Fire Sentry FSXP User manual

____________________________________________________________________________________________________________________

Fire Sentry Corporation Document No. 6178-007 - Rev. F ©Copyright 2012 All Rights Reserved

Fire Sentry Corporation

23311 La Palma Avenue

Yorba Linda, California 92887

Telephone: 714-694-2700

Fax: 714-694-2701

www.firesentry.com

FS17X WideBand IR

TM

Multi-Spectral Infrared Electro-Optical

Digital WideBand IR Sensor

Radiant Energy Fire and Flame Detector

FSX

P

TM

P

Fire and Flame Detectors

MODEL FS17X

TM

Installation Guide

and

Operating Manual

Fire Sentry Corporation Document No. 6178-007 - Rev. F ©Copyright 2012 All Rights Reserved

Fire Sentry Corporation

23311 La Palma Avenue

Yorba Linda, California 92887

Tel: (714) 694-2700

Fax: (714) 694-2701

www.firesentry.com

Read and understand this manual before

installing or operating equipment.

No part of this document may be copied or reproduced without the express

written permission of Fire Sentry Corporation.

This manual is subject to change without notice.

ACCTTL, ALERT-1, ALARM-2, ALERT-1: ALARM 2, ALERT-1: ALARM-2, ATAG, Clean

Room Sentry, COP-i, Complete Optical Path Integrity, CM1, CM1-A, DartLogic, FireLogic, Fire

Signature Analysis, FireBusI, FireBusII, FirePic, FirePicII, FirePicIII, FirePix, FirePicture, FSC,

Fire Sentry Corporation, Fire Sentry Corp., FSX, All FSX Nomenclature Variations (such as:

FS2, FS2X, FS2X, FS3, FS3X, FS3X, FS4, FS4X, FS4X, FS5, FS5X, FS5X, FS6, FS6X,

FS6X, FS7, FS7X, FS7X, FS8, FS8X, FS8X, FS9, FS9X, FS9X, FS10X, FS10X, FS11,

FS11X, FS11X, FS12, FS12X, FS12X, FS14, FS14X, FS14X, FS15, FS15X, FS15X, FS16,

FS16X, FS16X, FS17, FS17X, FS17X, FS18, FS18X, FS18X, FS19, FS19X, FS19X, FS20,

FS20X, FS20X, FS24, FS24X, FS24X, FS24XN, FS24XN, FS26, FS26X, FS26X, FS26XN,

FS26XN, FS7-2173-2RP, FS System 7, FS System 10, FS7-2173, FS7-2173-RP, FS2000, FS

System 2000, High Speed Flame & Surveillance Detector, Multi-Spectrum QuadBand Triple

IR, Multi-Spectrum TriBand, Multi-Spectrum Tri-Band, Near Band Infrared, Near Band IR,

NearBand IR, QuadBand IR, Room Sentry, RS, RS2, SM2, SM3, SS, SS2, SS2X, SS2-A,

SS3, SS3-A, SS3X, SS4, SS4-A, SS4X, SnapShot, SLR-BIT, SuperBus, SuperSentry, System

2000, Tri-Mode Plot, QuadBand Triple IR Plus, TriBand, Tri-Band, “FS & FSC triangle logo’s”,

WBIR, Wide Band Infrared, WideBand IR, Wide Band IR

are Trademarks of Fire Sentry Corporation, Yorba Linda, California.

©Copyright 1998 - 2012 by Fire Sentry Corporation

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

U

TABLE OF CONTENTS

U

U

PAGE

TU

SECTION 1: INTRODUCTION .................................................................................................................................... 1

TU

1.1

UT

TU

Product Overview .............................................................................................................................. 1

1.2 Detector Technical Specifications ..................................................................................................... 2

1.2.1 Mechanical Specifications ...................................................................................................... 2

TU

1.2.2 Electrical Specifications .......................................................................................................... 2

1.2.3 Environmental Specifications ................................................................................................. 2

1.2.4 Performance Specifications ................................................................................................... 2

1.2.5 Area Classification .................................................................................................................. 2

1.3 Features & Benefits ........................................................................................................................... 3

1.4 Applications ....................................................................................................................................... 3

SECTION 2: INSTALLATION ...................................................................................................................................... 4

2.1 Mounting Instructions ......................................................................................................................... 4

2.2 Detector Connections ........................................................................................................................ 5

2.3 Installation Practices .......................................................................................................................... 8

2.4 Start-Up and Commissioning ............................................................................................................. 8

U

SECTION 3: OPERATION .......................................................................................................................................... 11

U

3.1 Principle of Operation ....................................................................................................................... 11

3.2 LED Status Indicators ....................................................................................................................... 12

3.3 Normal Operation ............................................................................................................................. 12

3.4 ALARM ............................................................................................................................................. 12

3.5 Fault................................................................................................................................................... 13

3.6 Maintenance ..................................................................................................................................... 14

U

SECTION 4: APPENDIX ............................................................................................................................................. 15

U

4.1 Warranty Information ........................................................................................................................ 15

4.2 Product Variations ............................................................................................................................ 16

4.3 Test Lamps ....................................................................................................................................... 18

4.4 Drawings ........................................................................................................................................... 19

4.4.1 Outline and Dimensions ........................................................................................................ 19

4.4.2 Wiring and Terminal Connections ......................................................................................... 20

4.4.3 Detector Label Drawings ....................................................................................................... 24

U

INDEX ......................................................................................................................................................................... 25

U

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 1

SECTION 1: INTRODUCTION

1.1 Product Overview

The Model FS17X™Electro-Optical Multi-Spectral Detector

senses the WideBand Infrared™ (IR) radiant energy of

blackbody particulate and molecular emissions generated by

both hydrocarbon and non-

hydrocarbon flames and fires.

Additionally, the Detector’s sensor array senses Visible Band

(VIS) and NearBand IR to further discriminate against false fire

sources. The FS17X WideBand Multi-Spectral sensor array

spans 0.4 to 3.0 microns and features a wide 120° field of

view.

The Model FS17X Multi-Spectral Fire and Flame Detector

is Factory Mutual approved for use in Class

I,

Division

2

(

Zone

2) Hazardous Locations (see Figure 1-1).

The FS17X Detector available in a polypropylene housing, is

rated IP67, dust tight, leak-proof and water tight to 1 meter.

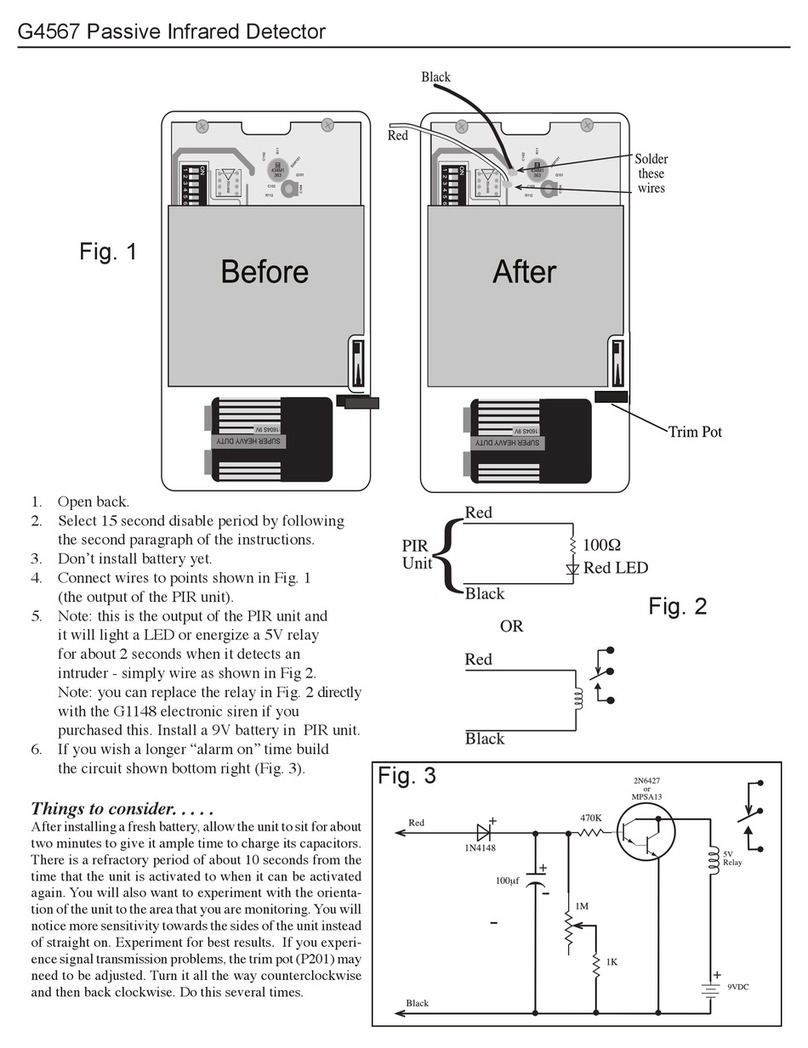

Figure 1-1

FS17X Detector

FS17X Connections

The Model FS17X uses an eight (8) conductor Standard Cable or an optional eight (8) conductor Cable with a

Phoenix Connector for inputs and outputs. Every FS17X has the following six (6) connections:

1. +24 Vdc & DC Return

2. Fault N.C. (Normally Closed) & COM (COMmon)

3. ALARM N.O. (Normally Open)¹ & COM (COMmon)

There are 2 options for the FS17X-S Detector:

S1. Quick Response - Fireball N.O. (Normally Open)¹ & COM (COMmon) or

S2. RS-485 Data A & Data B

There are 4 options for the FS17X-G Detector:

G1. RS-485 Data A & Data B or

G2. Quick Response - Fireball N.O. (Normally Open)¹ & COM (COMmon) or

G3. Fire Verification N.O. (Normally Open)¹ & COM (COMmon) or

G2. Current sinking 4-20mA (+) & (-)

¹ Optional N.C. (Normally Closed) Relay Contacts are available.

FS17X Configurations

The Model FSX has several factory configurations to choose from:

Auxiliary: Alert (-R) or Fireball Quick Response (-S or -G) or Fire Verification (-G)

Fire Verification Time: 5 or 10 second

Relay Outputs: Latching or Non-latching

Detection Sensitivity: High or Low

Digital Communication Address: 0 to 32

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 2

1.2 Detector Technical Specifications

1.2.1 Mechanical Specifications

Housing Material: Polypropylene

Physical Dimensions: 4.7 in. Height

3.2 in. Width

1.7 in. Depth

Weight: 1 lbs. 4oz. With standard 20 ft cable (0.57 kg)

Enclosure Rating: IP66 / IP67

1.2.2 Electrical Specifications

Input Voltage Range: 18 Vdc to 32 Vdc

Normal Operation Current: 47 mA (nominal)

Max Fire ALARM Current: 88 mA (maximum)

Relay Contact Rating: 1 Amp @ 24 Vdc resistive

Analog Current Output: 400 Ohms Max Load (loop resistance)

0.0 to 20.0 mA (Non-Isolated, Current Sinking)

0.0 mA (<0.6 mA) = Detector Fault

2.0 mA (±0.6 mA) = Dirty Detector Window Lens

4.0 mA (±0.6 mA) = Normal, Safe (no Fault, no Fire)

20.0 mA (±0.6 mA) = Fireball or Fire ALARM

20.0 mA (±0.6 mA) = Fire ALARM or Verified Fire ALARM

Cable: Eight (8) Conductor 24 AWG or fourteen (14) Conductor 24 AWG

Maximum Cable Length = 1,400 feet

1.2.3 Environmental Specifications

Operating Temperature: +32°F to +158°F (0°C to +70°C)

Operating Humidity Range: 0 to 95% RH,

100% RH condensing for short periods of time

Storage Temperature: -13°F to +170°F (-25°C to 77°C)

1.2.4 Performance SpecificationsPPPP

Field of View: 120°Horizontal and Vertical (conical)

Detector Sensitivity:

High One (1) sq. ft. heptane fire at 30 feet (± 60°from axis)

Low One (1) sq. ft. heptane fire at 15 feet (± 60°from axis)

Speed of Response: Less than 5 seconds (typical)

Quick Response: Less than 0.5 seconds to “fireball” type fires

Spectral Sensitivity:

VIS 0.4 to 0.7 micron wavelengths

NearBand IR 0.7 to 1.1 micron wavelengths

WideBand IR 1.1 to 3.0 micron wavelengths

1.2.5 Area Classifications

Class

I

, Division 2 Class

I

, Zone 2

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 3

1.3 Features and Benefits

Our Patented WideBand IR Detection Technology for detecting both hydrocarbon and non-hydrocarbon

fires in industrial environmental conditions.

Uses the proven Quantum WideBand IR sensors as the highly successful Model FS7 Detectors, which

have over 25,000 successful installations in Semiconductor Cleanroom applications worldwide since 1996.

False Alarm Immunity due to the patented software signal processing algorithms and due to full WideBand

Spectrum sensor array with WideBand IR sensor wth twin Visible sensors, and twin NearBand IR sensors.

Twin highly integrated Microprocessors reduce the number of discrete components, provides larger

software algorithm programming and memory capacity, and provides redundant processor self-checking.

Lower price Detector replacement for Model FS7 applications.

Low power consumption, 24Vdc, 47mA nominal (1.13 W), 88mA max ALARM current (2.11 W).

Multiple Detector output options for a variety of industrial applications.

Up to 32 unique digital communication addresses when RS-485 communication is used.

Optional RS-485 output available (FireBus

II

protocol) for use with the FS2100X System CPX Din Rail

Panels and the FS7-130-SX Controller.

Digitally stepped 4-20mA (current sinking) output (optional).

Latching or non-latching mechanical (dry contacts) relay outputs (same reliable relays as used in the

Model FS7-2173-2RP Detectors).

Class

I

, Zone 2 polypropylene housing (sames as proven Model FS7 housing) for Clean Room,

Semiconductor Wet Bench and Wet Chemical applications.

Three Separate Bright LEDs (Red, Yellow, Blue) for quick, easy identification of ALARM, Fault and Normal

status for semiconductor clean room environments.

Our Windows® based PC Software for remote FSX diagnostics and data retrieval.

Designed, Manufactured, Tested, and Patented by Fire Sentry Corporation (30 years of proven fire / flame

detection product excellence worldwide).

1.4 Applications

The applications for the FS17X Fire and Flame Detectors include:

Clean Rooms Gas Cabinets Hydrogen Gas Cabinets

Hydrogen Plants Hydrogen Storage Semiconductor Wet Benches

Semiconductor Wet Chemicals Silane Gas Cabinets Silane Gas Manufacturing

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 4

SECTION 2: INSTALLATION

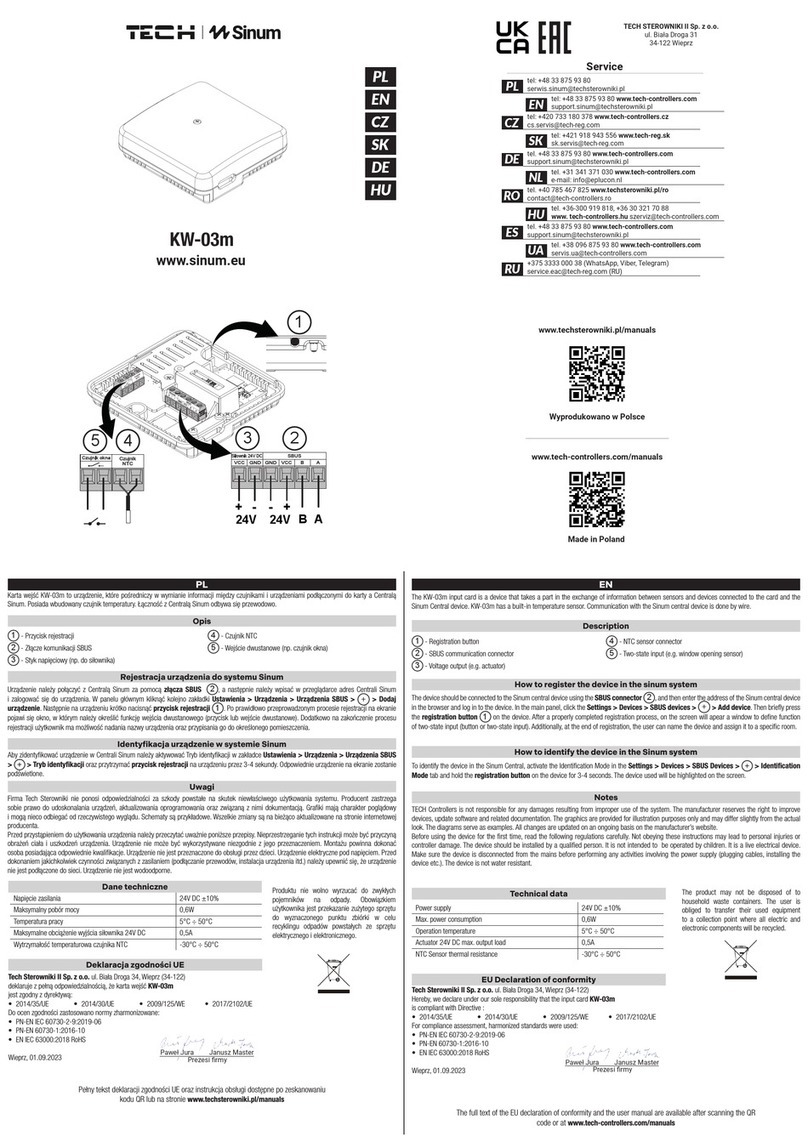

2.1 Mounting Instructions

Consider the following guidelines when selecting Detector location:

1. As with all flame and fire Detectors, avoid areas that contain radiant energy sources (such as radiant

heaters, high intensity lamps, flare-stacks, etc.) in close proximity to the Detector’s field of view.

2. Detectors should not be mounted outdoors. Additionally, for applications outside of an enclosed wet

bench/tool, use a minimum thirty degree (30°) downward angle with the recommended swivel mount

(Model SM-17).

3. Make sure the Detector has a clear, unobstructed view of the fire threat area. Physical obstructions

between a fire and the Detector may cause the fire to be undetected.

4. The rugged, stable, and calibrated Polypropylene Swivel Mount (SM17) is designed specifically for the

FS17X Detector housings. The mounting clip attaches to the back of the FS17X Detector. The

mounting plate, with the four (4) screw holes, is used for mounting to a solid surface. Each

adjustment increment along an axis is calibrated to 10°. For single axis adjustments, the center

section does not need to be installed.

5. Avoid mounting the Detectors in areas where temperatures exceeds the specified operating

temperature range (see Section 1.2.3).

Figure 2-1

Model SM17 Swivel Mount

There are no serviceable parts inside the Model FS17X Detector housing. If the Detector housing is opened

up or tampered with, all warranties are voided

Note: Do not attempt to modify the Model FS17X Detector as this voids all warranties.

CAUTION: Disconnect electrical power before unscrewing the Housing Lid.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 5

2.2 Detector Connections

The FS17X-G and FS17X-S Detectors have eight (8) connections available with the Standard Cable. These

connections are subject to the Output Configuration of the Detector at the time the order is placed. These

Output Configurations are:

#1 RS-485 FireBus

II

II II

II

(FS17X-G & FS17X-S)

#2 Quick Response Fireball Relay (FS17X-G & FS17X-S)

#3 Fire Verification Relay (FS17X-G & FS17X-S)

#4 Current sinking 4-20mA (FS17X-G & FS17X-S)

Color Code for

Standard Cable

Output

Configuration #1

Output

Configuration #2

Output

Configuration #3

Output

Configuration #4

Red

+24 Vdc +24 Vdc +24 Vdc +24 Vdc

Black

DC Return DC Return DC Return DC Return

Green

FireBusII

Data A RS-485

Quick Response

Fireball Relay

N.O. (Normally Open)

Fire Verification Relay

N.O. (Normally Open)

Current Sinking

4-20mA (+)

White

FireBusII

Data B RS-485

Quick Response

Fireball Relay

COM (COMmon)

Fire Verification Relay

COM (COMmon)

Current Sinking

4-20mA (-)

Orange

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Blue

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Yellow

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

Brown

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

The following Relays have a Normally Closed (N.C.) option: Fire ALARM, Quick Response Fireball, and Fire

Verification.

1. Make sure that the external 24 Vdc electrical power is turned

U

OFF

U

before connecting the Detector.

2. Avoid wire splices. However, if wire splices are required, all splices should be soldered and properly

insulated. The use of good wiring practices will simplify installation, improve reliability and facilitate

maintenance.

CAUTION:

Follow static protection procedures while handling the connectors and the

wiring of the FS17X Detector. Use a wrist strap connected to earth ground.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 6

Detector Connections (

continued

)

The FS17X-G and FS17X-S Detectors have eight (8) connections available with the Phoenix Connector.

These connections are subject to the Output Configuration of the Detector at the time the order is placed.

These Output Configurations are:

#1 RS-485 FireBus

II

II II

II

(FS17X-G & FS17X-S)

#2 Quick Response Fireball Relay (FS17X-G & FS17X-S)

#3 Fire Verification Relay (FS17X-G & FS17X-S)

#4 Current sinking 4-20mA (FS17X-G & FS17X-S)

Color Code for

Cable with Phoenix

Connector

Output

Configuration #1

Output

Configuration #2

Output

Configuration #3

Output

Configuration #4

Brown

+24 Vdc +24 Vdc +24 Vdc +24 Vdc

Blue

DC Return DC Return DC Return DC Return

Gray

FireBusII

Data A RS-485

Quick Response

Fireball Relay

N.O. (Normally Open)

Fire Verification Relay

N.O. (Normally Open)

Current Sinking

4-20mA (+)

Violet

FireBusII

Data B RS-485

Quick Response

Fireball Relay

COM (COMmon)

Fire Verification Relay

COM (COMmon)

Current Sinking

4-20mA (-)

Red

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Fire ALARM Relay

N.O. (Normally Open)

Yellow

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Fire ALARM Relay

COM (COMmon)

Green

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

Fault Relay N.C.

(Normally Closed)

White

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

Fault Relay

COM (COMmon)

The following Relays have a Normally Closed (N.C.) option: Fire ALARM, Quick Response Fireball, and Fire

Verification.

1. Make sure that the external 24 Vdc electrical power is turned

U

OFF

U

before connecting the Detector.

2. Avoid wire splices. However, if wire splices are required, all splices should be soldered and properly

insulated. The use of good wiring practices will simplify installation, improve reliability and facilitate

maintenance.

CAUTION:

Follow static protection procedures while handling the connectors and the

wiring of the FS17X Detector. Use a wrist strap connected to earth ground.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 7

Detector Connections (

continued

)

The The FS17X-R Detector has fourteen (14) connections available. These connections are:

Color Code Description

Red 24 VDC (+) Supply

Black 24 VDC (-) Return

Green FireBusII RS-485 Digital Data A Signal

White FireBusII RS-485 Digital Data B Signal

Gray Fault Relay Terminal A, Contact to B during Normal Operation

Purple Fault Relay Terminal B, Contact to A during Normal Operation

Brown Fire ALARM Relay Terminal A

Blue Fire ALARM Relay Terminal B

Brown / White Fire ALARM Relay Terminal A loop-through

Blue / White Fire ALARM Relay Terminal B loop-through

Yellow Fire ALERT Relay Terminal A

Orange Fire ALERT Relay Terminal B

Yellow / Black Fire ALERT Relay Terminal A loop-through

Orange / Black

Fire ALERT Relay Terminal B loop-through

1. Make sure that the external 24 Vdc electrical power is turned

U

OFF

U

before connecting the Detector.

2. Avoid wire splices. However, if wire splices are required, all splices should be soldered and properly

insulated. The use of good wiring practices will simplify installation, improve reliability and facilitate

maintenance.

CAUTION:

Follow static protection procedures while handling the connectors and the

wiring of the FS17X Detector. Use a wrist strap connected to earth ground.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 8

2.3 Installation Practices

For installations in a Hazardous Classified Area, consult the National Electric Code Handbook, Articles 500

through 517 for the proper installation practices. For locations outside of the United States, observe local

and/or regional regulations.

BEFORE APPLYING 24 Vdc ELECTRICAL POWER TO THE DETECTOR, MAKE SURE

U

:

1. Wire connections are correct (Section 2.2). Each wire must be stripped properly to the correct length,

loose wire strands must be removed and each wire must be securely and firmly screwed clockwise in

the connector.

2. If using the Teflon Sleeve, ensure a proper sleeve seal at the bulkhead, (appropriate for the area

classification), has been installed and

U

all measures to prevent moisture from entering the

Detector housing have been taken

U

.

3. The FS17X Detector is securely mounted and has an unobstructed view of the area of coverage

(Section 2.1).

4. The FS17X Detector window is unobstructed and clean.

The FS17X Detector is now ready for Power-Up. On Power-Up, the Fault Relay will change state and the

three front red, blue, and yellow LED’s will flash in a clockwise circular motion signifying the

microprocessors are successfully checking out the sensors and electronics in the Detector Module.

2.4 Start-Up and Commissioning

ATTENTION: FSX Power-Up – After the application of 24 Vdc electrical power or after resetting the FS17X

Detector, a Power-On Self-Test (POST) will be performed automatically. During this time

(approximately 10 seconds) the detector will sequence in a clockwise circular motion through the its

LED’s several times. Wait a mimimum of thirty (30) seconds after the POST is completed to allow

the Detector’s sensors to normalize to the spectral background conditions. Count four (4) Blue LED

flashes to be sure the minmum amount of time has passed before testing the Detector’s response

with a test lamp (TL-2055X or TL-1055X) or a test fire.

FSX Detector Testing - As with any intelligent flame and fire Detector, please wait a minimum of

thirty (30) seconds between tests (i.e., FSX test lamp, butane lighter, or test fires) to allow the

Detector’s sensors to normalize to the spectral background conditions.

During Start-Up and Commissioning, DISABLE all outputs from the Detector to any control panels or control

devices. After the Detector(s) is powered, as with all flame and fire Detectors, conduct an external Detector

test “end to end”. Using our external FSX hand-held test lamp ensures that the FS17X Detector has a clear

unobstructed view of the threat area and the Detector is aimed properly at the fire threat area.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 9

Start-Up and Commissioning (

continued

)

Note: As with

U

all

U

optical fire and flame Detectors, perform a fully functional "end to end" test of the

Detector since the optical path to the fire threat may be obstructed or the detector’s mount

may be damaged (see Section 3.6).

Note: In order to test the full functionality and operational readiness of

U

any

U

fire or flame Detector

"end to end", without starting a real fire (which is not permitted in hazardous areas), it is

necessary to test fire and flame detector(s) with an external test lamp.

Using a test lamp is the

U

only

U

non-hazardous and safe method to test any flame or fire

Detector’s sensors, internal electronics and its alarm activation software, viewing window lens

cleanliness, terminal wiring integrity, actual relay activation, and the proper functionality of

any other outputs that are used. Also, since most Detectors are installed in a fire protection

system, this is the only method to test the complete fire protection system, ensuring all the

system wiring and cabling and system control panel(s) are properly installed.

Additionally, using an external test lamp eliminates the following Detector conditions:

1. The fire or flame Detector(s)' viewing lens being covered up (such as paint, paint overspray,

paint masking material, plastic coverings left by cleaning persons, hanging garments, etc.),

2. Improperly positioned and orientated Detector (or defective or loose mount) for coverage of

the threat area,

3. Partial or full blockage of the Detector's line of sight by one or more objects (i.e., recently

installed air ducts or pipes, storage boxes, vehicles, etc.) such that the fire threat area is

not fully protected. Since all optical fire and flame Detectors are line-of-sight devices, they

must be properly positioned and oriented with an unobstructed view of the fire threat area

so that they can detect fires.

To test the full functionality of a FSX Detector, use either the Model TL1055X or TL2055X Test

Lamp in the manner prescribed in this Instruction Manual.

The TL-1055X and the TL-2055X are the ONLY Test Lamps that will activate the FSX Detectors.

Additionally, do not use these Test Lamps to activate other Fire Sentry Detectors such as the

Models SS2 or SS4 (nor any other conventional fire and flame detectors). Do not use other

Fire Sentry Test Lamps to test the FSX Detectors.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 10

Start-Up and Commissioning (

continued

)

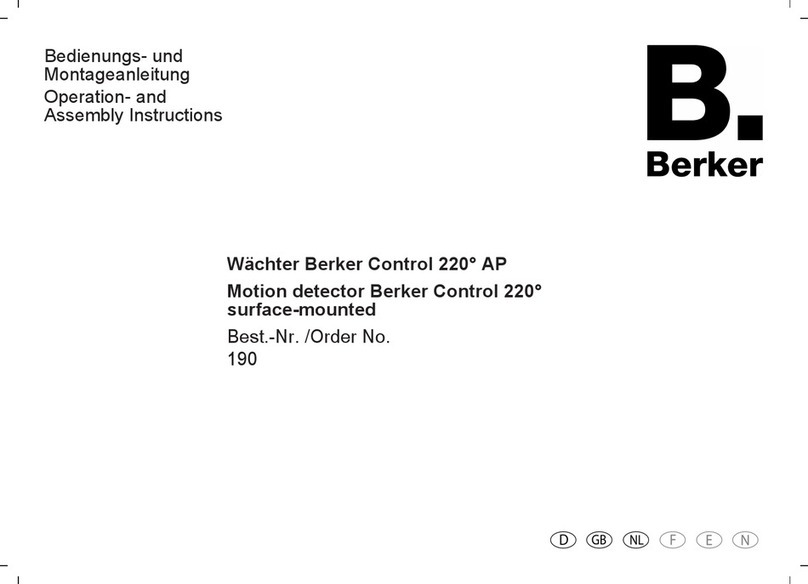

Figure 2-8

TL-1055X Hand Held Test Lamp (NEMA 1)

Figure 2-9

TL-2055X Hand Held Test Lamp for Hazardous Areas

FM, cFM, FM-ATEX Approved

Remember to disable the Detector outputs, as a full functional test includes activating the alarm outputs. A

FSX Fire Sentry Test Lamp must be used for this test (Section 4.3). Point the Test Lamp directly at the front

of the Detector (on axis as much as possible, within a distance of 1 to 25 feet). Activate the Test Lamp by

pressing and holding its pushbutton. While watching the red ALARM LED on the face of the Detector, slowly

move the Test Lamp’s boresight to ensure the Detector receives its full intensity. (

U

NOTE: Practicing this

technique may help to optimize testing of the FSX Detectors

U

). (Sections 3.6 and 4.3). The Detector’s

ALARM LED will illuminate, usually within three (3) to ten (10) seconds. Also, the ALARM Relay outputs will

activate and the 4-20 mA analog output will increase to 20 mA (±0.6 mA).

If the Detector does not respond within ten (10) seconds, do the following:

1. Wait thirty (30) seconds before performing another test.

2. Check the Distance: verify that the testing distance is between one (1) and fifteen (15) feet from

the FSX Detector(s).

3. Check Aiming Accuracy: verify that the proper testing technique (as described above) is followed.

4. Make sure the Test Lamp is either a Model TL-2055X or TL1055X Test Lamp.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 11

SECTION 3: OPERATION

3.1 Principle of Operation

Fire Sentry Corporation’s (line of Multi-Spectral and MultiBand™Infrared Fire and Flame Detectors are

sophisticated, state of the art, electro-optical digital radiant energy Detectors that sense the wideband radiant

energy emitted by fire’s combustion processes that include flames’ molecular emissions and hot particulate

blackbody emissions. Radiant Energy Fire Detectors respond much faster to flames and fires at a longer

distance than other types of conventional photoelectric and ionization smoke and heat detectors because a

fire’s emitted radiant energy travels at the speed of light. Fast response is critical for detecting flaming fires in

time to successfully activate suppression or activate other fire responses such as closing fire doors. Seconds

can make the difference between suppressing a small fire with little or no damage or having a disastrous fire

that overwhelms a suppression system.

Infrared (IR) consists of spectral wavelengths longer than the color Red. For the FS17X Detector, the IR

spectral range for fire detection, which a large portion of the spectrum is invisible to the human eye, is from

approximately 400 to 3000 nanometers (0.4 to 3.0 microns). Fire Sentry Corporation’s Detectors sense and

measure the radiant energy generated by a fire at the speed of light using high speed infrared quantum

sensors for its IR detectors.

Fire Sentry Corporation’s patented FSX Fire Detectors also use two additional spectral regions, the Visible

Band, that spans from about 400 to 700 nanometers (0.4 to 0.7 microns) and the NearBand IR that span from

about 0.7 to 1.1 microns. The Visible Band and NearBand IR are used primarily to further discriminate against

non-fire false alarm sources.

As with all Fire Sentry Corporation Detectors, the Model FS17X Detector senses radiant energy generated by

both hydrocarbon and non-hydrocarbon fires. Built-in microprocessors use sophisticated Digital Signal

Processing (DSP) to accurately distinguish radiant energy from a real fire and a false alarm source(s). Fire

Sentry Corporation has developed and refined these complex proprietary and patented WideBand IR

algorithms since 1981. These patented algorithms perform real-time DSP, and precisely analyze the signals

in high-resolution frequency and time domains. This decision making process involves thousands of real-time

calculations every second. Fire Sentry Corporation’s FSX Detectors use solid-state high speed quantum

sensors (not heat sensors such as pyroelectric or thermopile) that all respond to the fire’s radiant energy

emissions. The quantum sensors convert the rate of photonic energy directly into analog electrical signals.

These analog signals are converted to high resolution digital values for real-time microprocessor analysis.

The Detector microprocessors incorporate random access memory (RAM), read-only memory (ROM), and

non-volatile flash memory. When the microprocessors determine that a real fire has been detected, the pre-

alarm digital sensor data (FirePic™) and the event information are recorded in flash memory. Depending on

the configuration, other actions may include activating one or more status LEDs, relays, a current loop and

sending digital data via the RS-485 FireBus

II

™. If the microprocessors determine, based on internal testing

and “through-the-lens” testing, that the Detector is not operating correctly, it records the Fault data in flash

memory and activates the Fault outputs and the yellow status LED. The digital data in the Detector can be

accessed with a PC for later analysis and record keeping using Fire Sentry’s Windows

®

based PC software

and the FSIM USB Interface Unit.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 12

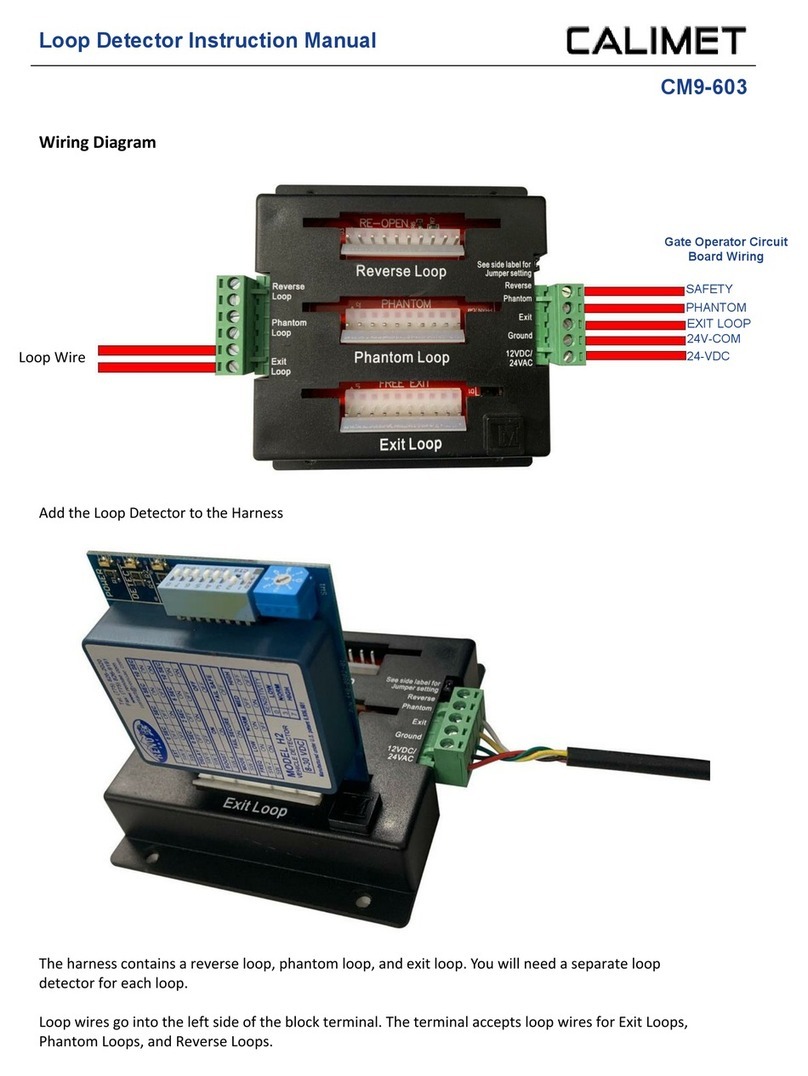

3.2 LED Status Indicators

As with all FSX Detectors, the Model FS17X Detector uses three (3) separate, bright LED’s (rather than one

tri-colored LED that can be difficult to recognize the different colors outdoors or in a brightly lit area) to indicate

the Detector’s status.

The Blue LED blinks (flashes) once every ten (10) seconds to indicate a Normal, safe operational

condition (i.e. no Faults and no Alarms). The Blue LED is OFF when no external 24 Vdc input power is

applied to the Detector.

The Red LED turns ON when the FS17X goes into ALARM. The Red LED flashes when the FS17X-R

version goes into ALERT.

The Yellow LED blinks (flashes) when the window lens is dirty. For all other Fault conditions, the

Yellow LED will turn ON solidly (see Section 3.5).

3.3 Normal Operation

In Normal Operation, the bright Blue LED blinks (flashes) every 10 seconds. See Figure 3-1 for the location

of the Blue LED. Normal Operation is defined as the Detector with 24 Vdc applied and no ALARM or Fault

conditions are present.

Flashes

LED

Status

1 Blue Normal Operation (No Faults and No Alarms)

2 Blue Normal Operation and Communication*

*The Blue LED will be OFF when there is a Detector Fault

Figure 3-1

Blue LED Location

The number of Blue LED flashes immediately following the

power-up sequence identifies the type of FS17X:

Two (2) Flashes for the

FS17X-S

(Semiconductor Detector)

Four (4) Flashes for the

FS17X-G

(General Purpose Detector)

Six (6) Flashes for the

FS17X-R

(Radiant Energy Detector)

3.4 ALARM

When an ALARM occurs, the Red LED will turn ON, (factory setting with the Auxiliary relay set to “0”

seconds). See Figure 3-2 for the location of the Red LED.

The Detector has the following ALERT, ALARM or Fire

Verification outputs:

ALERT Relay activation

ALARM Relay activation

Fire Verification Relay activation

1

4-20 mA

1

(sink 20 mA) ALARM Output

4-20 mA

1

(sink 20 mA) Fire Verifification Output

1

RS-485 FireBus

II

ALERT Notification

1

RS-485 FireBus

II

ALARM Notification

1

Figure 3-2

Red LED Location 1 Only one active output from this group

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 13

3.5 Fault

When a Fault (Trouble) occurs, the Yellow LED will illuminate. See Figure 3-3 for the location of the Yellow

LED.

The Detector has the following Fault outputs:

Fault Relay activation

4-20 mA (sink) Output

2

2 mA (Self-Test/Lens Obscuration Fault)

0 mA (All Other Faults)

RS-485 FireBus

II

Fault Notification

2

Figure 3-3

Yellow LED Location 2 Only one active Fault output from this group

The FS17X has the following Fault (Trouble) outputs:

Flashes

LED Fault Cause Remedy

3

Yellow Self Test Fault Sensor response is out of range.

Contact Fire Sentry

Corporation to speak

with a Technical

Representative.

4

Yellow Relay Coil Fault or Leak

Detection Fault

One or more Relay Coils has an

open or a short; OR Moisture is

inside of the Detector Housing.

Contact Fire Sentry

Corporation to speak

with a Technical

Representative.

5

Yellow High or Low Temperature

Fault

Less than -40°C or

Greater than +60°C (Zone 2) or

Greater than +85°C (Zone 1)

Contact Fire Sentry

Corporation to speak

with a Technical

Representative.

6

Yellow High or Low Input Voltage

Fault

Less than +18 Vdc or

Greater than +32 Vdc

Verify the DC Voltage

at the FS17X

Detector

is between 18 Vdc

and 32 Vdc. DC

voltage, not AC.

Solid

ON

Yellow Major Internal Fault

Microprocessor Fault

Communication Fault

Internal Electronic Self-Test Fault

Contact Fire Sentry

Corporation to speak

with a Technical

Representative.

The Blue LED will be OFF during Detector Faults.

In addition to the Remedies listed above, cycle (re-apply) primary input power to the Detector. If any of the

Faults listed above continues after taking the appropriate remedy, contact a Technical Representative at Fire

Sentry Corporation. It may be necessary to obtain a Return Merchandise Authorization Number (RMA #) and

return the Detector to the Factory.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 14

3.6 Maintenance

After the FS17X Detector is installed and commissioned, virtually no maintenance required in a clean room

environment. However, a complete “end-to-end” test of the entire fire detection system should be performed

monthly or more frequently, depending on the application. Additionally, semi-annual or quarterly testing should

be performed, using the correct Fire Sentry Test Lamp, to ensure the integrity of the entire fire protection

system. (see Note in Section 2.4 and Section 4.3)

Clean the FS17X Detector window:

Each time the Detector is taken out of or put back into to service.

Detector window is dirty or contaminated.

Detector does not respond to an end-to-end test with the Fire Sentry Corporation hand-held portable

Test Lamp (TL-1055X or TL-2055X).

Each time the Detector has been disassembled for wiring or replacement.

Use a blast of clean air or an oil-free cloth to clean the Detector window. Occassionally, the use of a solvent,

such as alcohol is acceptable. No disassembly of the Detector is required.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 15

SECTION 4: APPENDIX

4.1 Warranty Information

Fire Sentry Corporation warrants the FSX Detectors against defects in material and workmanship under

normal use and service for a period of three (3) years from the date of shipment as described herein.

Equipment manufactured by Fire Sentry Corporation is designed for use in Fire Detection applications in

industrial environments. Fire Sentry Corporation, at its option, will repair or replace, at no charge, such

products found to be defective during the warranty period provided that they are returned in accordance with

the terms of this warranty. Replaced parts or boards are warranted for the balance of the original applicable

warranty period. All Replaced parts of Products shall become the property of Fire Sentry Corporation. This

express limited warranty is extended by Fire Sentry Corporation to the original purchaser only and is not

assignable or transferable to any other party. This is the complete warranty for the Products manufactured by

Fire Sentry Corporation. Fire Sentry Corporation assumes no obligations or liability for additions or

modifications to this warranty unless made in writing and signed by an officer of Fire Sentry Corporation. Fire

Sentry Corporation does not warrant the installation, maintenance or service of its Products. Fire Sentry

Corporation is not responsible in any way for ancillary equipment not furnished by Fire Sentry Corporation,

which is attached to or used in connection with its Product(s), or for operation of the Product(s) with ancillary

equipment and all such equipment is expressly excluded from this warranty.

This Warranty is given in lieu of all other warranties, express or implied, including without limitation, implied

warranties of merchantability and fitness for a particular purpose. In no event shall Fire Sentry Corporation be

liable for damages in excess of the purchase price of the Product(s), for any loss of use, loss of time,

inconvenience, commercial loss, lost profits or savings or other incidental, special or consequential damages

arising out of or in connection with the use or inability to use such Product.

THIS WARRANTY DOES NOT COVER:

1. Defects or damage resulting from use of the Product(s) in other than the normal and customary

manner.

2. Defects or damage from misuse, misapplication, accident, or neglect.

3. Defects or damage from improper testing, operation, maintenance, installation, alteration,

modification or adjustment.

4. Product(s) subject to unauthorized Product modifications, disassemblies or repairs (including,

without limitation, the addition to the product of non-Fire Sentry Corporation supplied equipment)

which adversely affect performance of the Product(s) or which interfere with Fire Sentry’s normal

warranty inspection and testing of the Product(s) to verify any warranty claim.

5. Product(s) that have had the serial number removed or made illegible.

6. Freight cost to the repair facility.

7. A Product which due to illegal or unauthorized alteration of the software/firmware in the Product,

does not function in accordance with Fire Sentry Corporation specifications.

8. Scratches or other cosmetic damage to Product surfaces that do not affect the operation of the

Product.

9. Normal and customary wear and tear.

10. Product(s) which are not used in industrial applications.

Laws in the United States and other countries preserve for Fire Sentry Corporation certain exclusive rights for

copyrighted Fire Sentry Corporation software/firmware, such as the exclusive rights to reproduce in copies and

distribute copies of such Fire Sentry Corporation software/firmware. Fire Sentry Corporation

software/firmware may be used only in the Product(s) in which the software/firmware was originally embodied

and such software/firmware in such Product(s) may not be replaced, copied, distributed, modified in any way,

or used to produce any derivative thereof. No other use including, without limitation, alteration, modification,

reproduction, distribution, or reverse engineering of such Fire Sentry Corporation software/firmware or

exercise or rights in such Fire Sentry Corporation software/firmware is permitted. No license is granted by

implication, estoppel or otherwise under Fire Sentry Corporation patent rights or copyrights.

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 16

4.2 Product Variations

All options for the FS17X must be specified on the customer’s purchase order. Here is a list of current

ordering options for the Model FS17X™:

Model - # # # # # # #

Tubing Length

X No Tubing

A 41” (Standard)

Model # B 60 “

FS17X

Eight Conductor Cable Length

1 3 meters (10 feet)

2 6 meters (20 feet) (Standard)

3 12 meters (40 feet)

4 18 meters (60 feet)

5 24 meters (80 feet)

Connection Type

C Integral Cable, 8 conductor (Free End)

Z Integral Cable, 8 conductor (Kalrez O-Ring)

P Phoenix 8-Pin Connector

Relay Contact – Fault N.C., Normally Energized, Non-Latching

1 Fire Relays N.O., Normally De-Energized, Non-Latching

2 Fire Relays N.O., Normally De-Energized, Latching

3 Fire Relays N.C., Normally De-Energized, Non-Latching

4 Fire Relays N.C., Normally De-Energized, Latching

Output Options (FS17X-S / FS17X-G)

A Fault, ALARM, Aux Relays w/ Fireball (FS17X-S)

B Fault & ALARM Relays and RS-485 (FS17X-S)

1 Fault & ALARM Relays and RS-485 (FS17X-G)

2 Fault, ALARM, Aux Relays w/ 5 second Verify (FS17X-G)

3 Fault, ALARM, Aux Relays w/ 10 second Verify (FS17X-G)

4 Fault & ALARM Relays and 4-20mA (FS17X-G)

6 Fault, ALARM, Aux Relays w/ Fireball (FS17X-G)

Detector Sensitivity

H High Sensitivity (Standard)

L Low Sensitivity

Detector Type - Application

G General Purpose

S Semiconductor

Model FS17X

™

Fire and Flame Detector

INSTALLATION GUIDE and OPERATING MANUAL

Fire Sentry Corporation Document No. 6178-007 - Rev. F © Copyright 2012 All Rights Reserved

Page 17

Product Variations (

continued

)

Model - A B C D E - F G H

H Tubing Length

A 41" (Standard)

Model # B 60"

FS17X

G 14 Conductor Cable Length

1 3 meters (10 feet)

2 6 meters (20 feet) (Standard)

3 12 meters (40 feet)

4 18 meters (60 feet)

5 24 meters (80 feet)

F O-Ring

K Kalrez O-Ring

V Viton O-Ring (Standard)

E Relay Mode

N Non-Latching (Standard)

D Relay Contacts

Alert & Alarm Normally Open and Normally De-Energized,

1 Fault Normally Closed and Normally Energized (Standard)

C Outputs

A Fault, Alert & Alarm Relays with FireBusII (Standard)

B Detector Sensitivity

H High Sensitivity (Standard)

A Detector Type - Application

R Radiant Energy (Standard)

This manual suits for next models

1

Table of contents

Other Fire Sentry Security Sensor manuals

Popular Security Sensor manuals by other brands

Intermatic

Intermatic IOS-CMP-DT-U Installation and configuration instructions

steute

steute Ex HS Si 4-3G/D Mounting and wiring instructions

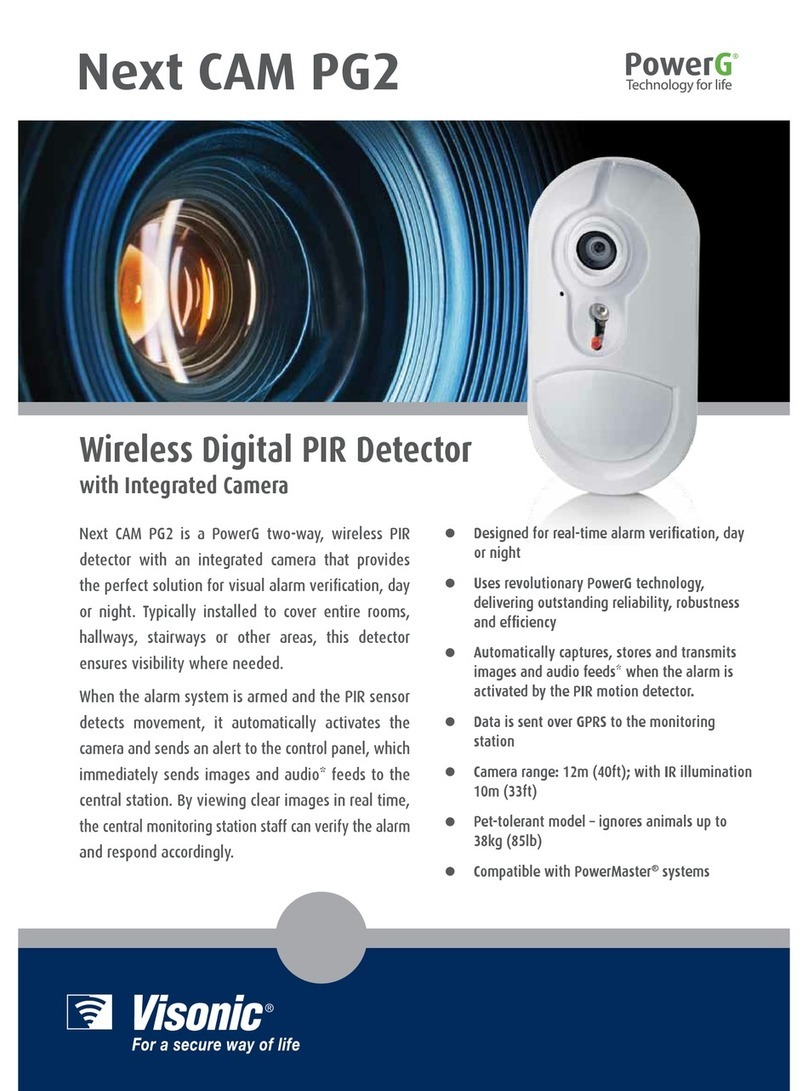

Visonic

Visonic NEXT CAM PG2 datasheet

Sperian

Sperian Miller Scorpion User instruction manual

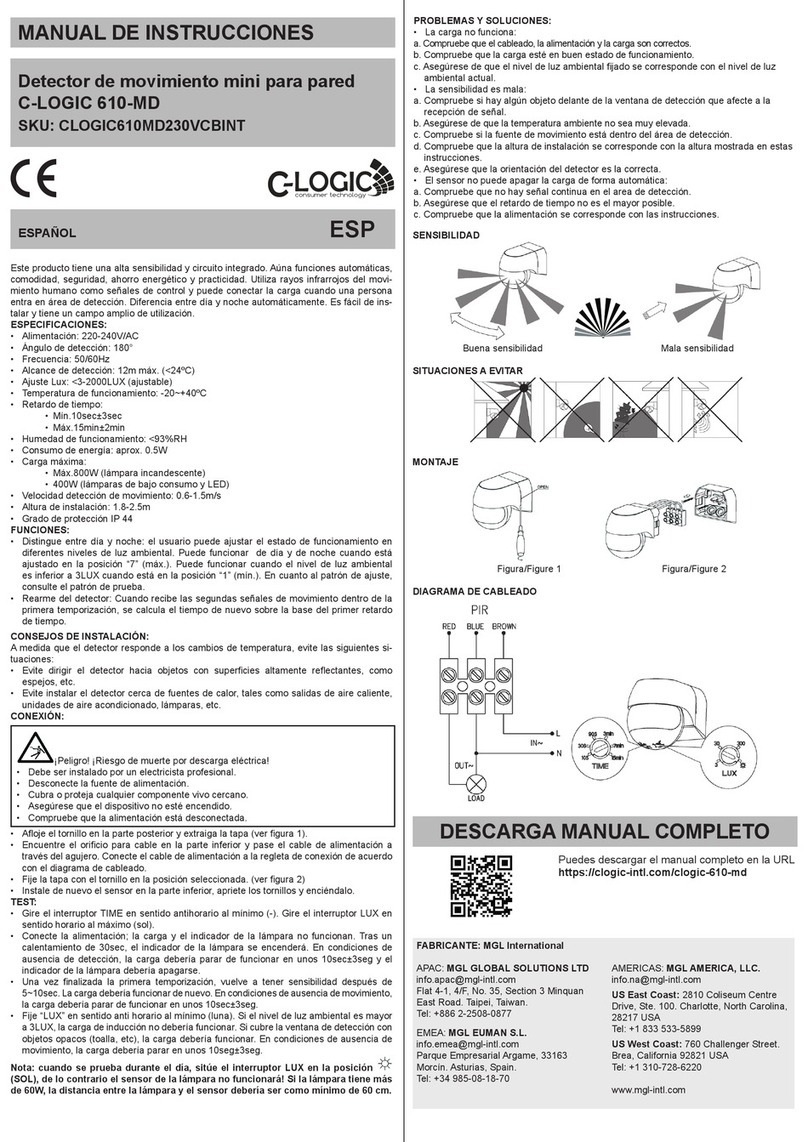

C-LOGIC

C-LOGIC 610-MD instruction manual

Radiodetection

Radiodetection RD7100 user guide