FINO VITESSE SF Operation manual

FINO VITESSE SF

50862

Original FINO

Germany

Mikromotor

Micromotor

Micromoteur

Micromotor

Micromotore

Micromotor

Mikromotor

Mikrosilnik

Gebrauchsinformation•User Information•Mode d’emploi

Información sobre el uso•Informazioni d’uso

Gebruiksaanwijzing•Instrukcja stosowania

FINO

•der feine Unterschied•the fine difference•la fine différence•la fina diferencia•la fine differenza

Version 1/2010. Vor Beginn aller Arbeiten Betriebsanleitung lesen!

1. Field of application 3

2. Safety precautions 3

3. Commencement of operation 3

• Assembly

4. Operation 4

• Basic functions • Handpiece • Working with the FINO VITESSE Micromotor

5. Maintenance and cleaning 5

• Removal of chuck • Separation of crank and motor • Change of motor cable

• Adjustment of magnetic sensor of knee-control plate • Testing of individual components

• Replacement of unit fuse

6. Storage 7

7. Technical data 7

8. Delivery includes 7

9. Guarantee 7

10. Troubleshooting 8

• Error codes • Emergency maintenance

11. Important 10

12. Disposal 10

• Registration number

13. Accessories 10

14. Components 11

TABLE OF CONTENTS

2

1. Field of application

The FINO Micromotor is a brush-free micromotor

suitable for all work in the dental lab or workshop. It

particularly excels in high performance and speed

stability. The control unit can either be used as

tabletop or knee controlled unit. If used as a tabletop

unit an additional foot switch for speed control can

be installed. The control unit is equipped with seve-

ral safety features to avoid any damage to the hand-

piece. All wearing parts are easily and economically

to replace.

2. Safety precautions

Safe operation and protection of the unit are only

ensured as long as it is used in compliance with spe-

cifications described in the user information using

only permitted tools. Additionally the following must

be observed:

• The directions of the manufacturer if the tools

• Never exceed the maximum allowed speed

of the tool in use

• Always wear eye protection and facemask

• The occupational safety regulations

• The accident prevention regulations

• Never operate the unit with moist hands!

If the safety precautions are not observed the hazard

of injuries for you and people in your surroundings

exists. FINO does not undertake any guarantee in

the case that these safety precautions are not obser-

ved!

3. Commencement of operation

Please check the unit for transportation damages

immediately after unpacking. All transportation

damages must be claimed promptly. Check the vol-

tage given on the type label of the unit and make

sure it corresponds with your mains supply.

3.1 Assembly

3.1.1 Tabletop unit

Danger of stumbling

Install all cables in a way that they do not

cause any occupational hazard. Place the con-

trol unit on an even and dry surface.

Push the knee-control plate 2

completely in and place the

tabletop stand 3 on the bottom

surface of the control unit.

Subsequently screw on the

tabletop stand 3 using the

included two screws. Place the

control unit on your workplace.

Now connect the plug of the

motor cable 5 with the socket 4

on the back of the control unit.

Thereby make sure that the

groove of the socket and the gap of the plug are

opposite each other. Tighten the nut firmly. Now you

connect the plug of the foot switch 7 with the socket

6. Also here the groove of the socket and the gap of

the plug must be opposite each other. Finally you

connect the power supply cable 9 with the power

supply socket 8. Put the control unit on the therefore

selected place on your workplace. Before you con-

nect the power plug with the mains socket check

again whether all cables are firmly connected to the

control unit.

3.1.2 Knee-control unit

Use only the included screws for

the fitting of the attachment

bracket. The use of other screws

could result in the damage of the

unit or your workbench.

We recommend installing the

attachment bracket 10 in a height

of approx. 520-580 mm depen-

ding on your body height. Mark

the holes with a pencil.

Make sure that the attachment

bracket 10 is kept horizontally. If

necessary use a water level. Drill

the holes with a thin drill. Screw

the screws completely in to

ensure a frictionless installation

of the control unit.

3

ENU

Slide the control unit forward on the attachment

bracket until it markedly catches.

Now connect the plug of the motor cable 5 with the

socket 4 on the back of the control unit. Thereby

make sure that the groove of the socket and the gap

of the plug are opposite each other. Tighten the nut

firmly. Finally you connect the power supply cable 9

with the power supply socket 8. Before you connect

the power plug with the mains socket check again

whether all cables are firmly connected to the con-

trol unit.

4. Operation

For the connection of the motor handpiece or the

foot switch switch the on/off switch 16 to position 0

(off).

4.1 Basic functions

4.1.1 Control unit

Switch the control unit 1 with the on/off switch 16 on.

Select the desired maximum speed between 1.000

and 50.000 rpm with the speed control 11. The range

between 40.000 and 50.000 rpm is blocked by a lock.

Pushing the lock button at the speed control 11 can

disengage this lock. Your selected maximum speed

is shown in the display 15. By pushing the hand/foot-

switch 12 you can switch between hand and foot con-

trol. If the control light next to the hand/foot-switch

12 glows the speed can be adjusted with the foot

switch or the knee-control plate. Pushing the directi-

on selector 13 sets the direction of rotation. If the

control light next to the direction selector 13 glows

the motor turns clockwise. If it is not glowing the

motor turns anti-clockwise (topview on the axis of

rotation). The motor switch 14 allows an automatic

locking of the selected speed. If the control light

next to the motor switch glows orange the function is

activated. If it glows green the function is deactivat-

ed. If a speed is kept for more than two seconds it is

automatically stored and you can release the foot

switch or knee-control plate. The storage of the

speed is indicated by an acoustic signal. By actua-

ting the previously used control device afresh the

speed can again be changed.

4.1.2 Handpiece

4.1.2.1 Opening of chuck

When the chuck is open the

motor is blocked. To prevent

damage to the motor or the

drive parts make sure that

after each change of tools the

chuck has been completely

closed. Never open the chuck while the motor is in

operation! Always operate the device with a tool!

Even if the device is not operated it is recommended

to insert a tool or the test drill and to close the

chuck. To prevent a falling down of the handpiece

always place it on the included handpiece tray 22.

The procedure is described for right-handers.

Lefthanders please proceed diametrically.

Take the handpiece 21 in your

right hand. The motor 20 is thus

in the palm of your right hand.

Take the crank 18 in your left

hand and turn the crank approx.

A quarter revolution clockwise

until you feel a marked resistance. The chuck is open

and the tool can be removed.

4.2 Working with the FINO VITESSE

Micromotor

Before you start with your work

check the selected speed.

Whenever you work with the FINO

VITESSE Micromotor wear pro-

tective eyewear and a facemask!

Never exceed the maximum speed and the maximum

allowed processing pressure of the tool in use!

Before each use check the firm fit of the tool! During

operation never try to hold or to block the tool or the

chuck! Never operate the unit with wet or moist

hands! If your workplace is unsuitably illuminated a

stroboscopic effect may occur. At certain speeds it

causes the impression that the tool does not turn.

This effect can only be prevented with a suitable illu-

mination. Switch the control unit off as long as it is

not in use. Always place the handpiece on the there-

fore provided handpiece tray. Insert the selected

tool into the chuck. See section 4.1.2. Make sure that

the tool is firmly fitting in the chuck. Turn the speed

selector 11 completely left to the lowest speed. Now

switch the control unit with the on/off switch 16 on.

Select the desired maximum speed.

4

4.2.1 Application as tabletop unit

without foot switch

If you want to use the unit as tabletop unit without

foot switch the control light next to the hand/foot

switch 12 must be off. If that is not the case push the

hand/foot switch 12. Simultaneously the control light

next to the motor switch 14 extinguishes. Select the

direction of rotation of the motor by pushing the

direction selector 13. Now you can start the motor by

pushing the motor switch 14. The selected maximum

speed can at any time be changed by turning the

speed control 11. Likewise the direction of rotation

can at any time be reversed by pushing the direction

selector 13. It is not necessary to stop the motor

beforehand. The motor stops when the motor switch

14 is pushed again.

4.2.2 Application as tabletop unit

with foot switch

If you want to use the unit as tabletop unit with foot

switch the control light next to the hand/foot switch

12 must be glowing. If that is not the case push the

hand/foot switch 12. Simultaneously the control light

next to the motor switch 14 glows. Select the directi-

on of rotation of the motor by pushing the direction

selector 13. Now you can start the motor by actuating

the foot switch 7. The selected maximum speed can-

not be changed during the operation of the motor.

The direction of rotation can at any time be reversed

by pushing the direction selector 13. It is not neces-

sary to stop the motor beforehand. If the control light

next to the motor switch 14 glows orange and you

work more than two seconds at a constant speed the

speed is stored and you can remove the foot from

the foot switch 7. To change the speed or to stop the

motor you actuate the foot switch 7 again and sub-

sequently release it completely.

4.2.3 Application as knee-control unit

without foot switch

If you want to use the unit as knee-control unit

without foot switch the control light next to the hand/

foot switch 12 must be glowing. If that is not the case

push the hand/foot switch 12.

Simultaneously the control light next to the motor

switch 14 glows. Select the direction of rotation of

the motor by pushing the direction selector 13.

Now you can start the motor by actuating the knee-

control plate 2. The selected maximum speed cannot

be changed during the operation of the motor. The

direction of rotation can at any time be reversed by

pushing the direction selector 13. It is not necessary

to stop the motor beforehand. If the control light next

to the motor switch 14 glows orange and you work

more than two seconds at a constant speed the

speed is stored and you can release the knee-

control plate 2. To change the speed or to stop the

motor you actuate the knee-control plate 2 again and

subsequently release it completely.

4.2.4 Application as knee-controlled

unit with foot switch

If you want to use the unit as knee-control unit with

foot switch the control light next to the hand/foot

switch 12 must be glowing. If that is not the case

push the hand/foot switch 12.

Simultaneously the control light next to the motor

switch 14 glows. Select the direction of rotation of

the motor by pushing the direction selector 13. Now

you can start the motor by actuating the knee-con-

trol plate 2 or the foot switch 7. The selected maxi-

mum speed cannot be changed during the operation

of the motor. The direction of rotation can at any

time be reversed by pushing the direction selector

13. It is not necessary to stop the motor beforehand.

If the control light next to the motor switch 14 glows

orange and you work more than two seconds at a

constant speed the speed is stored and you can

release the knee-control plate 2 or the foot switch 7.

To change the speed or to stop the motor you actua-

te the knee-control plate 2 or the foot switch 7 again

and subsequently release it.

5. Maintenance and cleaning

For maintenance work on the unit disconnect the

plug from the mains socket. Clean the unit only with

a dry cloth! It is recommended to clean the chuck

thoroughly at least once a week. The chuck may only

be screwed in hand-firm! Do not clean the handpiece

with compressed air!

5

ENU

5.1 Removal of chuck

Open the chuck 23 as

described in section

4.1.2. Insert a tool or

the included test drill

19. Now you place the

included maintenance tool 24 on the chuck and un-

screw it anti-clockwise. Clean the chuck thoroughly

with compressed air or in an ultrasonic bath. Sub-

sequently reinsert the chuck and tighten it.

5.2 Separation of crank and motor

The procedure is described

for right-handers. Lefthan-

ders please proceed diame-

trically. Take the handpiece

in your right hand. The

motor 20 is thus in the palm of your right hand. Take

the crank 18 in your left hand and turn the crank

clockwise until you feel a marked resistance. Now

turn the crank further until motor and handpiece

separate from each other. For the assembly of the

two parts you proceed in reversed order and screw

crank and motor firmly together. Turn the crank a

quarter revolution backwards to close the chuck.

5.3 Change of motor cable

The plug of the motor cable only fits in one position

on the motor. Do not try to force the plug on the

motor. This could damage the connector pins and

makes the motor unserviceable. The procedure is

described for right-handers. Lefthanders please pro-

ceed diametrically.

Take the handpiece back-

wards in your left hand. The

motor thus is in the palm of

your left hand. Unscrew

with your right hand the

protective sleeve anti-clockwise. Carefully pull the

motor cable. The plug connection comes loose. Put

the new motor cable carefully on the motor and

screw the protective sleeve clockwise tightly on.

5.4 Adjustment of magnetic sensor

of knee-control plate

The speed is leadlessly controlled through a magne-

tic sensor on the knee-control plate. It may happen

that the sensor must be adjusted from time to time.

Switch the control unit off. Press the hand/foot

switch 12 and the direction selector 13 simultaneously

and keep both switches pressed. Now switch the unit

on. After approx. 2 seconds you will hear an acoustic

signal and the display shows one of the three options

Hi, Lo or rc. Turn the speed control 11 until the display

shows Hi. Now push the knee-control plate comple-

tely in and keep it there. Acknowledge with the

direction selector 13. You will hear an acoustic

signal. The maximum knee-control plate position has

been stored. Turn the speed control 11 now until the

display shows Lo. The knee-control plate must not

be pressed. Acknowledge with the direction selector

13. You will hear an acoustic signal. The minimum

knee-control plate position has been stored. You

can finish the adjustment now.

Turn the speed control 11 now until the display shows

rc and acknowledge with the direction selector 13.

Switch the control unit off and subsequently on

again. The unit is now ready for operation.

5.5 Testing of individual components

Here the function of the different components can be

tested. To load the respective menu, switch the unit

off. Press the direction selector 13 and the motor

switch 14 now and keep them pressed down. Switch

the unit on. After approx. 2 seconds you will hear an

acoustic signal. By turning the speed control 11 you

can choose from the different options. You can only

choose the option Sc after the lock button on the

speed control has been pressed. You start the test

routine by pushing the direction selector 13. You end

the test routine by again pushing the direction

selector 13.

6

5.6 Replacement of unit fuse

Remove the fuse holder using a flat blade driver.

Replace the damaged fuse with the spare fuse,

which is inside the fuse holder. Put the fuse holder

back. Order a new 250 V/3,15 A fuse.

6. Storage

Store thee unit in a dry and dust-free place.

7. Technical data

Control unit:

Voltage: 220 - 240 V; 50/60 Hz

Power consumption: 40 VA

Exterior dimensions: W 94 x D 268 x H 228 mm

Weight: 2,9 kg

Handpiece:

Dimensions: L 159 mm, ø 27 mm

Speed: 1.000 - 50.000 rpm

Cable length: 1,4 m

Weight: 230 g (without cable)

Foot switch:

Cable length: 1,8 m

Weight: 384 g

Tabletop stand:

Dimensions: W 122 x D 268 x H 30 mm

Weight: 152 g

Handpiece tray:

Dimenstions: W 60 x D 110 x H 45 mm

Weight: 68 g

8. Delivery includes

Control unit, Tabletop stand, Motor handpiece,

Motor handpiece tray, Foot switch, Attachment bra-

cket for control unit, Maintenance tools, Test drill.

9. Guarantee

Our technical recommendations of application are

based on our own experiences and tests and should

only be regarded as guidelines. It rests with the skills

and experience of the user to verify that the products

supplied by us are suitable for the intended proce-

dures. Our products are undergoing a continuous

further development. We reserve the right of chan-

ges in construction and composition. It is under-

stood that we guarantee the impeccable quality of

our products.

7

ENU

Test setting Function Test procedure

Sc Switch Test the function of the switch and its control light

by pressing the switches 12, 13 and 14.

dc Display All segments of the display are switched on one after the other.

Hc Motor sensor Turn the motor shaft to test the function of the motor sensors.

The display shows two bars in different heights.

Fc Foot switch Press the foot switch. The display shows 0-9 and A-F.

nc Knee control plate Press the knee-control plate. The display shows 0-9 and A-F.

8

10. Troubleshooting

10.1 Error codes

Error code Status Possible reason

1E Motor sensor error 1. The motor cable is damaged or not connected.

2. The motor sensor is damaged.

2E Motor blocking error 1. The chuck is open.

2. The handpiece is damaged.

3E Overload protection error 1. The unit was operated under overload conditions.

2. The motor cable resp. the power cable is damaged.

4E Over-voltage protection error 1. The control unit is damaged.

2. The power supply is interrupted.

5E Overheating error 1. The unit was operated under overload conditions.

2. The control unit is overheated.

It should never be exposed to direct sunlight.

6E Overload error After normal starting the motors has blocked.

7E oder 8E Self-test error The control unit has a malfunction.

9

ENU

10.2 Emergency maintenance

Error code

1E

2E

3E

4E

5E

6E

7E + 8E

Problem

The unit cannot be switched on.

The motor

does not run.

The foot switch does not work.

The knee-control plate does not work

or not properly.

The handpiece gets unusually hot

during operation.

The handpiece vibrates and makes

unusual noises.

The chuck does not hold the tool.

What to check

Check whether the unit is switched on.

Check whether the power supply cable is connected

properly.

Check whether the fuses in the unit or your mains

circuit breakers have tripped.

Check whether the motor cable is connected properly.

Test the function of the motor sensor and the motor

cable. See section 5.5.

Make sure that the chuck is closed.

The unit was operated under overload for some time.

The power voltage fluctuates.

The unit was operated under overload for some time.

The control unit is too hot.

The temperature sensor is damaged.

Make sure that the chuck is closed.

Test the smooth rotation of the motor.

The control unit has determined a malfunction.

Check whether the foot switch cable is connected

properly.

Test the function of the foot switch.

The knee-control plate was pressed while the unit

was switched on.

Test the function of the knee-control plate.

The ball bearing is worn.

The chuck is dirty.

The used tool is not balanced or the speed is

too high for the tool.

The ball bearing is worn.

The chuck is loose.

The chuck is worn.

The used tool is to thin.

Help

Switch the unit on by pressing the on/off switch 16.

Connect the power supply cable properly.

Replace fuses.

Connect the motor cable properly. If the error is

still displayed replace the motor cable.

1. Replace the motor cable.

2. The motor sensor is damaged.

Close the chuck.

Switch the unit off and let it cool for

approx. 10 minutes.

1. Check the power voltage. It must correspond

to the voltage indicated on the type label.

2. Switch the unit off. Wait for approx. 5 seconds

and switch it on again.

Switch the unit off and let it cool for approx.

10 minutes.

Take care that the control unit is never exposed

to direct sunlight. Switch the unit off and let cool.

Let the technical customer service replace the

sensor.

Close the chuck.

Turn the chuck with your hand.

It must move smoothly and without noise.

Switch the unit off. Wait for approx. 5 seconds

and switch it on again. If the error still persists

contact the technical customer service.

Connect the cable properly.

See section 5.5, Test setting Fc.

Switch the unit off. Wait for approx. 5 seconds and

switch it on again. If the error still persists contact

the technical customer service.

See section 5.5, Test setting nc.

Replace the ball bearing with a new one.

Clean the chuck as described in section 5.1.

Use a new tool. Observe the maximum allowed

speed of the used tool.

Replace the ball bearing with a new one.

Screw in the chuck hand-firm

Replace the chuck.

Use a tool with a shank diameter of 2,35 mm.

Should the above-mentioned measures not be successful or should you encounter problems that are not described here, please contact the technical

customer service.

12. Disposal in accordance with

EC Guideline 2002/96/EG

This equipment may not be disposed in

domestic waste! Please contact the manu-

facturer or your dealer!

12.1 Registration number

30926170

10

11. Important!

The FINO GmbH has compiled the present user infor-

mation to the effect to support the user in the opera-

tion of the units and to facilitate the implementation

and operation of the unit. The FINO GmbH is not

responsible for damages that are attributed to an

incorrect application or alterations of the unit. An

application for purposes other than the described

leads to the loss of the guarantee. According to its

policy FINO GmbH permanently further develops its

products. FINO reserves the right to put on changes

or improvements to the products described in this

documentation or the document itself without prior

notice. FINO does not undertake any guarantee for

the completeness or correctness of the contents of

this document.

7-10 FINO TC-Cutters

Shank-ø 2,35 mm, ISO 104.

Recommended speed range for

all TC milling cutters:

Acc. to ISO 023 5-50.000 rpm

ISO 023-045 15-40.000 rpm

ISO 045-080 15-30.000 rpm

Cross-cut fine

Smoothens surfaces and enables the

delicate shaping of each structure.

Suitable for all dental materials.

13. Accessories

1-6 FINO DIADISC

1+2 Very flexible diamond discs.

Double-sided 3 mm circular coating with

fine grain (D 30); for crown and bridge work.

3+4 Very flexible diamond discs.

Double-sided 3 mm circular coating with

coarser fine grain (D 54);

5+6 Stable diamond discs with long service-life;

cutting on the edge, double-sided full coating

with coarser fine grain (D 54).

023 045 060 060

P-60364 C-60365 C-60366 C-60367

789 10

ISO: 190 220 190 220 190 220

Thickness: 0,14 0,14 0,20 0,20 0,30 0,30

T-65900 X-65901 Z-65904 Z-65905 Z-65908 Z-65909

1 2 3 4 5 6

14. Components

11

ENU

13 Direction selector

14 Motor switch

15 Display

16 On/off switch

17 Chuck

18 Crank

19 Test drill

20 Motor

21 Handpiece

22 Handpiece tray

23 Protective sleeve

24 Maintenance tool

1Control unit

2Knee-control plate

3Tabletop stand

4Socket for motor cable

5Motor cable

6Socket for foot switch

7Foot switch

8Socket for power supply

9Power supply cable

10 Attachment bracket

11 Speed control

12 Hand/foot switch

FINO GmbH

Mangelsfeld 18

D-97708 Bad Bocklet

Tel +49-97 08-90 94 20

Fax +49-97 08-90 94 21

This manual suits for next models

1

Table of contents

Popular Dental Equipment manuals by other brands

Josef Ganter Feinmechanik

Josef Ganter Feinmechanik FB-EV 065 GA User instructions

Bien Air

Bien Air CA 1:1 Instructions for use

Medidenta

Medidenta Freestyle Pro instruction manual

Renfert

Renfert SIMPLEX 3D-Filament-Drucker manual

W&H

W&H proxeo TWIST PL-40 H Instructions for use

Jordco

Jordco ENDORING II Instructions for use

Reborn Endo

Reborn Endo R-SMART PLUS user manual

Renfert

Renfert EASY view 3D quick start guide

Digiray

Digiray FireCR Flash installation manual

DentalEZ

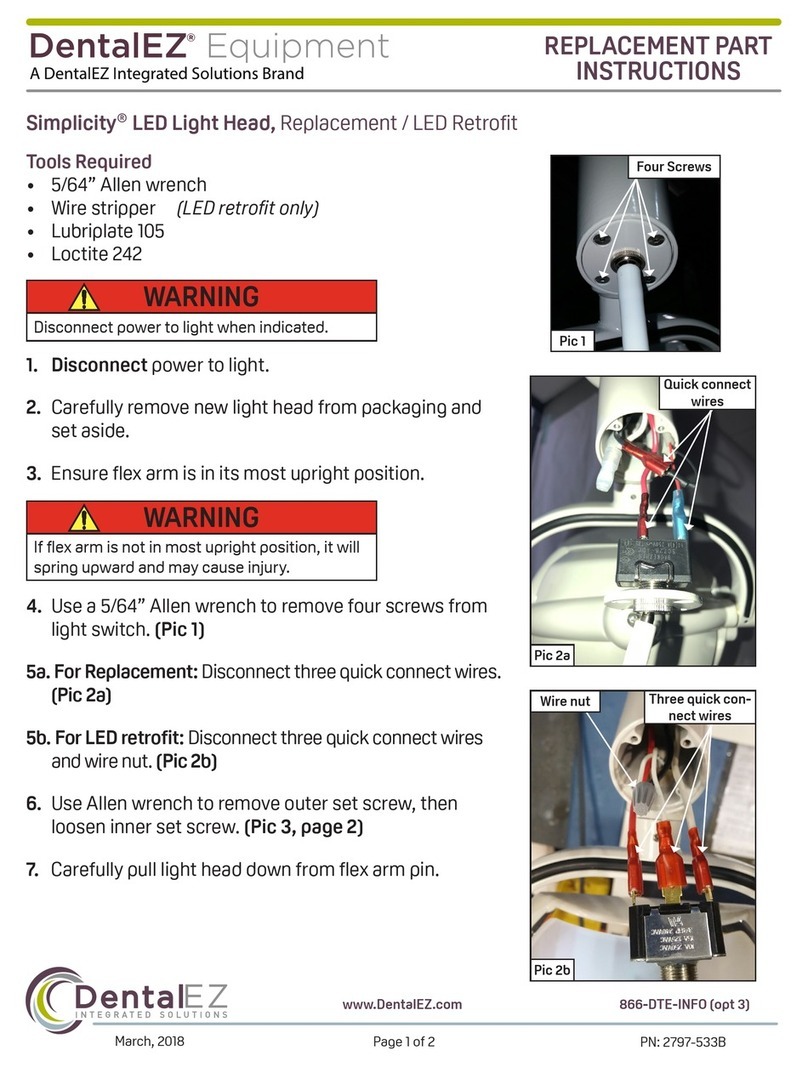

DentalEZ Simplicity LED Light Head REPLACEMENT PART INSTRUCTIONS

Nakanishi

Nakanishi NSK V10 instruction manual

Digital Doc

Digital Doc IRIS Installer manual