FineTek EAX30400-C User manual

Contents

1. Reading Labels.........................................................................................1

2. Product Warranty .....................................................................................2

2.1 New Product Warranty.........................................................................2

2.2 Repair Warranty...................................................................................2

2.3 Service Network.................................................................................3

3. Product Inspection...................................................................................4

3.1 Check content......................................................................................4

3.2 Safety inspection..................................................................................4

4. Summary...................................................................................................4

5. Product Features......................................................................................4

6. Ordering Information................................................................................5

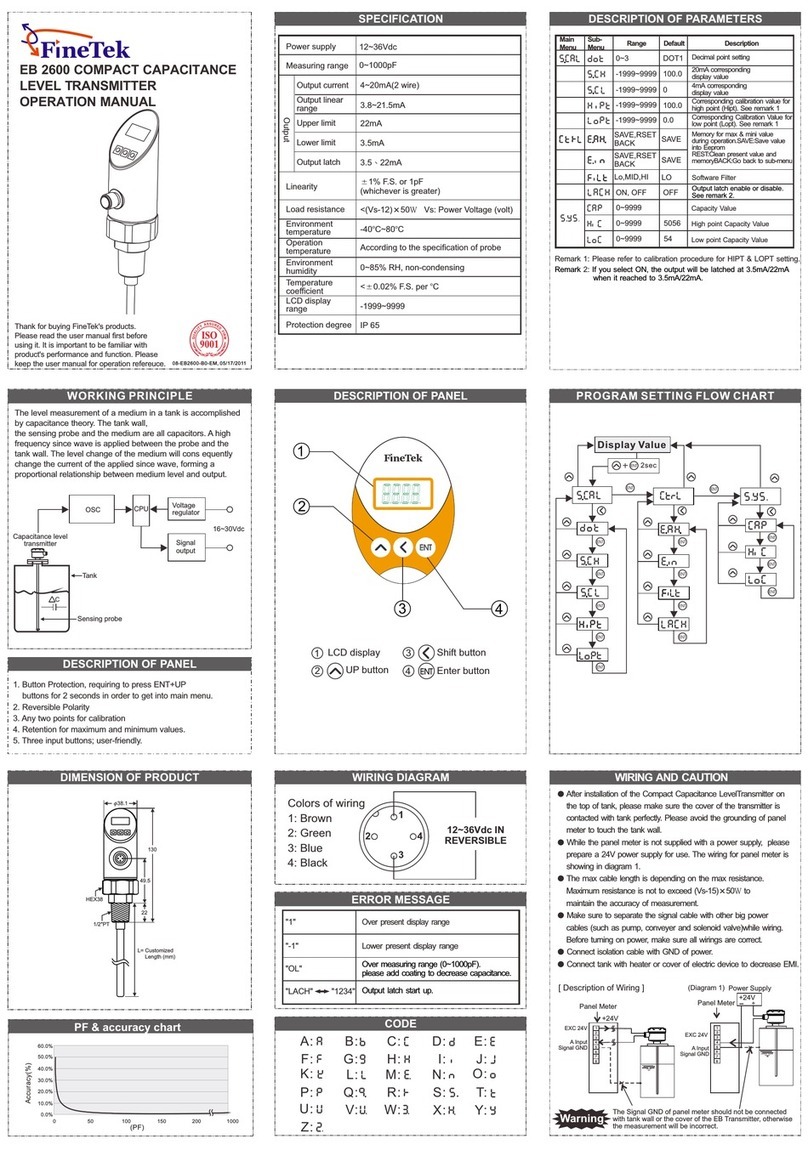

7. Demensions & Wiring...............................................................................6

8. Working Principles...................................................................................9

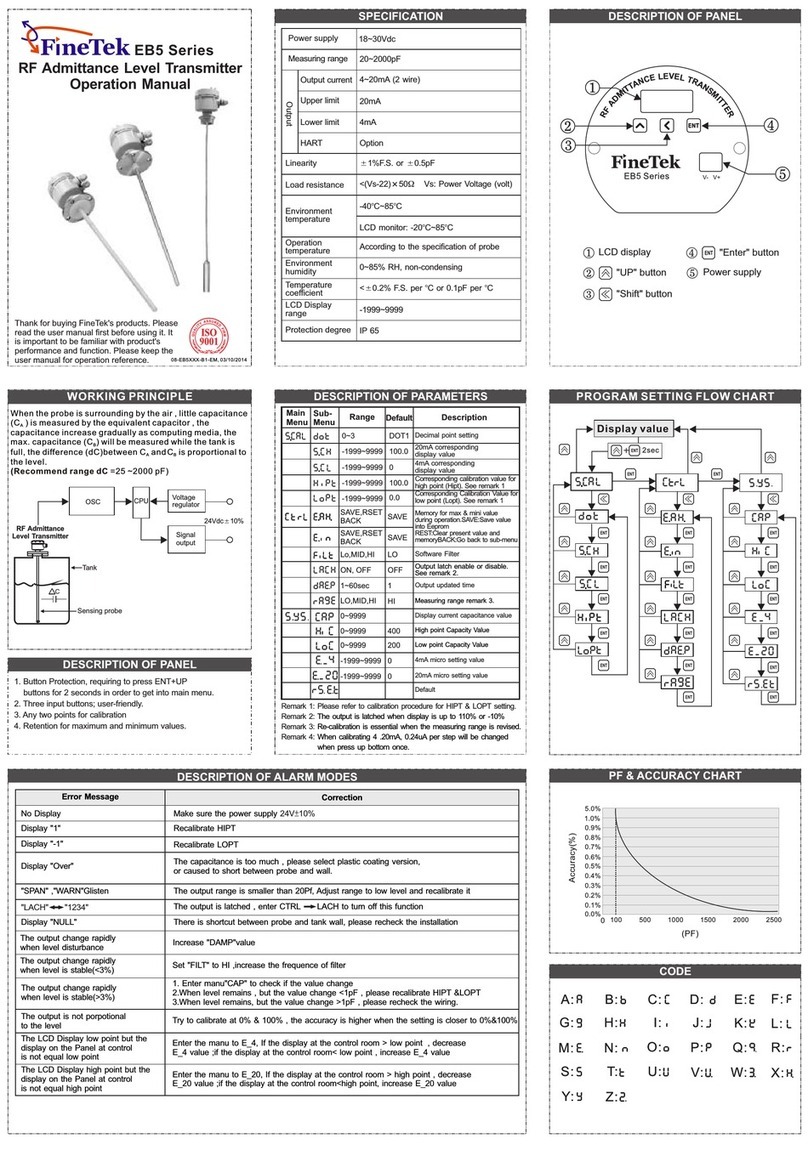

9. Specification.............................................................................................9

10.Installation..............................................................................................10

10.1 Mounting..........................................................................................10

10.2 Name of each part of main unit........................................................11

10.3 Settings to match the tank...............................................................11

11. Operating instructions..........................................................................12

11.1 Instructions ......................................................................................12

11.2 Menu setting....................................................................................21

12. Connection To The Computer (RS232C).............................................35

13. Communication To The Computer (RS485)........................................36

14. Transportation And Storage ................................................................42

1

1. Reading Labels

Thanks for purchasing FineTek’s Product. This operation manual describes the product

features, working principles, operation and maintenance methods. It makes the user fully

understand how to use the product correctly, so as to prevent dangerous situations such as

device damage or operator injury.

➢Please read this operation manual completely and carefully before using the product.

➢Please contact the company if this operation manual can’t satisfy your demands.

➢The content of the operation manual is updated based on the version upgrade, which will

be uploaded to the website for the user to access.

➢Please don’t disassemble or repair the product on your own, as this will make you

disqualified from availing of the warranty service. Please send the product back to the

company for repair and calibration, or just contact the company.

➢Explanation of warning signs:

Danger→ It indicates that wrong operation will cause death or major

disasters.

Note→ It indicates that wrong operation will cause injury and device damage

to some extent.

Electric shock→ It warns of possible electric shock.

Fire→ It warns of possible fire.

Prohibited→ It indicates the prohibited wrong behavior.

2

2. Product Warranty

2.1 New Product Warranty

➢Wedon’t charge for the inspection, part/s and repair for the product of the company

that has a defect within 12 months from the delivery date and meets the warranty

terms.

➢If the product defect is not due to human error during its transportation, user may

change to a new unit from the company within 7 days from delivery date.

➢When the product needs to be sent back to the factory for repair, please send the

whole set, and don’t disassemble the parts. Moreover, please be sure it is

completely packed to avoid damage and causing more loss and defect during the

transportation.

➢The warranty is not available for causes that fall under the following circumstances,

for which the company shall charge for the inspection, part/s and repair according

to the actual condition:

⚫The product or its parts are beyond the warranty period.

⚫Fault or damage is caused by not following the instruction and use

environment described on the operation manual.

⚫The product damage is caused by a force majeure factor (natural disasters, floods,

fire, earthquakes, lightning, typhoon, etc.), human destruction (scratches, dropping,

latch broken, tapping, cracks and punching), human error (using improper voltage,

high-humidity, water leakage, stain, corrosion, loss, improper storage, etc.) and

other abnormal factors.

⚫The damage is caused by the customer or the 3rd party through the installation,

addition, expansion, modification and repair of parts not authorized or certified by

the company.

⚫The volume label information is wrongor unclear, so the product serial number can’t

be confirmed.

2.2 Repair Warranty

A 6-month warranty service is provided for the repaired part of the product, during

which the same product can be repaired free of charge in case of the same fault.

3

2.3 Service Network

Company

Address

Telephon

Fax

Taipei Headquarters

(Taiwan)

No.16, Tzuchiang St.,

Tucheng Industrial Park,

New Taipei City 23678

+886 2 2269 6789

+886 2 2268 6682

Taichung

Sales office

(Taiwan)

+886 4 2465 2820

+886 4 2463 9926

Kaohsiung

Sales office

(Taiwan)

+886 7 333 6968

+886 7 536 8758

Fine automation

Co., Ltd.

(China)

No. 451, Duhui Road,

Zhuanqiao Township,

Minhang District, Shanghai

City 201109

+86 021 64907260

+86 021 6490 7276

Aplus FineTek

(Sensor Inc.)

355 S. Lemon Ave, Suite D,

Walnut,

CA 91789

1 909 598 2488

1 909 598 3188

FineTek Pte Ltd.

(Singapore Branch)

No. 60 Kaki Bukit Place,

#07-06 Eunos

Techpark 2 Lobby B,

Singapore 415979

+65 6452 6340

+65 6734 1878

FineTek GmbH

(Germany Branch)

Bei den Kämpen 26

21220 Seevetal-Ramelsloh,

Germany

+49 (0) 4185 8083 12

+49 (0) 4185 8083 80

FineTek Co., Ltd.

(Indonesia Branch)

Ruko Golden 8 Blok H

No.38

Gading Serpong,

Tangerang

Indonesia 15810

+62 (21) 2923 1688

+62 (21) 2923 1988

4

3. Product Inspection

3.1 Check Content

➢Ultrasonic Level Transmitter x1

➢Ultrasonic sensor 1 or 2 (Depending on order)

➢Operation Manual x1

3.2 Safety Inspection

➢Please check whether the external package is deformed or damaged. Please

remember to take a picture for evidence for compensation later.

➢After unpacking, please check whether the content is deformed or damaged,

or has any quality problem. Please remember to take a picture for evidence

for compensation later.

➢After unpacking, please check whether the content is consistent with the

ordering info,

and whether the quantity is right.

➢Please contact the company within 7 days if any of the above situations occur

(attach

the picture together with your complaint). Otherwise, we won’t compensate

for, change or repair the product defect.

4. Summary

EAX30400-C is a compact, remote type ultrasonic level transmitter for

continuous measurement of liquids. As a price leader, it does not compromise

on good value; and provides effortless and intuitive operation. Easy and

flexible mounting combined with high chemical compatibility and 20-metre

measuring range makes the EAX30400-C suitable in multiple applications in

all industries.

5. Product Features

➢4~20mA 4 wire output (Fully isolated, remote type)

➢IP66 protection

➢Transducer material: EPOXY , PVDF

➢False echo detection

➢Internal temperature compensation.

➢Not affected by liquid temperature, S.G, viscosity

5

6. Ordering Information

6

7. Demensions & Wiring

7

Wiring

Explanation of the terminal

1) Connect the power supply, 100 - 240VAC.

AC/N

AC/L

B1

B2

2) Connect FG terminal to ground.

F.G.

A1

3) Connect the ultrasonic sensor to CH1 or CH2.

CH1

CH2

WHITE

BLACK

RED

GREEN

GRAY

WHITE

BLACK

RED

GREEN

GRAY

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

4) Wirings for ALARM

CH1 ALARM

CH2 ALARM

PULSE OUT

HH

H

L

LL

COMMO

N

COMMO

N

HH

H

L

LL

SW+

SW-

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

HH and COMMON are short-circuited by relay.

H and COMMON, L-COMMON, LL-COMMON are short-circuited in the same manner.

[Caution] Provide the surge protection in case the induced load is driven.

5) Wirings for 4-20mA output

CH1

CH2

4-20mA

GND

4-20mA

GND

A9

A10

A11

A12

A11 and A12 are used for the output of the level difference between CH1 and CH2.

6) Wirings for RS-485

RS485

F.G.

A(+)

B(-)

GND

A5

A6

A7

A8

Use the shielded twisted pair cable for RS-485 line. Connect the shield to FG, A5.

8

7) Wirings for RS232C 115,200bit/sec 8bit Parity/none

Setting of the dip switch (SW1)

Setting of the terminating resistance of RS-485 and Profibus

RS-485: 3 and 4 of SW1 should be ON.

Profibus: 1 and 2 of SW1 should be ON.

In case the multiple main units are connected, the terminating resistance Rt (100 ohms) of

the main unit which is farthest from the host computer must be ON and those of others must

be OFF.

1 and 2 of SW1 or 3 and 4 of SW1 must be ON or OFF at the same time.

ALARM SW (Relay contact output) 4-20mA output

CH1 CH2 CH1

CH2

[Caution]

・Rating of ALARM output is 250 VAC 5A or 30 VDC 5A.

・Rating of Pulse output is 24 VDC 2.0A.

・A10 and A12 of 4-20mA are connected inside.

・Permissible load resistance and resolution of 4-20mA output:

600 ohms or less and 1/4000

RS232

GND

TX

RX

A2

A3

A4

AC250V5A

DC30V5A

AC250V5A

DC30V5A

C1 HH

C2 H

C3 L

C4 LL

C7 HH

C8 H

C9 L

C10 LL

A9

A10

A11

A12

C11

C12

DC24V2 0A

C6 COMMON

COMMON

C5 COMMON

COMMON

4-20mA

4-20mA

L

L

+

+

-

-

9

8. Working Principles

During operation, the device emits a wave to the medium to be measured. The

wave reflects off the surface and moves back to the device where a transducer

calculates the distance. The distance is based on the time interval between

transmission and reception of the wave. D= (334.1+0.6t) x T/2, where the D = the

transmission distance; t =temperature; and T= transmission time.

With 4~20mA output, it can be connected to the PLC, DCS and SCADA systems. In

addition, it is also equipped with exclusive PULSE and AGC (Auto Gain Control)

echo tracking technology to ensure accuracy and precision even in the harshest

environments.

9. Specification

Model

EAX30400-C

Number of channels

1 or 2

Frequency

10 - 60kHz

Measurement object

Liquid and powder

Measurement range

0.3 –20m

Measurement resolution

1mm

Measurement accuracy

+/- 0.25% F.S.

Operation temperature

-20 - +70 °C

Display

LCD display with backlight

Current output

4-20mA output

Contact output

Relay output: 4 points * 2 lines

Signal input/output

RS232, RS485 (PROFIBUS (Option))

Power source

100 –240 VAC +/- 15% 10VA

Dimensions(mm)

Main unit: 175.7(W) * 84(D) * 236.7(H)

Transducer B: Dia.84*60 / Transducer C: Dia.98*57

Weight

Main unit: 1.8kg

Transducer B: 500g / Transducer C: 860g

Installation

(Former JIS standard)

Main unit: Wall mount

Transducer B: Screw mount R1(1"PT)

Transducer C: Screw mount: G1(1"PF)

Sensor material

Transducer B: Epoxy (Sensor surface) and PP

(Housing)

Transducer C: PVDF(Sensor surface & Housing)

IP rating

Main unit: IP66 equivalent / Sensor: IP66 equivalent

Sensor cable

Dia. 7 * 5m

10

100

80

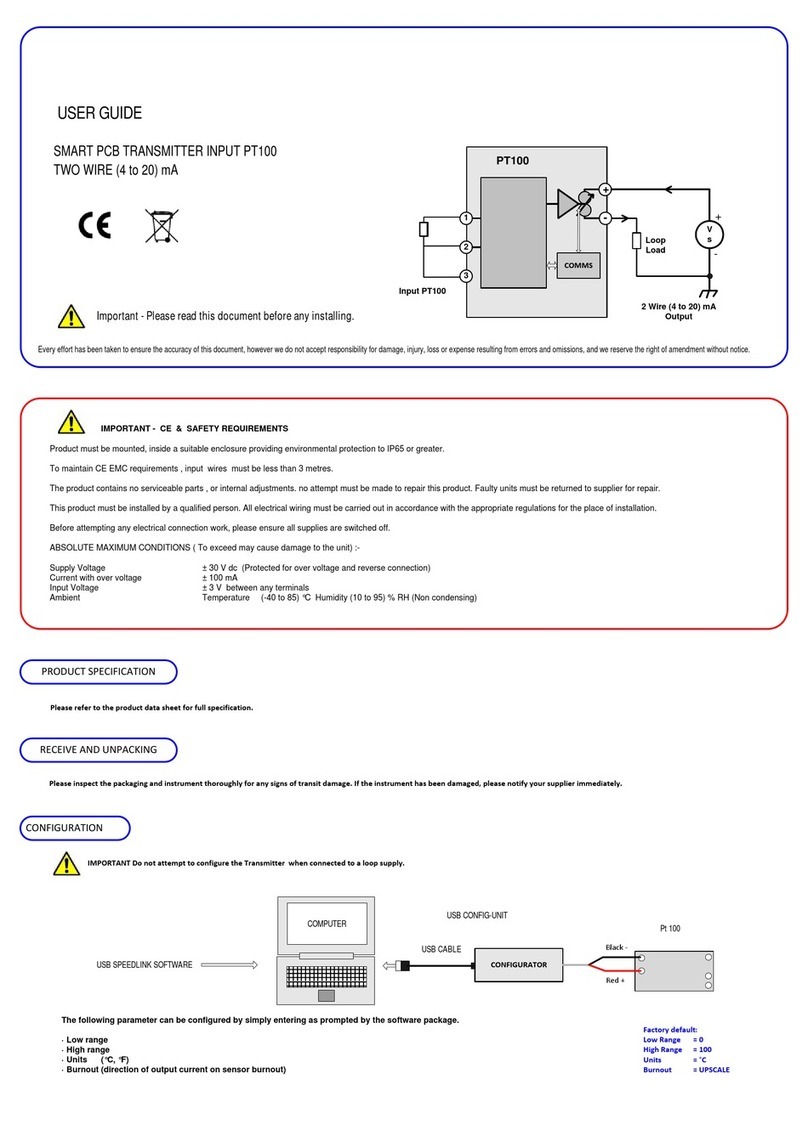

10. Installation

10.1 Mounting

➢Sensor should be mounted 1/3 the diameter of the vessel from the vessel wall

➢Unit should never be closer than 300mm (12) to the liquid surface

➢Install the ultrasonic sensor horizontally on the top of the tank.

➢Screw in the 1-inch screw of the sensor to install it.

➢Install the sensor so that the sensor surface is parallel to the surface of the

liquid.

➢If the installed sensor is closed to the side wall of the tank or an equivalent,

➢unnecessary reflection wave is detected and the incorrect measurement

occurs.

➢Do not use unnecessary force to screw in the sensor.

➢Prevent the sensor from the direct sun.

➢Do not install the multiple sensors in the same tank.

➢(Incorrect measurement occurs due to the mutual interference.)

Main unit installation

152.7

Secure with M4 screws. Screw pitch

152.7 * 80

152.7 * 100

152.7 * 180

11

10.2 Name of each part of main unit

LCD display window

SD card socket

Electrode

side

Setting key

Power switch Alarm LED

10.3 Settings to match the tank

←B ZERO

CH1 settings (MENU2) CH2 settings (MENU3)

1) Press MENU key to indicate MENU.

2) Display MENU2 or MENU3 by →key and select the item by ↑↓keys and change the

setting by ←→keys.

Press MENU key to fix the setting and exit MENU.

To press ESC key not to change the setting and exit MENU.

3) B ZERO: Distance from the sensor surface to the tank bottom

This does not necessarily have to be the distance to the tank bottom as it is the

distance to 0%.

4) SPAN: Setting of the distance for 0 - 100%

Set the distance from the tank bottom which is set by B ZERO to 100%.

5) SW HH-LL: Setting of the alarm switch level

Set the level for SW HH - LL.

Be aware of the relationship of ON and OFF.

6) 4mA OFST: Setting of 4mA offset

12

11. Operating Instructions

11.1 Instructions

Basic key operation

Press MENU key to move to MENU display.

Select the item by ↑↓keys and change the setting by ←→keys. Press MENU key to

exit MENU display.

How to read the LCD display screen

Select 1 display mode from the following 4 display modes.

DISPMODEA (Standard display)

Refer to P12 and P13.

DISPMODE B (Trend display)

Refer to P14.

DISPMODE C (Ultrasonic A mode display)

Refer to P15 to P18.

DISPMODE D (Character display)

Refer to P19.

13

DISPMODE

A (Standard display)

Date and time display

Main display: Numerical display of remaining amount in

percentage terms, the distance or the level in the tank.

Graphic display of the remaining amount in the tank

Select the unit, %, m or cm by ↑key.

Select the channel, CH1, CH2 or CH1&CH2, by← →keys.

Select the temperature or 4-20mA the by↓key.

4-20mA Rising the liquid level Lowering the liquid level

Current output display

Rising/Lowering the liquid level is indicated by the arrow.

? is indicated in case the ultrasonic reflection echo cannot be detected and

measurement error happens.

14

DISPMODE

A (Flowmeter standard display)

Flowmeter display

F

(Flow) is displayed in case the flowmeter function is worked.

T (Total flow): Integrating flow

i (Instantaneous flow): Instantaneous flow

Elapsed time for integrating flow

Integrating flow

Instantaneous flow

Display of the instantaneous flow in percentage

Select cm or mm as the unit of the overflow level at UNIT of MENU1.

Select % or Max. setting flow by ↑key.

Select the temperature or the current output value by ↓key.

Hold down ESC key for 2 seconds to reset the integrating flow and the elapsed

time for the integrating flow.

⇒

15

DISPMODE B (Trend display)

Graphic display of the ratio of the remaining amount

Select CH1, CH2 or CH1&CH2 by ←→keys.

Time graph

Time graph Distance or the ratio of remaining amount

How to change the time graph

Select the time display by ↑↓keys.

Select the time graph from 5 min. to 48 hours by ←→keys.

Flowmeter Level meter

Ratio of the instantaneous flow is displayed in case the flowmeter function is used.

[Caution] Select distance or the ratio of the remaining amount by the main display of

DISPMODE A.

16

DISPMODE C(Ultrasonic A mode display) Ultrasonic

reflection echo is displayed.

Select CH1 or CH2 by ←→keys, select the item by ↑↓keys and change the setting

value by ←→keys.

Ultrasonic A mode display: Ultrasonic reflection echo is displayed.

(S= Signal intensity, N= Noise value)

Threshold level line

Display range (RANGE)

Range of the displayed range is displayed. Setting range: 1 - 20m

The range is depending on the frequency of the

sensor.

If “bottom” is selected at MENU 1, B ZERO is the basing point of

scale. If top is selected at MENU 1, the sensor surface is the basing

point of the scale.

STC The sensitivity of the position where is close to the sensor is

decreased and the undesired reflections

from such position is cleared.

OFF

⇔

1

⇔

2

⇔

3 ⇔…⇔10

Distance of the reverb signal

17

Averaging (AVERAGE)

In case the ultrasonic reflection echo is not stable due to the fluctuation

of the liquid surface and etc., set AVERAGE to the larger value.

Setting range: 1 –30

[Caution] The larger the setting value of AVERAGE is, the slower response speed is.

Selection of ultrasonic sensor of CH2

Select either TD1 or TD2 as the sensor for CH2. Normally,

select TD2.

Ex) TD1 is selected in case both CH1 and CH2 are used with 1

sensor simultaneously.

Reverberation mask setting

In case the distance of the reverb signal prevent the measurement, adjust MASK

to avoid the incorrect measurement.

MASK = 30 cm (Default value)

MASK = 45 cm

MASK = 70 cm

[Caution] Dead zone from the sensor is 70 cm.

18

Frequency setting

12

⇔

21

⇔

30

⇔

40

⇔

50

⇔

Variable

Press ESC key at Variable to set the frequency at

1kHz step from 10kHz to 60kHz.

Distance correction

Distance correction can be done from -99 to 100mm.

Inversion of 4-20 mA current output

Inversion of the output current can be done.

4mA ⇒20mA 20mA ⇒4mA

In case the output current is inverted, the underline is indicated under the displayed current

value.

Table of contents

Other FineTek Transmitter manuals

Popular Transmitter manuals by other brands

Leuze electronic

Leuze electronic DDLS 548i manual

HumanTechnik

HumanTechnik lisa Operation instructions

Unitech

Unitech UT-9003 instruction manual

Emerson

Emerson Rosemount 248 Reference manual

Rochester Gauges

Rochester Gauges 9800 Series Installation & troubleshooting guide

AMG

AMG AMG4783BxE-SF instruction manual