manual

NIVELCO

NIVELCO PiloTREK W-200 User and programming manual