The BB-2F cabinet houses one or two MMF-302-6 modules on the internal

chassis that is part of the cabinet. Refer to cabinet installation documents for

dimensions.

INSTALLATION STEPS

1. Cabinet Mounting

In a clean, dry area, mount the backbox using the four holes provided in the

back surface of the cabinet (Figure 3).

2. Chassis Installation

The CH-6 chassis is mounted in the BB-6F cabinet. It is attached to the two

PEM studs on the back wall of the cabinet with two 8-32 hex nuts. The hex

nuts are included with the chassis (Figure 4).

FIGURE 3. TYPICAL MOUNTING HOLE LOCATIONS

C0235-00

FIGURE 4. MOUNTING THE CH-6 CHASSIS

Mount with hex nuts to PEM studs

on back of cabinet

C0239-00

The BB-2F cabinet comes with the chassis already installed, so no mounting

is necessary.

3. Module Installation

There are two methods for installing a module in the rear position of a chas-

sis. Method one is for installation of a rear module only, when no module will

be installed in front of it. Refer to Figure 5 for instructions. Method two is for

installation of a rear module when another module will be installed in the

chassis position in front of it. Refer to Figures 6a and 6b for method two. All

necessary screws and standoffs are supplied with the modules.

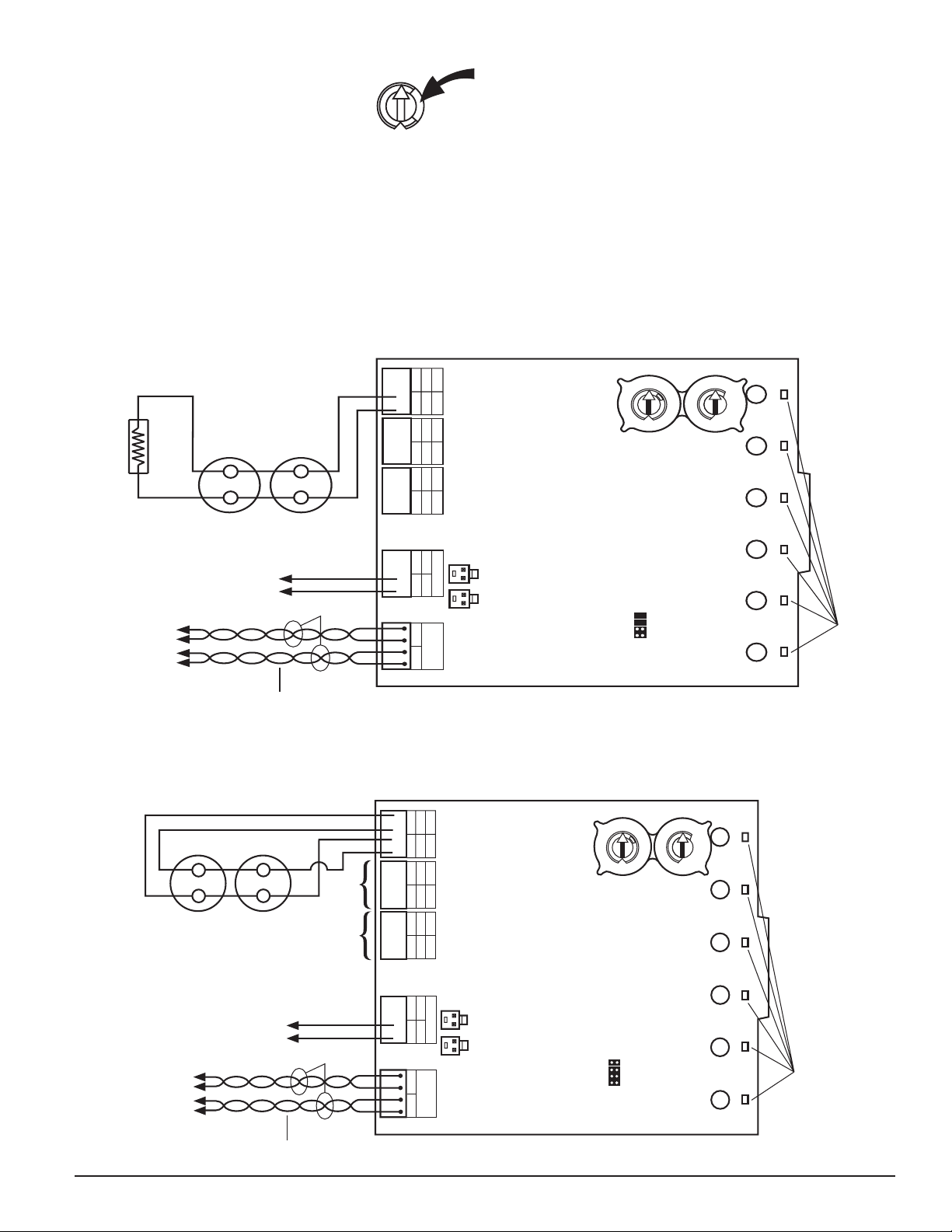

FIGURE 5. INSTALLATION OF REAR MODULE ONLY, METHOD ONE

2

3

1

C0237-00

Step 1: Insert the bottom of the MMF-302-6 module down into a

rear slot on the chassis.

Step 2: Carefully swing the upper edge of the board back towards the back of

the chassis until it touches the two standoffs.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instructions in this

manual.

The steps in Figures 6a and 6b describe and illustrate module installation

when the rear chassis position and the position in front of it will be filled.

Front position installation is possible only if the rear position is filled with

another module.

FIGURE 6A. INSTALLATION OF MMF-302-6 MODULE IN A REAR

CHASSIS POSITION, METHOD TWO

1

C0225-00

Step 1: Insert the bottom edge of the MMF-302-6 module down into a rear

slot of the chassis.

Step 2: Carefully swing the upper edge of the board towards the back of the

chassis until it touches the short standoff attached to the chassis.

Step 3: Align the long standoff with the short standoff and tighten.

FIGURE 6B. INSTALLATION OF MMF-302-6 MODULE IN FRONT CHASSIS

POSITION

2

3

1

C0226-00

Step 1: Insert the bottom edge of the MMF-302-6 module down into a front

slot of the chassis.

Step 2: Carefully swing the upper edge of the board towards the back of the

chassis until it touches the 1.25˝ (32 mm) standoffs installed on the

rear module.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instructions in this

manual.

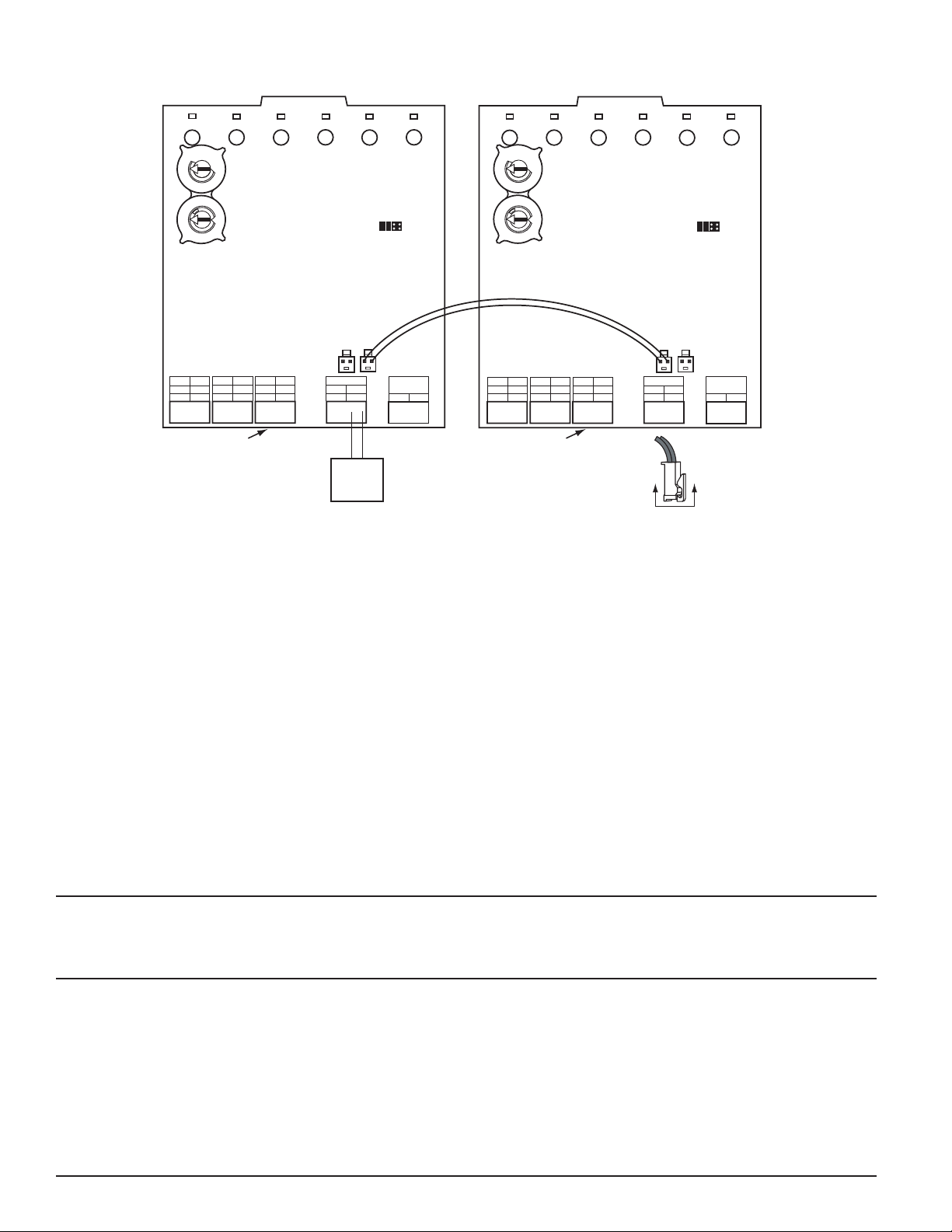

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations.

1. Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2. All wiring to the MMF-302-6 is done via terminal blocks. In order to

properly make electrical connections strip approximately 0.25˝ of insu-

lation from the end of wire, sliding the bare end of the wire under the

clamping plate screw.

3. Set the address on the modules per the job drawing. Use the rotary code

switches to set the address of the first module (between 01 and 154).

In Class B operation, the remaining modules are automatically assigned to the

next five higher addresses. For example, if the base address switch is set to 28,

the next five modules will be addressed to 29, 30, 31, 32 and 33.

The module is shipped in Class B position, remove shunts for Class A. When

operating in Class A, alternate modules are paired together (+0/+1, +2/+3,

+4/+5), resulting in a total of three modules. For example, if the base ad-

dress switch is set to 28, then 30 and 32 will be automatically assigned to the

modules while 29, 31 and 33 are available to be used for other modules on the

SLC. For Class A and B operation, DO NOT set the lowest address above 154,

as the other modules will be assigned to nonexistent addresses.

NOTE: Some panels support extended addressing. In order to set the module

above address 99 on compatible systems, carefully remove the stop on the

upper rotary switch (see Figure 7). If the panel does not support extended ad-

dressing, do not set the lowest address above 94.

2 I56-1900-023

7/1/2022