Fire Pants Fabrication Kelpie V1.2 Manual

2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 Introduction 3

2 Specifications 3

3 Unpacking 4

4 Setting Up 5

3

1. INTRODUCTION

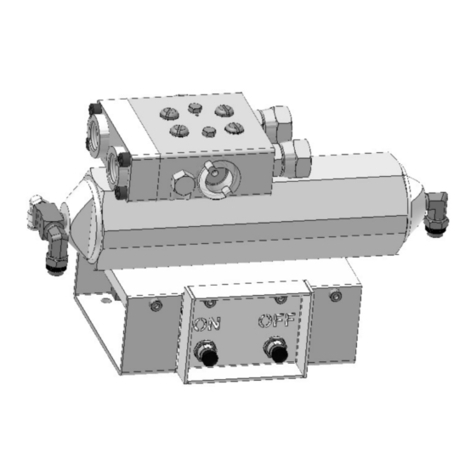

The Kelpie, named after the quintessential Australian working dog.

Known for being fast, reliable, and working hard all day, this forge is no

different.

With a bolt together ‘flat packed’ design, they are easy to assemble with

no welding required (but is recommended to retain the burner).

Features include:

Multiple burner configurations available.

No risk of breathing fibres from ceramic blanket insulation.

Through design to allow long work to be heated easily.

Multiple forges can be joined together if a longer forge is

required.

Allowance for extended sliding work holder for extra-long

support.

Re-lining is quick and easy,

Rated for 1400°c continuous.

Australian Designed and Built.

NOTE: PLEASE DO NOT OPERATE THE KELPIE FORGE UNTIL YOU HAVE

READ THESE INSTRUCTIONS AND ARE FAMILIAR WITH ITS CONTROLS.

THE KELPIE FORGE IS INTENDED FOR USE ONLY BY TRAINED

PERSONNEL.

ENSURE ALL BURNERS AND GAS COMPONENTS ARE COMPLIANT WITH

LOCAL STANDARDS, AND ARE APPROVED FOR USE. ALL FITTINGS AND

HOSES SHOULD BE TESTED BEFORE, DURING, AND AFTER EACH USE. DO

NOT USE IF THE EQUIPMENT IS NOT IN GOOD WORKING ORDER, OR YOU

ARE NOT FIT FOR WORK.

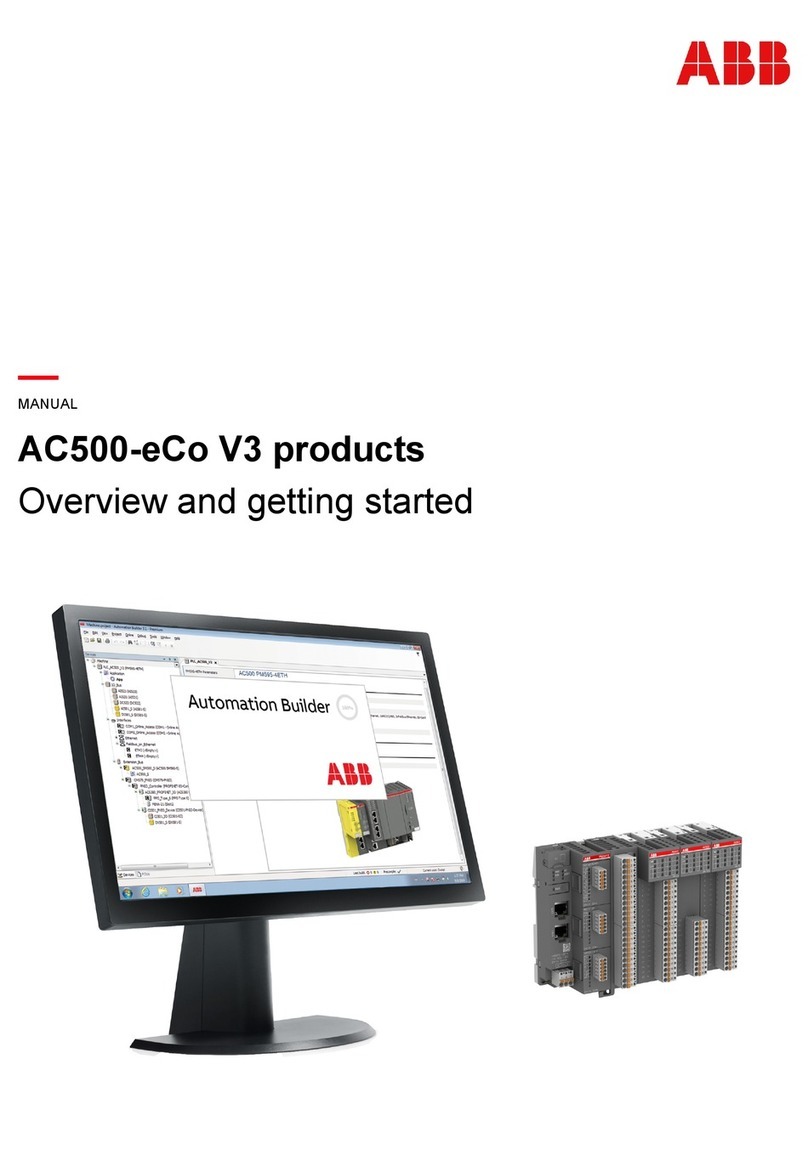

2. SPECIFICATIONS

Dimension of

forge (without

work rest/burner)

230 x 238 x 315

(LxWxH)

Weight

Approx. 25kg

Electrical

Specifications

N/A

Internal volume

2117cc / 129 CI

Environment

Must be used in

ventilated area.

Do not expose to

water.

4

3. UNPACKING

Carefully inspect the exterior of the packing box. Any visible damage

should immediately be reported to the Fire Pants Fabrication. Remove all

packing documents from the interior of the box and file in your records.

Remove the shipping box, the foam packaging material, and the Kelpie

Forge. Open the top flaps of the packing box to remove the Kelpie Forge

from the base of the box. Carefully remove all components from box,

using proper lifting techniques, and place it on a stable bench top.

Visually check the Kelpie Forge components to ensure that no damage

occurred during shipping.

IMPORTANT: THE BOLTS AND WASHERS SUPPLIED WITH THE KELPIE

FORGE MUST BE USED.

5

4. SETTING UP

Step

1

Unpack everything and find bag

of bolts (Not Shown).

Please note. All these parts do

get checked, but sometimes a

small piece of slag can be

missed. If some slag is found

on an edge, it is easily removed

with a hand file or a grinder.

Step

2

Start by inserting the 3 x

bottom plates into the lower

notches in the side plate. The

order of these is not important

at this stage.

Then insert the Front and rear

plates (not shown in earlier

picture), then the other side

plate.

6

Step

3

Insert 8 x flange nuts into the

bottom plates, and insert a

bolt & washer through the side

plate and secure loosely.

It is important to leave these

loose at this stage.

Step

4

Place your Insulating fire brick

(x2) onto the base, and slide

back and forth a couple of

times to mark the position of

the nuts on the brick.

The brick should be a snug fit,

but should still slide between

the side plates. If it does not,

loosen the bolts from step 3 a

little more.

Step

5

Using a coarse file, and the

markings from step 4, cut a

5mm deep groove to allow for

clearance over the nuts in the

base.

The bricks are soft, and can be

cut with a regular metal file.

7

Step

6

Place the 2 modified bricks on

the base, and use 4x more

bricks to build up the forge.

Step

7

Place the burner plate in the

desired position.

Place 8x flange nuts into the

side plates and gently tap with

a small hammer to seat them

into the top fire brick.

Fasten the work rest to the

work rest support (x2) using

the supplied counter sunk cap

screws and flange nuts, and a

5mm allen key. Then insert into

the allocated slots in the

front and rear plates.

At this point, use a 10mm

spanner to tighten All (x16)

bolts, being careful to ensure

the nuts are centralised in

their correct position.

Note, the Burner plate can be

positioned in any of the

positions, depending on the

intended work. Once the burner

hole has been drilled, if the

burner needs to be moved, any

bricks that were modified to

accept the burner should be

replaced to prevent damage to

the forge.

8

Step

8

Once the burner position has

been established, use a hole

saw (a regular hole saw for

cutting wood / metal can be

used).

Step

9

Using 2 different sizes will

allow you to create a step for

the burner nozzle to be

supported by the brick and

provide a better seal.

In this case, I used a 45mm and

a 38mm hole saw. The step is

approx. 45mm deep.

TIP: make the initial hole using

the larger hole saw first, using

the burner plate as a guide.

Then drill through with the

smaller saw. This will help

centralise the second hole.

Step

10

Place burner in hole, it should

be a firm fit.

It is recommended to weld the

burner in place to ensure it is

secure.

9

Please follow your burner manufactures assembly, inspection,

starting, running, and shutdown procedures.

Your forge is now ready for use.

Congratulations on your purchase, and thank you for supporting a

local business. Please check in on www.firepantsfab.com.au

regularly to keep up to date with any improvements, and new

tooling on offer.

Popular Industrial Equipment manuals by other brands

Genmitsu

Genmitsu Jinsoku LE-1620 user manual

rotork

rotork IQ Series Instructions for Safe Use, Installation, and Maintenance

ABB

ABB HT609939 Operation manual

Southern States

Southern States ICS Installation and instruction manual

ABB

ABB AC500-eCo V3 manual

Carlisle

Carlisle Ransburg TurboDisk A11376 Service manual