Fireray 2000 Installation and user guide

DOCUMENT CONTROL NUMBER /

© 2001 Tyco Electronic Product Group PAGE 1 of 5

Registered Office: 19-21 Denmark Street, Wokingham, Berks RG40 2QE

FIRERAY 2000

01B-05-S1

02 1/01

EQUIPMENT:

PUBLICATION:

ISSUE No. &DATE:

«¥¥³¸¾¯¼¸«¾³¹¸«¶¥¶¾®¥¹·º«¸Ã

FIRERAY 2000 OPTICAL BEAM SMOKE DETECTOR

SERVICE AND MAINTENANCE

1. GENERAL

This document details the routine servicing and maintenance

procedures and provides a fault finding guide for the Fireray

2000 optical beam smoke detector.

The publication comprises:

Yearly checks

Fault finding guide

Alignment procedures

Testing

Spares list

When an incorrect response is obtained from a check, locate and

rectify the fault as described in Section 3.

When returning a faulty unit or PCB for repair, package it in the

bag that was used for its replacement.

2. ROUTINE CHECKS

The recommended routine checks must be carried out as stated.

2.1 YEARLY CHECKS

Inspect the Control Box, Transmitter and Receiver Units for

damage and ensure they are physically secure.

Clean the lenses on the Transmitter and Receiver Units. (If the

units are installed in a ‘clean area’ or dust free environment the

lenses need be cleaned only every two years).

Align and the test system as necessary.

3. FAULT FINDING GUIDE

This section details some of the possible faults which may occur

during testing of the Beam Detector Set. Most of the faults can

be easily rectified.

If the unit is suspected as faulty, retry the alignment procedure.

If the Beam Detector Set is still faulty replace the Beam

Detector Set with a new one.

If the problem persists, contact the Helpdesk at Sunbury.

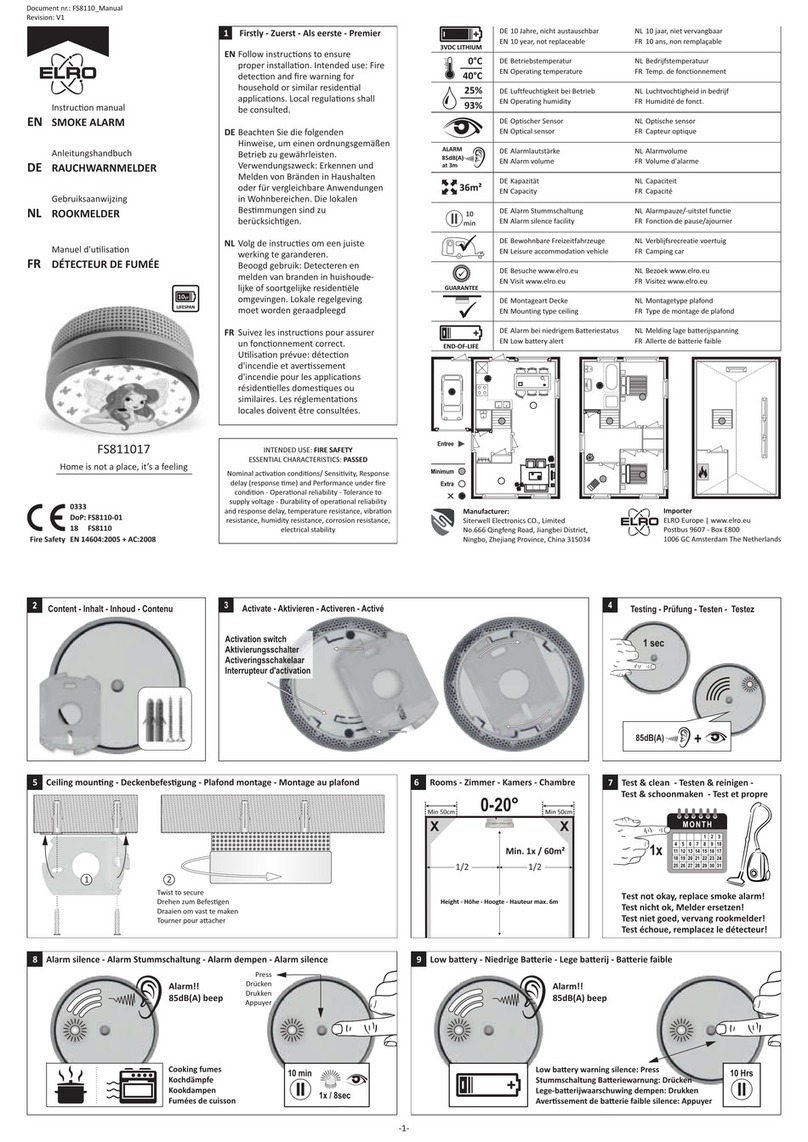

Table 1 lists the internal controls and their function.

3.1 POSSIBLE CAUSES OF FAULT ALARMS

a) Receiver placed in the Reset state. Check that

the Test/Reset Switch (Fig. 1) is set to OFF.

b) The beam between the Transmitter and the

Receiver is obscured for more than 94% of the

beam area for one second. Check the beam is

not obscured or that the round glass areas on

the Transmitter or Receiver are dirty. Clean as

required.

c) Signal Level Control set too low at the

Receiver. Turn control (RV1) clockwise.

d) Receiver in Test mode. Ensure the Test/Reset

switch set to OFF.

e) Misalignment of the Transmitter and Receiver

detectors. Re-align as in the Alignment

procedure.

f) Loss of power. Check out the power supplies.

g) Source of infra-red setting of the alarm. Check

for sources of infra-red. For example: heat

emitting lights (eg, incandescent light bulbs),

direct sunlight, heaters and radiators at close

proximity to detectors.

CONTROL FUNCTION

Signal

Level (RV1)

Alters the gain of the received signal from

the transmitter. If the gain is set too low the

Beam Detector Set will not work correctly.

Do not set to maximum position in

NORMAL working mode.

Test / Reset

Switch

Sets the AGC level for the alignment checks

(ON) and arms the Beam Detector Set after a

fire alarm (OFF). Reset can also be done by

removing the power for 2 seconds or by

connecting the external reset input to 0V.

Test/Reset switch is normally in the OFF

position.

Table 1 Controls and their Function

FIRERAY 2000

01B-05-S1

02 1/01

PAGE 2 of 5

Table 2 gives the meaning of the LED indications on the PCB in the Control Box - see Fig 1.

*When the received signal level changes, either an increase or decrease by more than 10%, the corresponding Signal High

(LED 2) or the Signal Low (LED 3) will come ON and an AGC change is requested.

If this request is continuous in each time period (9 hours in increase and about 2 minutes to decrease) the AGC responds

automatically by changing the receiver gain in order to bring the received signal level back to the nominal required level. Only

one stage gain (10%) is affected.

When 15 stages of the AGC gain have been used, ie, the gain increased, the fault relay is turned on then off at a rate of one

per 2 seconds (0.5Hz). The fire alarm will have no further levels of gain compensation available and must not be used.

Note: If maximum AGC gain is reached the alarm will not be reliable and must not be used.

If the signal is reduced any further then the alarm will be signalled.

Check any causes of reaching the AGC limit, such as dirty transmitter or detector round glass area or misalignment.

Clean the glasses thoroughly and check alignment.

LED INDICATION MEANING OF INDICATION ACTION

Fire Alarm

front panel (RED)

When ON smoke present for 5 seconds.

(40% to 93% obscuration of IR beam).

Wait for conditions to clear and reset the unit by

switching OFF/ON/OFF on Test/Reset switch

Both Signal High and

Signal Low lit

Normal for initial calibration state, both LEDs

should switch off within 45 seconds.

Signal High

(GREEN)

Increase of about 10% of signal input (by AGC) Ensure that the AGC will reduce the gain to bring

down the signal down to the nominal level

Signal Low

(GREEN)

Loss of about 10% of signal input Ensure that in normal operation the AGC will

increase the gain to bring the signal up to nominal

Fault

(YELLOW)

1 ON when maximum Gain is reached No more levels of compensation are available*

2 ON when Reset switch is ON Ensure Test/ Reset switch is in Test position when

returning the detector to normal operation

3 ON if the Both Signal High and Signal Low

fail to extinguish after the 45 second calibration

period.

Faulty unit

Table 2 LED Indication (Circuit Board in Control Box)

FIRERAY 2000

01B-05-S1

02 1/01

© 2001 Tyco Electronic Product Group PAGE 3 of 5

Registered Office: 19-21 Denmark Street, Wokingham, Berks RG40 2QE

EQUIPMENT:

PUBLICATION:

ISSUE No. &DATE:

«¥¥³¸¾¯¼¸«¾³¹¸«¶¥¶¾®¥¹·º«¸Ã

Fig. 1 PCB Layout

FIRERAY 2000

01B-05-S1

02 1/01

PAGE 4 of 5

4. ALIGNMENT

The detectors can be aligned by either using a dc voltmeter,

which is positioned at the Transmitter head and connected

via a 2-core cable to the Control Box or an Alignment Aid

which can be substituted for the voltmeter.

.

Fig. 2 Alignment Aid

The Alignment Aid (Fig. 2) is lighter and more robust than a

meter and provides a convenient method of aligning the

detector heads. The display LED flashes at a faster rate when

correct alignment is achieved.

Align the detector heads as follows:

a) Switch on the 24V dc Supply to the Control

Box and the Transmitter/Detector.

b) Ensure the Test/Reset Switch on the Control

Box is set to OFF.

c) Set the Test/Reset Switch to ON.

d) Check the Signal Level control RV1 in the

Control Box is set to the mid-way position.

e) The High Gain (LED 3) and Low Gain

(LED 2) may both be lit.

Note: At this stage other LEDs in the Control Box may

be lit. This is due to the beams not being aligned

exactly.

f) Connect the Alignment Aid or dc voltmeter

as shown in Fig. 1 using 2-core cable.

g) Adjust the Transmitter head horizontally and

vertically so that the receiver detects the

beam in the round glass area such that either:

i) The Alignment Aid LED flashes at a high

rate - adjust for the fastest flashing rate.

ii) Or if using a voltmeter, adjust for a

maximum reading. (A no-signal reading

is approximately 2.6 volts).

h) When this has been done fully tighten the

screws holding the receiver and transmitter

to the ceiling brackets. Ensure that all

fixings are firmly tightened. Re-check the

alignment aid for faster flashing of the light

(to check the Beam Detector Set is working

correctly).

i) At the Control Box adjust RV1 until the

High Gain (LED 2) just goes off.

j) Switch off the power and disconnect the

Alignment Aid or voltmeter.

k) Set the Test/Reset switch to the off position.

Wait at least 45 seconds before performing

any tests.

FIRERAY 2000

01B-05-S1

02 1/01

© 2001 Tyco Electronic Product Group PAGE 5 of 5

Registered Office: 19-21 Denmark Street, Wokingham, Berks RG40 2QE

EQUIPMENT:

PUBLICATION:

ISSUE No. &DATE:

«¥¥³¸¾¯¼¸«¾³¹¸«¶¥¶¾®¥¹·º«¸Ã

When the detector heads are fitted for retro-reflective

operation the alignment procedure is as for normal operation

but with an additional test as follows:

When the system is aligned and in operating

mode block off the reflector at the reflector

end. The detector should go into fault

condition. If the detector does not go into fault

condition then it is possible that the signal is

being returned, not by the retro-reflector, but by

some other reflecting surface.

5. TESTING THE BEAM DETECTOR

SET

The following tests must be carried out after the first

installation, after any maintenance, or after every fire or fault

alarm to ensure fail-safe operation of the Beam Detector Set.

Supplied inside the Control Box is an acetate test card (filter)

with black markings on it which is used to provide

obscuration of the beam during tests.

Note: After the tests have been performed this

acetate card should be held with the system log

book and not inside the Control Box.

5.1 SMOKE ALARM TEST

Proceed as follows:

a) Hold the test filter in the beam path

b) After approximately 9 seconds:

i) the Fire Relay contact operates (the relay

contacts will click once as it operates).

ii) the Fire alarm LED (red) on the front panel

will light.

c) Remove the test filter, the alarm will reset in

approximately 4 seconds (unless in latching

mode).

Fig. 3 Connection of Alignment Aid

d) Reset the Beam Detector Set either by:

i) Moving the Test/Reset switch to OFF, then

ON and then OFF, or

ii) Disconnecting the power for 2 seconds, or

iii) Taking the External Reset terminal to 0 volts

for one second.

e) The Beam Detector Set is now reset and armed.

5.2 FAULT ALARM TEST

Proceed as follows:

a) Totally obscure the beam with an opaque

object such as a piece of card.

c) After about 10 seconds check that Fault LED

(LED 1) lights, and the fault relay contacts

change state.

d) Remove the Test Card obscuring the beam.

e) Check that the Beam Detector Set resets itself

automatically within 4 seconds.

f) Secure the front cover, the Beam Detector Set is

now reset and armed.

Note: After the tests have been performed the recorded

values should be held with the system log book

and not inside the Control Box.

6. ORDERING INFORMATION

Fireray 2000 complete: 516-015-006A

Fireray 2000 complete: 516-015-006T

LPBD520: 557-180-217

Retro-Reflector (TKS 100 x 100): 516-015-007

Alignment Aid: 516-015-008

7. ASSOCIATED PUBLICATIONS

05A-02-S1 FIRE SYSTEMS - GENERAL SERVICE AND

MAINTENANCE INSTRUCTIONS

CB/jm

12th January 2001

Table of contents

Other Fireray Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

elsner elektronik

elsner elektronik Salva KNX TH Technical specifications and installation instructions

Weller

Weller WFE 2ES operating instructions

FireClass

FireClass Prescient III owner's manual

Visonic

Visonic SMD-426 installation instructions

American Sensor

American Sensor SA379 user manual

Brooks

Brooks EIB170RFAU Install