Rotar Plus 20-25 Easytronic - Cod.197AA2702 - Edition 00 01/2004 7

GB

MODIFIABLE PARAMETERS

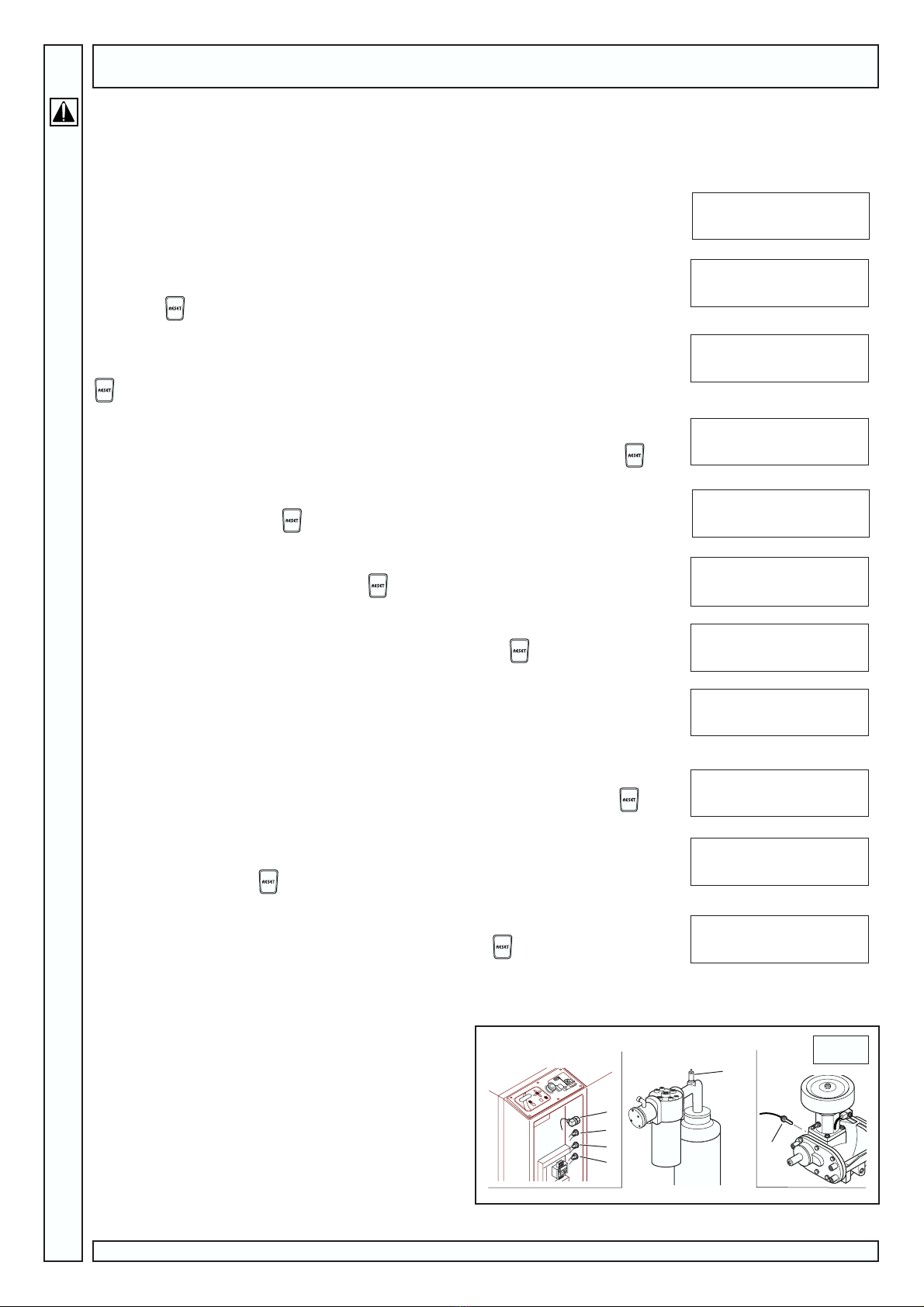

Pressing the key with the machine OFF, the operating parameters menu will be displayed; in certain cases a password

is required in order to make changes. The menu is scrolled using the keys and .

0) control unit ID (service password): selects the identification code of the control unit; if several compressors are connected

to the same RS485 line, multiple IDs can be selected.

1) Pre-alarm time lapse (service password): each hour of operation clocked by the machine is counted down automatically;

when the count reaches 0, the control unit trips a Maintenance alarm.

The count, preceded by a minus sign (-), indicates how many hours have elapsed since the last maintenance alarm; the keys

and can be used to set a new value (entering the new value has the effect of overriding the previous alarm).

2) Alarm history (no password required): this menu can be used to display the 30 most recent alarms.

3) Pre-alarm temperature (factory password): this menu is used to set the delta temperature (delta, in °C) referred to the

maximum alarm temperature; the value can be set between 1 and 20.

Example: if the maximum temperature is 120 °C and the differential is 10 °C, the maximum temperature pre-alarm will trip at 110 °C.

4) Maximum temperature (factory password): this menu is used to set the maximum permissible temperature; the adjustment

range is 0 to 150 °C.

5) Minimum temperature (factory password): this menu is used to set the minimum temperature; the adjustment range is 0 to -14 °C.

7) Duration of loadless operation (service password): this menu is used to change the duration of the no-load cycle; the range

of adjustment is 1 to 250 seconds.

8) Auto start (service password): this parameter enables automatic Start; if activated, the compressor will restart automatically

following an electrical power supply failure.

If the compressor starts up unexpectedly, persons happening to be nearby could be harmed or injured. With this in mind, use

of the automatic start function is not generally recommended.

9) Internal phase sequence (service password): this parameter enables control of the phase sequence internally, or disables

internal control and activates the phase sequence control input at the terminals.

10) Language (no password required): this parameter is used to select the language in which messages are displayed; there

are 5 available (English, French, German, Italian, Spanish).

11) Enable RS485 (no password required): this parameter is used to enable data transmission using RS485, and automatically

disable transmission on RS232.

12) Pressure sensor (service password): enables the 4-20 mA input to which the pressure sensor is connected. With this

parameter activated, the pressure measurement is displayed. To display machine operation time, press the key; the display will

revert to the pressure measurement automatically after 20 seconds.

Enabling this parameter, the external pressure switch contact changes function and becomes an input for the oil separator

minimum pressure switch; in this situation, the compressor is prevented from restarting if pressure in the oil separator is high.

13) PSI/BAR (no password required): selects the unit of measure used to display pressure.

14) No-Load/operating pressure set point (no password required): this parameter is used to set the pressure at which the

compressor must switch off; if inverter drive is enabled, it indicates the operating pressure at which the inverter will begin modulating

output to maintain the pressure steady.

15) Load/operating Delta set point (no password required): indicates the pressure at which the control unit enables compressor

restart.

For example, if the set differential value is 1 bar and maximum operating pressure is 9 bar, this means that the compressor will

switch off at 9.5 bar and switch on again at 8.5 bar.

16) Maximum pressure (service password): this parameter sets the maximum pressure value permissible in operation, i.e. the

maximum pressure of point 14.

17) Maximum alarm pressure (factory password): this parameter sets the maximum pressure value at which an alarm is

tripped in the control unit.

18) Remote pressure(service password): enabling this parameter, the pressure and the relative alarms continue to be displayed,

but the compressor starting sequence is controlled from an external pressure switch contact.

19) Load delay(factory password): this parameter sets the delay, in seconds, from the moment when the starting cycle terminates

to the moment when the air solenoid valve energizes.

AL AYS HIT KEYS AND PRESS TO CONFIRM ENTRY

°C

°C

°C

sec.

Hours

Max.

20

150

0

250

2768

NO

NO

BAR

Min.

0

0

-14

1

0

YES

YES

PSI

Standard

5

110

-7

20

000

NO

YES

BAR

MODIFIABLE PARAMETERS

Oil temperature pre-alarm (differential)

Maximum oil temperature

Minimum oil temperature

No-load (EMPTY) time

Maintenance pre-alarm

Automatic start

Pressure sensor

PSI/BAR

bar

bar

bar

bar

sec.

No-Load/operating pressure set point

Load/pressure differential set point

Maximum permissible pressure

Maximun alarm pressure

Load (CHARGED) delay

Internal phase sequence control

Language

Display contrast level

Enable RS485

Min.

0

0

0

0

0

YES

1

SI

Max.

15

15

15

16

200

NO

20

NO

Standard

10

8,5

11

1

10

YES

ITA

5

SI

SETTINGS AND CONTROLS