FineTek EB 2600 User manual

08-EB2600-B0-EM, 05/17/2011

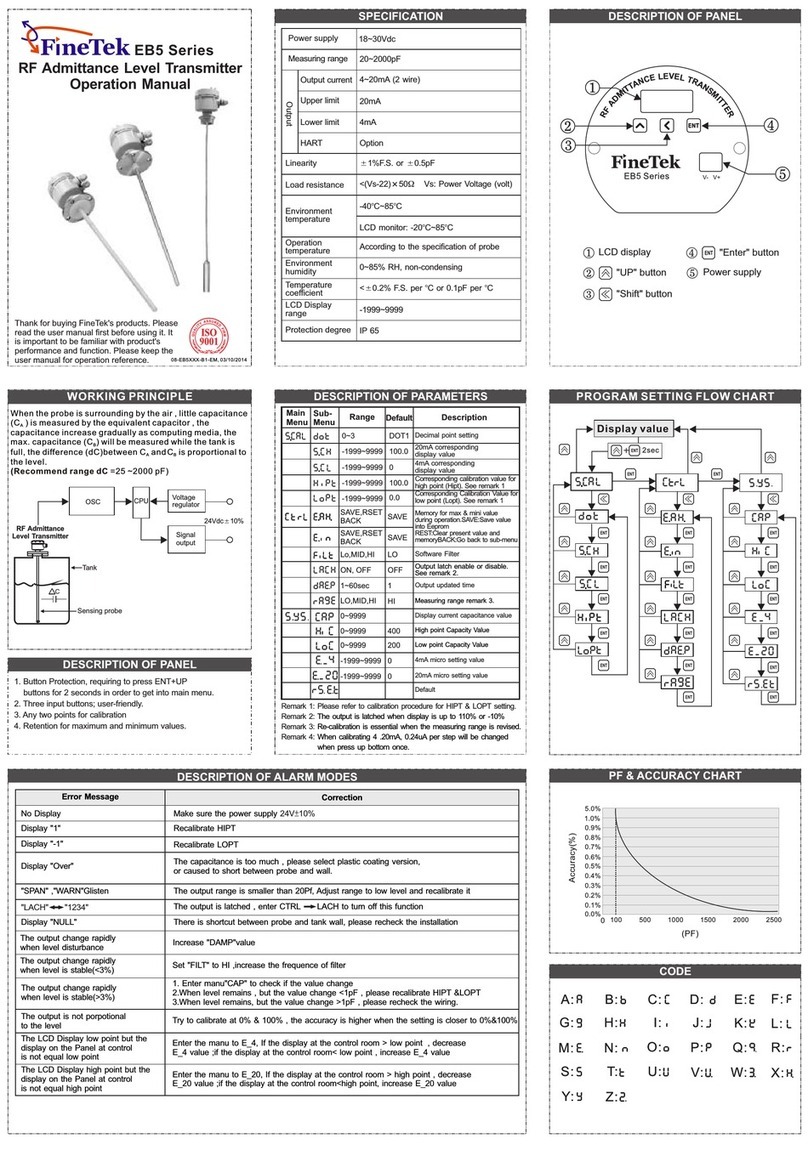

Main

Menu

Sub-

Menu Range Default Description

0~3

-1999~9999

-1999~9999

DOT1

100.0

0

100.0

0.0

ON, OFF OFF

SAVE,RSET

BACK

SAVE,RSET

BACK

Lo,MID,HI

SAVE

SAVE

LO

1/2"PT

HEX38

22

49.5

130

L= Customized

Length (mm)

f38.1

2

2

2

2

2 Connect isolation cable with GND of power.

2 Connect tank with heater or cover of electric device to decrease EMI.

After installation of the Compact Capacitance LevelTransmitter on

the top of tank, please make sure the cover of the transmitter is

contacted with tank perfectly. Please avoid the grounding of panel

meter to touch the tank wall.

While the panel meter is not supplied with a power supply, please

prepare a 24V power supply for use. The wiring for panel meter is

showing in diagram 1.

The max cable length is depending on the max resistance.

Maximum resistance is not to exceed (Vs-15)H50W to

maintain the accuracy of measurement.

Make sure to separate the signal cable with other big power

cables (such as pump, conveyer and solenoid valve)while wiring.

Before turning on power, make sure all wirings are correct.

4

2

3

1

ENTENT

Power supply

Measuring range

Output current

Output

Output linear

range

Upper limit

Lower limit

Output latch

Linearity

Load resistance

Environment

temperature

Operation

temperature

Environment

humidity

Temperature

coefficient

LCD display

range

Protection degree

12~36Vdc

0~1000pF

4~20mA( )2 wire

3.8~21.5mA

22mA

3.5mA

3.5、22mA

A1% F.S. or 1pF

(whichever is greater)

<(Vs-12)H50W Vs: Power Voltage (volt)

-40BC~80BC

According to the specification of probe

0~85% RH, non-condensing

<A0.02% F.S. per BC

-1999~9999

IP 65

-1999~9999

-1999~9999

12~36Vdc IN

REVERSIBLE

1

2 4

3

Lower present display range

Over present display range

Over measuring range (0~1000pF).

please add coating to decrease capacitance.

Output latch start up.

"OL"

"LACH" "1234"

"1"

"-1"

G:

Q:

B:

L:

V:

H:

R:

C:

M:

W:

O:

E:

Y:

T:

J:

A:

K:

U:

F:

P:

Z:

I:

S:

N:

D:

X:

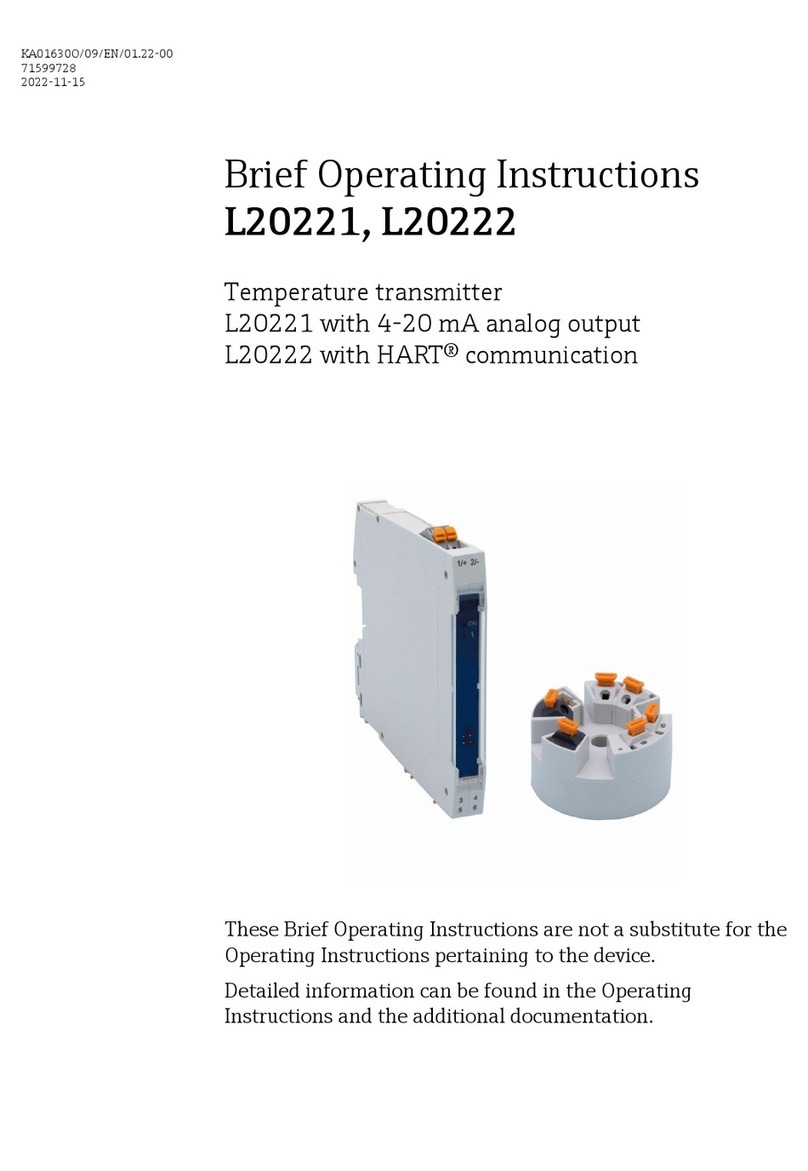

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

0 50 100 150 200 1000

(PF)

Accuracy(%)

EB 2600 COMPACT CAPACITANCE

LEVEL TRANSMITTER

OPERATION MANUAL

Thank for buying FineTek's products.

Please read the user manual first before

using it. It is important to be familiar with

product's performance and function. Please

keep the user manual for operation refereuce.

WORKING PRINCIPLE

The level measurement of a medium in a tank is accomplished

by capacitance theory. The tank wall,

the sensing probe and the medium are all capacitors. A high

frequency since wave is applied between the probe and the

tank wall. The level change of the medium will cons equently

change the current of the applied since wave, forming a

proportional relationship between medium level and output.

OSC CPU Voltage

regulator

Signal

output

Capacitance level

transmitter

Tank

Sensing probe

16~30Vdc

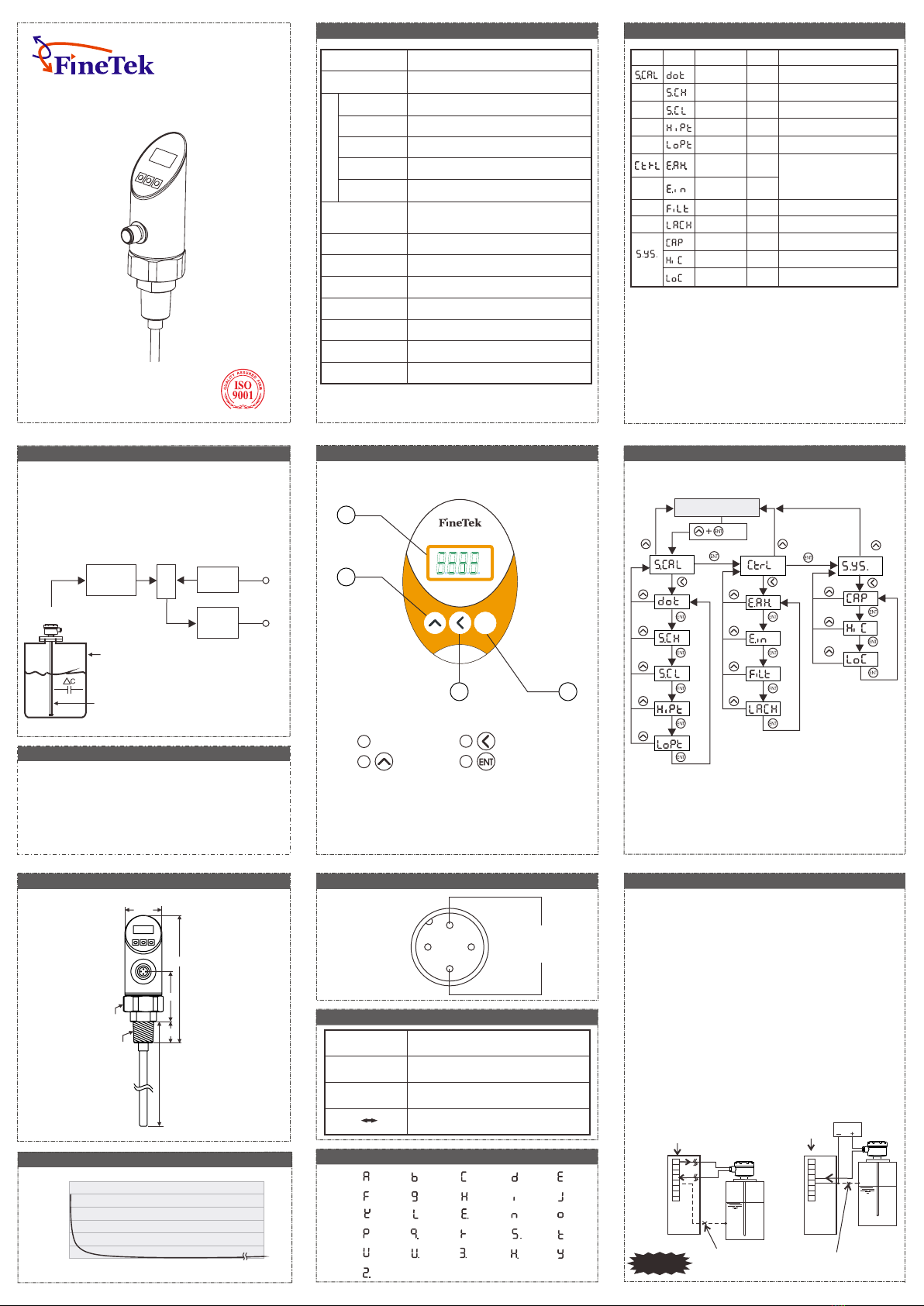

DESCRIPTION OF PANEL

1. Button Protection, requiring to press ENT+UP

buttons for 2 seconds in order to get into main menu.

2. Reversible Polarity

3. Any two points for calibration

4. Retention for maximum and minimum values.

5. Three input buttons; user-friendly.

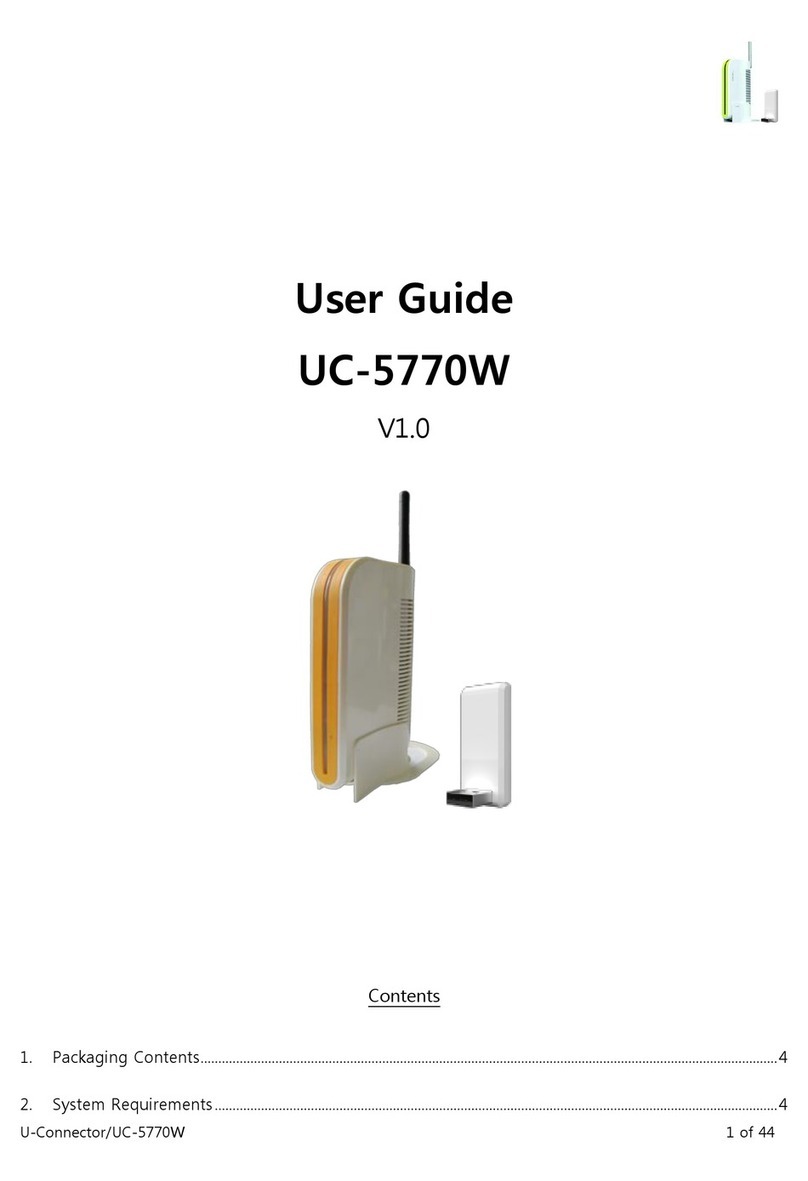

DIMENSION OF PRODUCT WIRING DIAGRAM

ERROR MESSAGE

CODE

SPECIFICATION

DESCRIPTION OF PANEL

LCD display

UP button

1

2

Shift button

Enter button

4

3

Colors of wiring

1: Brown

2: Green

3: Blue

4: Black

PROGRAM SETTING FLOW CHART

WIRING AND CAUTION

Signal GND

[ Description of Wiring ]

2

3

4

5

6

7

8

1

+24V

EXC 24V

A Input

The Signal GND of panel meter should not be connected

with tank wall or the cover of the EB Transmitter, otherwise

the measurement will be incorrect.

(Diagram 1)

Panel Meter Panel Meter

Power Supply

Signal GND

2

3

4

5

6

7

8

1

EXC 24V

A Input

+24V

Warning

DESCRIPTION OF PARAMETERS

PF & accuracy chart

Decimal point setting

20mA corresponding

display value

4mA corresponding

display value

Corresponding calibration value for

high point (Hipt). See remark 1

Corresponding Calibration Value for

low point (Lopt). See remark 1

Memory for max & mini value

during operation.SAVE:Save value

into Eeprom

REST:Clean present value and

memoryBACK:Go back to sub-menu

Output latch enable or disable.

See remark 2.

Software Filter

Remark 1: Please refer to calibration procedure for HIPT & LOPT setting.

Remark If you select ON, the output will be latched at 3.5mA/22mA

when it reached to 3.5mA/22mA.

2:

Display Value

2sec

Capacity Value

High point Capacity Value

Low point Capacity Value

0~9999

0~9999 5056

0~9999 54

CALIBRATION PROCEDURESSETTING FLOWCHART FOR EACH FUNCTION

Standard Procedures:

1.SCH : Set the max display value corresponding to 20mA at SCH.

2.SCL : Set the min display value corresponding to 4mA at SCL.

3.HIPT : Input and save the corresponding value at HIPT, while the

medium is in high level.

4.LOPT: Input and save the corresponding value at LOPT, while the

medium in is in low level.

Completed Calibration

Example 1:

The lowest value sets at 0 and the output sets at 4mA.

The highest value sets at 100.0 and the output sets at 20mA

Calibration is done in empty and full tank.

Example 2:

The lowest value sets at 100.0 and the output sets at 4mA.

The highest value sets at 200.0 and the output sets at 20mA

It is calibrated at 10% of tank high and 90% of tank high. The 0%

of the total height of the tank is corresponded to 4mA, while the

100% of the total height of the tank is corresponded to 20mA.

Procedures of calibration for example 2

1. Input:

Dot=1, SCL=100.0,

SCH=200.0

(It can be adjusted anytime; Nothing is related with the status

of tank.)

2. To fill the medium till reaching to

the 10% height of the tank, go to

the LOPT setting and input the

value of 10.0 and then press

"ENT" "SAVE'' (Remark 2).

3. To fill the medium till reaching

to the 90% height of the tank,

go to HIPT setting and input

the value of 90.0 and then

press "ENT" "SAVE''

(Remark 3).

3. When the tank is full, go to

HIPT setting and input 100.0,

then press "ENT" "SAVE"

(remark 1).

Procedures of calibration for example 1

1.Input:

Dot=1, SCL=0.0

SCH=100.0,

(It can be adjusted anytime; Nothing is related with the status

of tank.)

2. When the tank is empty, go to

the LOPT setting and input 0.0,

then press "ENT" "SAVE"

(remark 1).

10%

Lowest Point

Highest Point

90%

Empty TankEmpty Tank Full TankFull Tank

Remark 1: Under the setting for Hipt & Lopt, press "ENT" to show

(screen flashing)

Press "ENT" button to save the value and then press "UP" button

to escape the setting.

Note 2: When Hipt or Lopt setting is over range, the LCD show

"Err", Please reset the value.

Compact Capacitance Level Transmitter is to press the three

( )

buttons UP, SHIFT, ENTER on display panel. Firstly, selecting

the setting menu then input value by using three buttons

showing below:

Selection

Escape button

Enter button

Swap button

Setting

Increment button

Position shift button

Confirmation button

Up button

SHIFT button

ENTER button

●Swap button is for swapping

to different menus, such as

from main menu to main

menu or from sub menu to

sub menu.

Enter button

●Confirmation button. After revising

the SCH value, press enter button

to save the revised value.

Flashing alternately

:Revise Parameters

:Save Parameters

1 342

123 4

SHIFT button

●Shift button is for entering a

sub menu from main menu

or doing a position shifting

after entering sub menu.

●Position shift button. After entering

revision mode, press this button to

shift into revisable position.

Flashing alternately

(Digit flashing means

the value is revisable.)

1234

12 43

Flashing alternately

1234

1230

●Increment button. After entering

revise mode, press this button to

increase the revisable value.

For example, changing SCH

value from "1230" to "1234" is to

press this button fourth.

UP button

●Up button is enable to escape

from revision mode or to

escape from sub menu to

main menu.

Display value

Setting

Value

Setting

Value

Setting

Value

Setting

Value

Setting

Value

1.

2.

3.

4.

。

5.

6.

7.

8.

The rod probe or cable probe (depending upon which one you

purchased ) should be parallel to the tank wall and be positioned

as close as possible to the tank wall. Make sure the medium

does not stick in between the probe and the tank wall.

If the tank is not electrically conductive, a metal strap should be

added outside of tank wall (fig. 1) for either liquid or non-liquid

medium. Or place a metal tube, usually made out of stainless

steel, around the rod (fig. 2) for liquid medium. This metal tube

should come with a vent hole at top of the tube to allow the

medium to go up inside of the tube.

If the container is irregular-shaped, such as a cylindrical, and the

medium is liquid with low viscosity, the rod should be placed

inside a metal tube with vent hole at the top. (Fig. 2)

For non-conductive medium of powder or granuules in a new or

empty tank, the cable probe should be fixed to the bottom of tank

with ceramic isolator (EB2100 Series. If the tank is not empty,

please use the EB2300 Series. (fig. 3)

Make sure to fix the rod probe or cable probe to the container

wall with non-conductive supporting material. If an agitator is in

place (see fig. 4). This will prevent the deformation of the rod

probe and tangling of the cable probe around the agitator.

If the medium is conductive, make sure to coat the rod probe or

cable probe with PVDF or PP material.

During the installation, the process connection should be

grounded. An installation without proper grounding will not

guarantee normal operation of the device later on.

When all electrical connections inside of a Capacitance Level

Transducer housing are finished, the housing cover and the

conduit opening should be sealed and tightened to prevent

moisture from soaking in.

(Fig. 2)

Vent hole

Rod probe

Tube

INSTALLATION

(Fig. 1)

Rod probe

Metal strap

(Fig. 3)

Cable probe

Ceramic isolator

(Fig. 4)

Isolate

supporter

Rod probe

Agitator

1.Read installation notice before calibration.

2.It is recommended to have the media touched probe

bottom when users calibrate lowest value for empty tank.

3.Doring calibration, pribe should be put into the tank.

Don't calibrate the product outside the tank.

4.Please keep at least 50% distance between HIPT and LOPT

to ensure accuracy. It is recommended to calibrate with

empty and highest level in the tank.

4mA

20mA

Tel 886-2-22696789

Email: info@fine-tek.com http://www.fine-tek.com

: Fax: 886-2-22686682

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678, Taiwan.

F i n e T e k C o .,L t d .

Other FineTek Transmitter manuals

Popular Transmitter manuals by other brands

Greystone Energy Systems

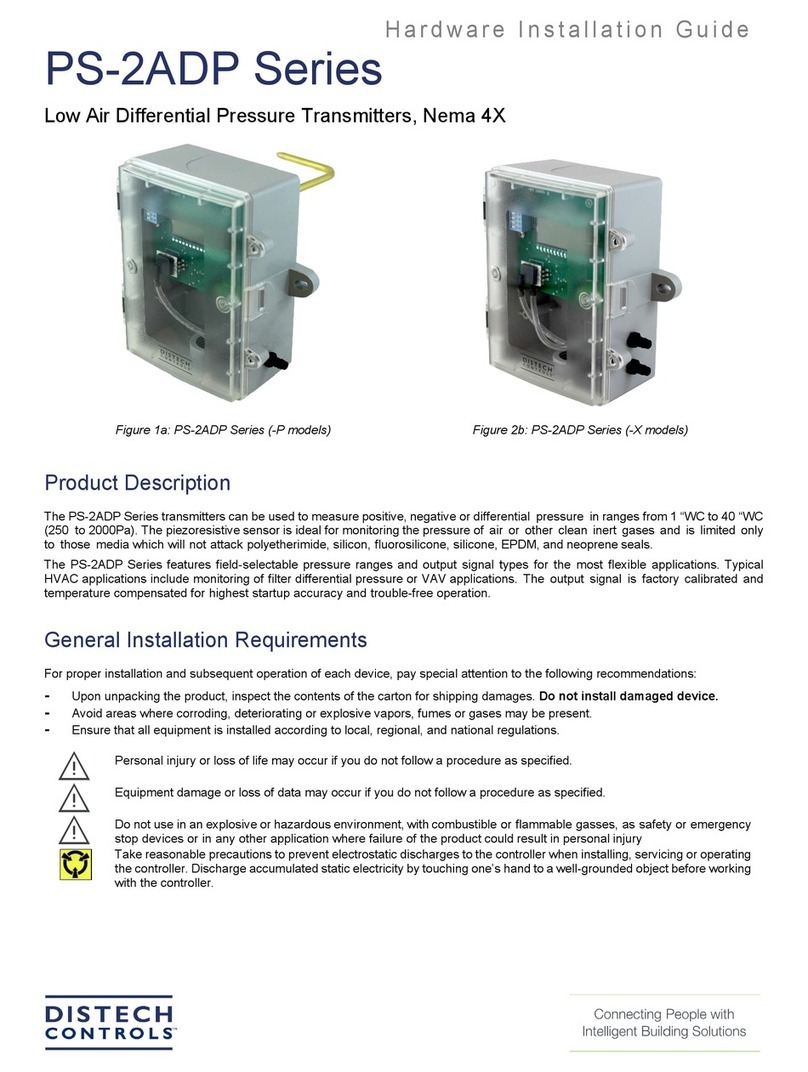

Greystone Energy Systems PS-2ADP Series Hardware installation guide

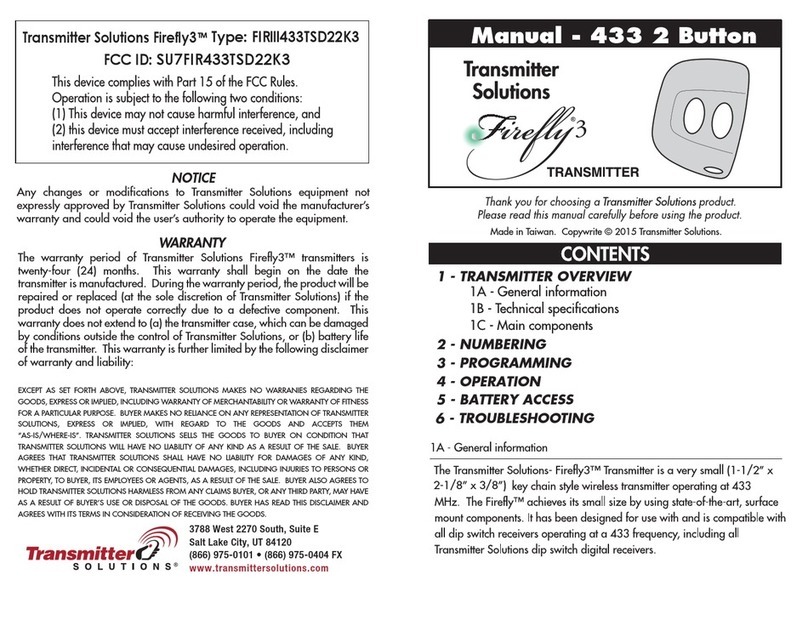

Transmitter Solutions

Transmitter Solutions Firefly3 FIRlll433TSD22K3 manual

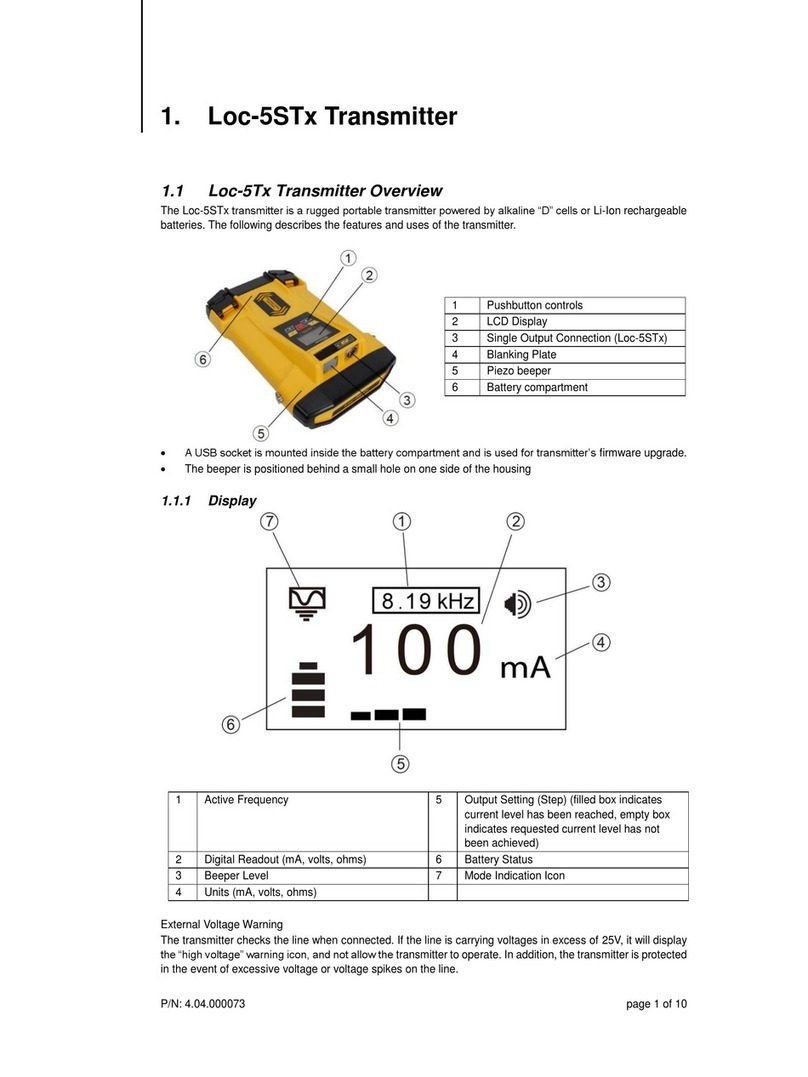

Vivax Metrotech

Vivax Metrotech Loc-5ST Series manual

NVT

NVT NV-ET1801 Condensed Installation Guide

Burkert

Burkert SE58 S operating instructions

SILENTRON

SILENTRON 5150 manual