Firelands X BOLT 250 User manual

Assembly Manual

Product specications are subject to change without notice.

Due to ongoing development, the actual product may vary from

images shown.

This product is not a toy! (14+) Recommended for ages 14 and

up. Adult supervision required for ages under 18 years old.

Contains small parts, keep out of reach of children 3 years of

age and younger.

Distributed in the

UK by:

J Perkins Distribution Ltd,

Lenham,

Kent, UK

ME17 2DL.

www.jperkins.com

Distributed in Australia by:

Model Engines (Aust.) Pty. Ltd.,

Unit 1, 158-168 Browns Road,

Noble Park,

Victoria,

3174,

Australia.

www.modelengines.com.au

Ph (03) 8793 5555

Distributed in the US by:

Firelands Customer Service/Product

Support

1133 Libra Drive, Lincoln, NE 68512

www.relandsgroup.com

1-800-205-6773

customerservice@relandsgroup.com

MADE IN CHINA

This product contains chemicals known to the State of California

to cause cancer, birth defects and other reproductive harm.

Electronics

Carbon Fiber Manufactured

and Machined in USA

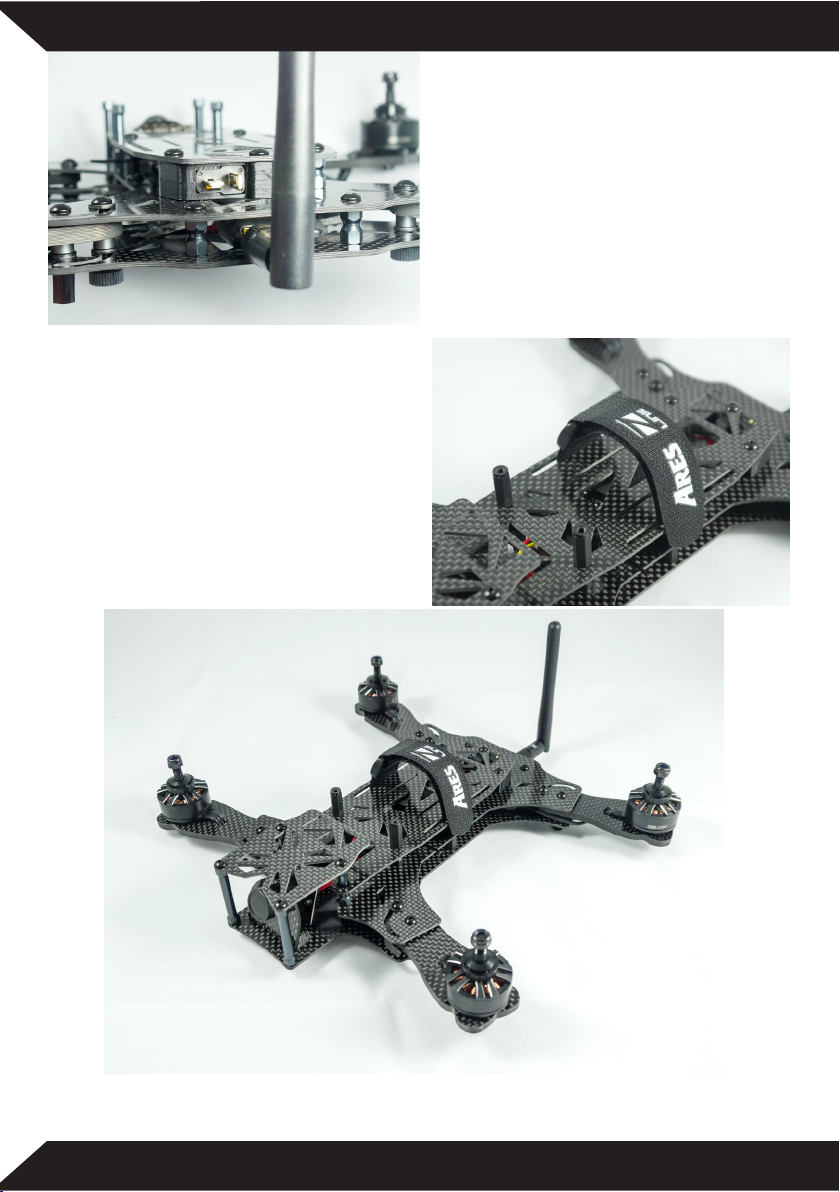

X Bolt FPV Racer Kit AZSZ2903

Packaged and Assembled

in USA

1 x X Bolt Frame (9 pieces)

1 x Flight Controller

1 x Power Distribution

1 x FPV Video Camera

1 x FPV Video Transmitter

4 x 18A Spreed Controls

4 x 2206 2250Kv Brushless Motors

1 x Battery Strap

2 x CW Prop

2 x CCW Prop

6 x 10mm Nylon Standos (F/F)

4 x 12mm Nylon Standos (M/F)

2 x 15mm Nylon Standos (M/F)

4 x Plastic M3 Hex Nuts

8 x 20mm M3 Screws

25 x 6mm M3 Screws

2 x 6mm M3 Grub Screw

4 x M3 Aluminum Thumb Nut

8 x M3 Aluminum 10mm Standos

2 x M3 Aluminum 23mm Standos

2 x M3 Aluminum 35mm Standos

1 x Plastic FPV Camera Mount

1 x Plastic HCT Mount

2.5mm Hex Wrench

3.0mm Hex Wrench

Soldering Iron

Solder

Needle Nose Pliers

Wire Cutters/Strippers

Blue Thread Locker

Sandpaper or Needle File

2.4GHz Transmitter

2.4GHz Satellite or Standard Receiver

5.8GHz Receiver Monitor or Goggles

1300-2200mAh 3-4 Cell Lipo Battery

LiPo Balance Charger

Contents List Tools Needed

Equipment

Kit Contents

2

Advisory

Please wipe o all carbon parts prior to

installation.

If you nd a machined hole that is too

tight, enlarge it slightly using a needle

le or correct size drill bit.

Forward

1234

5

6

1. Camera Plate

2. Battery Plate

3. Top Plate

4. Bottom Plate

5. Camera Mount

6. Motor Arms

Carbon Parts

Washers

On the bottom frame insert four

M3 6mm screws. Use four

washers to keep the PDB (Power

Distribution Board) from touching

the carbon frame.

Place the PDB. Orient the PDB so

that the solder pads for the ESC’s

face the front and rear of the quad.

3

Option 1 - No LED Bar

Install the two M3 35mm alumi-

num standos. Install two M3

10mm nylon standos at center of

frame. Install four M3 10mm alu-

minum standos. All standos are

mounted using M3 6mm screws

from bottom side of frame

Option 2 - LED Bar Install

Replace the two nylon 10mm

strandos with the 10mm alumi-

num standos from the rear of the

frame.

Install the LED bar at the rear of

the frame.

Screw the two M3 6mm grub

screw (threaded rod) into the

10mm aluminum standos at front

of frame. The grub screws should

only be seated a maximum of

3mm into the stando.

Use a drop of blue thread lock on

the grub screw.

Locate the plastic camera mount

and position it on the frame with

the two M3 holes facing forward.

Place a washer on each M3 screw

prior to screwing the camera

mount in place from the bottom of

the frame.

4

Locate the carbon ber camera

mount plate and FPV camera.

Unscrew the lens from the camera

and insert through the hole on the

camera mount, rescrewing the

lens back onto the camera base.

Focusing the camera will be per-

formed after the X Bolt is assem-

bled. Focus is accomplished by

screwing the lens in/out. The lock

ring will x the position of the cam-

era to the camera mount.

Mount the camera plate to the

plastic camera mount using two

M3 6mm screws.

Note that the camera power

connection is located nearest the

frame. (See Photo)

HCT mount option

Locate the carbon ber top plate.

Install three M3 10mm standos

as shown in photo to right. Locate

the two HCT plastic mount halves.

Install bottom half to the frame

using M3 6mm screw as shown in

photo at right.

5

No HCT mount option

Locate the carbon ber top plate.

Install four M3 10mm standos as

shown in photo to left. Install the

standos with M3 6mm screws

from the bottom side of frame.

Locate the 90 degree header pins.

Solder in place to channels 1-4 on

the ight controller. These are the

4 speed control connections.

NOTE: Double check polarity

marked on the ight controller for

your ESC’s

Satellite Receiver Option

Leave yourself 3” of wire to the

satellite receiver. Solder the three

leads to the ight controller.

External Receiver Option

Locate the wire loom and header

pins as shown in photo to right.

Solder header pins to ight con-

troller

6

Discard JST Plug

Cut 2-1/2” Long

Retain for

later step

Locate the VTX power wire with

the JST plug installed. This wire

will need to be modied for two

applications in the following steps.

Cut the JST plug o close to the

connector. Discard the plut. From

the remaining wire, cut a section

of wire 2-1/2” long. You will use

this wire to power the ight con-

troller from the PDB later in the

manual.

The remaining wire with the white

plug attached will power the VTX

and camera simultaneously.

Solder the VTX power leads to the

ground and 12V tabs on the PDB

as shown in photo to left.

Locate the 4” piece of 16 AWG

wire and cut in half. Solder one

end of each with to the PDB.

Leave the other end of the wires

unattached. These will be soldered

to the HCT plug after the wires are

fed through the frame.

NOTE: Maintain proper polarity.

7

Locate the four 18A brushless

ESC’s.

Solder the ESC power leads to the

PDB as shown in the photo to the

right.

NOTE: Maintain the correct polari-

ty as marked on the PDB.

Locate four 2206 Brushless mo-

tors and hardware.

Locate the carbon ber arms and

match the holes on the motors to

the holes on the arms. If they do

not match, ip the arm over.

8

Using a needle le or sandpaper

ease the edges of the hole in the

arms to avoid chang the motor

wires.

Feed the wires through the hole

and mount the motor to the arm,

using the screws provided with the

motors.

9

Option 1 Expert

Solder directly to the ESC. Make 2

slits on the sides of the ESC and

fold back the heat shrink to ex-

pose the 3 solder pads.

NOTE: Use caution when solder-

ing next to FETS.

Option 2 Intermediate

Splice ESC and motor wires

together as shown in the photo.

Only cut the wires from the ESC,

do not cut the motor wires. Cover

exposed solder joints with heat

shrink (not included).

Add top plate and feed the VTX

cable through the frame.

If you choose to add the optional

buzzer it should be installed at this

point.

In this step we will use the 2-1/2”

wires that you cut from the VTX

power cable earlier.

Solder these wires from the 5V on

the PDB to the ight controller.

10

Washers

Washers

Spacers

Thumbscrew

Standoff

Before you install the top plate you will need to install the motor arms. To

complete this step you will need.

8 M3 20mm screws

8 M3 aluminum spacers

24 Nylon washers

4 M3 Thumb screws

4 10mm Nylon standos F/F

Arm Assembly Sequence

11

Install the two M3 23mm standos.

These will thread onto the grub

screws that you installed earlier.

Wrap the VTX with the provided

piece of heatshrink. This will pro-

vide protection for your VTX.

12

Plug in all your components. The

camera, VTX, satellite receiver

and ESC’s.

Double check ESC polarity.

Diagram shows channel selection

for your ESC’s and motor rotation

direction.

Refer to the diagram to the right.

At this point you should have the

top and bottom plates assembled.

Install M3 nylon hex nuts to secure

the ight controller.

Fit battery tray over 23mm stand-

os. Secure with ve M3 6mm

screws.

13

The HCT plug adapter helps clean

up wiring and holds the battery

leads in place.

Locate two 15mm nylon standos

M/F. These are installed on the

battery tray as shown in photo to

right.

These are to protect the battery in

the event of a crash.

Locate the camera plate and install using four M3 6mm screws.

At this point you are ready to set up in Cleanight.

14

The download and installation of Cleanight is beyond the scope of this

assembly manual. Please go to: Cleanight.com for latest software. An addi-

tional source of good information is RCGroups.com

30-Day Limited Warranty Term Period:

We warranty that the Product(s) purchased (the “Product”) will be free

from defects in materials and workmanship when the product is new

(before being used) for the limited warranty term period, 30 days, from

the date of purchase by the Purchaser.

If you believe a defect in material, workmanship, etc. was not

apparent when the Product was new and only became evident after

the Product was used, take the following steps. If you purchased the

Product at a HobbyTown store, please contact your local HobbyTown

store for warranty support and/or service. If you purchased the

Product from the Firelands website, use the contact information found

under the Support heading to contact Firelands directly.

If you contact Firelands, you may be asked to send the product

to Firelands, at your cost, for inspection. Provided the warranty

conditions have been met within the warranty term period, the

components that are found to be defective, incorrectly manufactured

or assembled may be repaired or replaced, at the sole discretion of

Firelands. Your warranty item will be returned to you at Firelands’

expense. In the event your product needs repair or a replacement

part that is not covered by this warranty, your local HobbyTown store

or Firelands can assist you with support and in obtaining the genuine

replacement parts to repair your Product. Firelands will charge $40.00

per hour plus the cost of replacement parts to service your vehicle if

after contacting you, you so authorize such repairs. Your product will

be returned to you at your expense.

If you purchased your Product from a HobbyTown Internet site not

aliated with a local store, please consult that site for its support and

service policies. You can also nd more information at:

www.Hobbytown.com

or by emailing customerservice@relandsgroup.com

or call 800-205-6773

15

www.Ares-RC.com

© 2016

Rev. 1.0

1/16

Table of contents