Fiplex UHF Compact Guide

English

EnglishEnglish

English

TETRA and UHF Compact Repeater

User & Installation Manual

UM-0100-0 .09 – August 2010 II

Document History

Description Revision Date Issued

Preliminary release for early field trials 1.0 August 3

rd

, 2009

Indicator panel, and cabinet modifications 2.0 April 13

th

, 2010

Software screenshots updated 3.0 August 20

th

, 2010

UM-0100-0 .09 – August 2010 III

About this manual

This manual describes installation, commissioning, usage, function, operation and maintenance of Fiplex TETRA Compact

Repeater, UHF Compact Repeater and Fiplex portable Operational and Maintenance Software (pFOMS). The first part of

the manual describes the repeater hardware and the second part describes the software.

Hardware and software mentioned in this manual are subjected to continuous development and improvement. Consequently,

there may be minor discrepancies between the information in the manual and the performance and design of the hardware

and software. Specifications, dimensions and other statements mentioned in this manual are subject to change without

notice.

This manual or parts of it may not be reproduced without the written permission of Fiplex Europe SL.

Infringements will be prosecuted. All rights reserved.

Copyright © Fiplex Europe SL, Spain, 2009.

UM-0100-0 .09 – August 2010 IV

Contents

Abbreviations................................................................................................................................. V

Part 1 HARDWARE..........................................................................................................................1

1. Safety....................................................................................................................................... 1

Dangerous Voltage Warning......................................................................................................1

Radiation Hazard Warning......................................................................................................... 1

FCC............................................................................................................................................... 1

R&TTE Compliance Statement....................................................................................................1

Station Ground ...........................................................................................................................1

Electrostatic Discharge................................................................................................................ 1

Disposal of Electric and Electronic Waste...................................................................................1

2. Product Description.................................................................................................................2

Dimensions..................................................................................................................................

. Installation ..............................................................................................................................4

Sitting the repeater .................................................................................................................... 4

Mounting ....................................................................................................................................4

4. Commissioning........................................................................................................................ 8

Connection.................................................................................................................................. 8

Starting operation ......................................................................................................................9

Status Indicators........................................................................................................................ 11

Automatic Gain Control (AGC)................................................................................................. 12

Overload Protection.................................................................................................................. 12

Laboratory Measurements........................................................................................................ 12

Part 2 SOFTWARE .........................................................................................................................1

5. Installation ............................................................................................................................ 1

6. Overview ...............................................................................................................................19

General Tabsheet...................................................................................................................... 19

Status tabsheet ......................................................................................................................... 20

Configuration............................................................................................................................ 21

UM-0100-0 .09 – August 2010 V

Abbreviations

AGC Automatic Gain Control

AMPS Advanced Mobile Phone Service

ARFCN Absolute Radio Frequency Channel Number

BCCH Broadcast Control Channel (GSM broadcast channel time slot)

BS Base Station, BS antenna = towards the base station

CDMA Code Division Multiple Access

DC Direct Current

DCS Digital Communication System (same as PCN)

DL Downlink signal direction (from base station via repeater to mobile station)

DPLX Duplex filter

EEPROM Electrical Erasable Programmable Read Only Memory

EGSM Extended Global System for Mobile communication

ETACS Extended Total Access Communication System

ETSI European Telecommunications Standard Institute

GSM Global System for Mobile communication

HW Hardware

LED Light Emitting Diode

LNA Low Noise Amplifier, uplink and downlink

MS Mobile Station, MS antenna = towards the mobile station

OMS Operation and Maintenance System

OL Overload

PA Power Amplifier

PCN Personal Communication Network (same as DCS)

PCS Personal Communication System

pFOMS Portable Fiplex Operation and Maintenance Software

PS Power Supply

RF Radio Frequency

RSSI Received Signal Strength Indication

SW Software

TDMA Time Division Multiple Access

UL Uplink signal direction (from mobile station via repeater to base station)

WEEE Waste of Electric and Electronic Equipment

UM-0100-0 .09 – August 2010 1

Part 1 HARDWARE

1. Safety

Dangerous Voltage Warning

Any personnel involved in installation, operation or service of Fiplex repeaters must understand and obey

the following:

The power supply unit in repeaters supplied from the mains contains dangerous voltage level, which can cause

electric shock. Switch the mains off prior to any work in such a repeater. Any local regulations are to be

followed when servicing repeaters.

Authorized service personnel only are allowed to service repeaters while the main is switched on.

Any repeater, including this repeater, will generate radio signals and thereby give rise to electromagnetic

fields that may be hazardous to the health of any person who is extensively exposed to the signals at the

immediate proximity of the repeater and the repeater antennas.

Radiation Hazard Warning

FCC

To comply with FCC RF exposure requirements in Section 1.1307 and 2.1091 of FCC Rules, the antenna used

for this transmitter must be fixed-mounted on outdoor permanent structures with a separation distance of at

least 2 meter from all persons.

R&TTE Compliance Statement

This equipment complies with the appropriate essential requirements of Article 3 of the R&TTE Directive

1999/5/EC.

Station Ground

BTS chassis, Repeater, feeders, donor antenna, service antenna/s and auxiliary equipment (splitters, tabs, .etc)

are required to be bonded to protective grounding using the bonding stud or screw provided with each unit.

Electrostatic Discharge

Static electricity means no risk of personal injury but it can severely damage essential parts of the repeater, if

not handled carefully.

Parts on the printed circuit boards as well as other parts in the repeater are sensitive to electrostatic discharge.

Never touch printed circuit boards or uninsulated conductor surfaces unless absolutely necessary.

If you must handle printed circuit boards or uninsulated conductor surfaces, use ESD protective equipment, or

first touch the repeater chassis with your hand and then do not move your feet on the floor.

Never let your clothes touch printed circuit boards or uninsulated conductor surfaces.

Disposal of Electric and Electronic Waste

Pursuant to the WEEE EU Directive electronic and electrical waste must not be disposed of with unsorted waste.

Please contact your local recycling authority for disposal of this product.

UM-0100-0 .09 – August 2010 2

2. Product Description.

UM-0100-0 .09 – August 2010

Dimensions

UM-0100-0 .09 – August 2010 4

. Installation

Sitting the repeater

Fiplex repeaters are designed for outdoor usage. However, humidity and temperature changes may have

affect on the reliability. A preferable site for the repeater is thus indoor, in a tempered and ventilated room.

Repeaters are designed with a weather proof outdoor cabinet that can be mounted without any kind of

shelter from rain, snow or hail.

If a repeater is to be operated on the site when raining, snowing, or hailing there must be some kind of

permanent or temporary protection. This is applicable to gentle rainfall, snowfall or hail.

We extremely recommend not operating the repeater under very bad weather conditions, such as:

- Intense rainfall, snowfall or hail

- Storm or high wind

- Extremely low or high temperature

- High humidity of the air

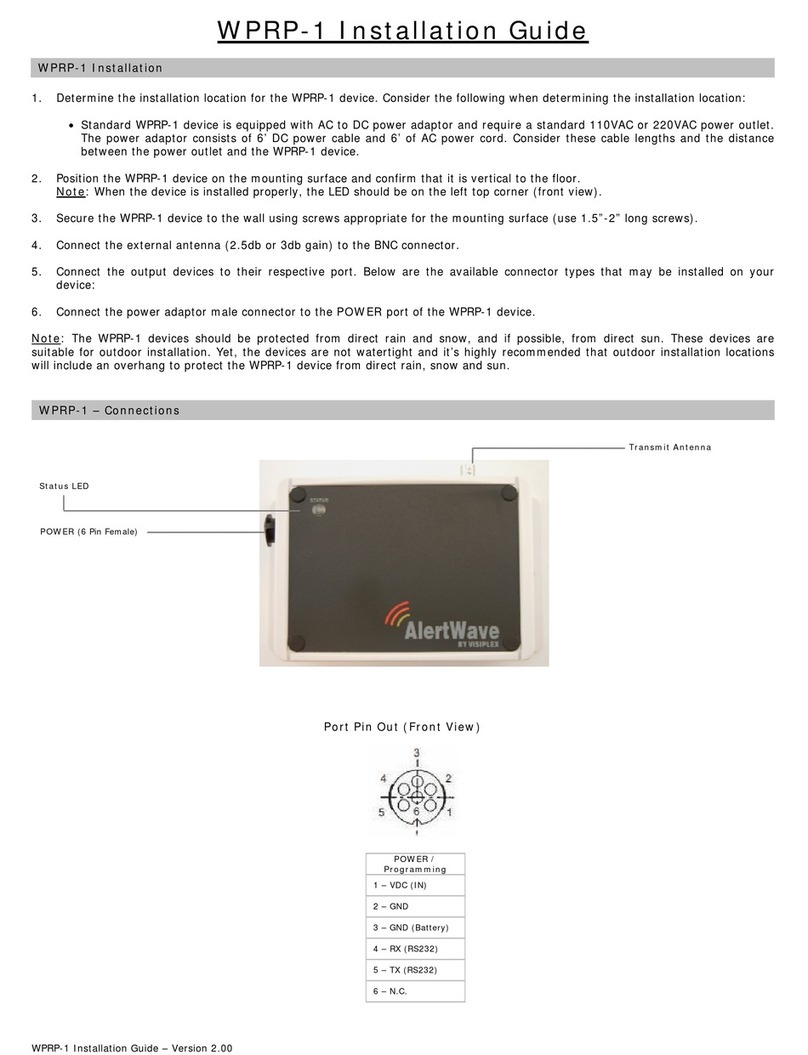

Mounting

1. Mount the provided bracket

Normally, the repeater is mounted on a wall or pole. These mounting cases are shown below.

Figure 1

Figure 1 shows a bracket attachment to a wall using three fixing screws.

Figure 2

Figure 2 shows a bracket attachment to a pipe using two inox hose clamps (provided with bracket).

UM-0100-0 .09 – August 2010 5

1. After attaching the bracket hang the repeater.

Figure 3

2. Screw the cabinet to the bracket

Attach repeater’s cabinet to the bracket using four M6 x 2” allen screws.

Release repeater cover

UM-0100-0 .09 – August 2010 6

Open repeater cover

Place and screw the four M6 x 2” allen screws

UM-0100-0 .09 – August 2010 7

Close repeater cover

Secure repeater cover

UM-0100-0 .09 – August 2010 8

4. Commissioning

Connection

Figure 4

Figure 5 shows RF ports and AC and DC cable glands location.

1. Connect service antenna (“TO MOBILE” port) and donor antenna (“TO BASE” port) coaxial cables. N

type female connectors are used in the repeater.

2. Once RF ports of the repeater are properly loaded connect mains to the AC source.

Electrical installation must provide differential and termo-magnetic breaker elements according to electric

safety international regulations.

L N

TMB

DB

UM-0100-0 .09 – August 2010 9

3. Auxiliary DC connection can be provided to the repeater from an external DC source.

There is a dedicated cable gland for this purpose (EXT DC INPUT in figure 4), and a dedicated DC

connector labelled P60002 located at the main board. A 5.5mm x 2.1mm center positive plug must be used.

Please check appropriate DC voltage at repeater specification sheet.

4. Once the repeater has been connected to power source (either AC mains or external DC), it takes about

20 seconds to run a booting routine. After that time repeater is ready to be connected via USB cable to a

computer running pFOMS in order to be properly configured.

See Part 2 Software of this manual to install pFOMS.

Starting operation

1. Setup desired filter configuration using pFOMS (only for programmable band selective and

programmable channel selective models).

For fixed bandwidth repeaters this feature will not allow user to make changes, so, skip this step for fixed

bandwidth models.

2. Setup desired operating gain using pFOMS. UL and DL chain are independent, so both values must be

set.

For nominal gain of the repeater these values must be set to zero.

UM-0100-0 .09 – August 2010 10

Figure 5

Figure 5 shows how to set up manual attenuation values.

UM-0100-0 .09 – August 2010 11

Status Indicators

There is an indicator panel located at the front panel of the repeater. This led panel works as a status

monitor, in order to advice different operational conditions of the repeater.

There are four leds, first one the power ON indication led, labelled “PWR”.

A Second led, labelled “STS” resumes warnings regarding critical operational conditions of the repeater.

Third and fourth led resumes operational conditions for uplink “UL” and downlink “DL” chains.

Signalling will be explained in table 1.

Operative Condition Indicator Panel

1 Start UP

2 Stationary state

3 AGC DL

4 AGC UL

5 Overload DL

6 Overload UL

Table 1

1. Start UP

Every time the repeater is plugged to AC mains (or auxiliary DC power), will start a self diagnosis and

booting sequence that lasts around 20 seconds, during this time repeater is not available for traffic, and the

reason is because an automatic antenna isolation control procedure runs in order to detect poor isolation

conditions. During this time all leds in the front panel will blink.

In case of bad isolation condition led “UL” or “DL” (depends on the path where auto-oscillation condition

was detected) will stay ON during five seconds.

2. Stationary state

Once the booting sequence is finished and under no AGC or Overload conditions only the PWR led must

keep ON.

3. AGC DL

Blinking condition indicates that AGC circuitry is active for downlink path. For further information

please read Automatic Gain Control (AGC) latter in this chapter.

UM-0100-0 .09 – August 2010 12

4. AGC UL

Blinking condition indicates that AGC circuitry is active for uplink path. For further information

please read Automatic Gain Control (AGC) latter in this chapter.

5. Overload DL

Led permanently ON indicates that Overload protection circuitry for downlink path is active.

For further information please read Overload Protection latter in this chapter.

6. Overload UL

Led permanently ON indicates that Overload protection circuitry for uplink path is active.

For further information please read Overload Protection latter in this chapter.

Automatic Gain Control (AGC)

Automatic Gain Control circuitry is intended to keep repeater’s output power at a fixed level when input

signals exceed maximum values, avoiding quality signal degradation by intermodulation generation.

When AGC is active AGC leds from UL or DL (or both) will blink, this means that signal level from donor

site (or from service area) plus repeater gain produces an output power that is above the maximum

composite output power of the repeater. This should not be considered an undesired working condition, far

from that; this is the best operating condition because you are getting the maximum composite output

power available from the repeater.

Anyway is a good practice to increase attenuation (reducing gain), until AGC led turns off, this operation

releases AGC circuitry dynamic range.

Also is a good practice to check signals from donor site to ensure that undesired signals are not being

amplified by the repeater, or even desired signal levels are not excessively high taking repeater to an

overload condition.

Overload Protection

When AGC circuit reaches its limit, the power amplifier stage is shut down to prevent harmful distortion and

potential damage to the repeater. After approximately ten seconds the system checks if overload condition

is still present, if this happens amplifiers will remain off. This cyclic check will continue until condition that

makes AGC circuitry reach its limits disappears.

Conditions that can cause AGC to reach its limits include the presence of one or more very strong

channels, a strong in-band noise source, or amplifier oscillation due to poor antenna isolation.

When overload protection lower row led from UL or DL (or both) will be ON permanently.

Laboratory Measurements

For specific parameters verification and laboratory tests, please contact factory.

Detailed procedures, recommended tests set up, and a knowledge engineering team will bring adequate

support to perform this measurements in a comfortable and safely way

.

UM-0100-0 .09 – August 2010 1

Part 2 SOFTWARE

5. Installation

The following section will describe the steps to be followed in order to install and use the pFOMS software

with your Fiplex repeater.

1. Execute the Fiplex Portable Foms installer and choose the default path “C:\program files\fiplex”.

Please do not change this location.

2. Turn on the Repeater

BE SURE THAT “TO MOBILE” AND “TO BASE” PORTS ARE PROPERLY LOADED

BE SURE THAT “TO MOBILE” AND “TO BASE” PORTS ARE PROPERLY LOADEDBE SURE THAT “TO MOBILE” AND “TO BASE” PORTS ARE PROPERLY LOADED

BE SURE THAT “TO MOBILE” AND “TO BASE” PORTS ARE PROPERLY LOADED

EITHER WITH 50 OHMS DUMMY LOADS

EITHER WITH 50 OHMS DUMMY LOADSEITHER WITH 50 OHMS DUMMY LOADS

EITHER WITH 50 OHMS DUMMY LOADS OR RADIATING SYSTEM.

OR RADIATING SYSTEM. OR RADIATING SYSTEM.

OR RADIATING SYSTEM.

3. Plug in USB cable to P50000 USB B male type connector. Repeater HW will trigger the installation of its

driver, which is a COM port emulator.

“New hardware found” advice should be noticed.

UM-0100-0 .09 – August 2010 14

4. Windows will start its hardware installation assistant, follow the steps and indicate the driver location.

Select “No, not this time”

Select “Install from a list or specific location (Advanced)

UM-0100-0 .09 – August 2010 15

Windows probably complains because this is not an official Microsoft Windows driver, click in “Continue

Anyway”

This manual suits for next models

1

Table of contents

Other Fiplex Repeater manuals