SMC Networks MGZ Series User manual

Other SMC Networks Industrial Equipment manuals

SMC Networks

SMC Networks EX600-ED Series User manual

SMC Networks

SMC Networks CY3B Series User manual

SMC Networks

SMC Networks KFG2 Series User manual

SMC Networks

SMC Networks CXS Series User manual

SMC Networks

SMC Networks MHK2-12 Series User manual

SMC Networks

SMC Networks IBG Series User manual

SMC Networks

SMC Networks EX600 Series User manual

SMC Networks

SMC Networks JMHZ2-16D-X7400B-CRX User manual

SMC Networks

SMC Networks MY3A Series User manual

SMC Networks

SMC Networks ZXPE5 011P Series User manual

SMC Networks

SMC Networks EX12 SCS Series User manual

SMC Networks

SMC Networks LEY series User manual

SMC Networks

SMC Networks INR-244-757 User manual

SMC Networks

SMC Networks AW20 Series Quick start guide

SMC Networks

SMC Networks MSQ Series Manual

SMC Networks

SMC Networks LFE series User manual

SMC Networks

SMC Networks SYJ3000 User manual

SMC Networks

SMC Networks CYP Series Instruction manual

SMC Networks

SMC Networks SGC Series User manual

SMC Networks

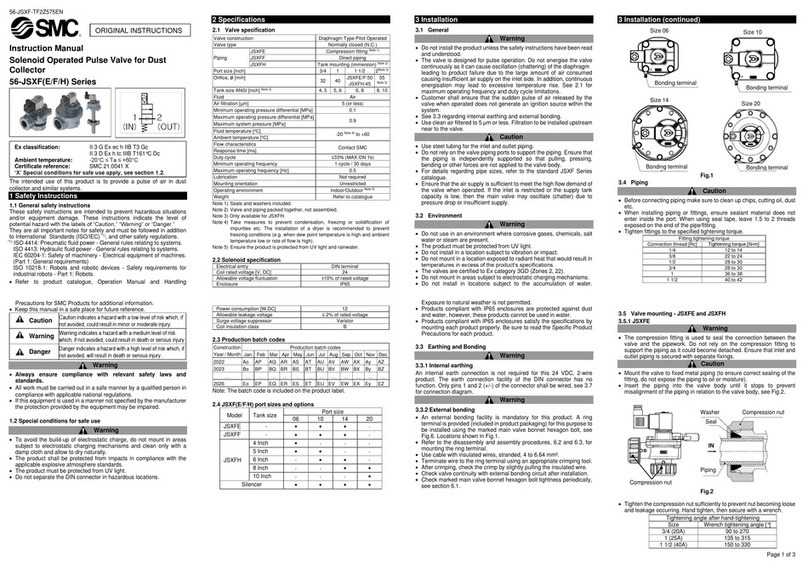

SMC Networks JSXFE Series User manual