FIORENTINI ECOSMALL55-N1 Operating instructions

ING. O. FIORENTINI S.p.A.

INDUSTRIAL CLEANING MACHINES

SCRUBBER MACHINE

Mod. ECOSMALL

OPERATING AND MAINTENANCE

MANUAL

CONTENTS

1.

GENERAL INFORMATION

1.1. Symbols used.......................…….............................................…………………page

4

1.2. Notes…….....…..............….....................................................................................

4

1.3. Consulting the manual……....….........………….……………………………………….

4

1.4. Warranty.................................................................................................................

4

1.5. Declaration of Conformity……................................................................................

5

2.

MACHINE CHARACTERISTICS AND TECHNICAL DATA

2.1. Identification……….................................................................................................

7

2.2. Description and components...….…………….….……...........................................

7

2.3. Technical data sheet……………….…….…............................................................

9

3.

SAFETY

3.1. Recommended machine use……....……………………………………………………

10

3.2. Misuse……………………….…..…………………………………………………………

10

3.3. Recommended equipment……………………………………………………………….

10

3.4. Operator qualifications..…………...........................................................................

11

3.5. Safety and warning devices …………….................................................................

11

3.6. Safety systems...............................................………………………………………….

12

3.7. Safety diagnostic signalling ………………………………………………………………

12

3.8. Residual dangers ………………………………………………………………………….

14

3.9. Safety signs…………………………………………………………………………………

15

4.

START-UP AND OPERATION INSTRUCTIONS

4.1. Transport and handling……...................….....................………………………………

18

4.2. Storage……………...................................................................................................

19

4.3. Machine unpacking...........................…………………………………………………….

19

4.4. Unpacked machine handling .........………………………..…….................................

19

4.5. Installation…...............................................................………………..…….…...........

20

4.5.1. Battery installation……..........……..….......…………………………………………….

20

4.5.2. Battery charger installation………………………………………………………………

20

4.6. Control and monitoring devices…………………………………………………………...

21

4.6.1. Control panel……………………………………………………………………………...

21

4.7. Operation…………………………………………………………………………………..

22

4.7.1. Machine preparation and start-up………………………………………………………

22

4.7.2. Choosing the right detergent…………………………………..……………………….

23

4.7.3. Control levers……………….…………………………………………………………….

23

4.7.4. Squeegee adjustment …………………………………………………………………..

24

4.7.5. Water draining……………..……………………………………………………………..

25

4.7.6. Brushes replacement ……………………………………………………………………

26

4.7.7. Squeegee replacement………………………………………………………………….

27

4.7.8 Squeegee blades replacement (Machine with two brushes)……………………….

29

4.7.9 Brush deck belt replacement (Machine with two brushes)…………………………..

30

Congratulations on your choice!

Thank you for having chosen to purchase a product by FIORENTINI S.p.A., a world-

leading manufacturer and distributor of industrial cleaning machines.

Our long-standing experience and acquired know-how are the best guarantee of the

technical quality of your purchase; all our products are built from top quality materials to

ensure maximum reliability, sturdiness and functionality and to meet the requirements of

even the most demanding customers. FIORENTINI was recently granted the quality

system certificate to certify compliance with the requirements of UNI EN ISO 9001.

Feel free to contact us with any technical or commercial inquiry; we will be happy to

supply any details and information that you may need.

5.

MAINTENANCE

5.1. Routine maintenance table……………..……………..................………………………

31

5.2. Battery maintenance………………………………………………………………………..

31

5.2.1. Hydrometrics.……………………………………………………………………………..

32

5.2.2. Water topping-up ………………………………………………………………………...

32

5.2.3. Charge limits………………………………………………………………………………

32

5.2.4. Standby or inactive batteries ……………………………………………………………

32

5.2.5. Battery charger technical features……………………………………………………...

32

5.2.6. Battery disposal…………………………………………………………………………..

33

5.3. Motor maintenance ………………..……………………………………………………….

33

5.3.1. Suction motor maintenance……………………………………………………………..

33

5.3.2. Brush motor maintenance ………….…………………………………………………..

35

5.3.3. Drive motor maintenance ………….……………………………………………………

36

5.4. Wiring system checks………………………………………………………………………

37

5.5. Inspection summary table………………………………………………………………….

37

5.6. Maintenance log…………………………………………………………………………….

38

6.

TECHNICAL ASSISTANCE

6.1. Technical assistance contact information............…………..................……………..

39

6.2. Claim report ……………………………..…………...…………………………………….

39

GENERAL INFORMATION

Ecosmall

Rev. 000

29/11/2017

4/41

1. GENERAL INFORMATION

1.1. SYMBOLS USED

This symbol is used to alert the operator to important procedures or precautions to be

followed in ordertopreventdamages tousersorthemachine

This symbol is used to alert the operator to important general information.

1.2. NOTES

1.3. CONSULTING THE MANUAL

This manual deals exhaustively with all the issues considered necessary for an easy and safe use of the

machine, in compliance with European Directives on product safety.

We therefore suggest to all authorised operators to carefully read this manual throughout and contact

FIORENTINI in case of any doubt. This manual should also be used for reference whenever there are

doubts concerning a procedure or operation to carry out or to train new operators.

In print, pictures and drawings can look slightly different from actual machine parts, without however being

perceived as confusing.

Special symbols and bold and/or Italic fonts are used to highlight important information, particularly

concerning safety.

The current revision code is indicated in the bottom left corner of every page.

1.4. WARRANTY

Warranty terms and conditions are stated here below unless otherwise specified in the order confirmation.

SCOPE OF THE WARRANTY

The machine has been designed and built for trouble-free use over several years. However, if any

malfunctioning is observed during the warranty period, FIORENTINI undertakes to repair or replace free of

charge any parts showing breaks and early wear due to faulty materials, working defects or incorrect

assembly. The manufacturer warranty will not cover any parts whose early breaking or wear-and-tear are caused

by:

FIORENTINI S.p.A. is the owner of this manual.

The reproduction of all or part of this manual or its transmission to third parties by any

mechanical or electronic system or otherwise is forbidden without a written authorisation

by the manufacturer. This manual is supplied to the customers in a single original copy

unless otherwise specified at the time of ordering.

This manual is supplied as an integral part of the machine and if the machine is transferred to a new owner,

this manual should also be transferred. This manual should be stored at a safe location throughout the

machine working life. The purchaser is responsible for making this manual available to all users. If this manual

islost,aduplicateshouldbeobtainedfromFIORENTINI.

FIORENTINI S.p.a. will not be held responsible for any damages to persons and/or property resulting from

failure to comply with the instructions in this manual.

FIORENTINI reserves the right to introduce any required technical and commercial changes without giving

any notice. Therefore, any data and information contained in this manual may be changed and/or updated.

GENERAL INFORMATION

Ecosmall

Rev. 000

29/11/2017

5/41

Failure to observe the instructions contained in this manual;

Tampering or alterations introduced without Fiorentini’s specific approval;

Use of non-original spare parts;

Wear parts for use as: brushes, blades, squeegee, etc…

Use of equipment different from the recommended equipment.

For installed electrical parts and commercially available parts, FIORENTINI S.r.l. will extend to purchasers

the same warranty terms granted to FIORENTINI itself by the parts' suppliers.

WARRANTY VALIDITY

The Ing.O.Fiorentini S.p.A. general terms conditions also apply to the warranty.

The manufacturer cannot be held responsible in any way for damages resulting from unauthorised

modifications made to the appliance, from the use of unsuitable brushes and accessories and after use of

the device other than that intended.

WARRANTY APPLICATION TERMS

Defective components must be returned to FIORENTINI S.p.a. in order to establish the causes of any

observed defects and determine warranty applicability. Repairing and replacement under the warranty will be

carried out on FIORENTINI’s premises, by subcontractors or on customer's premises. For work carried out

on site, the customer will have to provide power sources, special equipment and auxiliary personnel and

cover travelling and accommodation expenses and meals.

PRODUCT RETURNS

In case of parts to be returned for replacement or repairs under the warranty, a written authorisation must be

obtained in advance from FIORENTINI's Technical Assistance Department.

All defective parts must be carefully repacked in order to avoid damages during transport. Products must be

returned on a free-on-board basis, complete with:

Serial number read from the equipment ID plate (point 2.1);

Item code and installation position of the returned parts, read from the spare part list (point 7.2);

Detailed description of the observed defect and conditions under which it became apparent.

In case of defective electric or electronic components,

please return the parts separately from other materials,

so that waste containing dangerous substances can be separated

and Waste Electrical and Electronic Equipment (WEEE) can

be recycled according to the 2002/96/EC Directive.

Any parts acknowledged as being under the warranty will be returned on a free-on-board basis; replaced

parts will remain the property of FIORENTINI.

EXCLUSIONS

The warranty will not cover materials and components exposed to normal wear and those whose working life

cannot be established beforehand.

A missing machine data plate will imply the immediate loss of any warranty rights.

1.5. DECLARATION OF CONFORMITY

The Declaration of Conformity is supplied with the purchased machine and the use and maintenance

manual.

GENERAL INFORMATION

Ecosmall

Rev. 000

29/11/2017

6/41

MACHINE CHARACTERISTICS AND TECHNICAL DATA

Ecosmall

Rev. 000

29/11/2017

7/41

2. MACHINE CHARACTERISTICS AND TECHNICAL DATA

2.1. MACHINE IDENTIFICATION

An adhesive machine identification label containing indelible “CE” marking details is affixed on the rear side

of the machine next to the handle.

The label must never be removed and should always be kept legible. If the label is

damaged a duplicate should be ordered. The machine may be sold without the label.

2.2. DESCRIPTION AND COMPONENTS

The scrubber machine Ecosmall has been designed to clean flat surfaces by means of washing followed by

washing water suction. The electric drive system is equipped with a set of batteries supplying power to the

brushes motor and to the suction motor.

The machine can be equipped with either two brushes or one brush which can be operated to scrub the floor

with water and detergent. When the machine moves forwards, the squeegee or back brush, in contact with

the floor, takes up any water by suction for its subsequent delivery to the recovery tank.

Through the control panel, all the main machine functions can be activated. In particular, it is possible to:

Adjust the forward movement speed via the special potentiometer;

Select the forward or backward movement direction;

Display the battery charge;

Activate brush rotation (controlled simultaneously with machine movement);

Start vacuum suction;

Turn the machine on and off.

The main components of the machine are:

FIGURE N. 2.1

MACHINE CHARACTERISTICS AND TECHNICAL DATA

Ecosmall

Rev. 000

29/11/2017

8/41

Washing fluid PPL plastic tank with draining hose;

Washing effluent plastic PPL recovery tank with one suction hose and one draining hose;

Set of batteries located in the solution tank compartment;

Right side and left side scrubbing brushes (for two-brush versions);

Single scrubbing brush (for single brush version);

Squeegee (floor wiping unit);

Two front drive wheels with an electric motor with integrated differential;

Two rear idle pivoting wheels.

In consideration of recent EU concerns regarding product safety, FIORENTINI designed and built this

machine in compliance with the safety and health requirements provided by applicable Directives. The high

quality of the materials used, the applied advanced technology and FIORENTINI’s long-standing experience

are a guarantee of the performance and reliability of this machine. Each machine is submitted to rigorous

testing during construction and to a thorough final test.

MACHINE CHARACTERISTICS AND TECHNICAL DATA

Ecosmall

Rev. 000

29/11/2017

9/41

2.3. TECHNICAL DATA SHEET

SPECIFICATIONS

ECOSMALL 55

ECOSMALL 65

Power supply

4 x 12V –49.2 Ah / 5h GEL

4 x 12V –54 Ah / 5h ACID

Drive system

200W 48V differential gearmotor

Scrubbing width

550

650

Squeegee width

790

890

Brushes

1 x Ø 500mm

2 x Ø 330mm

Brush pressure

25 kg

30 kg

Max hourly output

2750 sq.m/h

3250 sq.m/h

Max working range

2.5-3 h

Solution tank

70 litres

Recovery tank

70 litres

Water lift

135 mBar

Forward speed

0-5 Km/h

ENGINE & MOTOR SPECIFICATIONS

Drive motor

200W 48V differential gearmotor

Suction motor

48V 500W

Brush motor

One 400W - 48V - 130rpm

DIMENSIONS AND WEIGHTS

Length

1200 mm

Width

790 mm

890 mm

Height

1100 mm

Weight without load

110 kg

120 kg

Battery weight

4 x 20Kg

Drive

Walk-behind operator

Max. gradient at full load

10 %

Noise level

73 dB

The above-mentioned specifications are not binding on the manufacturer and may therefore

be changed without notice. FIORENTINI can be contacted at any time for further information

(point 7.1.).

UNIT OF MEASURE CONVERSION TABLE

Length

1 inch = 1” = 25.4 mm

Power

1 kW = 1.36 CV = 1.34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1.8 t (°C) + 32

Pressure

1 bar =100 kPa = 14.5 psi

SAFETY

Ecosmall

Rev. 000

29/11/2017

10/41

3. SAFETY

3.1. RECOMMENDED USE

This is a floor scrubbing machine designed and built for use in industrial

environments, to carry out wet scrubbing, drying and effluent collection on flat

horizontal surfaces or surfaces with a gradient not exceeding 10% at speeds not

exceeding 3 km/h. U-turns are prohibited on any gradient slopes.

3.2. MISUSE

machine operation by unauthorised personnel;

scrubbing uneven and/or bumpy surfaces;

scrubbing sloping surfaces;

scrubbing surfaces whose gradient exceeds 10%;

doing U-turns on any (even minimal) gradient slopes;

using the machine in environments containing dangerous substances, and in

particular, in explosive atmospheres or inadequate microclimatic conditions;

cleaning machine surfaces in the presence of flammable substances;

the machine may not be used as a means of transport for people or other

vehicles;

altering or tampering with safety devices;

charging batteries at not sufficiently ventilated locations;

failure to comply with applicable safety standards currently in force;

fitting equipment/devices likely to interfere with machine operation;

introducing changes or alterations not authorised by FIORENTINI;

using acid solutions likely to damage the machine;

failing to comply with use and maintenance manual specifications.

The informative labels provided on the machine should be carefully read and should not be

covered for any reason. FIORENTINI shall not be liable in any case for any of the above

not recommended uses of the machine (instances of misuse).

3.3. SUGGESTED EQUIPMENT

To make the best use of your machine, equipment specially designed and tested by Fiorentini and original

spare parts should be used. The Design Department of FIORENTINI S.p.A. is willing to meet any design

requirements concerning parts and components for personalised applications.

SAFETY

Ecosmall

Rev. 000

29/11/2017

11/41

3.4. OPERATOR QUALIFICATIONS

The table here below specifies the operator qualifications required for each operation to carry out.

OPERATION

OPERATOR QUALIFICATIONS

Machine operation/control

Trained operator

Installation/removal

Fiorentini technician

Mechanical parts maintenance

Fiorentini technician

Electrical part maintenance

Fiorentini technician

Cleaning maintenance

Trained operator

Dismantling and scrapping

Fiorentini technician

The personnel in charge of operating the machine should be specifically trained, particularly in regard to

safety issues; machine operators must have read and become familiar with this manual.

FIORENTINI declines all responsibility for accidents involving persons or property caused by

not adequately skilled, unauthorised operators.

3.5. SAFETY AND WARNING DEVICES

It is strictly forbidden to tamper with, remove or deactivate safety and warning

devices while the machine is in operation.

The efficiency of safety and warning devices should be regularly checked (see point

5.1.).

Filter

The machine is equipped with an anti-foam filter

Solenoid valve (OPTIONAL):

The machine is equipped with a solenoid valve preventing water from

flowing out before brushes power-on.

SAFETY

Ecosmall

Rev. 000

29/11/2017

12/41

3.6 SAFETY SYSTEMS

The machine is equipped with the following safety systems:

Float: The recovery tank is equipped with a float which prevents suction in case of overfilling,

warning the operator via a sound alarm; in this case, to restart the machine the tank must be

emptied first (see section 4.7.5 WATER DRAINING);

Solenoid valve (OPTIONAL): The machine is equipped with a solenoid valve letting scrubbing

water out only after the brushes have been powered on, to prevent accidental leaking;

Voltage input buzzer (OPTIONAL): The machine is equipped with an input voltage buzzer causing

the machine to go off when the battery charge goes below a certain value, preventing the battery

from going fully flat and preserving its long-term life.

3.7 SAFETY DIAGNOSTIC SIGNALLING

The scrubbing machine is equipped with a system that ensures that all the errors detected by the machine

function control electronic board are signalled by a flashing LED.

Each error can be identified by counting the number of flashes before the first long pause. Flashing stops

when the fault is corrected and in certain cases, when the machine is turned off and then on again.

The damages and faults identified by the board prevent the operation relay closure and cause its opening -

ensuring safe operating conditions.

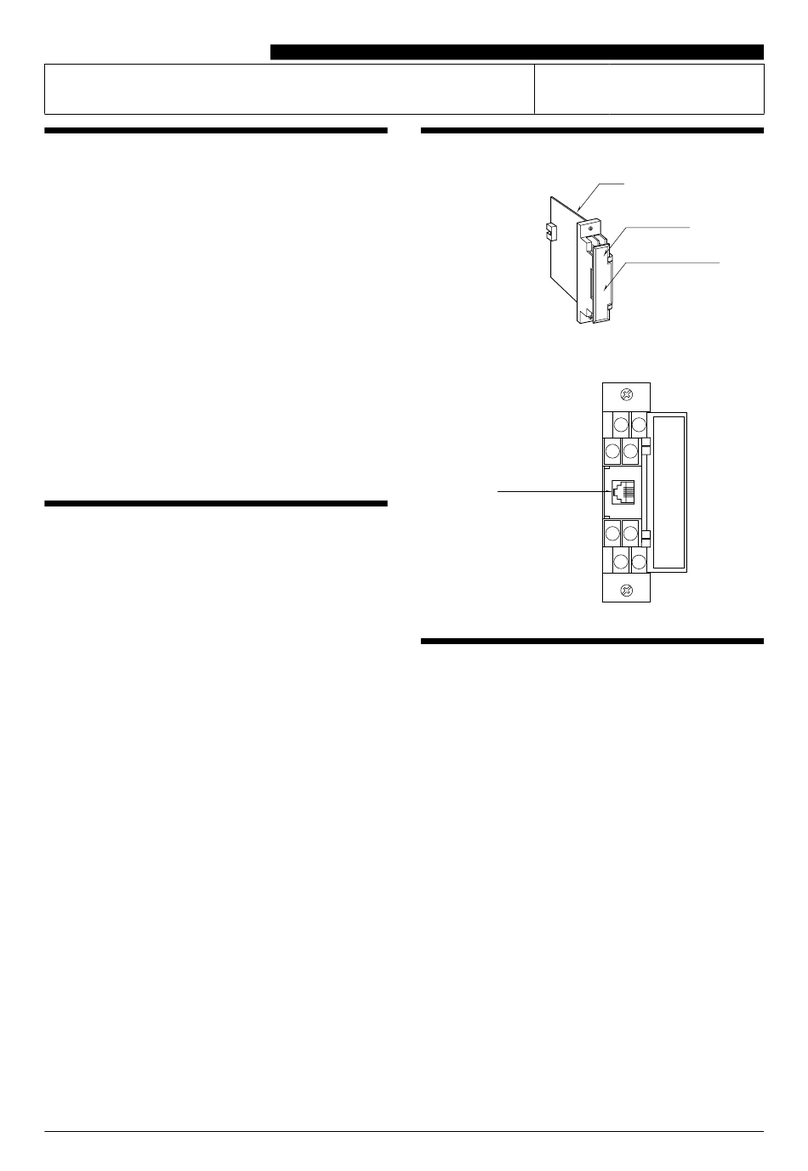

The diagnostic LED is located on the electronic board itself, therefore, to obtain access to it the control panel

must be removed (fig. 3.7).

FIGURE 3.7

SAFETY

Ecosmall

Rev. 000

29/11/2017

13/41

The following table shows the number of diagnostic LED flashes and the corresponding errors:

No. of flashes

Description

1

Motor not at a stop upon start

2

Motor not at a stop upon start

3

Battery voltage too low

4

Battery voltage too high

5

Potentiometer not at zero setting upon start

6

Potentiometer cutout

7

Overtemperature

9

Eeprom programming error

10

Control power error

Electronic system by Energy:

1 flash

Anomaly to traction micro-switches at the start. It signals that one of the traction

micro-switches is already active at the start

2 flashes

Battery voltage too low, not enough for a correct use of the machine

3 flashes

Inactive code

4 flashes

Open motor circuit

5 flashes

Motor control failure or earthling motor fail

6 flashes

Anomaly to the potentiometer. This alarm is not working with 2-wire

potentiometers

7 flashes

Overheated mosfets, this alarm is activated when the temperature gets to 75°C

+/- 5°C. This alarm is on until the temperature is high and reduces the maximum

motor current

8 flashes

Motor already running at machine start. Example: controller switching on when

going down from a slope

9 flashes

Software anomaly

Only for machine with Energy control card: when the direction selector is released with the

machine going backward, the scrubber goes a little bit forward in order to avoid any risk of

crushing

In order to limit the likelihood of electronic board failures, the following points should be observed:

It is strictly forbidden to disconnect the battery during running operation;

It is strictly forbidden to turn the key switch off and then back on during machine operation;

Do not operate the key switch while pushing the machine manually or going downhill;

Check that the key switch electrical contact is perfectly efficient to prevent bounces or false

contacts;

Check that the contact between connectors is steady; check that power connections are

tight and use deoxidizer spray between connectors;

It is forbidden to leave the key switch on during battery charging;

During cleaning operations, disconnect the battery; never wash the electronic board with

water and solvents, avoid pressurised jets and before restarting the machine, ensure that it

is perfectly dry.

SAFETY

Ecosmall

Rev. 000

29/11/2017

14/41

3.8 RESIDUAL DANGERS

Ever since the design phase, FIORENTINI has analysed all the possible dangers related to machine use in

order to eliminate or at the very least minimise the risk of injuries for machine operators. In order to minimise

the risk associated with residual dangers, danger signs and indications of accident-prevention systems and

procedures have been provided for machine operators.

DANGER OF CRUSHING

Crushing risks are possible:

during scrubbing brushes adjustment;

during battery charging due to possible tank falling risks.

During side brush adjustment, the operator must ensure that the ignition key is not in its slot in the

control panel, to prevent unwanted machine starts. During battery charging, the operator must keep

all body parts out of the battery compartment.

DANGER OF CRUSHING AND SHEARING

Crushing and shearing risks are possible:

during squeegee adjustment.

During squeegee adjustment, ensure that no-one close to the machine could operate the device up-

and down-stroke controls.

DANGER OF OVERTURNING

Machine overturning is possible:

during normal machine operation when going over slopes with a higher gradient than the

recommended value and when the machine is used to clean uneven/bumpy surfaces (see

3.2).

Do not use the machine to scrub surfaces with gradients exceeding 10% at

speeds exceeding 3 km/h or bumpy or uneven surfaces likely to affect the

stability of the machine.

FIORENTINI declines all responsibility for accidents involving persons or property caused by

machine use on stability-affecting floors. The buyer must provide suitable signage to inform

the user about the condition of the working surfaces.

SAFETY

Ecosmall

Rev. 000

29/11/2017

15/41

3.9. SAFETY SIGNS

The safety signs include signs indicating:

DANGERS

Danger signs are triangular with black

pictograms on yellow background

PROHIBITIONS

Prohibition signs are round with black

pictograms on white background and a red

stripe

If any signs become damaged, the purchaser must replace them with identical

signage. It is strictly forbidden to remove or tamper with these signs.

What is it?

This sign warns that it is forbidden to remove safety guards from

around moving parts.

What to do?

During installation/maintenance, before removing guards always

ensure that the starter key is not in its slot in the control panel. Keep

all body parts out of the machine during work.

SAFETY

Ecosmall

Rev. 000

29/11/2017

16/41

If any signs become damaged, the purchaser must replace them with identical

signage. It is strictly forbidden to remove or tamper with these signs.

What is it?

This sign shows that there is a risk of fire caused by

the presence of batteries.

What to

do?

Be extremely careful during battery charging or tank

filling.

What is it?

This sign indicates a general danger

What to do?

Be extremely careful during battery charging or tank filling and do not

place any body parts below the lifted tank.

SAFETY

Ecosmall

Rev. 000

29/11/2017

17/41

If any signs become damaged, the purchaser must replace them with identical

signage. It is strictly forbidden to remove or tamper with these signs.

What is it?

Explosion risk during battery charging due to the released hydrogen.

What to do?

During battery charging, ensure that the machine is under a suction

hood or in a ventilated area and keep it away from heat sources and

corrosive substances.

What is it?

Danger of crushing caused by suction tank overturning.

What to do?

During battery charging or tank filling, ensure that accidental impacts

are avoided.

START-UP AND OPERATION INSTRUCTIONS

Ecosmall

Rev. 000

29/11/2017

18/41

4. START-UP AND OPERATION INSTRUCTIONS

4.1. TRANSPORT AND HANDLING

The machine is delivered to the purchaser fully assembled and contained in a special package, the

characteristics of which are shown in figure 4.1. A black arrow on the package indicates the centre of gravity.

Truck or pallet truck forks must be inserted so as to ensure that the black arrow is centred between the forks.

The package must be handled carefully. Do not stack packaged items.

If agreed with the purchaser, the machine can be delivered unpacked, on a pallet and secured with straps.

The purchaser should check upon delivery that the machine has not been damaged during

transport and that all the material listed in the shipping documentation has been received;

otherwise, the forwarders and manufacturer should be promptly informed.

Unless otherwise agreed, purchased goods will travel at the purchaser's own risk.

Handling should be carried out with suitable lifting equipment, as shown in the following table. Always ensure

that the forks of the lift truck, or the harness straps, are positioned so as to ensure that the arrow printed on

the package is centrally positioned on the lifting equipment. The anchoring and/or harnessing points are

arranged so as to ensure that, during lifting, the machine is always steady and well balanced.

TYPE OF PACKAGING

HANDLING EQUIPMENT

FIG.

Paperboard or plywood box on

a pallet

Fork lift truck

N. 4.2

None

Fork lift truck or truck crane with a two-strap balance harness

N. 4.3

FIGURE 4.1

START-UP AND OPERATION INSTRUCTIONS

Ecosmall

Rev. 000

29/11/2017

19/41

The harness straps used must be suitable for the load to lift. All handling

operations should be carried out at very slow speed to prevent load swinging and

loss of stability. Any operation performed incorrectly may damage the machine and

expose operators to dangers.

Refer to point 2.3 for machine dimensions and weight. Machine handling should be

carried out by authorised personnel trained for lifting equipment use only.

LOADING DIAGRAM

4.2. STORAGE

If not immediately installed, the machine should be stored at a covered, dry location to ensure the perfect

efficiency of all its parts. Relative humidity must be below 80% and the storage temperature must be

between 3°C and + 45 °C.

4.3. MACHINE UNPACKING

Cut the straps bearing in mind that they might spring back

Remove the staples fixing the carton to the pallet

If the crate is made of plywood, remove the staples from each side and the base of each panel

Cut the straps that secure the machine

Place the machine on the floor

4.4 UNPACKED MACHINE HANDLING

Inspect the machine and install the batteries if not already installed

To prepare the machine for short distance handling after use, disconnect the battery cables and

remove the brushes and the squeegee; for longer-distance transport, the machine should be

repacked in its original packaging.

FIGURE N. 4.2

FIGURE N. 4.3

START-UP AND OPERATION INSTRUCTIONS

Ecosmall

Rev. 000

29/11/2017

20/41

4.5. INSTALLATION

Installation must be carried out by authorised personnel aware of the instructions

contained in this manual.

4.5.1 BATTERY INSTALLATION

Follow these instructions for battery installation:

Remove the key from the control panel to prevent an unwanted machine power-on;

Disconnect the squeegee hose from the recovery tank and lift it to obtain access to the battery

compartment (detail 1 fig. 4.4);

Install the batteries in their special compartment (see detail 2 fig. 4.4.) and make sure that there are

no cracks in the battery cases;

Never add distilled water after charging the batteries;

Clean the surfaces for connection;

Handles are provided on the top surface to make battery handling easier.

4.5.2 BATTERY CHARGER INSTALLATION

The battery charging area must be provided with an efficient suction system for the gases released during

charging. Alternatively, batteries must be charged in a dry, ventilated place, away from heat sources and

corrosive environments.

Protect the factory power grid with a time-delay type switch or a fuse with a load exceeding the battery

charger maximum load.

FIGURE N. 4.4

Plug the battery charger into the machine

outlet.

Observe the correct polarity of the battery

outlet.

1

2

FIGURE N. 4.5

This manual suits for next models

2

Table of contents

Other FIORENTINI Scrubber manuals

FIORENTINI

FIORENTINI 142TP-GB Operating instructions

FIORENTINI

FIORENTINI JOLLY 13 User manual

FIORENTINI

FIORENTINI L14 Installation and maintenance instructions

FIORENTINI

FIORENTINI SCOIATTOLO 75 User manual

FIORENTINI

FIORENTINI L14 Installation and maintenance instructions

FIORENTINI

FIORENTINI ECOMINI 430 Specification sheet

FIORENTINI

FIORENTINI TERMINATOR-1000 User manual

FIORENTINI

FIORENTINI I 42/60 GAS User manual

FIORENTINI

FIORENTINI ECOPRO40 User manual

FIORENTINI

FIORENTINI ET 65-75 User manual